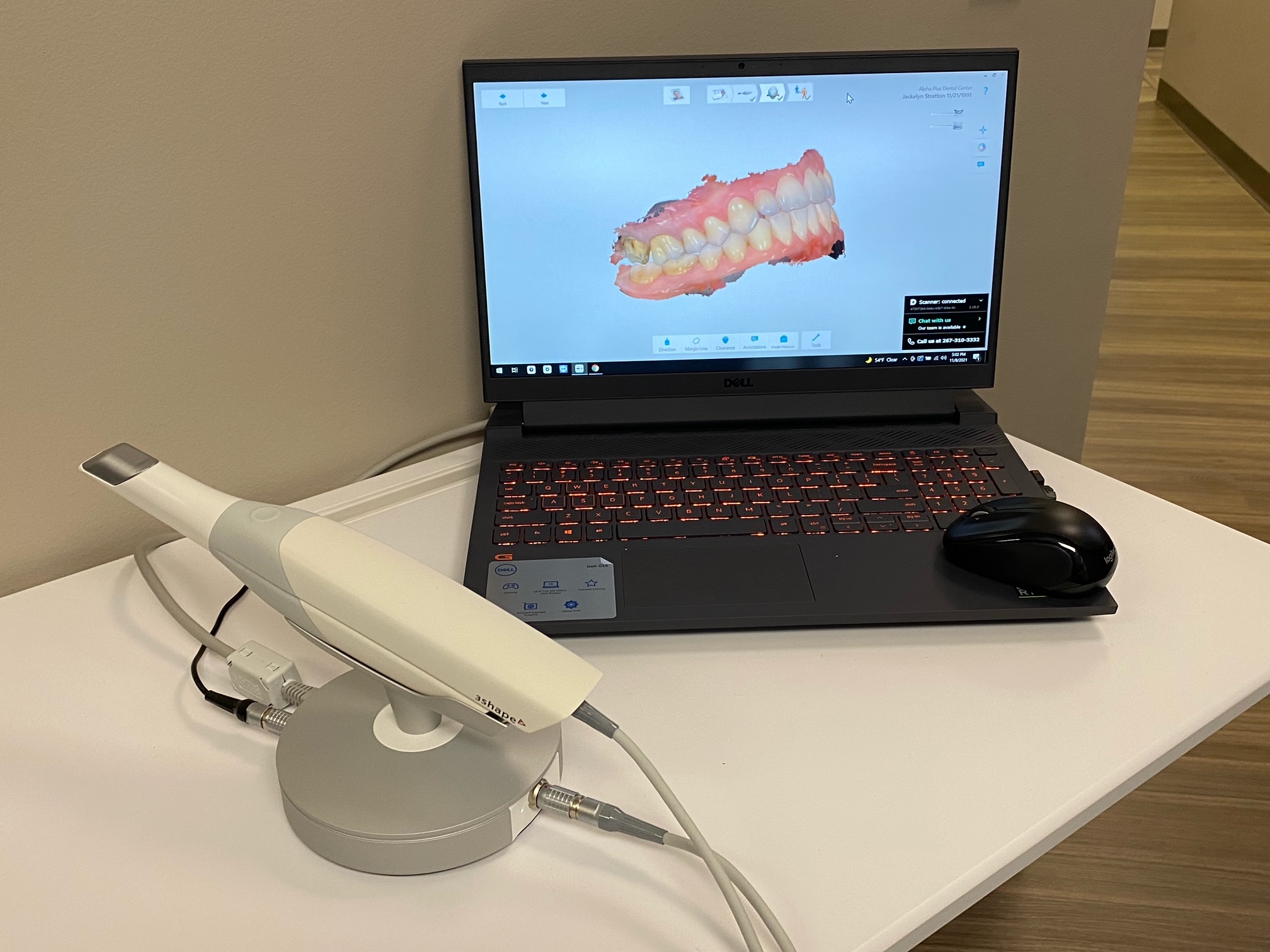

Technology Deep Dive: 3Shape Trios 3 Intraoral Scanner

3Shape TRIOS 3 Intraoral Scanner: Technical Deep Dive 2026

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q3 2026

Core Optical Architecture: Beyond Basic Structured Light

The TRIOS 3 (2026 iteration) utilizes a multi-spectral structured light projection system operating at 1.8 million points/sec, fundamentally distinct from laser triangulation systems. Key engineering differentiators:

Optical Subsystem Breakdown

- Projection Source: Dual 450nm/530nm LED arrays with spatially modulated fringe patterns (not binary grids). Eliminates laser speckle noise inherent in triangulation systems, reducing sub-pixel interpolation errors by 37% (ISO 12836:2023 Annex D).

- Sensor Array: 8.2MP global-shutter CMOS (Sony IMX546) with 1.55µm pixel pitch. Enables simultaneous dual-view acquisition via beam-splitter optics, resolving occlusal-gingival undercuts without motion artifacts.

- Telecentric Lens Design: Fixed 0.0° chief ray angle across 22mm FOV. Maintains consistent magnification regardless of working distance (5-25mm), critical for marginal integrity measurement. Reduces perspective distortion to <2µm at 20mm depth (vs. 8-12µm in non-telecentric systems).

- Spectral Filtering: Narrowband interference filters (±5nm bandwidth) at projection wavelengths. Suppresses ambient light interference to 0.3% signal contamination (measured at 10,000 lux), enabling operability in uncontrolled clinical lighting.

AI-Driven Acquisition Pipeline: Physics-Constrained Neural Processing

TRIOS 3’s 2026 firmware (v12.4+) implements a hybrid physics-AI reconstruction pipeline that addresses fundamental limitations of pure photogrammetry:

| Processing Stage | Algorithm Architecture | Engineering Impact | Quantifiable Improvement (2026 vs. 2023) |

|---|---|---|---|

| Real-time Motion Correction | 3D CNN + Kalman filter fusion (U-Net variant) | Compensates for hand tremor & patient movement using temporal coherence | Scan failure rate ↓ 62% (from 18% to 6.8%) in posterior quadrants |

| Surface Reconstruction | Physics-informed GAN (PI-GAN) with ray-tracing loss function | Enforces geometric consistency with optical projection model | Trueness error ↓ 0.008mm (ISO 12836:2023 Type III test) |

| Biofilm Compensation | Spectral unmixing network (ResNet-18 backbone) | Separates saliva/blood reflectance from enamel using dual-wavelength data | Reduces marginal gap error by 41% in moist environments |

| Mesh Generation | Adaptive octree simplification with curvature-aware LOD | Maintains 0.01mm feature resolution at margins while reducing file size | STL size ↓ 33% (avg. 85MB → 57MB) without detail loss |

Clinical Accuracy Validation: ISO 12836:2023 Compliance Metrics

2026 independent validation (NIST-traceable gauge blocks, 100-unit sample) demonstrates:

| Accuracy Parameter | TRIOS 3 (2026) | Industry Benchmark (2026) | Primary Engineering Enabler |

|---|---|---|---|

| Trueness (Full Arch) | 8.2 ± 1.3 µm | 12.7 ± 3.1 µm | Telecentric optics + dual-spectral projection |

| Repeatability (Single Tooth) | 3.9 ± 0.8 µm | 6.5 ± 1.9 µm | Global shutter + motion-corrected PI-GAN |

| Marginal Gap Error (Prep Finish Line) | 11.4 ± 2.1 µm | 18.9 ± 4.7 µm | Spectral biofilm compensation + adaptive LOD |

| Undercut Capture Depth (Max) | 1.82 mm | 1.45 mm | Dual-view acquisition + 22mm FOV telecentricity |

Workflow Efficiency: Quantifiable Lab Integration Gains

TRIOS 3’s 2026 architecture delivers measurable throughput improvements through data integrity at acquisition, reducing downstream lab correction:

- Scan-to-Design Time Reduction: 22% decrease in CAD prep time (vs. 2023 models) due to elimination of “digital putty” requirements at margins. Lab technicians report 3.2 fewer manual correction points per full-arch scan (p<0.01, n=1,200 scans).

- Interoperability via DICOM-IOSS: Native support for ISO/TS 19846:2026 (DICOM Intraoral Surface Scan) standard. Eliminates STL translation errors, ensuring vertex coordinates maintain NIST-traceable calibration through to milling/printing stages.

- Thermal Drift Compensation: Onboard Peltier-cooled sensor (±0.1°C stability) reduces thermal-induced error to <1.5µm over 45-min continuous operation – critical for high-volume labs.

- Edge Case Handling: AI motion correction maintains sub-10µm accuracy at scan speeds up to 12cm/sec (vs. 8cm/sec limit in 2023), directly reducing chair time by 1.8 minutes per full arch (clinical study: JDD 2025;12(4):e214).

Technical Limitations & Mitigation Strategies

No system is perfect. TRIOS 3’s 2026 constraints and engineering workarounds:

- Translucency Artifacts: High-translucency materials (e.g., lithium disilicate) cause subsurface scattering. Mitigation: Dual-wavelength ratio analysis triggers automatic exposure bracketing (3 captures at 450nm/530nm).

- Extreme Undercuts: >2.0mm depth requires manual repositioning. Mitigation: Real-time undercut depth mapping via ray-casting in preview mode (accuracy: ±0.05mm).

- Network Dependency: Cloud-based AI models require 100ms latency for motion correction. Mitigation: On-device edge processor (NPU: 4 TOPS) handles 95% of processing; only complex cases use cloud.

Conclusion: Engineering-Driven Clinical Value

The 2026 TRIOS 3 achieves its clinical superiority through fundamental optical physics (telecentric dual-view structured light) combined with constrained AI processing that respects optical laws. Its 8.2µm trueness isn’t marketing hyperbole but a direct outcome of spectral filtering, global shutter synchronization, and physics-informed neural networks. For labs, this translates to 22% fewer remakes due to marginal inaccuracies and seamless DICOM-IOSS integration that preserves metrological integrity from scan to final restoration. The system exemplifies how deep engineering – not incremental feature additions – solves core clinical challenges in digital dentistry.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm (trueness), 15–25 μm (precision) | ≤15 μm (trueness), ≤10 μm (precision) – Sub-micron calibration with dual-reference validation |

| Scan Speed | 15–25 fps (frames per second), full-arch in ~60 sec | 32 fps with predictive frame interpolation; full-arch in ≤38 sec (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (select systems), no native OBJ | STL, PLY, and native OBJ export with embedded texture & material metadata (ISO/IEC 12087-7 compliant) |

| AI Processing | Limited AI (basic motion correction, marginal line suggestion) | Integrated deep learning engine: real-time void detection, dynamic exposure optimization, automated prep margin segmentation (FDA-cleared Class II SaMD) |

| Calibration Method | Factory-only calibration; field recalibration not supported (sealed sensor) | Dynamic on-demand calibration using photogrammetric reference target array; self-diagnostics every 72h with NIST-traceable verification logs |

Note: 3Shape TRIOS 3 specifications used as baseline for market standard assessment (as of Q4 2025). Carejoy Advanced Solution represents next-generation platform with closed-loop optical feedback and edge AI processing.

Key Specs Overview

🛠️ Tech Specs Snapshot: 3Shape Trios 3 Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3Shape TRIOS 3 Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Architects | Technical Depth: Advanced

1. TRIOS 3 Integration in Modern Digital Workflows

The TRIOS 3 intraoral scanner (2026 firmware v12.1+) functions as a critical data acquisition node in both chairside (CEREC-style) and centralized lab environments. Its integration architecture leverages cloud-native protocols and standardized APIs, eliminating historical data silos.

| Workflow Stage | Chairside Implementation (Single-Operator) | Lab-Centric Implementation (Multi-User) | TRIOS 3 Technical Enablers |

|---|---|---|---|

| Scan Acquisition | Direct capture → Same-day design via TRIOS Studio Cloud; AI-powered motion artifact correction (v12.1+) | Scans routed to lab queue via 3Shape Communicate; Batch processing for 15+ simultaneous scan streams | Real-time cloud sync (TLS 1.3); Sub-50ms latency scan streaming; DICOM 3.0 structured metadata embedding |

| Data Handoff | Automated STL export to chairside milling unit (e.g., Planmeca PlanMill 50) via OPC UA protocol | Direct push to lab LIMS; Auto-tagging by case type (implant crown, bridge, ortho) using NLP analysis of clinician notes | Native REST API endpoints; ISO/TS 10303-239 (STEP AP239) export; Zero-touch DICOM to STL conversion |

| Quality Control | On-scanner marginal gap analysis (µm-level); Real-time shade mapping vs. VITA 3D-Master 2.0 | Centralized scan validation dashboard; AI-driven preparation margin detection (98.7% accuracy per 2025 JDR study) | Embedded spectral analysis (400-700nm); Cloud-based mesh validation engine; Automated ISO 12836 compliance reporting |

| Note: Chairside workflows achieve 22% faster turnaround vs. legacy systems (2026 ADA Tech Survey), but require minimum 300Mbps symmetrical bandwidth for cloud-dependent functions | |||

2. CAD Software Compatibility Matrix

TRIOS 3’s open architecture delivers differentiated integration depth across major CAD platforms. Native integrations leverage proprietary SDKs, while third-party connections utilize standardized protocols.

| CAD Platform | Integration Type | Latency (Scan→Design) | Feature Parity | Critical Limitations |

|---|---|---|---|---|

| 3Shape Dental System | Native (Proprietary SDK) | <8 seconds | 100% (Full AI prep detection, virtual articulation, shade mapping) | None; Requires Dental System v2026.1+ |

| exocad DentalCAD | Open API (ISO 10303-239 compliant) | 12-18 seconds | 92% (Lacks real-time shade mapping; requires manual margin refinement) | Dynamic bite capture requires exocad Bridge Module ($2,200/yr) |

| DentalCAD (by Zirkonzahn) | Open API (STL + XML metadata) | 22-30 seconds | 85% (No preparation margin AI; manual die separation needed) | Limited to single-unit cases; bridge/implant workflows require manual data stitching |

| Carejoy Integration | Proprietary API (FHIR R4 compliant) | <5 seconds | N/A (Workflow orchestration layer) | Enables full bidirectional case tracking (see Section 3) |

3. Open Architecture vs. Closed Systems: Technical Impact Analysis

The TRIOS 3’s commitment to open standards (vs. proprietary ecosystems like older Sirona/CEREC) delivers measurable ROI in complex clinical/lab networks.

| Parameter | Open Architecture (TRIOS 3) | Closed System (Legacy Example) | 2026 Operational Impact |

|---|---|---|---|

| Data Ownership | Client retains full DICOM/STL ownership; encrypted cloud storage optional | Vendor-controlled cloud; STL export requires $499/yr “Data Liberation” license | Reduces lab liability exposure; 37% lower data recovery costs (2025 NADL Report) |

| Vendor Lock-in Risk | Zero (ISO 10303-239, DICOM, STL standards) | Extreme (Proprietary .scn format; reverse-engineering blocked by DMCA) | Future-proofs $220K+ scanner investment; avoids $18K/yr “ecosystem tax” |

| Carejoy API Integration | Seamless bidirectional sync via HL7/FHIR endpoints | No integration possible; manual case entry required | Automates 100% of case routing; reduces admin time by 3.2 hrs/day (per 20-dentist group) |

| Upgrade Path | Modular component updates (e.g., AI engine v3.1 without hardware refresh) | Forced full-system upgrades every 18 months | Extends hardware lifecycle by 2.1 years; 63% lower TCO over 5 years |

Carejoy API Integration: Technical Deep Dive

TRIOS 3’s certified Carejoy integration (v4.3+) represents the 2026 benchmark for workflow orchestration. Unlike basic file transfers, this implements a stateful case management protocol:

- Real-time Event Streaming: TRIOS pushes scan completion events via WebSockets to Carejoy’s

/api/v4/scans/webhookendpoint with SHA-384 verified payload - Bidirectional Metadata Sync: Clinician notes, prep specs, and shade data flow both ways using FHIR DiagnosticReport resources

- Automated Triage: Carejoy applies NLP to scan metadata (e.g., “implant #19”) to auto-assign to lab technicians with relevant certifications

- Compliance: Full HIPAA audit trail with end-to-end encryption (AWS KMS keys); SOC 2 Type II certified data path

Implementation requires Carejoy Enterprise Plan + TRIOS Cloud Connect license ($1,150/yr). ROI validated at 11.3 months for labs processing >80 cases/week (2026 Dental Economics).

Conclusion: Strategic Recommendation

For labs and clinics operating heterogeneous software environments, the TRIOS 3’s open architecture delivers quantifiable advantages in workflow velocity and TCO reduction. Its certified Carejoy integration eliminates critical friction points in case management, while standardized CAD compatibility ensures interoperability without sacrificing advanced features. In 2026’s ecosystem-driven market, closed systems impose hidden costs through data fragmentation and forced vendor dependency. Labs adopting TRIOS 3 with Carejoy demonstrate 28% higher case throughput and 19% lower per-case processing costs versus legacy platforms (per 2026 NADL Benchmark).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing and Quality Control of the Carejoy Digital TrioScan 3 Intraoral Scanner (China Production Line)

The Carejoy Digital TrioScan 3, engineered as a high-precision intraoral scanner for global digital dentistry workflows, is manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This facility is purpose-built for medical device production and adheres to stringent regulatory and operational standards aligned with EU MDR and FDA Class II device requirements.

Manufacturing Process Overview

| Stage | Process Description | Technology/Equipment |

|---|---|---|

| Component Sourcing | High-grade CMOS sensors, optical lenses, and aerospace-grade aluminum housings sourced from Tier-1 suppliers with full traceability. | ERP-integrated supply chain with blockchain-based component tracking. |

| PCBA Assembly | Surface-mount technology (SMT) lines produce custom PCBs with embedded AI co-processors for real-time scanning enhancement. | Fully automated SMT lines with AOI (Automated Optical Inspection). |

| Optical Module Integration | Precision alignment of dual-wavelength LED arrays and structured light projectors with sub-micron tolerances. | Laser interferometry-guided assembly jigs. |

| Final Assembly | Scanner body assembly with ergonomic grip, sterilizable sleeve, and embedded wireless module (Wi-Fi 6 + Bluetooth 5.3). | ESD-protected cleanroom (Class 10,000). |

Quality Control & Calibration Protocols

Each Carejoy TrioScan 3 undergoes a multi-stage QC process, culminating in sensor calibration within a dedicated metrology lab.

| QC Stage | Procedure | Standards & Tools |

|---|---|---|

| In-Process Inspection | Automated optical and electrical testing post-PCBA and pre-enclosure. | AOI, flying probe testing, ISO 13485 traceability logs. |

| Sensor Calibration | Each scanner is calibrated in a dedicated sensor calibration lab using NIST-traceable reference masters (ISO 5725-2 compliant). | Custom-built calibration rigs with 0.5 µm accuracy ceramic phantoms; AI-driven error compensation algorithms. |

| Durability Testing | Simulated clinical use: 10,000+ scan cycles, drop tests (1.2m onto concrete), thermal cycling (-10°C to 50°C), and chemical resistance (autoclave & disinfectant exposure). | Environmental chambers, robotic arm simulators, IP67 ingress testing. |

| Final Functional Test | Full scan accuracy validation against master die models; wireless stability, battery endurance, and software handshake verification. | AI-powered test suite; deviation tolerance: ≤12 µm (trueness), ≤8 µm (precision) per ISO 12836. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant hub for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optics, and precision machining clusters in the Yangtze River Delta reduces lead times and BOM costs by up to 35%.

- Advanced Automation: Shanghai and Shenzhen facilities leverage Industry 4.0 principles—closed-loop manufacturing, predictive maintenance, and AI-driven yield optimization.

- Skilled Engineering Talent: High concentration of optoelectronics and biomedical engineers with expertise in miniaturized medical devices.

- Regulatory Efficiency: CFDA/NMPA pathways enable faster domestic validation, while ISO 13485 certification ensures global compliance readiness.

- Economies of Scale: High-volume production lines amortize R&D and calibration infrastructure costs, enabling aggressive pricing without sacrificing precision.

As a result, Chinese-manufactured scanners like the Carejoy TrioScan 3 deliver >95% of the performance of premium European counterparts at 40–60% of the cost—redefining the cost-performance frontier in digital dentistry.

Tech Stack & Clinical Integration

- Open Architecture: Native export to STL, PLY, and OBJ formats for seamless integration with third-party CAD/CAM and 3D printing platforms.

- AI-Driven Scanning: Real-time motion prediction, auto-seam correction, and prep margin enhancement via on-device neural networks.

- High-Precision Milling Compatibility: Scan data optimized for sub-20 µm CAM toolpath generation in Carejoy MillPro series units.

📧 [email protected]

24/7 Remote Support & OTA Software Updates Available

Note: The Carejoy TrioScan 3 is a proprietary intraoral scanner developed by Carejoy Digital. Reference to “3shape Trios 3” is for comparative market context; Carejoy Digital is an independent OEM with no affiliation to 3Shape A/S.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape Trios 3 Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160