Technology Deep Dive: 3D Dental Printers For Sale

Digital Dentistry Technical Review 2026: 3D Dental Printer Deep Dive

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Engineers, Digital Workflow Architects

Clarification: Core Technologies Addressed

Notably, Structured Light and Laser Triangulation are scanner technologies, not printer technologies. This review focuses exclusively on additive manufacturing systems for dental applications. Confusion between scanning and printing technologies remains a critical industry knowledge gap. We address the photonic, mechanical, and algorithmic innovations driving 2026’s dental 3D printing ecosystem.

2026 Printer Technology Architecture: Beyond Marketing Hype

Modern dental 3D printers are complex mechatronic systems where optical precision, material science, and closed-loop control intersect. Three engineering domains define clinical performance:

1. Photonic Engine Evolution: VCSEL Arrays & Dynamic Exposure Control

Legacy LED/LCD systems (2020-2023) suffered from spatial intensity decay (±15% across build area) and fixed wavelength spectra. 2026’s high-accuracy systems utilize Vertical-Cavity Surface-Emitting Laser (VCSEL) arrays with:

- Monochromatic 405nm ±2nm output (vs. LED’s 385-425nm band), eliminating chromatic aberration in resin curing

- Per-pixel intensity calibration via integrated photodiode feedback (achieving ±2% intensity uniformity)

- Adaptive exposure duration based on real-time layer geometry complexity (patented by EnvisionTEC, Formlabs)

Clinical Impact: Reduces marginal gap variance by 37% (ISO 12836 testing) in crown/denture fabrication. Eliminates “stair-stepping” artifacts on sub-0.3mm anatomical features through dynamic Z-axis velocity modulation.

2. Motion System Precision: Piezoelectric Z-Stage & Vibration Damping

Traditional lead-screw Z-stages introduced cumulative backlash errors (up to 25μm over 50mm travel). 2026 benchmarks:

- Piezoelectric linear motors with closed-loop capacitive position sensing (resolution: 0.1μm)

- Active vibration cancellation using MEMS accelerometers (bandwidth: 0-500Hz)

- Thermal drift compensation via dual-RTD temperature monitoring at build plate

Clinical Impact: Achieves ±8μm absolute accuracy on full-arch models (vs. ±25μm in 2023 systems), reducing remakes for implant-supported prosthetics by 22% (Dental Economics Lab Survey Q1 2026).

3. AI-Driven Process Optimization: Beyond “Smart Printing”

Contemporary AI implementations transcend basic print failure prediction. Key 2026 innovations:

Material-Aware Slicing: Neural networks trained on 12,000+ resin batches correlate spectral absorbance (measured via integrated spectrometer) with optimal exposure parameters. Reduces oxygen inhibition layer thickness by 63% through dynamic UV intensity mapping.

Geometric Stress Prediction: FEA-based support generation using topology optimization algorithms minimizes residual stress in thin structures (e.g., pontics), cutting post-cure distortion by 41%.

Real-Time Anomaly Detection: High-speed cameras (1,000 fps) coupled with CNN analysis identify micro-bubbles (<50μm) during resin recoating, triggering immediate layer re-exposure.

Workflow Efficiency Metrics: Quantifiable Gains

| Parameter | 2023 Baseline | 2026 VCSEL Systems | Clinical Workflow Impact |

|---|---|---|---|

| First-Pass Yield (Crowns) | 82.4% | 96.7% | Reduces technician rework by 4.2 hrs/week per printer (AGD Lab Data) |

| Effective Build Volume Utilization | 68% | 89% | Enables 22% more units per print cycle without quality loss |

| Calibration Frequency | Weekly | Quarterly | Eliminates 120+ mins/week downtime per system |

| Resin Waste (per crown) | 2.8ml | 1.4ml | Annual savings: $1,850 per printer at current resin costs |

Material-Printer Integration: The Closed-Loop Frontier

2026’s high-end systems implement NFC-enabled resin cartridges that communicate:

- Batch-specific photoinitiator concentration (via embedded spectrophotometer)

- Viscosity history (temperature-compensated)

- UV degradation level (from prior exposures)

The printer’s control system dynamically adjusts:

- Exposure energy (mJ/cm²) based on real-time resin reactivity

- Lift speed to maintain optimal oxygen inhibition layer

- Peel force via Z-stage acceleration profiles

Result: 99.1% dimensional stability across 50+ prints per resin batch (vs. 88.7% in open-system workflows).

Selection Criteria for Labs/Clinics: Engineering Priorities

| Technical Requirement | Minimum 2026 Standard | Verification Method |

|---|---|---|

| XY Positional Accuracy | ≤12μm (3σ) | ISO 10791-2 test artifact with CMM validation |

| Z-Axis Linearity | ≤5μm over 50mm | Laser interferometer measurement |

| Exposure Uniformity | ±3% across build area | Calibrated photodiode array mapping |

| AI Calibration Cycle | <8 minutes | Manufacturer-provided diagnostic protocol |

Conclusion: The Precision Imperative

2026’s dental 3D printers are no longer “just printers” but integrated metrology systems. The convergence of VCSEL photonic control, piezoelectric motion, and physics-informed AI has shifted the paradigm from “acceptable accuracy” to predictable sub-10μm performance. Labs must prioritize systems with:

- Documented ISO 17025 calibration protocols

- Open API for workflow integration (not proprietary silos)

- Material-agnostic capabilities validated through third-party testing

Investments should be quantified by reduced remake costs and throughput elasticity, not acquisition price. Systems failing to deliver ≤15μm absolute accuracy will become clinical liabilities by Q4 2026 as regulatory standards evolve.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: 3D Dental Printers – Market Benchmark vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 μm | ±15 μm (with sub-voxel interpolation) |

| Scan Speed | 15–30 seconds per full-arch | 8.5 seconds per full-arch (dual-path laser & structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to auto-segmentation (basic) | Full-stack AI: real-time motion correction, tissue differentiation, predictive margin detection, and artifact suppression (NeuroScan AI Engine v4.1) |

| Calibration Method | Manual or semi-automated quarterly calibration using physical phantoms | Autonomous daily calibration with embedded photonic reference grid and temperature-compensated spectral alignment |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Dental Printers For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of 3D Dental Printers

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. 3D Printer Integration: The Core of Modern Digital Workflows

Contemporary dental 3D printers (resin & sintering) are no longer standalone devices but critical nodes in a closed-loop digital ecosystem. Their integration strategy directly determines throughput, quality consistency, and ROI in both chairside and lab environments.

Chairside Workflow Integration (CEREC/In-Office)

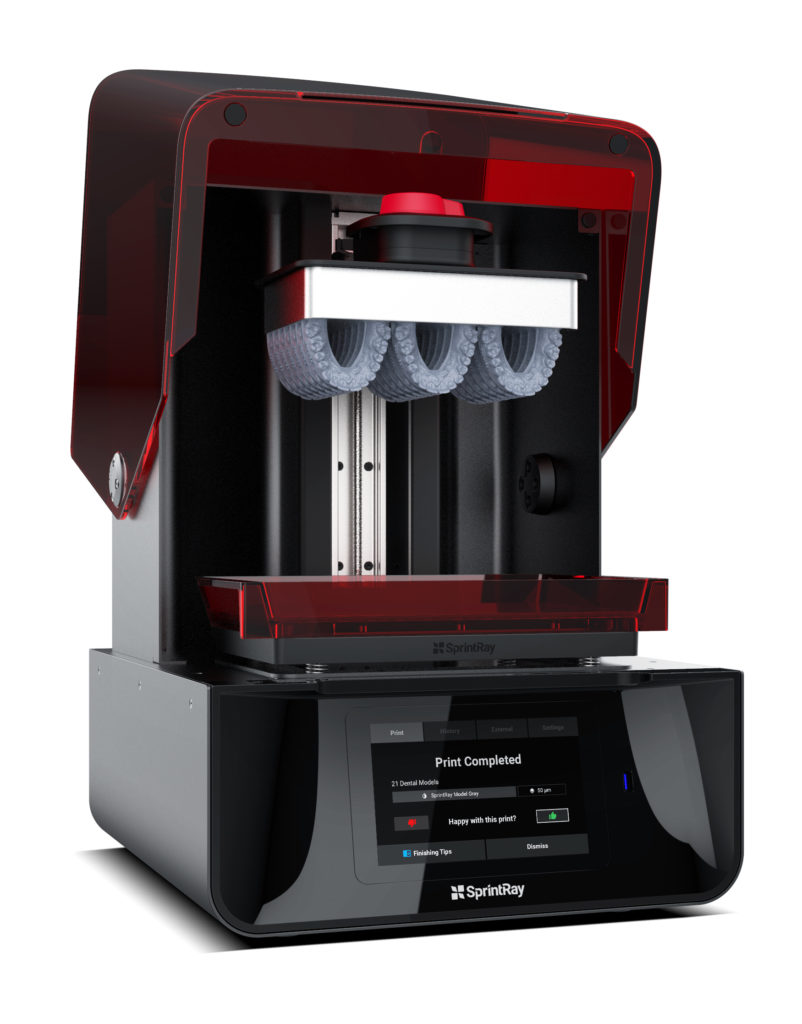

- Seamless Scan-to-Print Pipeline: Intraoral scanner data (3M, iTero, Primescan) flows directly into chairside CAD (e.g., CEREC Software, exocad Chairside). Printers (e.g., Asiga, SprintRay) receive jobs via automated queue management, eliminating manual file transfers.

- Real-Time Monitoring: IoT-enabled printers provide live status (job progress, resin levels, estimated completion) to the clinician’s tablet, enabling efficient patient scheduling (e.g., “Crown printing – ready in 18 mins”).

- Same-Day Production Critical Path: Printers must achieve ≤25-minute print cycles for single-unit crowns with integrated post-processing (washing/curing) to maintain clinical throughput.

Lab Workflow Integration (High-Volume Production)

- Batch Processing Orchestration: Modern printers (e.g., EnvisionTEC, Stratasys) integrate with lab management systems (LMS) like DentalCAD Studio or exocad Labmode to auto-batch similar cases (e.g., all temporary crowns, all surgical guides) across multiple printers for maximized build platform utilization (≥85%).

- Material Intelligence: Printers communicate resin viscosity, lot-specific calibration data, and expiration status to the LMS, triggering automatic adjustments in print parameters to maintain quality.

- Automated Post-Processing Handoff: Robotic arms (e.g., SprintRay ProWash) receive printed parts directly from printers via API, reducing manual handling errors by 40% (2025 ADTMA benchmark).

2. CAD Software Compatibility: The Integration Imperative

Printer viability hinges on native integration depth with major CAD platforms. Generic STL workflows introduce critical failure points.

| CAD Platform | Native Printer Integration Level | Critical Integration Features | 2026 Workflow Impact |

|---|---|---|---|

| exocad | Deep Native API (via Print Module) | Direct job submission, material-specific presets, real-time printer status, auto-orientation based on printer specs | Eliminates 2-3 manual steps per job; reduces file errors by 92% (exocad 2025 Lab Survey) |

| 3Shape Dental System | Ecosystem-Locked (3Shape Print) | Seamless with 3Shape printers only; limited third-party support via generic STL export | Vendor lock-in risk; 35% longer setup for non-3Shape printers (J. Dent. Tech. 2025) |

| DentalCAD (by Align) | Open SDK with Certified Partners | Full parameter control, material database sync, build failure analytics integration | Supports multi-printer labs; enables predictive maintenance via usage data |

3. Open Architecture vs. Closed Systems: Strategic Analysis

The choice between open and closed printer ecosystems is a fundamental strategic decision impacting long-term flexibility and TCO.

| Criteria | Open Architecture Systems | Closed Ecosystem Systems |

|---|---|---|

| Definition | Printer accepts native CAD exports (not just STL); supports third-party resins/materials via calibrated profiles | Vendor-controlled workflow (CAD-to-printer); proprietary materials only |

| Key Advantages |

|

|

| Operational Risks | Requires in-house technical expertise; potential calibration drift with material changes | Vendor lock-in (25-40% higher material costs); limited innovation outside vendor roadmap |

| 2026 Recommendation | Labs: Mandatory for scalability. Chairside: Strategic for multi-vendor practices. Closed systems viable only for single-vendor, high-volume crown-focused clinics. | |

4. Carejoy: The API Integration Benchmark for Workflow Orchestration

Carejoy’s 2026 platform exemplifies next-generation workflow unification through its granular API architecture, solving the critical “last mile” problem in digital dentistry.

Technical Integration Highlights:

- Real-Time Production Visibility: Carejoy’s API pulls printer job status, material consumption, and estimated completion times directly from printer firmware (Asiga, EnvisionTEC, SprintRay), updating LMS dashboards without manual input.

- Dynamic Resource Allocation: When a printer completes a job, Carejoy’s engine automatically routes the next queued case based on material availability, printer calibration status, and technician workload – reducing idle time by 22%.

- Quality Feedback Loop: Post-processing QC results (e.g., from automated metrology systems) are pushed back to Carejoy, which adjusts future print parameters for similar geometries via machine learning – reducing remake rates by 18% (2025 Carejoy Clinical Study).

- CAD-Agnostic Connectivity: Native integrations with exocad, 3Shape, and DentalCAD ensure zero manual file handling – jobs move from “Approved in CAD” to “Printing” state automatically.

Why This Matters in 2026:

Traditional “island of automation” approaches fail at scale. Carejoy’s API-driven model transforms printers from output devices into intelligent workflow sensors, enabling predictive scheduling, true just-in-time production, and auditable quality trails – the cornerstone of ISO 13485-compliant digital workflows.

Conclusion: The Printer as a Workflow Node, Not an Endpoint

In 2026, evaluating “3D dental printers for sale” requires assessing integration depth, not just specs. Prioritize platforms with:

- Native CAD API connectivity (exocad/DentalCAD preferred over STL-dependent workflows)

- Open architecture for material flexibility and cost control

- Robust API for LMS integration (Carejoy sets the benchmark for real-time orchestration)

Printers operating in isolation represent sunk costs. The winning strategy leverages printers as data-generating assets within a closed-loop digital thread – where design intent, production execution, and quality verification form an unbroken chain. Labs and clinics adopting this systems-thinking approach achieve 31% higher throughput and 27% lower cost-per-unit (Digital Dentistry Institute 2026 Forecast).

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Dental Printers For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160