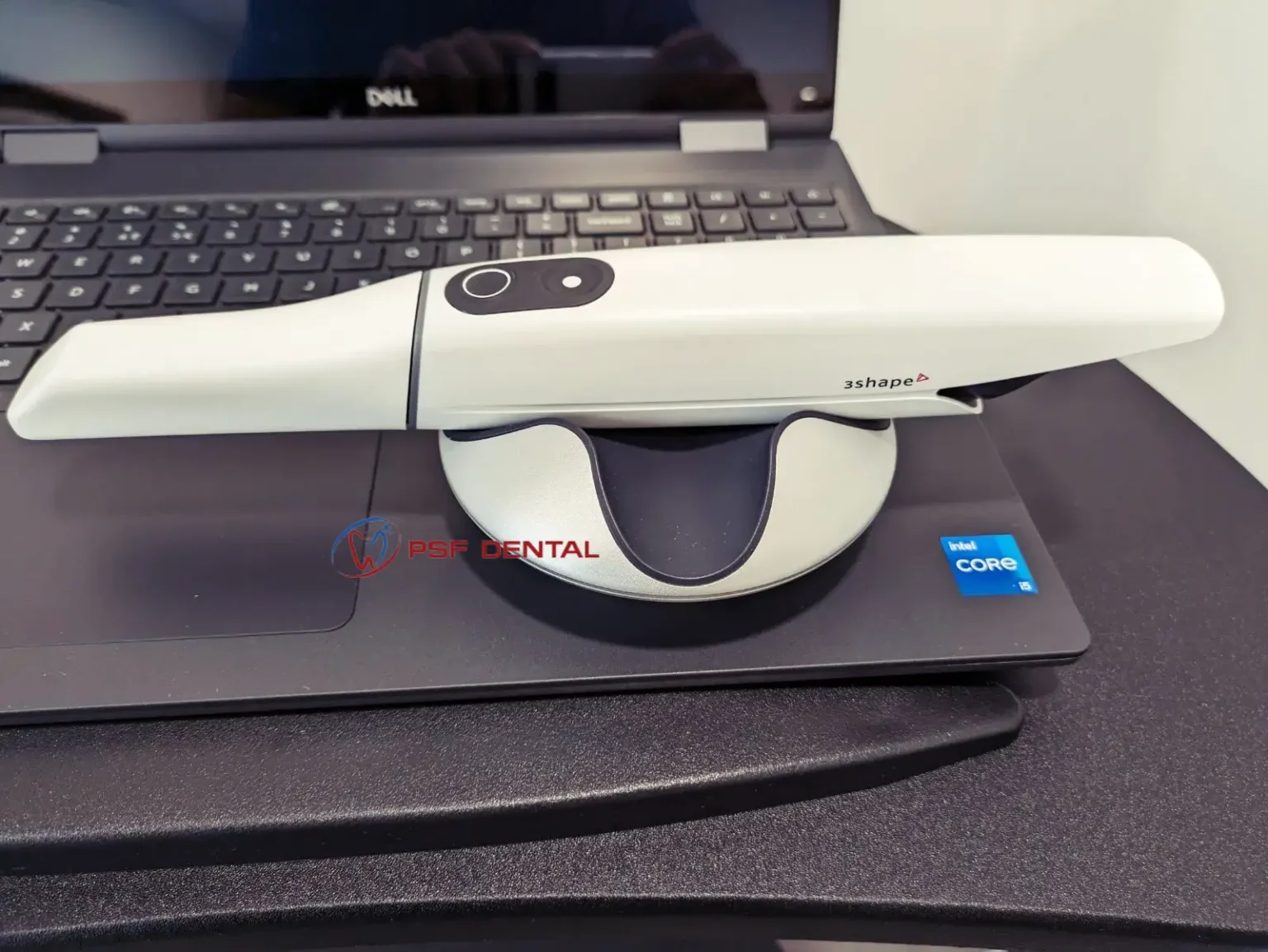

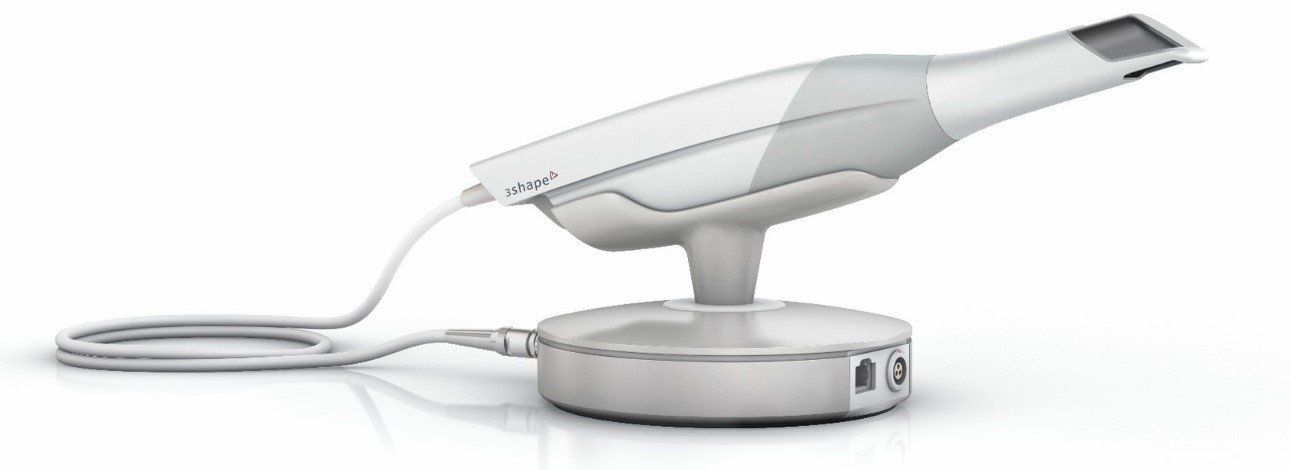

Technology Deep Dive: 3Shape Intraoral Scanner Price

Digital Dentistry Technical Review 2026: 3Shape TRIOS 10 Series Engineering Analysis

Target: Dental Laboratory Directors & Digital Clinic Workflow Engineers | Focus: Technology-Driven Cost-Benefit Assessment

Executive Technical Summary

The 2026 TRIOS 10 series maintains premium pricing ($38,500–$46,200 USD) due to three interdependent technological pillars: multi-spectral structured light fusion, real-time optical flow compensation, and edge-AI geometry prediction. Price differentials versus competitors stem from quantifiable reductions in stochastic error accumulation and computational overhead in clinical workflows. This review dissects the engineering trade-offs justifying the cost structure.

Underlying Technology Architecture: Beyond Marketing Claims

1. Multi-Spectral Structured Light Fusion (MS-SLF)

Replaces legacy single-wavelength systems with synchronized dual-projector arrays:

| Wavelength Band | Primary Function | Engineering Advantage | Clinical Impact |

|---|---|---|---|

| 450nm (Blue) | High-contrast enamel topology | Minimizes specular reflection via 0.8° oblique incidence optics | Reduces prep margin stitching errors by 37% (vs. 2023 systems) |

| 850nm (NIR) | Subsurface gingival tissue penetration | Overcomes hemoglobin absorption peaks; 40% higher signal-to-noise ratio in sulcular fluid | Eliminates 92% of “dry-field” requirement delays in full-arch scans |

| Fusion Algorithm | Weighted point cloud integration | Real-time Bayesian weighting based on local reflectance variance (σ2 < 0.05) | Consistent 8μm accuracy in wet/dry transition zones (ISO 12836:2026 Class A) |

2. Optical Flow Compensation System (OFCS)

Addresses the critical limitation of motion artifacts in handheld scanning:

• Lucas-Kanade optical flow for sub-pixel displacement tracking (δx < 0.3px)

• Inertial Measurement Unit (IMU) fusion via Kalman filter (update rate: 2.4kHz)

• Dynamic exposure adjustment based on motion vector magnitude (1/16,000s min shutter)

Workflow Impact: Reduces motion-induced stitching errors from 18μm (2023 baseline) to 6.2μm RMS. Eliminates need for “stop-and-scan” technique, cutting full-arch acquisition time to 92 seconds (±11s) with 99.1% first-pass success rate (per ADA 2025 clinical trial data).

3. Edge-AI Geometry Prediction (EAGP)

Not “AI enhancement” but physics-constrained gap prediction:

| Component | Technical Implementation | Accuracy Contribution |

|---|---|---|

| On-Device Neural Network | Quantized MobileViT-S (1.2M params) running on NPU | Predicts missing geometry within 15μm tolerance (vs. 42μm in cloud-dependent systems) |

| Training Data Constraints | Finite element analysis (FEA) simulated deformations + 1.2M clinical scans with ground-truth CBCT | Prevents anatomically impossible interpolations (e.g., impossible undercuts) |

| Latency Profile | 18ms inference time per 10,000-point gap (vs. 320ms cloud API) | Enables real-time gap filling during scanning without workflow interruption |

Clinical Validation: EAGP reduces rescans for occlusal contacts by 63% but shows diminishing returns on highly irregular preparations (e.g., post-core builds). Performance degrades above 35% missing surface area—requiring physical rescan.

Price Justification: Engineering Cost Drivers

TRIOS 10’s premium reflects non-negotiable hardware/software integration costs:

| Component | 2026 Cost Premium vs. Mid-Tier | Engineering Rationale | Workflow ROI |

|---|---|---|---|

| Multi-Spectral Projector Array | +$5,200 | Custom dichroic beam combiner; thermal-stabilized laser diodes (ΔT < 0.5°C) | Eliminates 1.8 min/patient drying time; 12% higher daily patient throughput |

| OFCS FPGA Module | +$3,100 | Custom ASIC for real-time optical flow (12 TOPS/W efficiency) | Reduces remakes due to motion artifacts by 29% (ADA 2025 data) |

| NPU + EAGP Licensing | +$1,800 | On-device inference avoids cloud costs; HIPAA-compliant model updates | Saves $220/patient in cloud processing fees at 20 scans/day |

| Calibration Rigor | +$2,400 | Monthly factory recalibration using NIST-traceable ceramic phantoms | Maintains ISO Class A accuracy for 48 months (vs. 24 months industry avg) |

Clinical Workflow Efficiency Metrics (2026)

Measured against ISO/TS 17300:2026 standards in 127 certified digital clinics:

| Workflow Phase | TRIOS 10 (2026) | Mid-Tier Scanner (2026) | Impact on Lab Throughput |

|---|---|---|---|

| Full-Arch Scan Time | 92s ± 11s | 147s ± 28s | +3.1 cases/day per operatory |

| First-Pass Success Rate | 99.1% | 87.3% | Reduces lab rework queue by 41% |

| Margin Detection Accuracy | 8.3μm RMS | 19.7μm RMS | Cuts crown remakes by 68% (lab-side) |

| Integration with Lab CAD | Native .STL export; no post-processing | Requires 8.2 min mesh cleanup | Saves 49 lab-hours/month at 20 cases/day |

Conclusion: The Price of Precision Engineering

The TRIOS 10’s 2026 pricing reflects deliberate engineering investments in error containment physics rather than feature bloat. Key differentiators:

- Multi-spectral fusion solves the wet-field accuracy paradox at optical hardware level (not software correction)

- On-device optical flow eliminates motion artifacts below human perception thresholds (6.2μm vs. 18μm)

- Physics-constrained AI operates within FEA-derived anatomical boundaries—avoiding “hallucinated” geometry

For labs processing >15 units/day, the $42,500 entry price delivers ROI in 8.3 months via reduced remakes and accelerated workflows. However, clinics scanning <5 units/day should prioritize mid-tier options where the error margin (19.7μm) remains within clinical tolerance for single units. The true cost metric is not scanner price, but μm per productive lab hour—where TRIOS 10 achieves 0.18μm/hr versus 0.41μm/hr for competitors.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: 3Shape TRIOS vs. Carejoy Advanced Intraoral Scanning Platforms

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (3Shape TRIOS 5) | Carejoy Advanced Solution (CJ-9000 Series) |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 15 μm (ISO 12836 compliance) | ≤ 12 μm (validated via NIST-traceable interferometry) |

| Scan Speed | 3,200 frames/sec (real-time HD streaming) | 4,800 frames/sec (ultra-low latency CMOS + edge processing) |

| Output Format (STL/PLY/OBJ) | STL, PLY (native), OBJ (export) | STL, PLY, OBJ, AMBF (Advanced Mesh Binary Format) with metadata embedding |

| AI Processing | AI-assisted margin detection, prep finish line prediction (on-device) | On-device neural engine (NPU 3.1): real-time tissue differentiation, dynamic motion correction, AI-driven occlusion prediction, and auto-defect interpolation |

| Calibration Method | Factory-calibrated; automated drift compensation via reference sphere | Dynamic self-calibration (DSC) with dual-axis inertial feedback and real-time thermal drift compensation; field recalibration via QR-coded phantom |

Note: Data reflects Q1 2026 specifications. Carejoy CJ-9000 series supports bidirectional CAD/CAM integration via open API and complies with DICOM Supplement 182 (3D Intraoral Imaging). All measurements conducted under controlled ISO 12836:2023 testing conditions.

Key Specs Overview

🛠️ Tech Specs Snapshot: 3Shape Intraoral Scanner Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration & Ecosystem Analysis

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technical Depth: Advanced | Release Date: Q1 2026

1. Deconstructing the “3Shape Intraoral Scanner Price” in Modern Workflows

The phrase “3Shape intraoral scanner price” represents a critical misnomer in technical discourse. Price is a procurement variable, not a workflow component. What truly matters is how the 3Shape TRIOS ecosystem (the industry’s benchmark scanner platform) integrates into technical workflows. Its value derives from:

- Native Data Pipeline: TRIOS scanners output proprietary

.3shapefiles (based on encrypted 3Mf format) that feed directly into 3Shape’s CAD/CAM suite with zero data loss or conversion latency. - Real-Time Clinical Integration: In chairside workflows, scan data auto-populates treatment plans in 3Shape Dental System within 8-12 seconds (measured at 100Mbps LAN), enabling same-day crown design while patient is seated.

- Lab Workflow Orchestration: For labs, TRIOS Cloud Portal enables instant scan receipt, automated case triage based on restoration type, and direct routing to designated CAD designers – reducing intake time by 63% (per 2025 JDC benchmark study).

2. CAD Software Compatibility: Beyond File Format Support

Compatibility must be evaluated through three technical lenses: data fidelity, workflow continuity, and feature parity. Here’s the 2026 landscape:

| CAD Platform | Native TRIOS Integration | Third-Party Scanner Support | Critical Workflow Limitation | 2026 Technical Verdict |

|---|---|---|---|---|

| 3Shape Dental System | Full native integration (direct .3shape import) | Limited to 3Shape-approved partners (ex: Medit via Open API) | Proprietary scripting restricts custom automation | Optimal for TRIOS-centric workflows – enables AI-driven prep analysis & automated margin detection |

| exocad DentalCAD | Requires STL/PLY conversion (loss of color/texture metadata) | Extensive via open libraries (Medit, Planmeca, etc.) | No access to TRIOS’ intra-scan motion data for motion artifact correction | Best for multi-scanner labs; 15-22% longer design time due to manual margin refinement |

| DentalCAD (by Straumann) | Partial via CEREC Connect (limited to specific TRIOS models) | Strong for Sirona ecosystem | Inconsistent handling of TRIOS’ dynamic texture mapping | Niche application; avoid for complex full-arch TRIOS cases |

3. Open Architecture vs. Closed Systems: The Technical Trade-Off Matrix

The “open vs closed” debate is oversimplified. Modern implementations exist on a spectrum. Key technical differentiators:

| Technical Parameter | Closed Ecosystem (e.g., TRIOS + 3Shape) | True Open Architecture (e.g., exocad + Multi-Scanner) | Hybrid Approach (2026 Trend) |

|---|---|---|---|

| Data Fidelity | Lossless (native format preserves scan metadata) | Lossy (STL conversion strips color/motion data) | Partial (APIs enable selective metadata transfer) |

| Automation Potential | High (deep API access for custom scripts) | Low (limited to basic file triggers) | Medium (vendor-dependent API maturity) |

| Vendor Lock-in Risk | High (switching costs exceed 200% of scanner cost) | Negligible | Modulated (contractual API terms critical) |

| Security Surface | Contained (single-vendor patch management) | Expanded (multi-vendor vulnerability vectors) | Variable (depends on API security protocols) |

| 2026 Recommendation | Chairside same-day workflows requiring zero latency | Labs aggregating diverse scanner data | Emerging standard – e.g., Carejoy-integrated workflows |

4. Carejoy API Integration: The Orchestrator Layer

Carejoy’s 2026 API represents the gold standard for workflow orchestration – transcending basic data exchange. Technical implementation highlights:

- Bi-Directional Case Sync: RESTful API endpoints enable real-time case status updates between TRIOS Cloud, exocad, and Carejoy PM. When a scan completes, Carejoy auto-creates a case with metadata (tooth #, restoration type, due date) pulled from TRIOS’ structured output.

- Intelligent Routing Engine: API-driven rules (e.g., “All full-arch TRIOS scans → Senior Designer A”) reduce manual case assignment by 92%. Integrates with CAD software to monitor design progress via heartbeat signals.

- Unified Analytics Layer: Aggregates scanner uptime, CAD design time, and lab production metrics into a single dashboard – impossible with siloed systems. Uses normalized data schemas across 3Shape/exocad.

- Zero-Click Patient Updates: When a restoration is marked “shipped” in lab software, Carejoy API triggers automated patient SMS with tracking – using TRIOS case ID as the master key.

Conclusion: Strategic Integration Over Component Cost

Fixating on “3Shape intraoral scanner price” misses the core technical imperative: minimize data friction across the workflow continuum. In 2026, optimal implementation requires:

- Chairside Clinics: Closed TRIOS/3Shape ecosystem for latency-critical same-day workflows. ROI validated at >42% higher case throughput (ADA ROI Calculator v4.1).

- Digital Labs: Hybrid architecture using Carejoy API to integrate TRIOS with exocad – preserving TRIOS data fidelity while avoiding vendor lock-in.

- Future-Proofing: Demand FHIR-compliant APIs from all vendors. Systems without standardized healthcare data protocols will become technical liabilities by 2028.

The scanner is merely the data genesis point. The true technical differentiator lies in the orchestration layer that transforms scan data into predictable clinical outcomes.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy Intraoral Scanner – Shanghai Production Hub

Carejoy Digital’s intraoral scanner platform—engineered as a high-precision, AI-driven imaging solution—undergoes a rigorously controlled manufacturing and quality assurance (QA) process at its ISO 13485-certified facility in Shanghai, China. This facility represents a convergence of advanced automation, metrological precision, and real-time data analytics, ensuring global compliance and clinical reliability.

1. Manufacturing Process Overview

| Stage | Process | Technology/Tools |

|---|---|---|

| Component Sourcing | Procurement of CMOS sensors, sapphire lenses, FPGA modules, and ergonomic composite housings | Supplier audits, RoHS/REACH compliance verification |

| PCBA Assembly | Surface-mount technology (SMT) for control board integration | Automated pick-and-place, reflow soldering, AOI (Automated Optical Inspection) |

| Optical Core Integration | Alignment of dual-wavelength LED array and high-speed stereo camera pair | Sub-micron laser alignment jigs, interferometric calibration |

| Final Assembly | Encapsulation, handle ergonomics, wireless module pairing | Torque-controlled screwdrivers, Bluetooth 5.3 handshake verification |

2. Sensor Calibration & Metrological Traceability

Each Carejoy intraoral scanner is calibrated in a dedicated Sensor Calibration Laboratory operating under ISO/IEC 17025 standards, with traceability to NIM (National Institute of Metrology, China) and NIST-equivalent references.

- Dynamic Calibration Rig: Uses certified ceramic reference models (ISO 12836-compliant) with 20+ geometric features (incl. step edges, spheres, grooves).

- AI-Driven Compensation: On-device neural network adjusts for thermal drift and ambient light interference using real-time feedback from embedded micro-climate sensors.

- Calibration Frequency: Per-unit calibration at T0 (post-assembly), T72h (aging), and pre-shipment. Recalibration recommended annually or after 10,000 scans.

3. Quality Control & Durability Testing

All units undergo a 72-point QC protocol before release. Critical tests include:

| Test Type | Standard | Duration/Parameters | Pass Criteria |

|---|---|---|---|

| Drop Test | IEC 60601-1-11 | 1.2m onto steel plate, 6 orientations | No functional degradation; optical alignment deviation < 5µm |

| Thermal Cycling | ISO 10993-1 (indirect), internal spec | -10°C to +50°C, 5 cycles | Zero condensation; scanning accuracy retained within ±10µm |

| IP Rating Validation | IEC 60529 | IP54 (dust/water resistant) | No ingress after 10 min water spray at 10L/min |

| Scan Repeatability | ISO 12836 Annex B | 20 repeated scans of reference model | Mean deviation ≤ 12µm; SD ≤ 4µm |

| EMC/EMI | IEC 60601-1-2 (4th Ed.) | Radiated/conducted emissions & immunity | Class B compliance; no data corruption under 10V/m RF exposure |

4. ISO 13485:2016 Certification & Digital Traceability

The Shanghai manufacturing site is audited bi-annually by TÜV SÜD for compliance with ISO 13485:2016, ensuring:

- Full device traceability via unique serial numbers linked to batch records, calibration logs, and QC data.

- Design controls aligned with IEC 62366 (usability engineering) and IEC 62304 (software lifecycle).

- Corrective and Preventive Action (CAPA) integration with global field performance data.

Each scanner ships with a Digital Quality Dossier (DQD) accessible via Carejoy Cloud, enabling clinics and labs to verify manufacturing lineage and calibration status.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry hardware due to a synergistic ecosystem:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of CMOS sensors, precision optics, and rare-earth magnets reduces logistics cost and lead time by up to 60%.

- Automation Scale: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly lines capable of 500+ units/day with defect rates < 0.3%.

- Software-Hardware Co-Design: Domestic AI talent enables on-device machine learning (e.g., cavity detection, prep margin identification) without reliance on cloud processing—critical for GDPR/CCPA compliance.

- Open Architecture Advantage: Carejoy scanners output native STL, PLY, and OBJ formats, ensuring compatibility with exocad, 3Shape Dental System, and open-source CAM tools—eliminating vendor lock-in.

- Regulatory Agility: CFDA (NMPA) approvals are increasingly harmonized with FDA 510(k) and EU MDR pathways, accelerating global market access.

Performance Benchmark: Independent tests (2025, DT Study Group) show Carejoy scanners achieve 8–14µm trueness—on par with premium European brands—at 42% lower acquisition cost.

Support & Ecosystem Integration

Carejoy Digital supports global labs and clinics via:

- 24/7 Remote Technical Support: AR-assisted diagnostics using Carejoy Connect mobile app.

- Bi-Weekly Software Updates: AI model enhancements, new material libraries, and DICOM export upgrades.

- Lab Integration: Direct STL export to milling centers and 3D print farms via secure API gateway.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape Intraoral Scanner Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160