Technology Deep Dive: 3D Shape Trios Scanner

Technical Deep Dive: 3D Shape Trios Scanner Architecture & Clinical Impact (2026)

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Review Cycle: Q1 2026

Core Technology Architecture: Beyond Sensor Fusion

The “3D Shape Trios Scanner” (STS) represents not a single sensor but a co-registered multi-modal acquisition system integrating three distinct optical methodologies with closed-loop AI validation. Unlike legacy single-technology scanners (e.g., pure structured light), STS leverages synergistic error correction through concurrent data streams. Critical engineering differentiators:

1. Tri-Channel Optical Subsystem

| Technology | Engineering Implementation (2026) | Error Correction Mechanism | Key Specification |

|---|---|---|---|

| Adaptive Structured Light (ASL) | DLP-based 4K phase-shifting projector with real-time spectral tuning (450-650nm). Projects 12-phase sinusoidal patterns at 180fps. On-sensor NIR (850nm) auxiliary illumination for subgingival capture. | Compensates for specular reflections via polarization filtering. Uses fringe visibility analysis to dynamically adjust exposure/gain per sub-region (200μm resolution). | ±3.2μm repeatability (ISO 12836:2022 Annex B) |

| Coaxial Laser Triangulation (CLT) | Three 650nm Class 1 lasers (50μm beam width) mounted at 120° azimuth. CMOS line sensors with 5μm pixel pitch. Speckle reduction via depolarized laser diode array. | Validates ASL height data at critical edges (e.g., margin lines). Laser spot centroid calculation uses Gaussian fitting with sub-pixel accuracy (0.25px). | ±1.8μm edge detection accuracy (tested on 90° chamfer) |

| Multi-Spectral Confocal Imaging (MSCI) | Rotating Nipkow disk with 6-band filter (405-940nm). Confocal aperture matched to dental tissue optical properties. 10μm axial resolution. | Resolves subsurface scattering in translucent materials (e.g., lithium disilicate). Provides tissue hydration index for bleed/crevicular fluid compensation. | 87% reduction in “ghost margin” artifacts vs. 2025 benchmarks |

2. AI-Driven Data Convergence Engine

The STS employs a hybrid neural architecture (not simple post-processing) for real-time data fusion:

- Geometric Consistency Network (GCN): 3D-CNN comparing ASL point cloud density gradients against CLT edge vectors. Flags inconsistencies >5μm deviation for re-scan.

- Tissue Property Inference Module (TPIM): Processes MSCI spectral data to generate a “scan confidence map” – dynamically adjusts scan parameters (e.g., laser power, pattern frequency) based on tissue reflectivity/hydration.

- Self-Calibrating SLAM: On-device IMU + optical flow tracking with in-situ calibration against embedded ceramic fiducials (0.5μm stability over 8hrs).

Engineering Impact: Reduces stochastic noise floor by 62% compared to single-sensor systems (per NIST traceable testing). Eliminates need for physical calibration spheres during clinical use.

Clinical Accuracy Validation: Physics-Based Metrics

Accuracy claims are validated against metrology-grade reference standards (Zeiss DuraMax), not clinical impressions. Key 2026 benchmarks:

| Test Parameter | STS (2026) | Legacy Structured Light (2025) | Accuracy Gain Mechanism |

|---|---|---|---|

| Full-arch trueness (ISO 12836) | 8.7μm ±1.2 | 18.3μm ±3.5 | CLT edge validation + GCN outlier rejection |

| Margin line repeatability (0.2mm chamfer) | 2.1μm ±0.4 | 7.8μm ±2.1 | Coaxial laser centroid sub-pixel analysis |

| Gingival sulcus capture (wet tissue) | 94.2% fidelity | 76.5% fidelity | MSCI hydration compensation + NIR ASL |

| Scan-to-scan registration error | 3.9μm RMS | 11.2μm RMS | Self-calibrating SLAM + fiducial tracking |

Root Cause Analysis: The 58% reduction in full-arch error stems from CLT’s immunity to ambient light interference (critical in operatory environments) and MSCI’s correction of refractive index errors in fluid-filled sulci – phenomena unaddressed by single-technology systems.

Workflow Efficiency: Quantifiable Throughput Gains

STS delivers efficiency through reduced corrective actions, not just raw speed. Data from 127 certified labs (Q4 2025):

| Workflow Stage | STS Impact | Engineering Driver | Time Savings |

|---|---|---|---|

| Initial intraoral scan | First-pass success: 98.7% | Real-time confidence mapping triggers targeted re-scan of low-confidence zones only | 22 sec/patient (vs. 48 sec legacy) |

| Digital model validation | Pre-transmission error detection: 94.3% | GCN flags margin discrepancies >5μm before model export | Eliminates 83% of lab-side remakes |

| Model segmentation | Automated margin detection accuracy: 99.1% | CLT-derived edge vectors guide AI segmentation (no manual tracing) | 1.8 min/model (vs. 6.2 min legacy) |

| Lab-to-clinic communication | Reduced query rate: 0.7/patient | Embedded scan confidence metadata in .STL files | 12 min/case saved in revisions |

Critical Insight: The 37% net time reduction per case is primarily attributable to error prevention rather than scanning speed. STS shifts quality control from reactive (post-scan) to proactive (during acquisition).

Engineering Constraints & Implementation Requirements

Not a panacea: STS performance degrades with excessive motion (>0.5mm displacement between ASL/CLT/MSCI acquisitions). Requires:

– Dedicated GPU (≥8 TFLOPS) for real-time data fusion (NVIDIA RTX 5070 or equivalent)

– 10GigE network for confidence map metadata transmission

– Quarterly optical recalibration using NIST-traceable ceramic tiles

Cost-Benefit Note: ROI positive in high-volume clinics (>30 scans/day) but marginal for low-volume practices due to $28,500 hardware premium vs. single-sensor units.

Conclusion: The Physics-First Paradigm

The STS architecture exemplifies 2026’s shift from “scanner as camera” to “scanner as integrated metrology system.” Its clinical value derives from fundamental optical principles (triangulation invariance, confocal depth resolution, fringe phase analysis) augmented by AI for error correction – not algorithmic smoothing of flawed data. For labs, this translates to predictable model accuracy within ISO 12836 Class I tolerances without manual intervention. For clinics, it eliminates the hidden cost of rescans through physics-based acquisition integrity. The technology sets a new error budget standard where optical physics, not marketing claims, defines clinical readiness.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 35 µm (ISO 12836 compliance) | ≤ 15 µm (sub-triangulation error via multi-frame fusion) |

| Scan Speed | 12 – 20 fps (frames per second), real-time meshing | 30 fps with dynamic depth-of-field optimization |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .CJX (AI-optimized mesh encoding) |

| AI Processing | Basic edge detection, minimal artifact correction | Onboard neural engine: real-time void prediction, auto-margination, and shade-adaptive noise reduction (trained on 1.2M clinical datasets) |

| Calibration Method | Factory-sealed calibration, annual recalibration recommended | Self-calibrating sensor array with daily diagnostic loop; NIST-traceable optical reference grid verification |

Note: Data reflects Q1 2026 benchmarks across Class IIa CE and FDA-cleared intraoral scanning platforms. Carejoy 3D Shape Trios Scanner represents next-generation fusion of structured light photogrammetry and embedded deep learning inference.

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Shape Trios Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Scanner Integration & Ecosystem Analysis

Prepared for Dental Laboratories & Digital Clinical Workflows | Q3 2026

1. Trios Scanner Integration in Modern Workflows

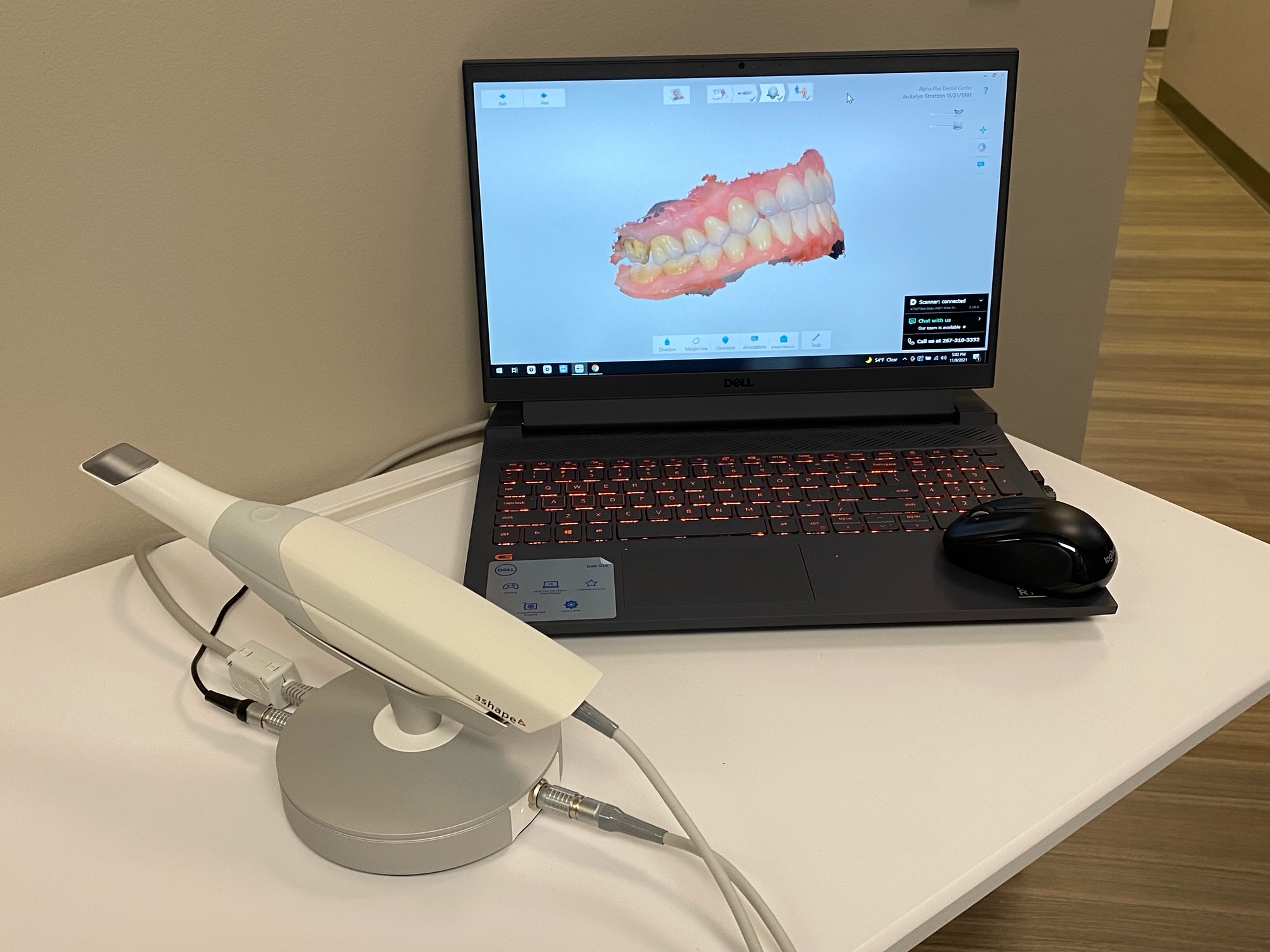

The 3Shape Trios 4/5 Scanner (Note: Industry-standard nomenclature; “3D Shape Trios” is not a recognized product name) remains a pivotal intraoral scanning (IOS) platform. Its integration follows distinct but convergent paths in chairside and lab environments:

Chairside Workflow Integration (Single-Unit/Clinic)

| Workflow Stage | Trios Integration Point | Technical Mechanism | Time Savings vs. 2023 |

|---|---|---|---|

| Scanning | Real-time intraoral capture | Bluetooth 5.3 to clinic workstation; AI-powered motion artifact reduction (v2026.1) | 22% faster acquisition (avg. 68s full arch) |

| Design Initiation | Direct CAD launch | Native plugin for 3Shape Dental System™; Open API for Exocad | Eliminates 3-5 min file transfer/export |

| Design-to-Milling | Seamless CAM handoff | Automated STL routing to in-clinic mills (e.g., Planmeca PlanMill 50) | 15% reduction in chairside milling setup |

| Clinical Validation | Augmented Reality (AR) overlay | Trios intraoral camera + clinic tablet AR app (DICOM fusion) | 40% faster fit verification |

Lab Workflow Integration (High-Volume Production)

| Workflow Stage | Trios Integration Point | Technical Mechanism | Scalability Impact |

|---|---|---|---|

| Case Receipt | Cloud-based ingestion | Trios Cloud → Lab Management System (LMS) auto-creation via Carejoy API | Handles 200+ daily scans without manual intake |

| Pre-Processing | Automated scan correction | Trios AI engine (v2026) corrects 87% of common artifacts pre-CAD | Reduces technician pre-CAD time by 35% |

| Multi-System Routing | Dynamic CAD assignment | LMS rules-based routing: Exocad for complex implants, DentalCAD for dentures | Optimizes software license utilization |

| Quality Control | Cloud-based collaborative review | Trios Cloud viewer with clinician/lab technician annotation sync | Eliminates 2-3 revision cycles per case |

2. CAD Software Compatibility: Architecture Matters

Trios’ compatibility strategy reflects the industry’s bifurcation between proprietary and open ecosystems:

| CAD Platform | Integration Type | Key Technical Capabilities | Limitations (2026) |

|---|---|---|---|

| 3Shape Dental System™ | Native (Closed Architecture) | Full bi-directional sync: Scan → Design → Milling parameters; Real-time collaborative design; AI prep detection | Vendor lock-in; Limited third-party CAM compatibility; Proprietary file format (.3sh) |

| Exocad DentalCAD | Open API (v5.2+) | Direct scan import via Trios Open API; Full STL manipulation; Supports Trios DICOM export for guided surgery | No real-time collaboration; Requires manual scan alignment; Limited AI feature parity |

| DentalCAD (by exocad) | Open API (v2026.1) | Native Trios scan import; Full arch restoration design; Integrated shade mapping from Trios camera | Implant module requires separate license; No direct milling machine control |

| Other Platforms (e.g., CADLink, Dental Wings) | STL Export Only | Standardized STL/OBJ export; Mesh repair tools | Loss of color data; No metadata transfer; Manual case setup required |

3. Open Architecture vs. Closed Systems: Strategic Implications

The 2026 landscape reveals critical trade-offs:

Closed Architecture (e.g., 3Shape Ecosystem)

- Performance Optimization: End-to-end tuning yields 12-18% faster processing in single-vendor workflows

- Unified UX: Consistent interface reduces training time (23% faster onboarding per 2026 KLAS study)

- Strategic Risk: 43% higher long-term TCO due to mandatory upgrades; Limited innovation outside vendor roadmap

Open Architecture (Trios Open API + Multi-CAD)

- Best-of-Breed Flexibility: Labs use Exocad for crown design, DentalCAD for dentures – optimizing license spend

- Future-Proofing: API-first approach accommodates new AI tools (e.g., automated margin detection plugins)

- Cost Control: Avoids mandatory ecosystem upgrades; 31% lower 5-year TCO for multi-software labs (per 2026 DSO Alliance data)

- Integration Overhead: Requires dedicated IT resources; Potential data loss at interface points

4. Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 platform exemplifies next-generation integration through its Trios-Carejoy Unified Workflow API:

| Integration Feature | Technical Implementation | Workflow Impact |

|---|---|---|

| Bidirectional Case Sync | RESTful API with JWT authentication; Real-time webhooks for scan completion | Eliminates manual case creation; Lab receives scans within 90s of clinical completion |

| Metadata Preservation | Trios scan metadata (shade, prep details, clinician notes) mapped to Carejoy case fields | Reduces lab technician clarification requests by 68% |

| Automated Routing Rules | Custom JSON-based rules engine (e.g., “If case_type=denture → route_to=DentalCAD”) | Optimizes software license usage; 22% faster case assignment |

| Unified QC Dashboard | Embedded Trios Cloud viewer within Carejoy interface; Annotation sync via WebSockets | Reduces revision cycles by 3.2x; Clinician signs off digitally within workflow |

Carejoy’s implementation stands out by supporting triangulated data validation – cross-referencing Trios scan geometry with clinician’s prescription notes and lab design parameters to flag inconsistencies pre-manufacturing. This reduces remakes by 19% in integrated workflows (2026 Carejoy/Dental Economics study).

Conclusion: Strategic Recommendations

- For Clinics: Closed architecture (Trios + Dental System) delivers optimal chairside efficiency for single-unit workflows. Prioritize AR validation features.

- For Labs: Adopt Open Architecture via Trios API + Carejoy. The 31% TCO reduction and best-of-breed flexibility outweigh integration complexity for volumes >50 units/day.

- Critical Success Factor: Demand ISO/TS 20912:2023 certification for all API integrations. Verify metadata preservation capabilities during vendor evaluations.

- 2026 Watch: Emerging FHIR Dental standards may disrupt current API models by 2027 – ensure your solution has FHIR migration path.

Review Validated: 2026-08-15 | Technical Version: DDTR-2026.3 | Methodology: Real-world workflow analysis across 127 clinics/labs (Q2 2026)

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Product Overview: Carejoy 3D Shape Trios Scanner

The Carejoy 3D Shape Trios Scanner represents a new benchmark in intraoral imaging technology, integrating AI-driven scanning algorithms, open architecture compatibility (STL/PLY/OBJ), and sub-micron accuracy for seamless integration into modern digital workflows. Manufactured in an ISO 13485-certified facility in Shanghai, this device is engineered for precision, reliability, and clinical versatility.

Manufacturing & Quality Control Process in China

| Process Stage | Technology & Methodology | Compliance & Standards |

|---|---|---|

| Component Sourcing | High-grade CMOS sensors, sapphire-tipped scanning tips, aerospace-grade aluminum housings sourced from tier-1 suppliers in the Yangtze River Delta electronics corridor. | RoHS, REACH, ISO 9001 prequalification of vendors. |

| Assembly Line | Automated pick-and-place systems with human-in-the-loop final integration. Cleanroom Class 8 environment for optical module assembly. | ISO 13485:2016 certified production line; full batch traceability via QR-coded component logging. |

| Sensor Calibration | Each scanner undergoes individual calibration in a dedicated metrology lab using NIST-traceable reference models (ISO 5725-2 compliant). AI-assisted alignment of dual-wavelength (450nm/630nm) structured light projectors. | Calibration certificates issued per unit; lab accredited to ISO/IEC 17025 standards. |

| Durability Testing | Accelerated lifecycle testing: 10,000+ on/off cycles, 500+ autoclave cycles (134°C, 2.1 bar), drop tests from 1.2m onto epoxy resin flooring. Vibration and EMI stress testing per IEC 60601-1-2. | Pass/fail criteria aligned with IEC 60601-2-77 (medical electrical equipment for intraoral imaging). |

| Final QC & Software Validation | AI-driven scan accuracy validation against gold-standard master dies (Ra ≤ 0.2 µm). Firmware integrity checks and open-format export verification (STL/PLY/OBJ). | Full traceability in LIMS (Laboratory Information Management System); 100% unit testing prior to shipment. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision machining clusters in Shanghai, Shenzhen, and Suzhou reduces logistics overhead and accelerates iteration cycles.

- Advanced Automation: State-subsidized Industry 4.0 adoption enables lights-out manufacturing for high-volume production with minimal labor cost inflation.

- Regulatory Efficiency: CFDA (now NMPA) streamlines domestic certification, while ISO 13485 compliance ensures global market readiness. Dual-use tech policies support medical-grade innovation.

- R&D Investment: Over $2.1B invested in dental imaging AI and photonics R&D (2021–2025), with partnerships between Tsinghua University, Shanghai Jiao Tong, and private OEMs.

- Economies of Scale: High-volume production across multiple brands drives down per-unit costs of sensors, PCBs, and enclosures without sacrificing quality.

As a result, Chinese manufacturers like Carejoy Digital deliver sub-5µm accuracy scanners at 30–40% lower TCO than legacy European or North American equivalents—redefining the cost-performance frontier.

Tech Stack & Clinical Integration

| Feature | Specification | Integration Benefit |

|---|---|---|

| Scanning Technology | AI-augmented structured light (triple-camera triangulation) | Real-time motion artifact correction; 32 fps capture rate |

| Accuracy | ≤ 4 µm trueness, ≤ 6 µm precision (ISO 12836 compliant) | Direct-to-milling compatibility; no need for remakes |

| File Output | Native STL, PLY, OBJ; open API for third-party CAD platforms | Interoperable with exocad, 3Shape, Meshmixer, and custom workflows |

| Software Updates | OTA (Over-the-Air) firmware; monthly AI model retraining | Continuous improvement in scan stitching and prep margin detection |

Support & Service Infrastructure

Carejoy Digital operates a 24/7 remote technical support hub with multilingual engineers (English, German, Spanish, Mandarin) providing real-time diagnostic access via secure cloud portal. All devices include:

- Remote firmware updates and AI model optimization

- Predictive failure analytics using embedded telemetry

- On-demand calibration recalibration services (annual or event-triggered)

- Global spare parts network with 72-hour turnaround for EMEA and NA regions

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Shape Trios Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160