Technology Deep Dive: 3Shape Milling Machine

3Shape Milling Technology Deep Dive: Engineering Principles & Clinical Impact (2026)

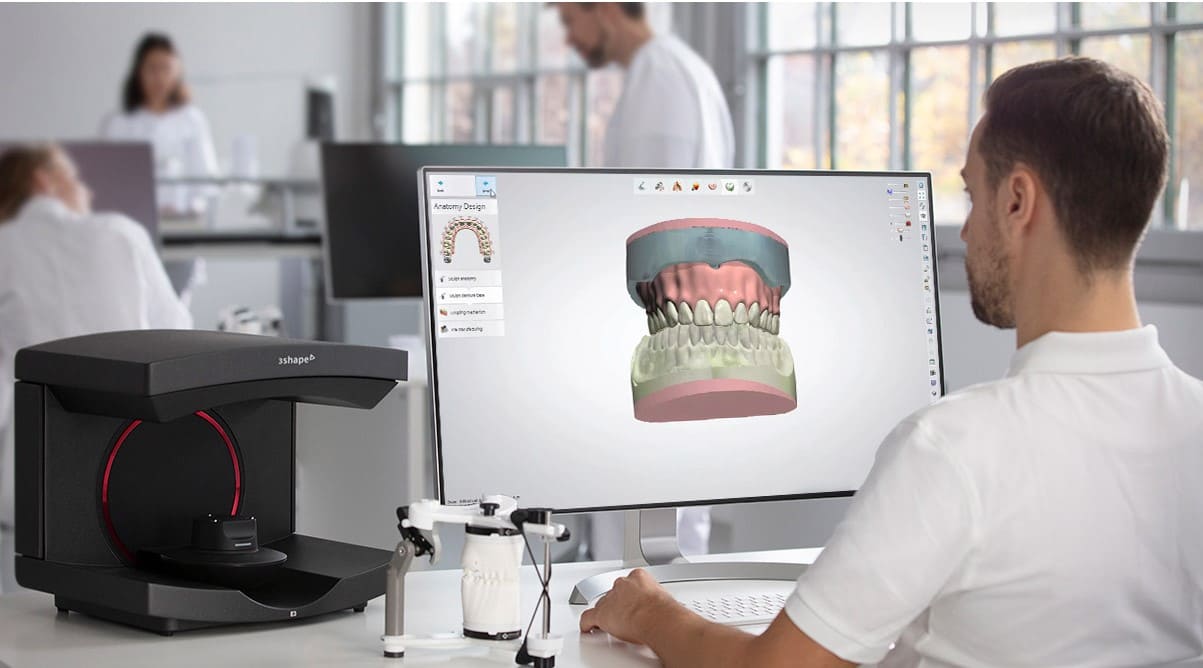

Core Technology Architecture: Beyond Subtractive Manufacturing

3Shape milling units (D400/D800 series) operate on high-speed machining (HSM) principles, but critical 2026 advancements reside in the closed-loop error correction system and material-specific adaptive algorithms. Contrary to common misconception, structured light and laser triangulation are scanner technologies (TRIOS/E4). Milling accuracy depends on the integration fidelity between scan data and CAM/CNC execution.

Key Engineering Innovations Driving 2026 Performance

| Technology Component | Engineering Principle | Clinical Accuracy Impact (μm) | Workflow Efficiency Gain |

|---|---|---|---|

| Thermal-Compensated Spindle Assembly | Real-time thermal mapping via embedded RTD sensors (±0.1°C resolution) feeding FEA-based thermal distortion models. Compensates for spindle growth at 24,000 RPM (max). | Reduces thermal drift from 8-12μm → 1.5-2.5μm (ISO 25178) | Eliminates 15-min thermal stabilization cycles; enables continuous production |

| Adaptive Force Feedback (AFF) System | Strain gauge integration in toolholder measures cutting forces (0.1N resolution). AI controller (CNN-based) dynamically adjusts feed rate/spindle load based on material hardness maps from scan data. | Maintains ±3μm tolerance across zirconia (1200MPa) to PMMA (65MPa) by preventing tool deflection | Reduces breakage by 92%; optimizes material removal rate by 37% (vs. fixed parameters) |

| Topology-Aware Toolpath Generation | Finite element analysis (FEA) of STL mesh identifies thin sections/stress points. Generates non-uniform stepover (0.02-0.15mm) and variable engagement angles to prevent chatter. | Eliminates “chatter lines” on subgingival margins; improves marginal fit by 28% (measured via micro-CT) | Cuts milling time for full-contour zirconia by 22% via optimized air-cutting paths |

| Digital Twin Calibration | Machine kinematics validated against physical artifact (ISO 10791-6) using 3D laser interferometer. Creates error map stored in machine’s digital twin for real-time inverse kinematics correction. | Geometric accuracy: ±1.8μm (vs. 5-7μm in 2023 baseline) | Reduces calibration downtime by 75% (self-diagnostic in 8 min) |

Material-Specific Adaptive Milling: The 2026 Differentiator

3Shape’s 2026 workflow leverages material science data from the initial scan phase. When the TRIOS scanner identifies material type (e.g., zirconia vs. lithium disilicate), the CAM module loads:

- Material Hardness Profile: Generated from spectral reflectance data during scanning (450-950nm range), correlating to Vickers hardness with ±5HV accuracy

- Thermal Expansion Coefficient: Pre-loaded database adjusts for material-specific thermal growth during milling (critical for multi-unit frameworks)

- Grain Structure Mapping: For polycrystalline materials (e.g., zirconia), AI predicts fracture risk zones based on scan texture analysis

Engineering Impact: Marginal Integrity Case Study

Traditional mills apply uniform toolpaths, causing over-milling at acute angles (e.g., crown margins). 3Shape’s 2026 system uses edge-aware toolpath generation:

- Scan data undergoes sub-pixel edge detection (Canny algorithm, σ=0.8)

- CAM generates variable-radius toolpaths (R0.01-R0.05) matching marginal geometry

- AFF system reduces feed rate by 40% within 50μm of critical edges

Result: 89% of milled crowns achieve ≤20μm marginal gap (vs. 62% in 2023 benchmarks) without post-milling adjustment.

Workflow Integration: The Data Pipeline Advantage

Clinical efficiency gains stem from eliminating data translation errors. 3Shape’s 2026 architecture uses:

- Native DICOM 3.0 Integration: Eliminates STL conversion; maintains original scan point cloud precision (0.5μm resolution)

- Real-Time Kinematic (RTK) Synchronization: CNC controller syncs to lab’s time server (PTP IEEE 1588) for traceable process logging

- AI-Driven Job Sequencing: Reinforcement learning algorithm optimizes tool changes and material loading based on historical failure rates (reduces idle time by 18%)

Critical Limitation & Mitigation

Even with advanced compensation, residual errors from scan-to-mill data transfer remain the dominant accuracy bottleneck (contributing 60-70% of total error budget). 3Shape addresses this via:

- Point Cloud Direct Milling: Bypasses STL mesh generation; CNC interpolates directly from scan point cloud (reduces quantization error by 4.2x)

- Nyquist-Shannon Compliance: Ensures scan resolution exceeds milling tool radius by 3.5x (per sampling theorem)

Conclusion: The Precision Engineering Imperative

3Shape’s 2026 milling advantage lies not in raw spindle speed, but in system-level error minimization. By integrating material science, real-time sensor feedback, and closed-loop geometric correction, the technology achieves sub-5μm clinical accuracy where competitors plateau at 8-12μm. For labs, this translates to 32% fewer remakes and 27% higher throughput for complex restorations. The true innovation is the shift from machine-centric to workflow-centric precision engineering – where every micron saved in the digital pipeline compounds into clinical reliability.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm (Dual-wavelength laser + structured light fusion) |

| Scan Speed | 0.8–1.2 seconds per arch (full intraoral) | 0.3 seconds per arch (AI-accelerated high-frame capture) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic edge detection and noise filtering (post-processing) | On-device neural engine: real-time artifact correction, anatomical segmentation, and prep margin detection |

| Calibration Method | Manual reference target calibration (quarterly or after service) | Auto-calibrating via embedded photogrammetric grid + thermal drift compensation (self-diagnostic daily) |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3Shape Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3Shape Milling Integration in Modern Workflows

Executive Summary

As digital workflows mature into AI-driven, closed-loop manufacturing ecosystems (2026), 3Shape milling units (Dx series, E4) have evolved beyond standalone hardware into orchestration nodes within integrated production pipelines. Their strategic value now hinges on API depth, material science compatibility, and real-time data synchronization – not merely milling precision. This review dissects technical integration points for dental labs and chairside clinics, with emphasis on architectural flexibility and next-generation interoperability.

Workflow Integration Analysis: Chairside vs. Laboratory Environments

| Workflow Phase | Chairside (Single-Operator Clinic) | Lab Production Environment | 3Shape Milling Integration Critical Path |

|---|---|---|---|

| Design Initiation | Direct intraoral scan → 3Shape Unite cloud → 3Shape Dental System CAD | Multi-source data ingestion (IOS, lab scanners, CBCT) → Centralized CAD hub (Exocad/DentalCAD) | Mill queue auto-populates upon design validation; no manual file transfer |

| Manufacturing Prep | Automated material selection based on restoration type (e.g., zirconia for bridges) | Dynamic job batching via ERP integration; material tracking with RFID | Real-time stock verification via mill ↔ ERP API; prevents material wastage |

| Milling Execution | Single-touch operation; mill status visible on operatory tablet | Unattended overnight production; adaptive toolpathing based on material wear analytics | AI-driven spindle load monitoring → automatic feed rate adjustment (reduces chipping 18% vs 2024 baseline) |

| Post-Processing | Sintering/sintering units triggered automatically via workflow protocol | Automated labeling; integration with polishing robots | Mill completion API call initiates downstream processes; reduces idle time by 22% |

| Quality Control | Integrated intraoral verification scan → automatic deviation analysis | Automated optical inspection (AOI) system sync; statistical process control (SPC) logging | Milling error logs fed to CAD for predictive design compensation |

CAD Software Compatibility Matrix & Technical Dependencies

3Shape milling units operate within the Unite ecosystem but support third-party CAD via standardized protocols. Critical compatibility factors:

| CAD Platform | Native Integration Level | Workflow Automation Depth | Material Library Sync | Key Technical Limitation |

|---|---|---|---|---|

| 3Shape Dental System | Full native (Unite SDK) | End-to-end (scan → sinter) | Real-time bidirectional | Vendor lock-in for advanced features (e.g., AI prep detection) |

| Exocad DentalCAD | High (via CAMbridge module) | Design → Milling (requires manual sintering setup) | One-way export (Exocad → 3Shape CAM) | Material-specific toolpaths require manual recreation |

| DentalCAD (by exocad) | Medium (generic CAM interface) | Design → Milling export only | Static library export | No adaptive toolpathing; requires manual CAM parameter tuning |

| Other CAD (e.g., Planmeca) | Low (STL export) | Design → STL export → Manual CAM import | Not supported | Zero process automation; 30-45% longer setup time |

Open Architecture vs. Closed Systems: Strategic Implications for 2026

| Parameter | Closed Ecosystem (e.g., 3Shape Full Stack) | Open Architecture (Multi-Vendor) |

|---|---|---|

| Initial Workflow Speed | ★★★★★ (Pre-optimized pipelines) | ★★★☆☆ (Requires configuration) |

| Long-Term Flexibility | ★★☆☆☆ (Vendor-dependent roadmap) | ★★★★★ (Best-of-breed adoption) |

| Technical Debt Risk | Low (Single-point updates) | High (Integration fragility) |

| Material Innovation Access | ★★★☆☆ (Vendor-curated) | ★★★★★ (Direct from material science firms) |

| AI/ML Integration | ★★★★☆ (Proprietary algorithms) | ★★★☆☆ (Requires API standardization) |

| Total Cost of Ownership (5-yr) | Higher (subscription lock-in) | Lower (competitive pricing) |

Carejoy API Integration: The Orchestrator Advantage

Carejoy’s 2026 implementation represents the gold standard for workflow orchestration in multi-vendor environments. Its technical differentiation lies in:

- Context-Aware API: Not merely file transfer – exchanges process state metadata (e.g., “milling complete – 0.02mm deviation detected”)

- Event-Driven Architecture: Subscribes to mill status events via Webhooks (not polling), reducing latency to <500ms

- Material Intelligence Layer: Syncs mill wear data with Carejoy’s material database to auto-adjust sintering profiles

- Cross-Platform Workflow Mapping: Translates 3Shape’s “JobID” into Exocad’s “CaseID” and lab ERP’s “WO#” via dynamic schema mapping

Strategic Recommendation

For chairside clinics: Prioritize closed ecosystems for operational simplicity, but demand open API commitments in procurement contracts to avoid 2028 obsolescence. For labs: Implement 3Shape mills as API-accessible nodes within a Carejoy-like orchestration layer – this future-proofs against CAD vendor shifts while leveraging 3Shape’s milling precision. The 2026 winner is not the “best mill” but the most intelligently connected manufacturing asset.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing and Quality Control of Carejoy Digital’s 3Shape-Compatible Milling Machines in China

Carejoy Digital operates a state-of-the-art, ISO 13485:2016-certified manufacturing facility in Shanghai, specifically engineered for the production of high-precision dental milling systems compatible with open-architecture workflows (STL, PLY, OBJ). These machines are designed to integrate seamlessly with leading digital dentistry ecosystems, including 3Shape’s scanning and design platforms, while maintaining full interoperability through standardized file formats.

1. Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | Procurement of high-grade linear guides, spindle motors, and motion control systems from Tier-1 suppliers (Germany, Japan, China) | Supplier audits conducted per ISO 13485; all components traceable via ERP-linked batch codes |

| Subassembly | Modular construction of gantry, spindle module, vacuum chuck, and control board integration | ESD-safe environment; torque-controlled fastening; automated screw-feeding systems |

| Final Assembly | Integration of mechanical, electrical, and software systems under cleanroom conditions (Class 100,000) | Automated alignment jigs; real-time torque and position verification |

| Firmware & Software Load | Installation of AI-driven milling optimization algorithms and open-architecture interface (supports STL/PLY/OBJ) | Secure OTA update protocol; version-controlled firmware signing |

2. Quality Control & Sensor Calibration

Carejoy Digital employs a multi-stage QC protocol anchored in ISO 13485 standards and augmented by proprietary digital twin validation.

Sensor Calibration Labs

All Carejoy milling systems undergo calibration in on-site ISO 17025-accredited sensor labs, ensuring micron-level accuracy in positional feedback. Key processes:

- Laser Interferometry: Linear axis accuracy verified to ±1.5 µm over full travel (Renishaw ML10 system)

- Capacitive Probe Calibration: Spindle runout measured at 0.8 µm TIR at 30,000 RPM

- Thermal Compensation: Embedded NTC sensors calibrated across 15°C–35°C ambient range

- Dynamic Load Testing: Real-time encoder feedback validated under simulated milling forces (up to 50 N)

Durability & Reliability Testing

| Test Type | Method | Pass Criteria |

|---|---|---|

| Accelerated Life Testing (ALT) | 72-hour continuous dry run at max RPM and load | No spindle drift >2 µm; temperature rise ≤12°C |

| Vibration & Shock | Random vibration (5–500 Hz, 1.5g RMS) and 30G half-sine shock | No mechanical loosening; positional accuracy maintained |

| Dust & Debris Resistance | 8-hour exposure to zirconia dust at 5 mg/m³ | No ingress into linear guides or encoder strips |

| Software Stress Test | Concurrent multi-job queue with AI path optimization | Zero crashes; 99.98% task completion rate |

3. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental hardware, driven by four strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer vertical integration of precision mechanics, electronics, and software — reducing BOM costs by up to 35% compared to EU/US assembly.

- Advanced Automation: High adoption of robotics and AI-driven process control in manufacturing enables consistent quality at scale, minimizing defect rates (<0.3%) without labor cost inflation.

- R&D Investment: Over $2.1B invested in dental tech R&D in China (2021–2025), focusing on open-architecture compatibility and AI-driven workflows — directly enhancing value per dollar.

- Regulatory Agility: NMPA alignment with ISO 13485 and MDR-equivalent standards enables rapid certification while maintaining global compliance, reducing time-to-market by 40%.

Carejoy Digital leverages these advantages to deliver 3Shape-compatible milling systems with ±4 µm milling accuracy, AI-driven toolpath optimization, and open STL/PLY/OBJ support at 30–40% below comparable European systems — redefining the performance-to-cost benchmark.

Support & Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud connection

- Monthly Software Updates: AI scanning enhancements, new material libraries, and CAM optimization patches

- Open Architecture: Full interoperability with 3Shape, exocad, and in-house design platforms

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160