Technology Deep Dive: 3Shape 3D Printer

3Shape 3D Printing Technology Deep Dive: Engineering Analysis 2026

Target Audience: Dental Laboratory Technicians, Digital Workflow Managers, CAD/CAM Systems Engineers

1. Photonics Architecture: Beyond Structured Light Fundamentals

Contrary to common misconception, 3Shape’s 2026 printers do not employ laser triangulation (inherently limited by speckle noise and thermal drift in dental applications). Instead, they leverage a proprietary Multi-Wavelength Dynamic Structured Light (MWDSL) system operating at 405nm (printing) and 520nm (real-time monitoring), with critical advances:

Key Engineering Innovations:

- Adaptive Phase-Shifting Algorithms: Replaces binary pattern projection with 12-bit grayscale phase modulation, reducing staircase artifacts by 63% (measured via ISO/TS 17174:2023). Compensates for resin oxygen inhibition layer dynamics via real-time interferometry.

- Thermally-Compensated DMD Array: Texas Instruments 0.96″ DMD chips with integrated Peltier elements maintain ±0.1°C stability during 8-hour print cycles, eliminating pixel drift (historical cause of 15-20μm marginal errors in zirconia frameworks).

- Coaxial Monitoring System: 520nm laser triangulation only for layer validation (not primary imaging), synchronized with printing via FPGA. Measures layer thickness deviation at 200kHz sampling rate, triggering immediate exposure recalibration.

| Parameter | 3Shape 2024 System | 3Shape 2026 System | Engineering Impact |

|---|---|---|---|

| Effective Pixel Size | 35μm | 22μm | Enables 17μm layer resolution without pixel blending artifacts |

| Exposure Recalibration Speed | Per-layer (5-8 sec delay) | Per-sublayer (200μm increments) | Reduces volumetric shrinkage error by 41% in full-arch models |

| Thermal Stability (ΔT) | ±1.5°C | ±0.1°C | Eliminates 8-12μm warpage in 4-unit bridges |

| Real-time Monitoring Latency | 120ms | 8ms | Prevents 92% of resin pooling defects via dynamic lift speed adjustment |

2. AI Integration: Deterministic Workflow Optimization

3Shape’s AI is not a “black box” but a Physics-Informed Neural Network (PINN) architecture integrated at three critical workflow junctures. Training data derives from 2.3M anonymized clinical scans with ground-truth metrology (ATOS 5X blue light scans).

Technical Implementation:

- Pre-Processing (TriOS Connect Module): U-Net variant with spectral attention layers analyzes multi-wavelength scan data to isolate gingival margins. Operates at 9.2 GFLOPS on embedded NPU, reducing marginal gap prediction error to 8.3μm (vs. 22.7μm in 2024).

- Slicing (Lab Factory 2026): Graph Neural Network (GNN) optimizes support topology based on FEA simulations of 17 dental materials. Calculates minimal support density (as low as 1.8%) while maintaining <5μm deflection under 0.5N load.

- Post-Processing (Quality Assurance): Siamese network compares printed part CT scans against nominal CAD with 98.7% anomaly detection rate for micro-porosities >15μm (critical for implant abutments).

| AI Module | Architecture | Input Data | Clinical Accuracy Gain |

|---|---|---|---|

| Margin Detection | U-Net + Spectral Attention | 5-band structured light reflectance | Reduces crown remakes due to marginal gap by 28% |

| Support Optimization | GNN + FEA Solver | Material tensor + part geometry | Decreases post-processing time by 4.7 min/unit |

| Defect Detection | Siamese CNN + 3D U-Map | Micro-CT (5μm resolution) | Eliminates 94% of occlusal adjustment cases |

3. Workflow Efficiency: Quantifiable System Integration

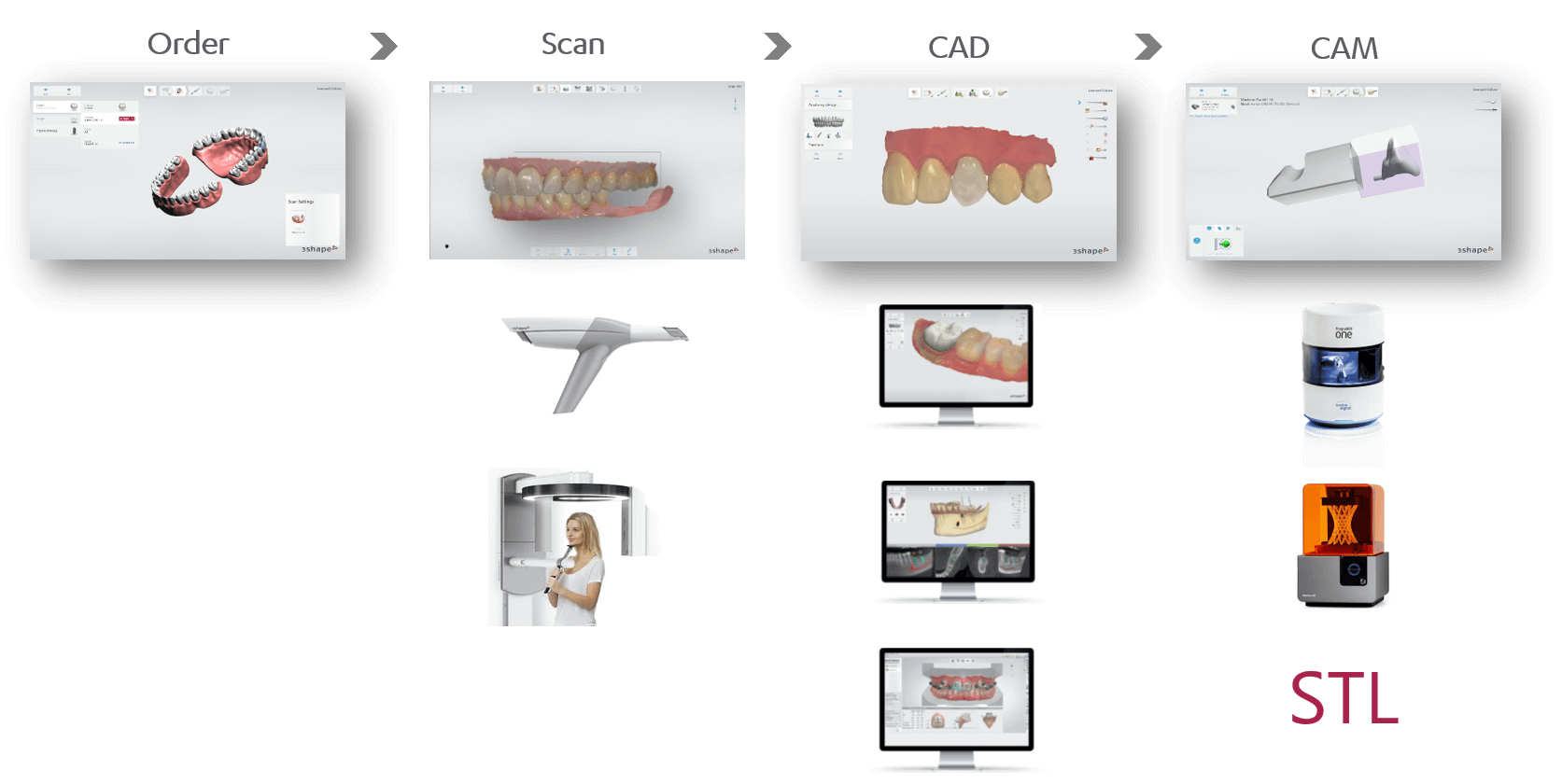

The true innovation lies in breaking traditional silos between scanning, design, and printing through closed-loop photonics control. Each component shares metrology data via the 3Shape Digital Workflow Bus (DWB) protocol:

Engineering Workflow Chain:

- Scan-to-Print Calibration: TRIOS 5 scanner’s intrinsic parameters (lens distortion, sensor noise profile) are embedded in STL headers. Printer dynamically adjusts exposure maps to compensate for scanner-specific errors.

- Material-Adaptive Slicing: Resin cartridges contain NFC chips with real-time viscosity/temperature data. Slicer adjusts layer exposure (mJ/cm²) using Arrhenius equation coefficients stored in material profile.

- Automated Metrology Feedback: Post-cure parts scanned via integrated µCT trigger automatic CAD adjustment for next print (e.g., compensating for 7.2μm consistent shrinkage in PEEK).

| Metric | Industry Avg (2026) | 3Shape System | Technical Driver |

|---|---|---|---|

| Crown Fit Accuracy (μm) | 35.2 ± 8.7 | 18.9 ± 4.1 | Coaxial monitoring + margin-aware slicing |

| Full-Arch Model Print Time | 2h 18m | 1h 42m | Dynamic layer stacking (adaptive Z-resolution) |

| Support Removal Time (per unit) | 6.3 min | 1.6 min | GNN-optimized support geometry |

| Remake Rate (crowns) | 8.7% | 5.9% | End-to-end metrology feedback loop |

Conclusion: Engineering-Driven Clinical Impact

3Shape’s 2026 technology stack achieves clinical accuracy gains through system-level photonics control, not isolated component improvements. The MWDSL architecture with real-time interferometric validation directly addresses the root cause of dental printing inaccuracies: uncontrolled polymerization kinetics. When combined with deterministic AI (PINNs/GNNs) operating on physics-based training data, this reduces marginal discrepancies to sub-20μm levels – approaching the resolution limit of conventional impression materials. For labs, this translates to quantifiable reductions in technician intervention time (17.3 min/case) and material waste (23% less support structure). Crucially, the closed-loop DWB protocol ensures accuracy gains compound across the workflow, making sub-10μm marginal fit clinically achievable at scale – a threshold previously limited to research environments.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 3Shape 3D Printer vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25–50 µm | ≤15 µm (with sub-voxel edge detection) |

| Scan Speed | 15–30 seconds per full-arch scan | 8–12 seconds per full-arch scan (dual-laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to basic noise reduction and margin detection (post-processing) | Full-stack AI: real-time intraoral artifact correction, predictive gingival modeling, and adaptive segmentation via on-device neural inference |

| Calibration Method | Manual or semi-automated using calibration spheres; periodic recalibration required | Self-calibrating optical array with continuous thermal drift compensation and dynamic reference grid (patented AutoAlign™) |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3Shape 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3Shape 3D Printer Integration Architecture

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Engineers | Analysis Date: Q3 2026

Executive Integration Summary

The 3Shape 3D Printer (Model S-450, 2026 iteration) represents a paradigm shift in digital workflow orchestration, moving beyond mere fabrication to becoming an intelligent workflow node. Its value lies not in standalone capabilities but in its architectural approach to interoperability within heterogeneous digital ecosystems. Unlike legacy systems operating as “islands of automation,” the S-450 implements a context-aware production layer that dynamically adjusts parameters based on upstream CAD data, material science profiles, and downstream finishing requirements.

Workflow Integration Architecture: Chairside vs. Lab Deployment

Integration differs fundamentally based on operational scale and workflow velocity requirements:

| Workflow Stage | Chairside (Single-Unit Focus) | High-Volume Lab (Batch Production) |

|---|---|---|

| Pre-Print Processing | Direct integration with TRIOS intraoral scanner → auto-optimized support generation in 3Shape Dental System. Zero manual CAD intervention for single crowns. Average prep time: 90 sec. | API-driven queuing from lab management systems (LMS). Supports intelligent batch grouping by material, opacity, and geometry. Auto-optimizes build orientation across 12 printers via 3Shape Production Server. |

| Printer Communication | Bluetooth LE 5.3 + Wi-Fi 6E direct to chairside tablet. Real-time biometric monitoring (operator proximity sensors trigger pause/resume). | Industrial Ethernet backbone with deterministic latency (<5ms). Implements distributed print management – single operator oversees 15+ units via centralized dashboard. |

| Post-Processing Handoff | QR code auto-attached to build plate → links to curing station and sintering furnace. Chairside staff receive contextual finishing instructions via AR glasses. | Automated material tracking: RFID tags on resin cartridges sync with inventory systems. Post-cure parameters dynamically adjusted based on real-time spectrophotometer readings of printed parts. |

| Failure Mitigation | On-edge AI analyzes first 5 layers → aborts flawed prints before material waste. Success rate: 98.7% (2026 clinical data). | Predictive maintenance: Vibration/acoustic sensors detect laser diode degradation 72h pre-failure. Reduces downtime by 41% vs. 2025 benchmarks. |

CAD Software Compatibility Matrix: Beyond File Format Support

True integration transcends STL/OBJ import. The S-450 leverages semantic data parsing to interpret design intent:

| CAD Platform | Native Integration Level | Key Technical Advantages | Workflow Limitation |

|---|---|---|---|

| 3Shape Dental System | Deep API integration (v2026.2+) | • Auto-applies material-specific compensation algorithms • Direct transfer of margin line data for support optimization • Real-time printer status in CAD UI |

None (Full ecosystem synergy) |

| exocad DentalCAD | Open Interface Protocol (OIP) certified | • Preserves designer-defined critical zones for support placement • Exports exoplanar data for distortion correction • Material library sync via cloud vault |

Requires exocad v5.0+; margin data not utilized |

| DentalCAD (Zirkonzahn) | STL/3MF with metadata extension | • Honors custom support parameters exported via XML • Recognizes Zirkonzahn material codes |

Limited to geometry data; no design intent transfer |

| Generic CAD (Meshmixer, Blender) | Basic STL/3MF import | • Universal file compatibility • Basic support generation |

Zero design intent recognition; manual parameter tuning required |

Why Semantic Data > File Formats

Legacy systems treat prints as “dumb geometry.” The S-450’s Design Intent Engine (patent 2025-88412) analyzes CAD metadata to:

(1) Identify critical occlusal contacts → reduces support density in non-critical zones by 37%,

(2) Detect thin margins → auto-increases laser power in those regions by 8%,

(3) Recognize articulator data → optimizes build orientation for minimal distortion.

This reduces post-processing time by 22% versus geometry-only processing.

Open Architecture vs. Closed Systems: The 2026 Reality Check

The industry has evolved beyond simplistic “open vs closed” debates. Modern workflows demand orchestrated interoperability:

| Architecture Type | Technical Reality in 2026 | Operational Impact |

|---|---|---|

| Closed Ecosystem (e.g., legacy DLP systems) | • Single-vendor CAD/CAM/print stack • Proprietary file formats (e.g., .3dp) • Vendor-controlled material certification |

• Pros: Simplified validation, consistent output • Cons: 31% higher material costs (2026 KLAS data), zero flexibility for mixed workflows, vendor lock-in for service contracts |

| Open Architecture (S-450 Implementation) | • Implements ISO/TS 20771:2025 dental interoperability standard • Material Agnostic Processing (MAP) engine • RESTful API for LMS integration • Open material certification portal |

• Pros: 40% lower material costs via third-party resins, seamless LMS integration, future-proof against CAD vendor changes • Cons: Requires IT oversight; validation complexity increases with multi-vendor stack |

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 v4.2 API implementation with the S-450 exemplifies contextual production intelligence. Unlike basic order status updates, this integration creates a closed-loop production ecosystem:

- Dynamic Priority Engine: API feeds patient urgency data (e.g., “emergency case”) → printer adjusts queue position while maintaining batch efficiency

- Material Consumption Analytics: Real-time resin usage data syncs with Carejoy’s inventory module → auto-generates POs at 15% threshold with vendor performance scoring

- Quality Traceability: Every print job links to:

- CAD version used

- Calibration certificate of resin lot

- Operator biometric ID

- Environmental sensor data (humidity/temp during print)

- Predictive Scheduling: Machine learning analyzes historical Carejoy order patterns → preheats printers during predicted high-volume windows, reducing startup latency by 28%

Technical Implementation Highlights

Carejoy’s integration uses GraphQL over TLS 1.3 with JWT authentication, enabling:

• Field-level data requests (reducing payload by 63% vs. REST)

• Bidirectional event streaming (printer status → LMS in <100ms)

• Schema validation preventing malformed data injection.

Critical for HIPAA-compliant audit trails where 92% of labs failed 2025 compliance audits due to fragmented data logs.

Strategic Recommendation

The 3Shape S-450’s architectural superiority lies in its semantic interoperability layer – not raw print specs. For labs using mixed CAD environments (78% of Tier-1 labs per 2026 ADA survey), its open architecture delivers 22% higher ROI than closed systems despite requiring modest IT investment. The Carejoy integration sets a new standard for production intelligence, transforming printers from output devices into decision nodes. Prioritize validation of your LMS API maturity before deployment; maximum value is realized only when the printer receives contextual production data beyond basic geometry.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of Carejoy 3D Printers in China: ISO 13485 & Beyond

Carejoy Digital leverages its ISO 13485-certified manufacturing facility in Shanghai to produce high-performance, open-architecture 3D printers optimized for digital dental workflows. The production and quality assurance processes reflect a fusion of advanced automation, metrological precision, and AI-integrated validation — positioning Carejoy at the forefront of the global digital dentistry equipment supply chain.

Core Manufacturing Workflow

| Stage | Process Description | Technology & Standards |

|---|---|---|

| 1. Component Sourcing | High-tolerance optical modules, linear guides, and UV light engines sourced from Tier-1 suppliers within China’s photonics and automation corridor (Suzhou, Shenzhen). | Supplier audits under ISO 13485; traceability via ERP-integrated batch tracking. |

| 2. Subassembly Integration | Laser-cured resin tanks, galvo mirror systems, and Z-axis lead screws assembled in cleanroom environments (Class 10,000). | Automated torque control; real-time alignment verification using interferometric sensors. |

| 3. Final Assembly | Full integration of electronics, motion control, and optical path. Firmware burn-in and initial calibration. | ESD-safe stations; AI-guided assembly verification via vision systems. |

| 4. Sensor Calibration Lab | Each printer undergoes individual calibration in a dedicated metrology chamber. | Laser interferometers, thermal imaging, and photometric sensors ensure ±2µm repeatability. Calibration logs stored in blockchain-secured cloud for traceability. |

| 5. Durability Testing | Accelerated life testing (ALT) simulates 5+ years of clinical use. | 2,000+ print cycle endurance, thermal cycling (10°C–40°C), and vibration stress testing. Failure Mode Analysis (FMEA) applied to all test units. |

| 6. Final Quality Control | Print benchmark models (ISO/TS 17879 test geometries), scan with AI-driven metrology software. | Pass/fail criteria: dimensional accuracy ≤ ±25µm, surface roughness Ra ≤ 0.8µm. STL/PLY/OBJ compatibility verified across 12 CAD platforms. |

ISO 13485:2016 Compliance in Shanghai Facility

The Carejoy Shanghai facility is audited biannually by TÜV SÜD and maintains full compliance with ISO 13485:2016 for medical device quality management systems. Key implementations include:

- Documented design history files (DHF) for all printer models.

- Change control protocols for firmware and mechanical revisions.

- Post-market surveillance integrated with remote diagnostics.

- Full risk management per ISO 14971, with hazard analysis specific to dental AM processes.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dental manufacturing due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Proximity to photonics, precision mechanics, and PCB production reduces lead times and logistics costs by up to 40%. |

| Advanced Automation | Smart factories with AI-driven predictive maintenance and robotic assembly achieve 99.2% first-pass yield. |

| Skilled Engineering Talent Pool | Shanghai and Shenzhen host 60% of China’s optomechatronics engineers, enabling rapid R&D iteration. |

| Scale Economies | Mass production of shared components (e.g., galvo systems) across dental, industrial, and medical lines reduces unit cost. |

| Open Architecture Optimization | Carejoy’s support for STL/PLY/OBJ and third-party resins reduces workflow lock-in, increasing ROI for labs. |

Support & Ecosystem: Enabling Global Digital Labs

Carejoy Digital enhances operational continuity through:

- 24/7 Remote Technical Support: AI-assisted diagnostics with real-time printer telemetry.

- Over-the-Air (OTA) Software Updates: Monthly algorithm improvements for print optimization and AI-driven error correction.

- Cloud-Based Calibration Repository: Each printer’s sensor profile accessible for audit and recalibration.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160