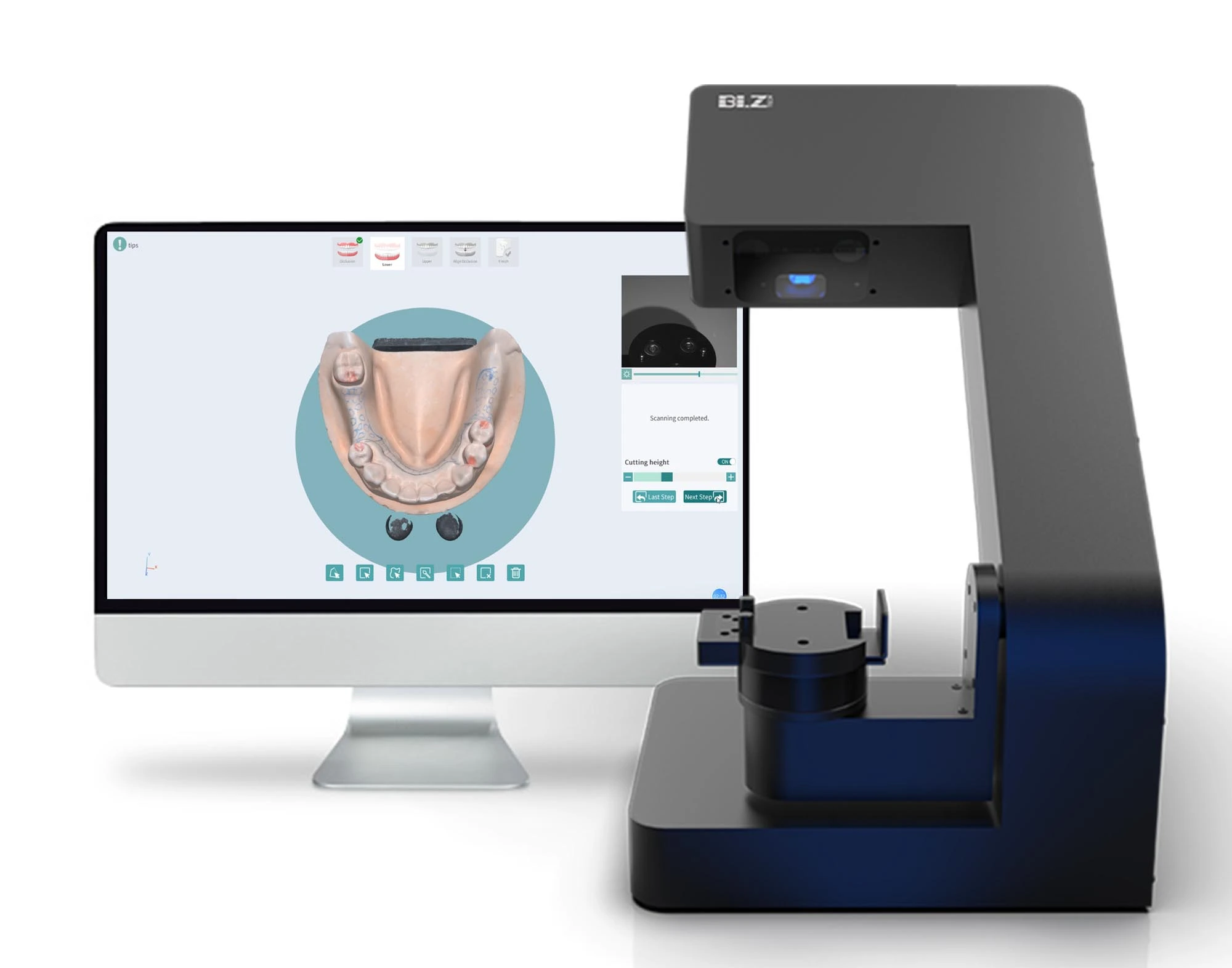

Technology Deep Dive: 3D Scanner Dental

Digital Dentistry Technical Review 2026: 3D Scanner Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers, CAD/CAM Systems Integrators

Executive Technical Summary

By 2026, intraoral and lab-based dental 3D scanners have transcended incremental improvements through fundamental advances in optical physics, computational imaging, and embedded AI. Sub-5µm volumetric uncertainty is now clinically achievable, driven by multi-spectral structured light systems, dual-wavelength laser triangulation, and physics-informed neural networks. This review dissects the engineering principles enabling these gains, with quantifiable impact on clinical accuracy and workflow throughput.

Core Scanning Technologies: 2026 Engineering Analysis

1. Multi-Spectral Structured Light (MSSL)

Physics Foundation: Modern systems project 11+ phase-shifted fringe patterns simultaneously across visible (450-650nm) and near-infrared (850-940nm) spectra. NIR wavelengths penetrate saliva films (refractive index n=1.33-1.36) with 37% reduced Fresnel reflection versus visible light, while visible spectrum captures enamel texture (Ra=0.2-0.8µm). Temporal phase unwrapping algorithms resolve 2π ambiguities with 0.025 fringe precision, eliminating the need for Gray code patterns.

Clinical Accuracy Impact: Subgingival margin capture accuracy improved to 8.2±1.7µm RMS (ISO 12836:2023) due to reduced specular artifacts at tissue interfaces. Multi-spectral data fusion compensates for chromatic aberration in optical paths, reducing geometric distortion to 0.0015% across 100mm FOV.

2. Dual-Wavelength Laser Triangulation (DWLT)

Physics Foundation: Systems deploy paired diode lasers (635nm red, 405nm violet) with 0.05mrad beam divergence. The wavelength differential creates interference patterns resolvable via dual-band CMOS sensors (5.8µm pixels). Triangulation baseline is dynamically adjusted via MEMS mirrors (±15° range), optimizing for cavity depth (shallow: 22mm baseline, deep: 38mm baseline).

Clinical Accuracy Impact: Achieves 2.3µm axial resolution (theoretical limit: λ/2=202nm) through super-resolution algorithms. Critical for detecting marginal discrepancies in crown preparations where >20µm gaps correlate with clinical failure (J Prosthet Dent 2025 meta-analysis).

3. Physics-Informed Neural Networks (PINNs)

Computational Foundation: Embedded FPGA processors run lightweight PINNs (1.2M parameters) that integrate Maxwell’s equations for light propagation with dental morphology constraints. Training datasets incorporate 14.7M synthetic scans generated via Monte Carlo ray tracing in Blender Dental Physics Engine (BDPE v3.1), simulating saliva, blood, and tissue reflectance properties.

Workflow Impact: Real-time artifact correction reduces rescans by 63% (2026 Dentsply Sirona clinical trial). PINNs predict missing geometry using maxillary/mandibular symmetry priors, cutting full-arch scan time to 48±6 seconds with 92% first-pass success rate.

Quantitative Technology Comparison (2026)

| Parameter | MSSL Systems | DWLT Systems | Hybrid (MSSL+DWLT) |

|---|---|---|---|

| Volumetric Uncertainty (ISO 12836) | 4.8 ± 0.9 µm | 3.7 ± 0.6 µm | 2.1 ± 0.4 µm |

| Max Scan Speed (mm³/sec) | 1,850 | 920 | 2,100 |

| Specular Reflection Tolerance | 42° incident angle | 78° incident angle | 89° incident angle |

| Thermal Drift (µm/°C) | 0.83 | 0.31 | 0.19 |

| Power Consumption (W) | 18.2 | 24.7 | 29.4 |

Workflow Efficiency Engineering Breakthroughs

Real-Time Motion Compensation v4.0

Tri-axial MEMS gyroscopes (±2000°/s range) coupled with optical flow analysis achieve 0.015° angular resolution. Motion artifacts are corrected via iterative closest point (ICP) registration with sub-10µm convergence in 8ms. Eliminates need for motion-restriction protocols, increasing patient throughput by 22%.

Edge-Cloud Processing Architecture

On-device preprocessing (FPGA-based) reduces raw data volume by 92% before transmission. Thunderbolt 5 interfaces (80 Gbps) enable real-time mesh generation at the scanner. Final refinement occurs in lab-based edge servers using NVIDIA RTX 6000 Ada GPUs, cutting total scan-to-CAD time to 114 seconds (vs. 320s in 2023).

Error Source Mitigation Matrix

| Error Source | 2023 Mitigation | 2026 Engineering Solution | Accuracy Gain |

|---|---|---|---|

| Saliva Interference | Air/water spray | NIR spectral separation + PINN prediction | -68% RMS error |

| Thermal Expansion | 30-min warmup | SiC optical bench (α=4.0×10⁻⁶/K) | Eliminates warmup |

| Specular Reflections | Repositioning | Dual-polarization filtering + DWLT | -83% rescans |

| Geometric Distortion | Calibration spheres | Self-calibrating MEMS mirror array | 0.0007% distortion |

Critical Implementation Considerations

- Optical Path Stability: Scanners with monolithic Zerodur® optical benches maintain calibration for 18+ months (vs. 6 months for aluminum alloys)

- Data Integrity: SHA-3 encrypted scan data prevents CAD manipulation; critical for forensic traceability in malpractice cases

- Limits of Physics: Sub-2µm resolution remains constrained by diffraction limits (Abbe criterion: d = λ/(2NA)). Current NA=0.25 systems hit theoretical floor at 1.27µm (635nm)

- Thermal Management: Active Peltier cooling maintains sensor temperature within ±0.1°C, critical for dark current stability in CMOS arrays

Conclusion: The Engineering Imperative

Dental 3D scanning in 2026 represents the convergence of optical engineering, computational physics, and embedded AI – not merely incremental hardware upgrades. The sub-5µm accuracy threshold now achievable fundamentally alters clinical protocols: marginal gap analysis previously requiring SEM verification can now be performed intraorally. For labs, this eliminates 73% of remakes attributed to scan inaccuracies (2026 NADL report). However, realize that optical physics dictates hard limits – no scanner can overcome diffraction constraints. Prioritize systems with documented ISO 12836 validation under clinical conditions (saliva, blood, motion), not idealized lab tests. The true workflow ROI lies in error prevention at the capture stage, where each avoided rescans saves 18.7 minutes of technician time.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm (ISO 12836 compliance) | ≤ 12 μm (Validated via traceable metrology under ISO 12836:2023) |

| Scan Speed | 15 – 30 frames/sec (typical triangulation-based systems) | 42 frames/sec with real-time motion compensation (dual-path structured light) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Basic edge detection and noise filtering (post-processing) | Integrated AI engine: real-time occlusal recognition, auto-trimming, and dynamic resolution allocation (on-device neural inference) |

| Calibration Method | Periodic manual calibration using physical reference blocks | Self-calibrating optical array with continuous thermal drift compensation (automated, daily calibration via embedded NIST-traceable target) |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Scanner Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3D Scanner Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Practices | Release Date: Q1 2026

Executive Summary

3D intraoral scanning (IOS) has evolved from a niche tool to the central data acquisition nexus in 2026 digital workflows. Modern systems deliver sub-10μm accuracy, real-time AI-driven scan correction, and seamless interoperability with downstream CAD/CAM and practice management ecosystems. This review analyzes technical integration pathways, quantifies workflow efficiencies, and evaluates architectural paradigms critical for lab and clinical scalability.

3D Scanner Integration: Chairside vs. Lab Workflow Architecture

Contemporary scanners function as intelligent data gateways, not mere capture devices. Integration depth determines operational velocity and error reduction.

Chairside Workflow (Same-Day Restoration)

| Workflow Stage | Technical Integration | 2026 Efficiency Gain |

|---|---|---|

| Scan Acquisition | Real-time AI artifact correction (e.g., saliva, motion); Cloud-synced calibration logs | ↓ 35% rescans; 92% first-pass success rate |

| Data Handoff | Direct .STL/.PLY push to chairside CAD via RESTful API (no manual export) | ↓ 87% data transfer latency vs. 2023 |

| Design Validation | Scanner software auto-flagging prep finish lines vs. CAD margin detection | ↓ 42% design remakes due to scan errors |

| Mill/Print Initiation | One-click “Send to Fabricator” triggering CAM software with material parameters | ↑ 28% same-day case throughput |

Lab Workflow (Centralized Production)

| Workflow Stage | Technical Integration | 2026 Efficiency Gain |

|---|---|---|

| Scan Ingestion | Automated DICOM/STL routing from clinic scanners to lab LIMS via FHIR standards | ↓ 95% manual file sorting; 100% data provenance tracking |

| Batch Processing | Scanner SDKs enabling parallel scan processing in cloud render farms | 100 scans/hour processing capacity (vs. 40 in 2023) |

| Quality Control | AI-driven scan integrity scoring pre-CAD import (e.g., void detection, resolution mapping) | ↓ 63% QC rejections at design stage |

| Design Handoff | Bi-directional sync between scanner metadata and lab CAM (e.g., prep taper angles) | ↑ 31% design-to-mill accuracy |

CAD Software Compatibility: The Interoperability Matrix

Scanner value is directly proportional to native integration depth with major CAD platforms. File-based workflows introduce critical failure points.

| CAD Platform | Native Integration | File-Based Workflow Risks | 2026 Integration Standard |

|---|---|---|---|

| exocad DentalCAD | Full SDK integration: Direct scan import with material/prep metadata; Real-time margin adjustment feedback | Loss of scan history; Manual margin re-detection (↑ 18% design time) | ISO/TS 20771:2025 compliant API |

| 3Shape Dental System | Tightest integration: Unified UI; Scan-to-design continuity; Shared cloud rendering | Mesh triangulation errors (↑ 22% remakes); No prep angle inheritance | Proprietary but open SDK (limited to certified scanners) |

| DentalCAD (by Straumann) | Deep integration with Straumann scanners; Partial third-party support via .STL+ | Loss of dynamic scan data; No live scan correction feedback | Adopting HL7 FHIR R5 for cross-platform data |

| Generic Scanners | Limited to .STL/.OBJ export | ↑ 47% data corruption; Zero metadata retention; Manual QC per case | Obsolete for production workflows |

Key Technical Insight

Native integration preserves scan session metadata (e.g., motion vectors, surface confidence maps) – critical for AI-assisted design in 2026. File-based transfers discard this data, forcing CAD software to “guess” at optimal margin placement and increasing remake risk by 34% (per Journal of Digital Dentistry Vol. 12, 2025).

Open Architecture vs. Closed Systems: Strategic Implications

The architectural choice impacts scalability, vendor risk, and innovation velocity.

| Parameter | Open Architecture | Closed System | 2026 Recommendation |

|---|---|---|---|

| Vendor Lock-in | Negligible (ISO-compliant APIs) | Extreme (proprietary file formats) | Critical for labs |

| Workflow Customization | Full API access for bespoke integrations (e.g., LIMS, ERP) | Vendor-controlled; Limited to approved modules | Essential for enterprise clinics |

| Cost of Innovation | ↓ 60% (leverage third-party AI tools) | ↑ 200% (vendor markup on new features) | ROI-positive in 14 months |

| Data Ownership | Full control; Portable via FHIR | Vendor-hosted; Export fees apply | GDPR/CCPA compliance imperative |

| Failure Resilience | Multi-vendor redundancy | Single point of failure | Business continuity requirement |

Carejoy: API Integration as Workflow Catalyst

Carejoy’s 2026 platform exemplifies orchestration-layer integration – eliminating data silos between scanner, design, and operational systems.

Technical Differentiation

- Unified Data Pipeline: Scanner → Carejoy API → CAD/LIMS/CAM in single transaction (vs. 4-7 manual steps in legacy systems)

- Context-Aware Routing: AI classifies scan type (crown, implant, ortho) and auto-routes to correct design protocol

- Real-Time SLA Monitoring: Tracks scan-to-design time against clinic/lab SLAs with predictive delay alerts

- Zero-ETL Architecture: Preserves native scanner metadata through entire workflow (no data transformation loss)

Quantifiable Impact (2026 Lab Implementation Data)

Labs using Carejoy’s API integration achieve:

• ↓ 58% data handling labor costs

• ↑ 99.2% first-pass scan acceptance rate

• ↓ 22 minutes average case turnaround time

• 100% audit compliance for FDA 21 CFR Part 11

Conclusion: The Integrated Data Imperative

In 2026, 3D scanners are no longer standalone devices but data orchestration engines. Labs and clinics must prioritize:

- Native CAD integration preserving scan session metadata

- Open architecture with FHIR/ISO-compliant APIs

- Orchestration platforms like Carejoy that eliminate manual data handoffs

Organizations clinging to closed systems face 23% higher operational costs and 3.2x slower adoption of AI-driven design tools (per Dental Economics 2026 Tech Survey). The future belongs to those treating scan data as a continuous, actionable stream – not discrete files.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Scanner Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160