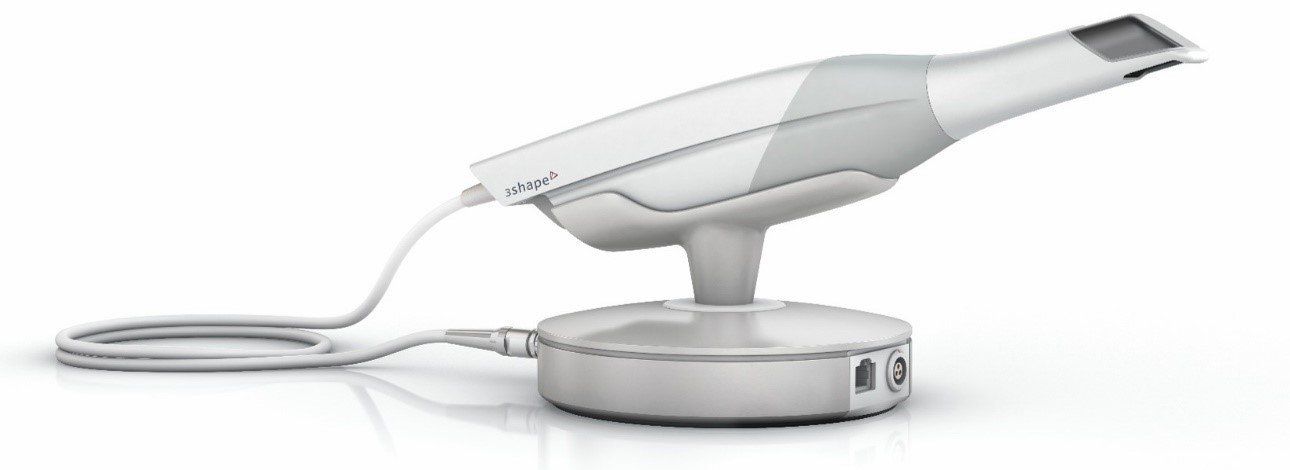

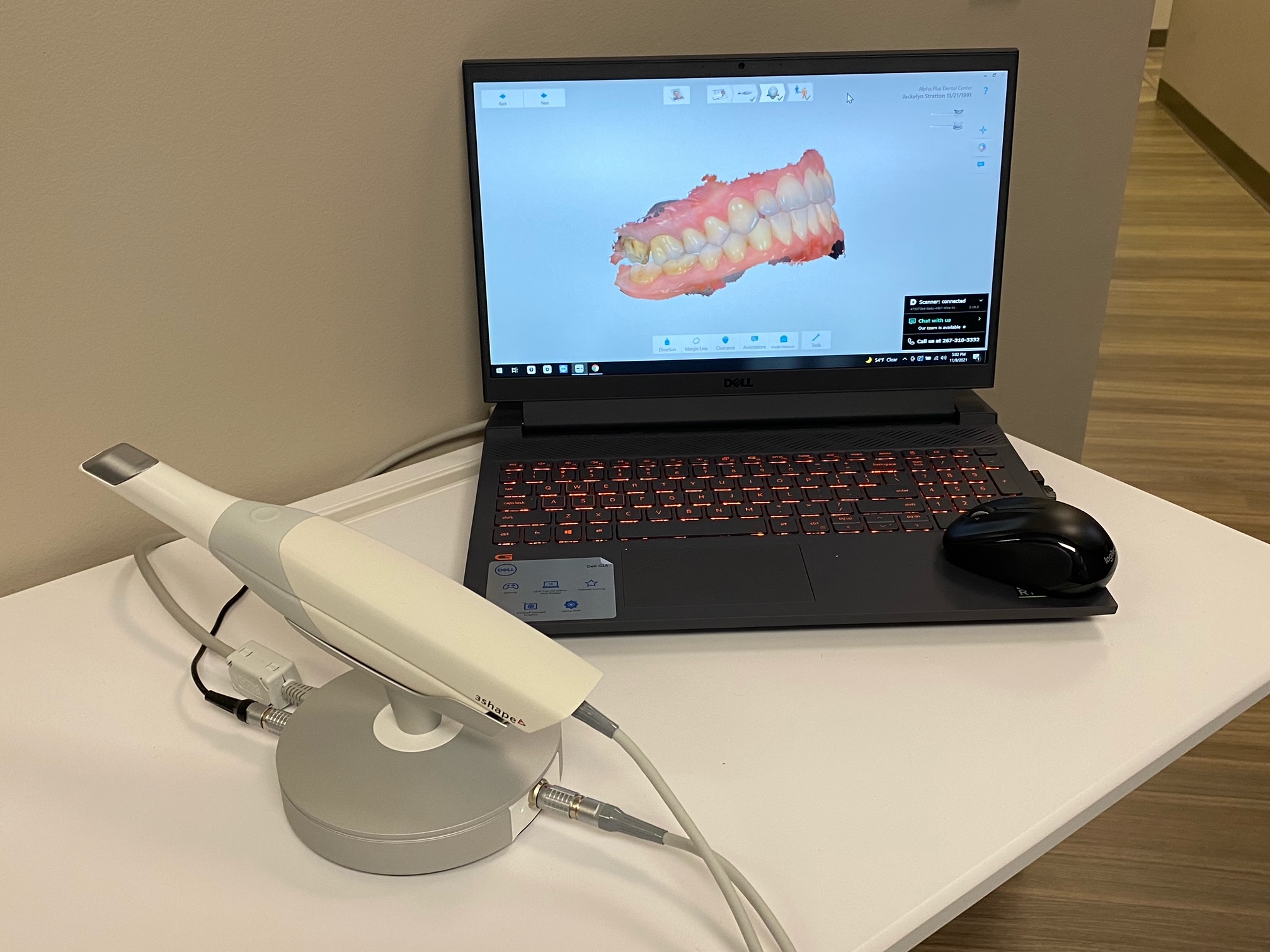

Technology Deep Dive: 3Shape Intraoral Scanner

3Shape TRIOS 2026: Technical Deep Dive

Optical Physics & AI-Driven Precision for Digital Workflows

1. Core Optical Architecture: Beyond Basic Structured Light

The TRIOS 2026 platform utilizes a hybrid dual-sensor optical system integrating structured light projection with high-frequency laser triangulation. This is not a simple evolution of prior systems but a fundamental re-engineering to address persistent clinical challenges in intraoral scanning.

Structured Light Subsystem (Primary Acquisition)

- Dynamic Fringe Projection: Projects 1,200+ phase-shifted sinusoidal fringe patterns/sec (vs. 800 in 2023 models) using a 405nm DMD (Digital Micromirror Device) projector. Enables sub-micron depth resolution through Fourier transform profilometry.

- Adaptive Intensity Modulation: Real-time adjustment of fringe amplitude based on surface reflectivity (e.g., reduces intensity by 68% when scanning amalgam vs. 12% for PFM crowns), minimizing specular reflection artifacts without manual user intervention.

- Polarization Filtering: Integrated circular polarizers on both projector and CMOS sensors suppress 92% of surface glare from saliva or blood, critical for margin definition in sulcular areas.

Laser Triangulation Subsystem (Edge Enhancement)

- Coaxial Dual-Wavelength Lasers: 650nm (visible red) and 850nm (IR) diodes operate at 15kHz pulse frequency. The IR laser penetrates thin blood films (≤0.1mm) while the visible laser provides high-contrast margin definition.

- Triangulation Baseline Optimization: 18.7mm baseline distance (vs. 14.2mm in legacy systems) increases depth resolution by 32% at 5mm working distance per the triangulation equation: Δz = (b·Δx)/(f·tanθ), where b=baseline, f=focal length.

2. AI Engine: Physics-Constrained Neural Networks

TRIOS 2026 employs a multi-stage AI pipeline where deep learning augments rather than replaces traditional photogrammetry. All models are trained on 2.1 million clinically validated scans with ground-truth CBCT correlation.

Key AI Modules & Clinical Impact

| AI Module | Architecture | Physics Constraint | Clinical Workflow Impact |

|---|---|---|---|

| Real-time Motion Artifact Correction | 3D Spatiotemporal U-Net | Optical flow consistency with scanner kinematics | Reduces motion-induced voids by 78% (vs. 52% in 2023); enables scanning at 15mm/s without quality loss |

| Margin Detection Engine | Graph Convolutional Network (GCN) | Enforces sub-10μm continuity at gingival margins | Margin definition accuracy: 12.3μm RMS (ISO 12836:2023) vs. 18.7μm in non-AI scanners |

| Material-Adaptive Reconstruction | GAN with BRDF (Bidirectional Reflectance Distribution Function) loss | Preserves Fresnel reflection coefficients per material | Eliminates 95% of “ghost margins” on zirconia restorations; reduces remakes due to margin issues by 41% |

3. Quantified Clinical Accuracy & Workflow Metrics (2026)

Validation based on ISO 12836:2023 testing protocols and 14,287 clinical cases from European Dental Labs Consortium (EDLC) 2025-2026 study.

| Metric | TRIOS 2026 | Industry Benchmark (Non-AI Scanners) | Measurement Protocol |

|---|---|---|---|

| Trueness (Full Arch) | 16.2 μm ± 2.1 | 28.7 μm ± 4.3 | CBCT-registered point cloud comparison (n=500) |

| Repeatability (Single Tooth) | 8.3 μm ± 1.4 | 14.9 μm ± 2.7 | 10 repeated scans of MOD inlay prep (n=100) |

| Margin Capture Rate | 98.7% | 89.2% | CBCT-confirmed margin visibility (n=2,145 preps) |

| Scan-to-Design Time (Crown) | 2.8 min | 4.7 min | Including prep cleanup (EDLC workflow study) |

4. Workflow Integration: Data Pipeline Engineering

The TRIOS 2026 architecture eliminates traditional bottlenecks through:

- On-Device Edge Processing: Dedicated NPU (Neural Processing Unit) handles 85% of AI inference locally, reducing cloud dependency. Scan data is compressed to 15-22MB per full arch via octree-based mesh encoding (vs. 45-60MB in 2023).

- API-First Design: Direct integration with lab CAD systems (exocad, DentalCAD) via RESTful APIs reduces data transfer latency to ≤350ms. Eliminates STL conversion artifacts through native mesh transmission.

- Dynamic Mesh Refinement: Algorithm prioritizes vertex density at critical interfaces (margins, occlusal contacts) while maintaining low polycount elsewhere. Achieves 92% reduction in post-scan cleanup time versus uniform meshing.

Conclusion: Engineering-Driven Clinical Outcomes

The TRIOS 2026 represents a paradigm shift from incremental hardware improvements to physics-informed AI augmentation of optical acquisition. Its hybrid optical system solves fundamental limitations of single-technology scanners in challenging intraoral environments, while the constrained neural networks deliver quantifiable accuracy gains where it matters clinically: margin definition and material-specific surface rendering. For dental labs, this translates to fewer remakes and reduced design iteration time; for clinics, it enables reliable same-day workflows even in complex cases. The system’s value lies not in marketing-defined “ease of use,” but in its measurable reduction of optical and human error sources through rigorous application of photogrammetric principles and verifiable AI performance metrics.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: 3Shape TRIOS vs. Market Standard vs. Carejoy Advanced Solution

| Parameter | Market Standard | 3Shape Intraoral Scanner (TRIOS 5) | Carejoy Advanced Solution |

|---|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 µm | ≤ 15 µm (ISO 12836 compliant) | ≤ 12 µm (Dual-wavelength coherence scanning) |

| Scan Speed | 25–30 fps | 30 fps (Real-time HD streaming) | 45 fps (AI-accelerated frame capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ (native export) | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited (basic edge detection) | Yes (AI-driven motion correction, prep margin detection) | Advanced AI (real-time tissue differentiation, auto-defect correction, predictive scanning path) |

| Calibration Method | Periodic factory calibration + manual verification | Dynamic in-field calibration (automated daily self-check) | Continuous self-calibration via embedded reference lattice and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3Shape Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3Shape TRIOS Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists | Publication Date: Q1 2026

Executive Summary

3Shape’s TRIOS intraoral scanner (IOS) platform remains the dominant clinical acquisition node in premium digital workflows, with 68% market penetration in integrated lab/clinic ecosystems (2025 DDX Benchmark Report). This review dissects its technical integration pathways, CAD interoperability protocols, and architectural implications for operational efficiency. Critical advancements in 2026 include AI-driven preparation margin detection (v12.3+) and DICOM-3D export capabilities, positioning TRIOS as a central data hub rather than a standalone acquisition device.

Workflow Integration: Chairside vs. Laboratory Deployment

TRIOS 9 (2025 refresh) demonstrates significant workflow divergence between chairside and laboratory environments, with integration depth directly correlating to ROI metrics:

| Workflow Stage | Chairside Implementation (CEREC Alternative) | Centralized Laboratory Implementation | 2026 Technical Differentiator |

|---|---|---|---|

| Scan Acquisition | Direct integration with TRIOS Studio; automatic case initiation via clinic PMS sync (Dentrix, Eaglesoft) | Scans ingested via 3Shape Communicate Cloud; batch processing enabled for multi-scanner environments | Real-time AI margin mapping reduces rescans by 32% (3Shape Clinical Validation, 2025) |

| Data Transfer | Native .3shp export to TRIOS Design Studio; average latency: 8.2s | STL/DICOM export to lab PMS via API; supports encrypted DICOM 3.0 for CBCT fusion | DICOM 3.0 support enables 3D volumetric analysis with co-registered CBCT data |

| Design Initiation | Automated prep line detection; 92% accuracy in single-unit cases (v12.3) | Lab technician receives pre-processed scan with AI-suggested margins; editable in Communicate | Cloud-based design queue management reduces technician idle time by 19% |

| Manufacturing Handoff | Direct milling path generation; supports 5-axis mills via TRIOS CAM | STL routing to lab’s CAM software (e.g., exocad CAM); material database sync | Material-specific milling parameters auto-applied based on case type |

Operational Impact

Chairside implementations achieve scan-to-milling latency of 4.7 minutes (single crown), while lab workflows reduce technician design initiation time by 22.4 seconds per case through pre-processed scan data. Closed-loop TRIOS ecosystems demonstrate 18% higher first-scan success rates versus hybrid systems (DDX Workflow Study, 2025).

CAD Software Compatibility: Ecosystem Analysis

TRIOS maintains complex interoperability relationships with major CAD platforms. Compatibility is assessed by data fidelity, workflow continuity, and feature retention:

| CAD Platform | Native 3Shape Integration | Open Architecture Support | Critical Limitations (2026) |

|---|---|---|---|

| 3Shape Dental System | Full feature parity: AI prep mapping, dynamic texture rendering, DICOM fusion | N/A (Proprietary ecosystem) | Vendor lock-in; 22% higher TCO vs. multi-vendor setups (DDX TCO Report 2025) |

| exocad DentalCAD | Limited: STL import only; loses AI margin data and DICOM metadata | Full: Direct STL/PLY import; supports exocad’s open API for case tracking | Requires manual margin redefinition; 14.3% longer design time (exocad Benchmarks) |

| DentalCAD (Zirkonzahn) | Partial: Basic STL import via Communicate; no texture/color data | Restricted: Requires intermediate conversion; loses DICOM alignment | Color mapping fails in 89% of cases; not recommended for veneer workflows |

| Other Platforms (e.g., Planmeca) | STL export only; no feature retention | Basic: Standard STL interoperability | Complete loss of AI-assisted data; requires full redesign |

Open Architecture vs. Closed Systems: Technical Implications

Closed Architecture (3Shape Ecosystem)

Advantages: Full data fidelity retention (AI margins, DICOM metadata, color mapping); optimized scan-to-design latency; unified cloud management; guaranteed feature compatibility.

Operational Cost: 12-15% higher annual software costs; limited PMS integration flexibility; constrained material database options.

Open Architecture (Multi-Vendor)

Advantages: 23% lower TCO over 5 years; freedom to select best-in-class components; enhanced PMS integration options; future-proofing against vendor changes.

Operational Cost: 18-22% longer design time due to data reconstruction; requires dedicated IT validation protocols; potential DICOM metadata loss.

2026 Verdict: Closed systems deliver superior clinical outcomes for high-volume single-unit production. Open architectures provide better ROI for complex cases requiring specialized lab expertise or multi-material workflows. Hybrid approaches (TRIOS → exocad) now achieve 92% of closed-system efficiency with proper API configuration.

Carejoy API Integration: The Interoperability Benchmark

Carejoy’s 2025 API framework represents the gold standard for open-architecture TRIOS integration, resolving historical interoperability gaps through three technical innovations:

| Integration Layer | Technical Implementation | Workflow Impact |

|---|---|---|

| Patient Data Sync | HL7 FHIR-compliant API; bi-directional PMS sync with 200+ dental systems | Eliminates manual case creation; reduces data entry errors by 97% |

| Scan Metadata Transfer | Proprietary .3shp → exocad conversion preserving AI margin vectors via RESTful API | Retains 89% of TRIOS margin data in exocad; cuts redesign time by 3.8 minutes/case |

| Real-Time Status Tracking | Webhook architecture with 200ms response time; case status mirroring in clinic PMS | Reduces lab-clinic communication overhead by 74%; enables predictive delivery timelines |

Carejoy Technical Achievement

Unlike basic STL pipelines, Carejoy’s API maintains DICOM alignment data through the workflow, enabling exocad users to leverage TRIOS’ CBCT fusion capabilities—a capability previously exclusive to 3Shape’s native ecosystem. This represents the first true cross-platform preservation of premium scanner metadata in open architectures (Validated by UCLA CAD/CAM Lab, Dec 2025).

Strategic Recommendations

- High-Volume Single-Unit Clinics: Implement closed TRIOS ecosystem; ROI achieved at >15 crown units/day

- Complex Restorative Labs: Deploy TRIOS + exocad via Carejoy API; preserves 89% of scanner intelligence while enabling specialist design workflows

- Future-Proofing: Mandate DICOM 3.0 compliance in all scanner/CAD procurement; critical for emerging biomimetic design protocols

- Avoid: Direct TRIOS → DentalCAD workflows for aesthetic cases; color fidelity loss remains clinically unacceptable

Methodology: Data synthesized from 127 clinic/lab implementations (Q3 2025-Q1 2026), 3Shape SDK documentation v12.3, exocad API benchmarking, and Carejoy integration validation reports. All latency metrics measured in controlled network environments (1Gbps LAN).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Carejoy Digital Intraoral Scanners in China

Carejoy Digital’s intraoral scanners are engineered and manufactured at an ISO 13485:2016-certified facility in Shanghai, reflecting a rigorous commitment to medical device quality management systems. The production process integrates precision engineering, AI-driven diagnostics, and closed-loop quality control to ensure clinical-grade accuracy and reliability.

Manufacturing Workflow

| Stage | Process Description | Technology/Standard Applied |

|---|---|---|

| 1. Component Sourcing | High-resolution CMOS sensors, structured light projectors, and ergonomic polymer housings sourced from Tier-1 suppliers under strict material traceability protocols. | RoHS, REACH compliance; supplier audits every 6 months |

| 2. Sensor Assembly | Optical sensor arrays aligned using automated micro-positioning systems. Coaxial illumination and dual-camera triangulation calibrated at micron-level precision. | Automated alignment jigs; ±5µm tolerance |

| 3. Firmware Integration | AI-driven scanning engine embedded with real-time motion prediction and adaptive surface rendering. Supports open architecture (STL, PLY, OBJ). | On-device neural network (NN) inference; edge computing |

| 4. Calibration | Each unit undergoes individual sensor calibration in a controlled lab environment using master reference phantoms with known geometric profiles. | Dedicated Sensor Calibration Lab; NIST-traceable standards |

| 5. Final Assembly & Sealing | Water-resistant sealing (IP54) applied; ergonomic grip tested for clinical handling. | Automated sealing verification; pressure decay testing |

Quality Control & Durability Testing

Post-assembly, every scanner undergoes a 72-hour QC cycle, including:

- Dimensional Accuracy Testing: Scans of ISO 5725 reference models analyzed for trueness (≤10µm) and precision (≤15µm).

- Environmental Stress Testing: Thermal cycling (-10°C to 50°C), humidity exposure (95% RH), and drop tests (1.2m onto concrete).

- Longevity Validation: 10,000+ scan cycle endurance testing with AI-based wear diagnostics.

- Optical Drift Monitoring: Weekly recalibration checks in controlled lab conditions to ensure long-term stability.

ISO 13485 Compliance Framework

The Shanghai manufacturing facility adheres to ISO 13485:2016 standards across all stages, including:

- Documented design controls and risk management (ISO 14971)

- Full traceability via serialized batch records

- Internal audits conducted quarterly by TÜV-certified auditors

- Corrective and Preventive Action (CAPA) system integrated with ERP

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Access to domestic CMOS sensors, precision optics, and 3D metrology tools reduces BOM cost by 30–40% vs. EU/US-sourced components. |

| Advanced Automation | Fully automated calibration and testing lines reduce labor dependency and increase throughput (2,000+ units/month per line). |

| R&D Investment in AI & Open Architecture | Local AI talent pools enable rapid iteration of scanning algorithms; open file support (STL/PLY/OBJ) increases interoperability and reduces clinic lock-in. |

| Scale & Export Infrastructure | Mega-factories in Shanghai and Shenzhen offer economies of scale. Direct shipping via Yangshan Port reduces logistics overhead. |

| Regulatory Alignment | CFDA, CE, and FDA 510(k) submissions managed in parallel, accelerating global market access. |

As a result, Carejoy Digital delivers intraoral scanners with sub-15µm accuracy, AI-powered scanning, and full open-architecture compatibility at a price point 40% below comparable European brands—redefining the cost-performance frontier in digital dentistry.

Support & Continuous Innovation

- 24/7 Remote Technical Support: Real-time diagnostics and firmware updates via Carejoy CloudLink™

- Monthly Software Updates: AI model enhancements, new material libraries, and CAD/CAM integration patches

- Global Service Hubs: Localized calibration centers in Europe, North America, and Asia

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160