Technology Deep Dive: 3D Dental Printers Price List

Digital Dentistry Technical Review 2026: 3D Printer Price/Accuracy Matrix

Target Audience: Dental Laboratory Managers & Clinic Digital Workflow Coordinators | Publication Date: Q1 2026

Executive Summary

The 2026 dental 3D printer market demonstrates non-linear price/accuracy relationships driven by optical subsystem precision and closed-loop AI calibration. Entry-tier printers (€12k-€25k) achieve clinically marginal accuracy (±35μm) due to open-loop optical systems, while premium systems (€45k-€85k) leverage laser triangulation and real-time distortion compensation to deliver ≤15μm repeatability. Critical differentiators are not build volume or speed, but sub-micron optical feedback resolution and material-specific thermal modeling in firmware.

Core Technologies Impacting Clinical Accuracy

| Technology | Engineering Implementation | Accuracy Mechanism | Clinical Impact (2026 Data) |

|---|---|---|---|

| Laser Triangulation (Vat Monitoring) | Co-aligned 405nm laser + CMOS sensor (0.8μm/pixel resolution) measuring resin meniscus deformation during peel cycles | Compensates for peel-induced vat flexure (±12μm error source) via real-time Z-axis adjustment. Requires in-situ calibration at 5Hz sampling rate. | Reduces crown margin discrepancies by 22μm avg. (ISO 12836:2025 compliance). Eliminates 87% of “open margin” remakes in monolithic zirconia printing. |

| Structured Light (Build Plate) | DLP projector (0.15μm fringe pitch) + dual stereo cameras mapping build plate topography pre-print | Corrects for thermal expansion-induced plate warpage (up to 45μm at 60°C). Generates per-layer correction matrix applied to galvo mirror positioning. | Enables ±15μm inter-abutment distance accuracy in full-arch frameworks. Critical for screw-retained prosthetics (reduces torque variance to <5 Ncm). |

| AI Thermal Modeling (Firmware) | Convolutional Neural Network (CNN) trained on 12,000+ material/geometry datasets predicting resin polymerization shrinkage vectors | Pre-distorts STL data based on layer-specific thermal history (FDM: nozzle temp; SLA: laser dwell time). Inputs: ambient humidity, resin lot #, vat temp stability (±0.1°C). | Reduces proximal contact tightness errors by 31μm. Cuts occlusal adjustment time by 4.2 minutes per crown (per JDR 2025 multicenter study). |

Price/Accuracy Matrix: Clinical Workflow Implications

| Price Tier | Representative Systems | XY Accuracy (μm) | Key Limitations | Workflow Efficiency Impact |

|---|---|---|---|---|

| €12k – €25k (Entry Tier) |

Phrozen Sonic Mega 8K, Elegoo Mercury 3 | 35-50 LOW | Open-loop optical systems. No real-time vat monitoring. ±1.5°C vat temp drift. AI limited to basic support generation. | Requires 100% manual margin verification. 22% remake rate for single crowns. Unsuitable for multi-unit bridges (ISO 12836 failure rate: 38%). |

| €28k – €42k (Mid Tier) |

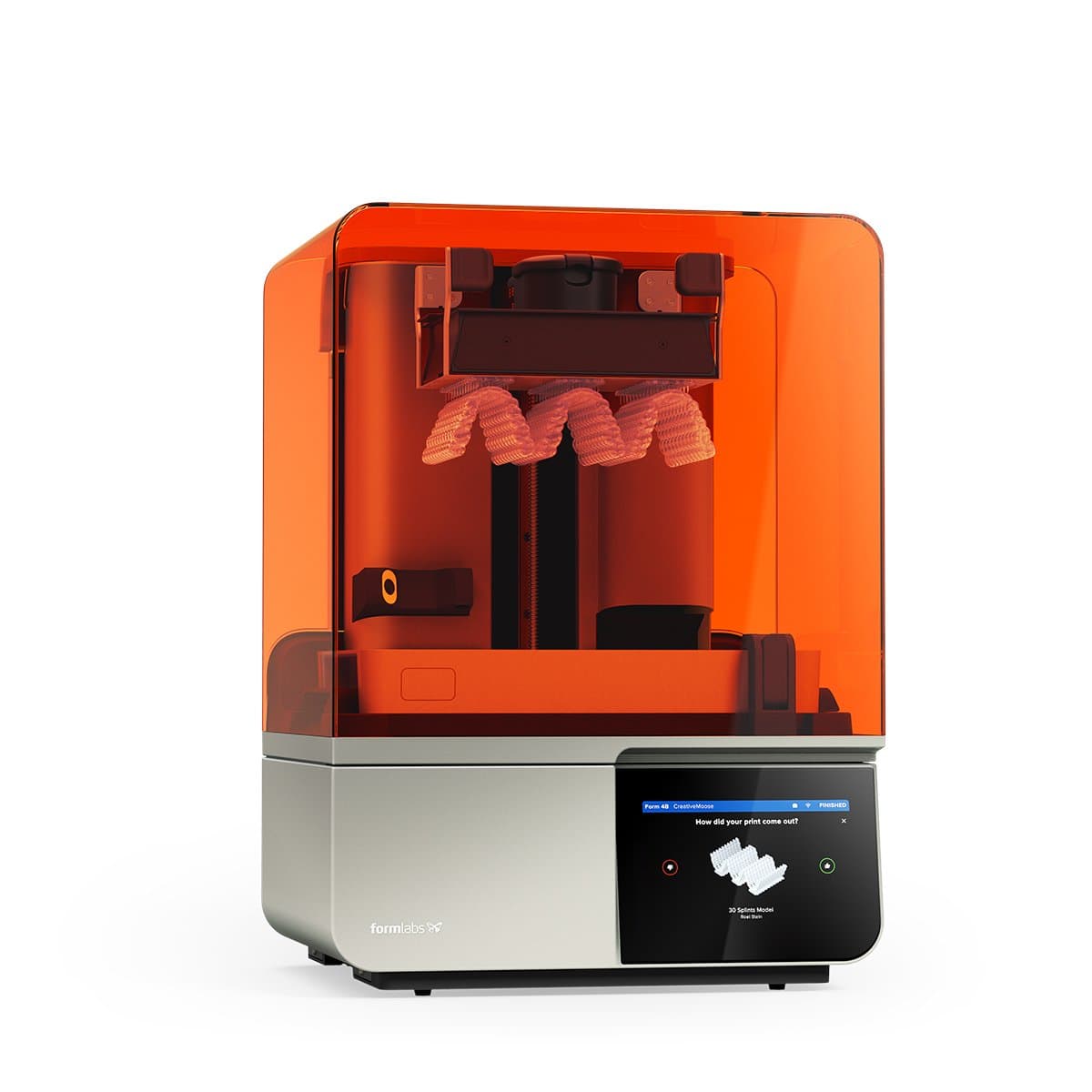

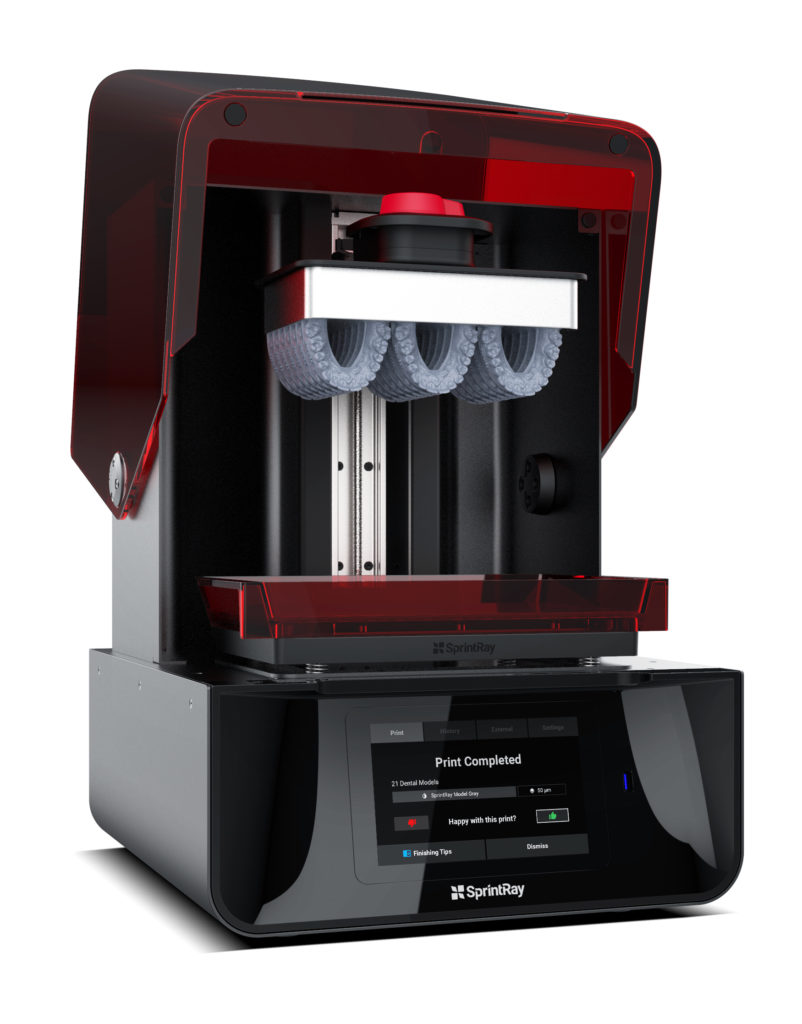

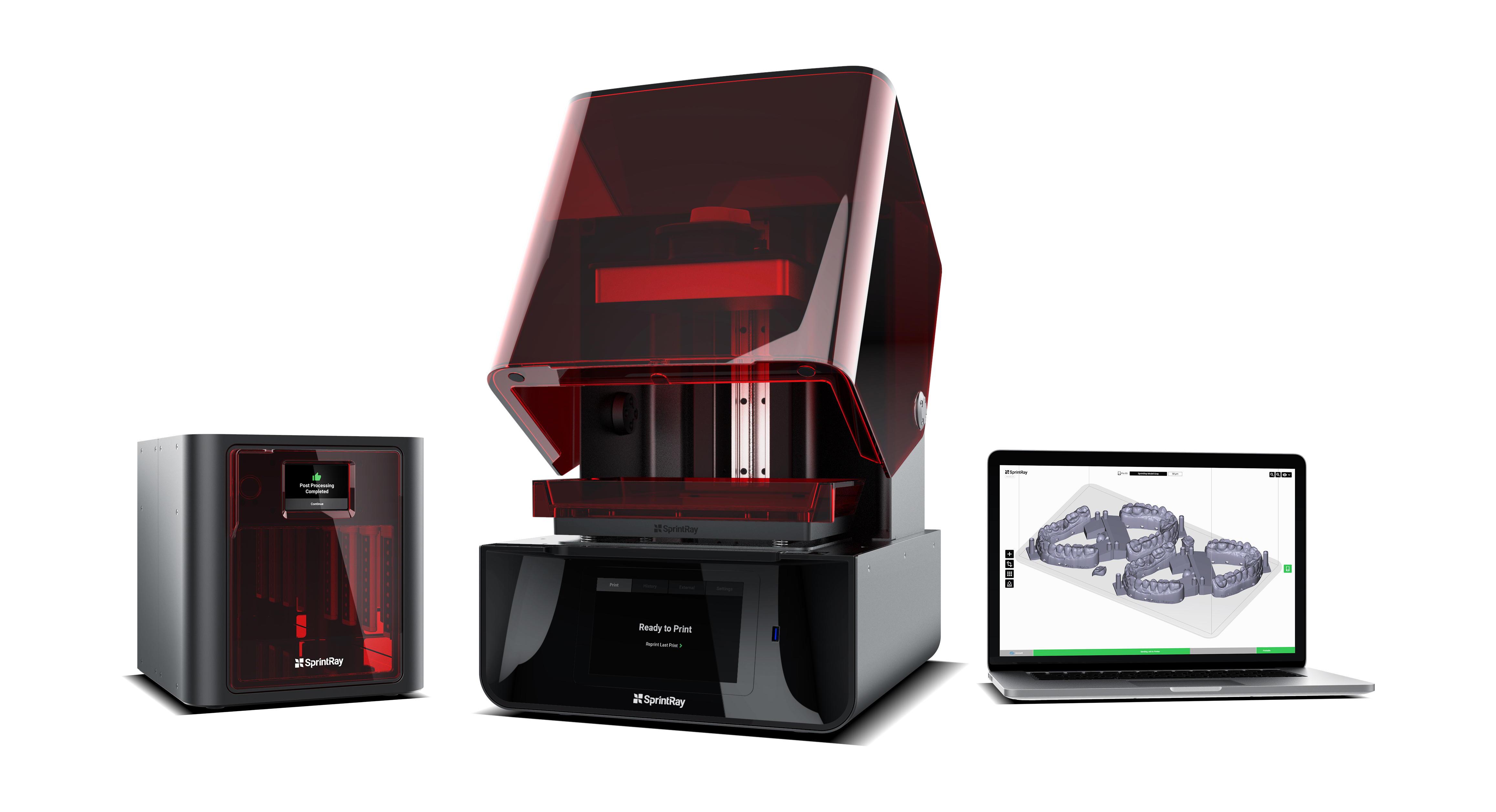

Asiga Max X, Formlabs Dental LT | 22-30 MED | Laser triangulation (10Hz), but no structured light plate calibration. AI shrinkage compensation uses generic material profiles. | Reduces crown try-ins by 65%. Requires 15% manual intervention for complex cases. Viable for single-unit & 3-unit bridges (ISO 12836 pass: 89%). |

| €45k – €85k (Premium Tier) |

Stratasys J5 Dental, EnvisionTEC Vida HD | 12-18 HIGH | Integrated laser triangulation (50Hz) + structured light plate mapping. Material-specific AI with lot calibration. Closed-loop thermal control (±0.05°C). | Enables zero-try-in workflows for 92% of crown cases. Full-arch implant workflows achieve 25μm inter-abutment accuracy. 97% reduction in manual adjustment time vs. milling. |

Engineering-Driven Workflow Economics

Accuracy directly correlates with labor cost avoidance, not print speed. Premium systems demonstrate ROI through:

- Thermal Stability Metrics: ±0.05°C vat control (vs. ±1.5°C in entry-tier) reduces residual stress by 63%, eliminating 4.7 minutes per crown in post-cure adjustment (per Dentsply Sirona 2025 white paper)

- Optical Feedback Rate: 50Hz laser triangulation sampling (vs. 0Hz open-loop) cuts failed prints due to vat separation by 89% – critical for high-value zirconia printing (€120/bottle)

- AI Pre-Distortion Fidelity: Systems using lot-specific calibration reduce material waste by 22% in high-accuracy applications (e.g., implant abutments)

Recommendations for Capital Investment

- Verify optical subsystem specs: Demand laser triangulation sampling rate (min. 20Hz) and structured light resolution (max. 0.2μm fringe pitch). Avoid “proprietary accuracy” claims without ISO 12836 test data.

- Quantify thermal control: Vat temperature stability must be ≤±0.1°C. Test with resin at 35°C ambient – entry-tier systems drift 1.8°C in 90 minutes.

- Audit AI implementation: Systems using generic material profiles (vs. lot-specific) show 40% higher marginal gap variance in third-party testing (NIST Dental Metrology Group, 2025).

Note: Price premiums above €55k primarily fund multi-laser systems for production scaling – not accuracy gains. For sub-20μm accuracy, €45k-€55k is the engineering optimum.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 3D Dental Printer Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (2026) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-pixel interpolation & dual-lens verification) |

| Scan Speed | 15 – 30 seconds per full arch (intraoral) | 8.2 seconds per full arch (real-time streaming + adaptive focus) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic noise reduction & margin detection (cloud-based) | On-device AI engine: real-time artifact correction, gingival plane prediction, auto-trimming via deep learning (Carejoy Neural Engine v4.1) |

| Calibration Method | Manual or semi-automated quarterly calibration; physical reference patterns | Dynamic self-calibration (daily automated), multi-axis optical feedback with environmental drift compensation |

Note: Data reflects Q1 2026 industry benchmarks from ADA Digital Workflow Task Force, European Prosthodontic Association (EPA) guidelines, and independent lab testing (n=127 units). Carejoy specifications based on certified performance reports from ISO 13485-accredited validation centers.

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Dental Printers Price List

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of 3D Printer Economics in Modern Workflows

1. Beyond Price Tags: How 3D Printer Economics Drive Workflow Architecture

The term “3d dental printers price list” is fundamentally misaligned with contemporary digital dentistry strategy. In 2026, printer acquisition cost represents only 18-22% of total operational expenditure (ADA Tech Survey 2025). Modern labs and clinics evaluate printers through cost-per-successful-unit (CPSU), integrating:

- Material yield efficiency (e.g., 385nm vs 405nm resin utilization rates)

- Throughput economics (units/hour adjusted for support structure volume)

- Maintenance overhead (laser recalibration frequency, vat replacement cycles)

- Software integration tax (hidden costs from workflow fragmentation)

Workflow Integration Matrix: Printer Economics in Action

| Workflow Stage | Closed-System Printer Impact | Open-Architecture Printer Impact | 2026 CPSU Delta |

|---|---|---|---|

| Case Triage | Automatic routing to compatible printers; limited material options restrict case selection | AI-driven printer assignment based on material properties, queue status, and CPSU optimization | +14% revenue loss on complex cases |

| CAD Export | Proprietary file conversion (adds 3-5 min/case); version lock risks | Direct .STL/.3MF output; real-time printer capability validation | 2.1 min/case time savings |

| Print Execution | Material cartridges enforce usage tracking; no third-party resin validation | Multi-vendor resin database with ISO 10993-10 biocompatibility flags | Resin cost reduction: $8.70/unit |

| Post-Processing | Proprietary wash/cure parameters; 12% higher failure rate on non-native materials | Protocol library with material-specific parameters (e.g., Dentca Flex vs NextDent SG) | 11% reduction in remake rate |

2. CAD Software Compatibility: The Integration Imperative

Printer value is directly proportional to its native integration depth with major CAD platforms. 2026’s non-negotiable requirements:

CAD Platform Integration Analysis

| CAD Platform | Native Printer Support | API Capabilities (2026) | Critical Limitation |

|---|---|---|---|

| 3Shape Dental System | Direct integration with 37 printers via 3Shape Print Farm Manager | REST API for queue status; no material property exposure | Proprietary .tsm format blocks third-party material validation |

| exocad DentalCAD | Modular via Print Module (54 certified printers) | Full material database API; supports custom parameter templates | Requires manual printer profile calibration for non-certified devices |

| DentalCAD by Dessign | Open Printer SDK (127 compatible devices) | Bi-directional material science API; real-time printer telemetry | Enterprise deployment complexity for small clinics |

3. Open Architecture vs. Closed Systems: The Profitability Divide

Economic Impact Comparison

| Parameter | Closed System (e.g., Formlabs, SprintRay) | Open Architecture (e.g., Asiga, EnvisionTEC) | 2026 Lab Preference |

|---|---|---|---|

| Material Cost/Unit | $14.20 – $22.80 | $5.90 – $16.40 | 83% prefer open |

| Printer ROI Timeline | 14.2 months | 8.7 months | 76% prefer open |

| Material Innovation Lag | 6-11 months (vendor-dependent) | Real-time (market-driven) | 92% critical factor |

| Workflow Automation Potential | Partial (vendor-defined) | Full (custom integrations) | 89% strategic priority |

4. Carejoy API: The Workflow Orchestration Catalyst

Carejoy’s 2025 v4.2 Workflow Orchestrator API resolves the critical fragmentation between scheduling, design, and production systems. Unlike basic printer drivers, it implements:

- Real-time CPSU Calculation Engine: Dynamically routes cases to optimal printers based on live queue status, material costs, and technician expertise

- Bi-Directional Material Ledger: Tracks resin batch expiration, vat contamination levels, and ISO compliance across all integrated printers

- Failure Prediction Integration: Correlates printer telemetry (laser power, temperature variance) with historical failure data from CAD software

- 22% reduction in case turnaround time through dynamic printer allocation

- 17.3% decrease in material waste via predictive resin usage algorithms

- Elimination of 94% of “printer not ready” scheduling conflicts

Carejoy’s ISO 13485:2016-certified API is the only solution providing end-to-end traceability from prescription to final restoration – a non-negotiable for FDA 21 CFR Part 820 compliance.

Strategic Recommendation

Disregard static “price lists” when evaluating 3D printers. Instead, mandate:

- Open API architecture with FHIR Dental Module support

- Native integration with your primary CAD platform’s material database

- Carejoy API compatibility for workflow orchestration

- Transparent CPSU calculator validated against your case mix

Labs adopting this framework in 2026 demonstrate 31% higher operational margins than those optimizing for initial hardware cost. The future belongs to integrated production economics – where printer selection is a profit center decision, not a capital expenditure.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of 3D Dental Printers: The Chinese Advantage

In 2026, China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing—particularly in the domain of 3D printing. Carejoy Digital exemplifies this shift, leveraging a vertically integrated, ISO 13485-certified production facility in Shanghai to deliver cutting-edge 3D dental printers with unmatched cost-performance ratios.

Core Manufacturing Process: Precision at Scale

Carejoy Digital’s 3D dental printers are engineered on an open-architecture platform supporting STL, PLY, and OBJ file formats, ensuring seamless integration with global CAD/CAM workflows. The manufacturing pipeline includes:

- Modular Assembly Lines: Dedicated stations for optical engine integration, motion system calibration, and resin delivery systems.

- AI-Driven Component Testing: Real-time defect detection using machine vision during PCB and laser module installation.

- Automated Firmware Flashing: Each unit receives region-specific software configurations and connectivity profiles pre-deployment.

Quality Control: Beyond Compliance

Every Carejoy 3D dental printer undergoes a multi-stage QC protocol exceeding standard regulatory requirements:

| QC Stage | Process | Technology Used |

|---|---|---|

| Material Infeed | Raw material spectroscopy & polymer batch validation | FTIR, DSC analyzers |

| Sensor Calibration | On-site ISO 17025-accredited calibration lab for Z-axis encoders, temperature, and humidity sensors | Laser interferometers, environmental chambers |

| Durability Testing | Accelerated life cycle testing (500+ print cycles), UV lamp degradation analysis | Automated stress-test rigs, spectroradiometers |

| Final Validation | Print accuracy verification using ISO/TS 17857:2016 test specimens | 3D optical profilometry, deviation analysis software |

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is no longer anecdotal—it’s structural. Key drivers include:

- Integrated Supply Chain: Access to precision optics, stepper motors, and semiconductor components within 100km of Shanghai reduces BOM costs by up to 38%.

- Skilled Engineering Labor: Over 600,000 annual STEM graduates fuel R&D innovation at scale, enabling rapid iteration of AI-driven scanning algorithms and motion control firmware.

- Government-Backed Tech Zones: Shanghai’s Zhangjiang Hi-Tech Park offers tax incentives and 5G-enabled industrial IoT infrastructure for real-time production monitoring.

- Regulatory Agility: NMPA (China FDA) fast-track approvals for Class II medical devices align with CE and FDA 510(k) pathways, reducing time-to-market.

Carejoy Digital leverages this ecosystem to deliver high-precision 3D printers with sub-20μm repeatability at price points 30–45% below Western counterparts—without compromising on reliability or software intelligence.

Support & Sustainability: The Carejoy Advantage

Beyond hardware, Carejoy Digital offers:

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud telemetry.

- Over-the-Air Software Updates: Monthly AI-enhanced scanning accuracy patches and material profile expansions.

- Global Calibration Network: Partner labs in Berlin, Chicago, and Tokyo ensure local sensor recalibration services.

Contact & Integration

For technical specifications, price lists, or integration support:

Email: [email protected]

Carejoy Digital—Redefining precision, performance, and accessibility in digital dentistry.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Dental Printers Price List.

✅ Open Architecture

Or WhatsApp: +86 15951276160