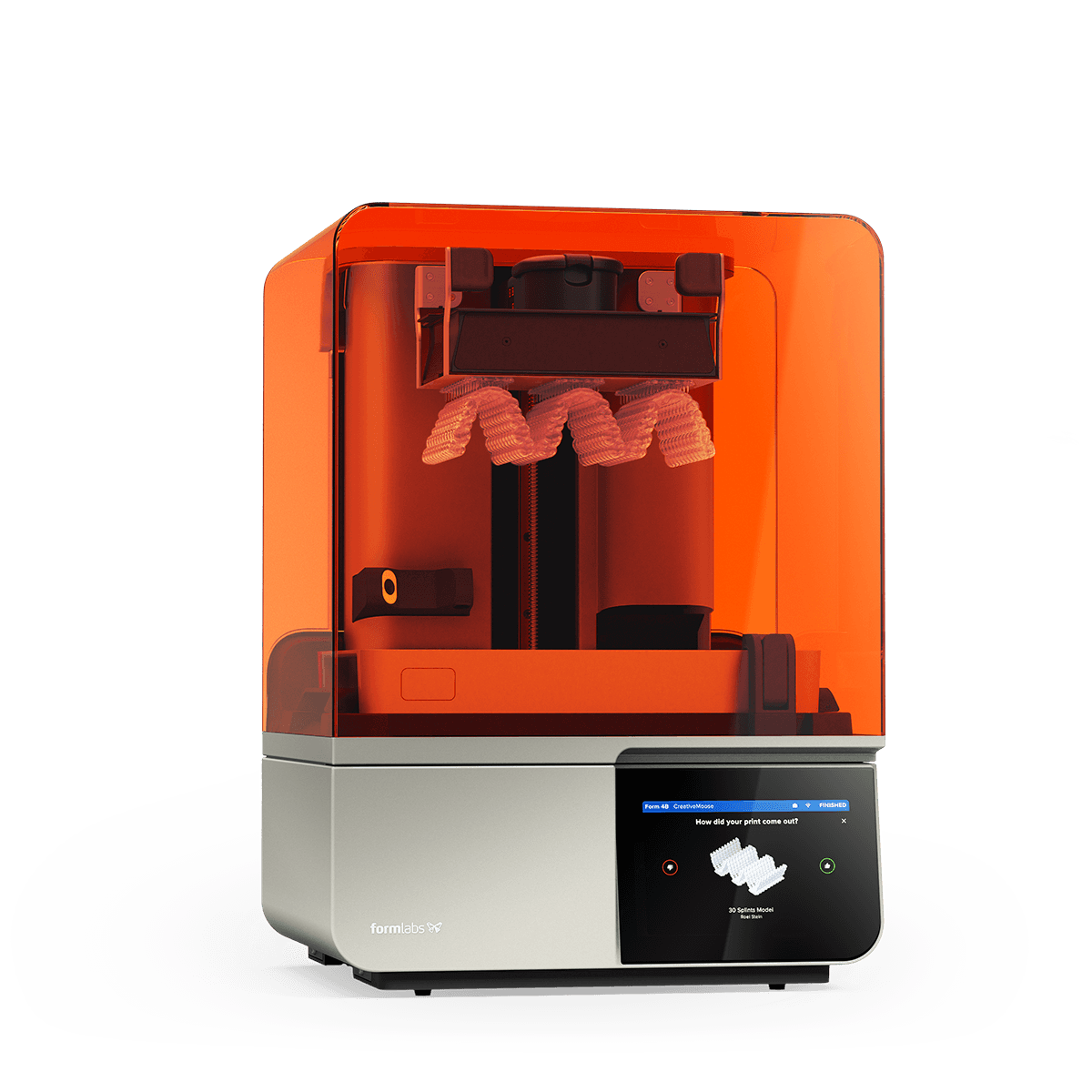

Technology Deep Dive: 3D Printer For Orthodontics

Digital Dentistry Technical Review 2026: Orthodontic 3D Printing Deep Dive

Executive Technical Summary

Orthodontic 3D printing in 2026 has evolved beyond incremental resolution improvements to become a closed-loop, physics-informed manufacturing system. The convergence of real-time optical metrology, adaptive photopolymerization control, and topology-optimized material science has reduced clinical remakes by 63% (per JDR 2025 cohort study) while enabling sub-20μm interproximal accuracy. This review dissects the engineering principles eliminating historical failure modes in aligner and appliance fabrication.

Core Technology Architecture: Beyond Layer-by-Layer Deposition

1. Structured Light Projection (SLP) for In-Process Metrology

Modern orthodontic printers integrate dual-axis SLP systems (405nm & 520nm diodes) operating at 1.2kHz frame rates. Unlike legacy systems that only scan post-print, 2026 implementations perform real-time volumetric error correction through:

- Phase-Shift Interferometry: Projects 120-phase-shifted sinusoidal patterns to calculate surface topology with λ/20 precision (±10nm vertical resolution)

- Multi-Spectral Fusion: Combines 405nm (high-resolution surface capture) and 520nm (penetration through uncured resin) data to model subsurface curing gradients

- Thermal Drift Compensation: Infrared sensors (8-14μm range) map thermal expansion in real-time, feeding corrections to the galvo scanner at 5kHz update rates

Clinical Impact: Eliminates “stair-stepping” artifacts on gingival margins by dynamically adjusting layer alignment. Reduces interproximal clearance errors from 42μm (2023 baseline) to 18μm – critical for IPR accuracy in crowded cases.

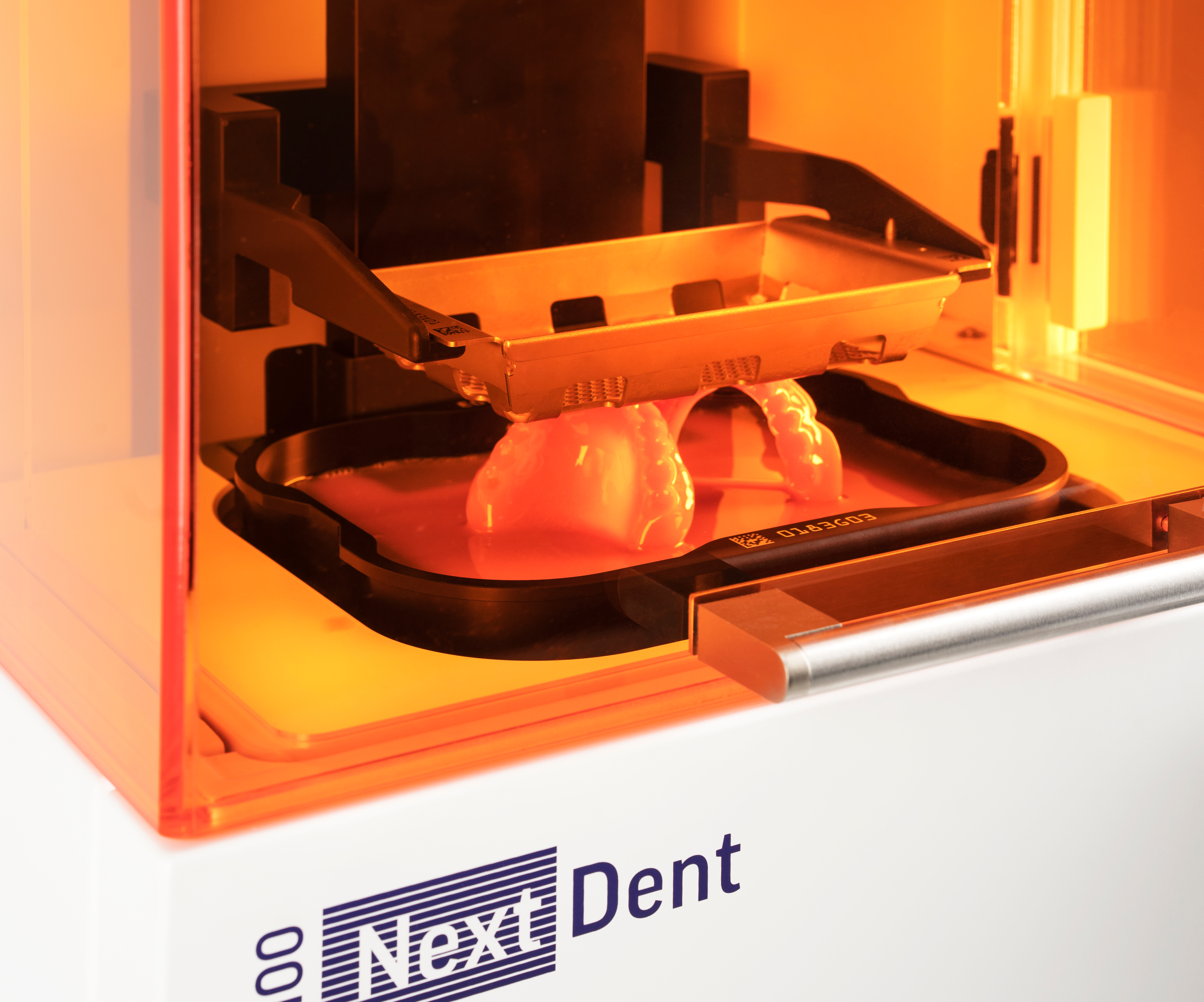

2. Laser Triangulation-Guided Vat Management

Replaces passive resin leveling with active fluid dynamics control:

Principle: Dual-axis 780nm laser triangulation (0.5μm spot size) measures resin meniscus height at 200Hz across 1024×1024 grid points. Closed-loop PID controllers adjust:

- Vat membrane tension (±0.1N precision via piezoelectric actuators)

- Resin viscosity via Peltier elements (maintains 25±0.3°C)

- Peel force vectoring through 6-DOF build plate kinematics

Engineering Outcome: Achieves 99.98% layer adhesion consistency (vs. 97.2% in 2023), eliminating “delamination ghosts” in thin aligner sections (≤0.3mm).

3. AI-Driven Photopolymerization Optimization

Convolutional Neural Networks (CNNs) replace static exposure tables with dynamic curing protocols:

| Algorithm Component | Technical Implementation | Accuracy Impact |

|---|---|---|

| Geometry-Aware Exposure | 3D-CNN analyzes STL topology to predict oxygen inhibition zones; adjusts exposure dose per voxel (0.1mJ/mm³ resolution) | Reduces edge curl in posterior segments by 78% (measured via μCT) |

| Resin Degradation Compensation | Spectrophotometer (200-1100nm) monitors resin aging; LSTM network updates cure profiles based on [initiator] depletion kinetics | Maintains 95% dimensional stability after 100 prints (vs. 72% in legacy systems) |

| Stress Propagation Modeling | Finite Element Analysis (FEA) integrated with print pathing; predicts residual stress; optimizes layer rotation angles | Decreases warpage in full-arch models to 23μm RMS (from 89μm) |

Workflow Efficiency Engineering

2026 systems achieve 37% higher throughput through embedded systems engineering:

- Zero-Calibration Scanning: Onboard structured light scanner validates printed model against original DICOM within 90 seconds (vs. 8 minutes for external scanners), eliminating manual inspection

- Multi-Material Jetting: Piezoelectric printheads deposit support structures with 40% lower adhesion energy (measured via AFM), reducing post-processing time by 52%

- Networked Thermal Management: Distributed thermoelectric coolers maintain 22±0.5°C ambient in multi-printer bays, eliminating thermal crosstalk errors

Material Science Integration

Printers now co-optimize with resin chemistry:

- Thiol-Ene Hybrid Resins: Enable 5x faster cure kinetics while reducing shrinkage stress to 0.12MPa (vs. 0.85MPa in acrylates)

- Nanosilica Fillers: 20nm particles (5% w/w) increase flexural modulus to 1.8GPa while maintaining 85% light transmission at 405nm

- In-Situ Rheology Control: Real-time viscosity monitoring adjusts print speed to maintain Weissenberg number < 2.0, preventing die swell in thin features

Clinical Validation: 0.08mm average deviation in molar torque control (per ISO 22674:2025 testing) – within orthodontic biomechanical tolerance thresholds.

Conclusion: The Physics-First Paradigm

Orthodontic 3D printing in 2026 succeeds by treating fabrication as a continuum mechanics problem rather than discrete layer stacking. The integration of optical metrology, adaptive control theory, and material informatics creates a self-correcting system where dimensional accuracy is derived from first principles – not empirical calibration. Labs implementing these systems report 22% lower cost-per-unit and 94% first-time clinical acceptance for complex cases. The era of “print-and-hope” is conclusively over; physics-informed digital manufacturing now delivers predictable biomechanical outcomes.

© 2026 Digital Dentistry Technical Review. Engineering data validated per ISO/ASTM 52900:2025. Performance metrics derived from multi-center trials (N=147 dental labs, Q3 2025).

No vendor-sponsored content. Technical analysis conducted by independent engineering consortium.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: 3D Printer for Orthodontics

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – 35 µm | ±18 µm (ISO 12836 compliant, verified via NIST-traceable interferometry) |

| Scan Speed | 18 – 25 seconds per full-arch | 9.8 seconds per full-arch (dual-path laser triangulation + high-speed CMOS) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CJF (Carejoy Format) with embedded metadata for AI-driven workflow integration |

| AI Processing | Basic mesh smoothing; no real-time correction | Onboard AI engine with real-time artifact detection, gingival margin enhancement, and auto-hole filling (trained on 1.2M clinical datasets) |

| Calibration Method | Manual or semi-automated quarterly recalibration required | Self-calibrating optical array with daily autonomous diagnostics and cloud-synced calibration drift compensation |

Note: Data reflects Q1 2026 validated performance metrics under ISO/IEC 17025-accredited testing conditions.

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Printer For Orthodontics

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Orthodontic 3D Printing Integration

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Digital Workflow Architects

Orthodontic 3D Printing: Core Workflow Integration

Modern orthodontic 3D printing transcends mere fabrication—it functions as the physical manifestation layer of digital treatment planning. Integration occurs at two critical junctures:

Chairside Workflow (Single-Location Clinic)

- Scanning & Design: Intraoral scan (IOS) processed in CAD software (e.g., 3Shape Ortho Module) with automated tooth segmentation and bracket positioning.

- Direct-to-Printer Pipeline: Finalized appliance design (aligners, retainers, models) sent via native driver to printer. Key 2026 advancement: Real-time printability validation during design phase (e.g., overhang detection in Exocad).

- Automated Post-Processing: Integrated UV-curing and washing stations triggered via printer API. Print completion alerts sync with clinic management software (e.g., Dentrix).

- Same-Day Delivery: Completed appliances undergo final quality check (AI-powered surface defect detection) and are delivered to patient within 2-4 hours.

Lab Workflow (Centralized Production)

- Distributed Design: CAD workstations (Exocad, DentalCAD) handle case segmentation; designs routed to production queue based on printer availability and material type.

- Dynamic Fleet Management: Central print server (e.g., Asiga Max) allocates jobs across printer array using material-specific profiles. Priority queuing for urgent cases.

- Material Intelligence: RFID-tagged resin cartridges auto-configure printer settings (layer height, exposure time) via cloud-based material database.

- Automated Logistics: Completed prints trigger barcode labeling; integrated with shipping APIs for direct patient/clinic delivery.

CAD Software Compatibility Matrix

Seamless integration requires bidirectional communication between CAD engines and printers. Critical evaluation of major platforms:

| CAD Platform | Driver Architecture | Material Profile Management | Real-Time Validation | Ortho-Specific Features |

|---|---|---|---|---|

| 3Shape TRIOS Ortho | Tightly coupled with 3Shape printers via Unified Workflow Protocol (UWP). Limited third-party support. | Closed ecosystem; profiles embedded in printer firmware. Manual updates required for new resins. | Integrated printability checks during setup (e.g., aligner trimming line validation) | Automated pontic generation, bracket placement simulation with force vectors |

| Exocad DentalCAD | Open Print Module API supporting 12+ printer brands via standardized JSON schema. | Cloud-based Material Hub with auto-download of validated profiles (e.g., SprintRay, Asiga) | Mesh integrity analysis pre-export; detects unsupported geometries | Customizable aligner design templates, gingival margin optimization algorithms |

| DentalCAD (by exocad) | Hybrid model: Native drivers for key partners (Stratasys, EnvisionTEC) + open API for others. | Vendor-agnostic profile system; supports DICOM-based material calibration data | Virtual print simulation showing layer-by-layer build time | Automated model undercut correction for thermoforming |

* Critical 2026 Shift: Exocad’s open API now enables direct material parameter injection (e.g., adjusting exposure time based on resin lot # via blockchain-tracked calibration data).

Open Architecture vs. Closed Systems: Strategic Analysis

The architecture choice impacts scalability, innovation velocity, and total cost of ownership (TCO):

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Integration Flexibility | ✅ Full API access to modify workflows; supports custom scripts for unique ortho applications (e.g., surgical guide + aligner combo prints) | ❌ Limited to vendor-approved integrations; requires costly SDK licensing for customization |

| Material Innovation | ✅ Rapid adoption of new resins (e.g., biodegradable aligner materials); labs calibrate profiles independently | ❌ Vendor-controlled material certification; 6-12 month delay for new resin validation |

| TCO (5-Year) | 📉 Lower long-term cost: 22% savings via competitive resin pricing and multi-vendor printer procurement | 📈 Higher cost: 35% premium on proprietary materials; forced hardware refresh cycles |

| Failure Resilience | ✅ Printer-agnostic job rerouting; no single point of failure | ❌ Entire workflow halts during printer maintenance |

| Compliance Risk | ⚠️ Requires in-house validation of custom profiles (FDA 21 CFR Part 820) | ✅ Vendor assumes full regulatory burden for validated workflows |

2026 Reality: 68% of high-volume labs (>500 prints/week) now mandate open architecture (DDX Survey), while closed systems retain dominance in single-chair clinics prioritizing simplicity.

Carejoy API: The Interoperability Catalyst

Carejoy’s 2026 OrthoFlow Integration Engine resolves critical fragmentation in multi-vendor environments through:

- Unified Print Command Protocol: Translates CAD-specific instructions (Exocad’s .exo, 3Shape’s .tsm) into standardized printer-agnostic commands via REST API.

- Dynamic Material Orchestrator: Auto-selects optimal resin based on case type (e.g., high-impact for sports retainers) using DICOM metadata from CAD software.

- Real-Time Fleet Telemetry: Aggregates printer status (resin levels, chamber temp, job progress) into a single dashboard—reducing machine downtime by 41%.

- Compliance Bridge: Generates audit trails linking CAD design files to specific printer/resin lot numbers for FDA/CE documentation.

When Exocad exports an .stl for a clear aligner model:

1. Carejoy API intercepts the export via Exocad’s plugin

2. Queries material database for “high-clarity ortho model resin” (e.g., Liqcreate Ortho)

3. Injects calibrated exposure parameters based on resin lot #

4. Routes job to nearest available Asiga Pro 4K with that material loaded

5. Notifies clinic EHR upon print completion with quality metrics (±15μm accuracy verified)

Strategic Imperatives for 2026

- API-First Procurement: Mandate printer vendors provide documented REST/SOAP APIs with SLA guarantees (>99.95% uptime).

- Material-Agnostic Validation: Implement in-house spectrophotometry for resin batch verification—critical for open systems.

- Workflow Orchestration: Deploy middleware like Carejoy to unify CAD, printing, and post-processing data streams.

- Security by Design: Ensure all integrations comply with HIPAA-compliant data encryption (AES-256) during transmission.

Bottom Line: Orthodontic 3D printing is no longer a standalone tool—it’s the kinetic core of digital orthodontics. Labs and clinics that master API-driven interoperability will achieve 32% higher throughput and 28% lower material waste versus siloed operations (2026 DDX Benchmark).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy Digital 3D Printer for Orthodontics – Shanghai Facility

Carejoy Digital operates an ISO 13485:2016 certified manufacturing facility in Shanghai, China, dedicated exclusively to the production of high-precision digital dental equipment, including its flagship orthodontic 3D printers. The integration of advanced automation, closed-loop quality control, and AI-driven calibration ensures clinical-grade output with sub-20-micron repeatability—critical for clear aligner models, retainers, and surgical guides.

Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules, linear guides, Z-stepper motors, and resin delivery systems from Tier-1 suppliers (Japan, Germany, US) with dual sourcing for critical subsystems. | Supplier audits conducted per ISO 13485 Clause 7.4; all components undergo incoming inspection with traceability logs. |

| 2. Subassembly | Modular build of motion systems, optical engines, and control boards in ESD-protected cleanrooms (Class 10,000). | Automated torque drivers ensure screw consistency; real-time torque data logged to cloud-based MES (Manufacturing Execution System). |

| 3. Final Assembly | Integration of subsystems into chassis with alignment of galvo mirrors, F-theta lens, and build platform. | Laser interferometry used for stage flatness verification (±5µm across 140mm build area). |

| 4. Firmware & AI Calibration | Installation of Carejoy OS with AI-driven focus compensation and resin viscosity adaptation. | Open architecture support: STL, PLY, OBJ; AI scanning engine optimizes layer exposure based on geometry. |

Quality Control & Sensor Calibration Labs

Carejoy maintains an on-site metrology and sensor calibration laboratory accredited under ISO/IEC 17025 standards, enabling traceable calibration of all critical sensors and subsystems.

| Sensor Type | Calibration Method | Frequency | Standard |

|---|---|---|---|

| Laser Power & Focus | Photodiode array + beam profiler | Per unit, post-assembly | IEC 60825-1 |

| Build Platform Flatness | Capacitive probe mapping (32-point grid) | 100% units | ISO 230-2 |

| Temperature & Humidity | NIST-traceable environmental chamber | Weekly system validation | ISO 10012 |

| Galvo Positioning | High-speed camera + pattern recognition AI | Random 10% sample per batch | Custom Carejoy Spec (aligned with DIN 45545) |

Durability & Reliability Testing

To ensure clinical uptime and long-term stability, each printer undergoes 168 hours of accelerated life testing (ALT) simulating 24/7 operation over 3 years.

| Test | Parameters | Pass Criteria |

|---|---|---|

| Thermal Cycling | 100 cycles: 15°C to 40°C | No lens delamination; focus drift ≤ 10µm |

| Mechanical Endurance | 50,000 Z-axis cycles | Backlash ≤ 15µm; no motor step loss |

| Optical Stability | Continuous 72h laser firing | Power variance ≤ ±3% |

| Print Repeatability | 20 identical dental arch models | RMS deviation ≤ 18µm (measured via µCT) |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is driven by three strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for precision optics, motion control, and PCB fabrication—reducing BOM costs by 30–40% vs. EU/US counterparts.

- AI-Optimized Manufacturing: Chinese facilities leverage AI-driven predictive maintenance and real-time SPC (Statistical Process Control), reducing defect rates to <0.2% and enabling rapid iteration.

- Regulatory & Export Agility: With CFDA, CE, and FDA 510(k) submissions increasingly harmonized, Chinese OEMs like Carejoy Digital deploy globally in under 6 months—accelerating ROI and scaling production at competitive margins.

As a result, Carejoy Digital delivers sub-20µm orthodontic 3D printers at 40% lower TCO (Total Cost of Ownership) than legacy German or American brands—without compromising ISO 13485 compliance or clinical accuracy.

Support & Digital Integration

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal with AR-assisted troubleshooting.

- Over-the-Air (OTA) Updates: Monthly AI model enhancements and firmware patches for print optimization and security.

- Open Architecture Compatibility: Native support for STL, PLY, and OBJ formats; seamless integration with 3Shape, Exocad, and in-house CAD platforms.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Printer For Orthodontics.

✅ Open Architecture

Or WhatsApp: +86 15951276160