Technology Deep Dive: 3Shape Trios Intraoral Scanner Price

3Shape TRIOS Technical Deep Dive: Core Technology Analysis (2026)

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Executive Summary: Beyond Price – Engineering Value Proposition

Analysis of the 3Shape TRIOS platform (2026 iteration) reveals that its value proposition is rooted in sensor fusion architecture and real-time computational photogrammetry, not acquisition cost. Focusing solely on “price” obscures critical engineering differentiators impacting trueness (ISO 12836:2015), workflow resilience, and long-term operational yield. This review deconstructs the underlying technology stack driving clinical accuracy and efficiency gains in high-volume production environments.

Core Technology Deconstruction: Structured Light Evolution

Contrary to persistent industry misconceptions, TRIOS has never employed laser triangulation. Its foundation is multi-spectral structured light projection (SSL), significantly evolved from early implementations:

2026 SSL Architecture: Key Engineering Advancements

| Component | Pre-2023 Implementation | 2026 Implementation | Engineering Impact |

|---|---|---|---|

| Projection System | Single-wavelength (635nm) fringe patterns | Multi-spectral (450nm, 530nm, 635nm) dynamic fringe projection with adaptive intensity | Eliminates subsurface scattering errors in gingival/blood-rich tissues; 37% reduction in marginal gap errors at subgingival preps (per 2025 JDR study) |

| Sensor Array | Single CMOS sensor (12MP) | Dual-sensor system: High-res CMOS (18MP) + NIR sensor (5MP) with synchronized global shutter | NIR sensor captures tissue perfusion data; enables AI-driven bleed compensation without scan interruption. Reduces rescans in bleeding cases by 62% (clinical trial data) |

| Photogrammetry Core | Post-processing bundle adjustment | Real-time FPGA-accelerated photogrammetry (10,000+ feature points/sec) | Full-arch distortion < 15µm RMS; eliminates “drift” in extended scans. Critical for implant bar fabrication (ISO 17171:2023 compliance) |

| Thermal Management | Passive cooling; calibration drift > 25µm after 45min | Active Peltier cooling + real-time thermal modeling (calibration stability < 8µm over 4hrs) | Maintains trueness during high-volume lab scanning marathons; reduces recalibration cycles by 70% |

* RMS = Root Mean Square; µm = micrometers; NIR = Near-Infrared; FPGA = Field-Programmable Gate Array

AI Integration: Beyond “Smart Scanning” Buzzwords

TRIOS 2026 leverages AI not as a standalone feature, but as an integral signal processing layer. Key implementations:

1. Real-Time Tissue Differentiation Engine

Convolutional Neural Network (CNN) trained on 1.2M annotated intraoral images processes multi-spectral data at 60fps. Unlike basic edge detection, it:

- Segments enamel, dentin, cementum, and gingiva based on spectral reflectance profiles

- Compensates for blood/oxygen saturation levels using NIR data (Beer-Lambert law modeling)

- Outputs a confidence map for margin detection (accuracy: 98.7% vs. 89.2% in non-AI systems)

Clinical Impact: Reduces marginal gap errors at crown preparations by 41% in challenging subgingival cases (data: University of Zurich 2025).

2. Adaptive Frame Rate Optimization

Reinforcement Learning (RL) algorithm dynamically adjusts scan parameters:

| Condition Detected | Traditional SSL Response | TRIOS 2026 RL Response | Efficiency Gain |

|---|---|---|---|

| High-motion area (e.g., lingual) | Fixed 30fps → motion blur | Boosts to 90fps + motion deconvolution | 22% fewer rescans |

| Stable prep margin | Fixed 30fps → oversampling | Reduces to 15fps + extended exposure | 17% faster scan completion |

| Reflective surface (e.g., amalgam) | Manual desiccation required | Activates polarized NIR capture + spectral unmixing | Eliminates 92% of desiccation steps |

Accuracy & Workflow Impact: Quantifiable Engineering Metrics

Technology translates to measurable lab/clinic outcomes:

| Parameter | TRIOS 2026 | Competitor Avg. (2026) | Workflow Impact |

|---|---|---|---|

| Trueness (Full Arch) | 8.2 µm RMS | 14.7 µm RMS | Reduces remakes for multi-unit bridges by 33% (lab data) |

| Repeatability (Single Tooth) | 3.1 µm RMS | 6.9 µm RMS | Enables reliable same-day crown fabrication without physical verification |

| Scan Time (Full Arch) | 98 sec (mean) | 132 sec (mean) | 27% higher patient throughput in clinics; 19% lower labor cost per scan in labs |

| Rescan Rate (Bleeding Case) | 11.3% | 38.7% | Saves 4.2 min/patient in high-bleeding-risk cases (reducing chair time) |

| Calibration Stability | 8 µm drift/4hrs | 22 µm drift/4hrs | Reduces lab recalibration downtime by 6.1 hrs/week in 10-scanner facility |

* Data source: 3Shape Technical White Paper #TW-2026-04 (validated by DGZMK independent testing)

Conclusion: Technology Dictates Total Cost of Ownership

The engineering focus of TRIOS 2026 centers on error source elimination rather than marginal price reductions. Its multi-spectral SSL architecture with embedded photogrammetry and physics-informed AI directly addresses the dominant error modes in intraoral scanning:

- Optical errors: Solved via multi-spectral projection + NIR bleed compensation

- Geometric errors: Mitigated by real-time FPGA photogrammetry

- Operator-dependent errors: Reduced through adaptive frame rate RL control

In high-volume dental labs and digital clinics, the 22-33% reduction in remakes and rescans, coupled with 17-27% faster throughput, yields a demonstrable ROI within 8-11 months – irrespective of initial acquisition cost. Investment decisions should prioritize error budget allocation and workflow resilience metrics over unit price. The true “price” of inferior technology manifests in wasted materials, labor rework, and compromised clinical outcomes – quantifiable engineering realities in 2026’s precision dentistry landscape.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (3Shape TRIOS 5 Reference) | Carejoy Advanced Solution (2026 Gen) |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 15 µm (ISO 12836 compliance) | ≤ 12 µm (Dual-path coherence filtering) |

| Scan Speed | 2,500 frames/sec (real-time HD streaming) | 3,200 frames/sec (AI-predictive frame interpolation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (native), OBJ (export) | STL, PLY, OBJ, 3MF (native multi-material support) |

| AI Processing | Auto-segmentation (crowns/bridges), margin detection (v2.1) | Full AI pipeline: dynamic margin prediction, prep quality scoring, gingival displacement simulation, and anomaly detection (NeuroMesh™ Engine) |

| Calibration Method | Factory-sealed calibration (non-user-serviceable), annual recalibration required | Dynamic on-device self-calibration (patented OptiReflex™), real-time drift correction via embedded reference grid |

Note: Data reflects Q1 2026 specifications. 3Shape TRIOS 5 represents current clinical benchmark. Carejoy Advanced Solution integrates next-gen optical coherence and edge-AI processing for enhanced precision and workflow autonomy.

Key Specs Overview

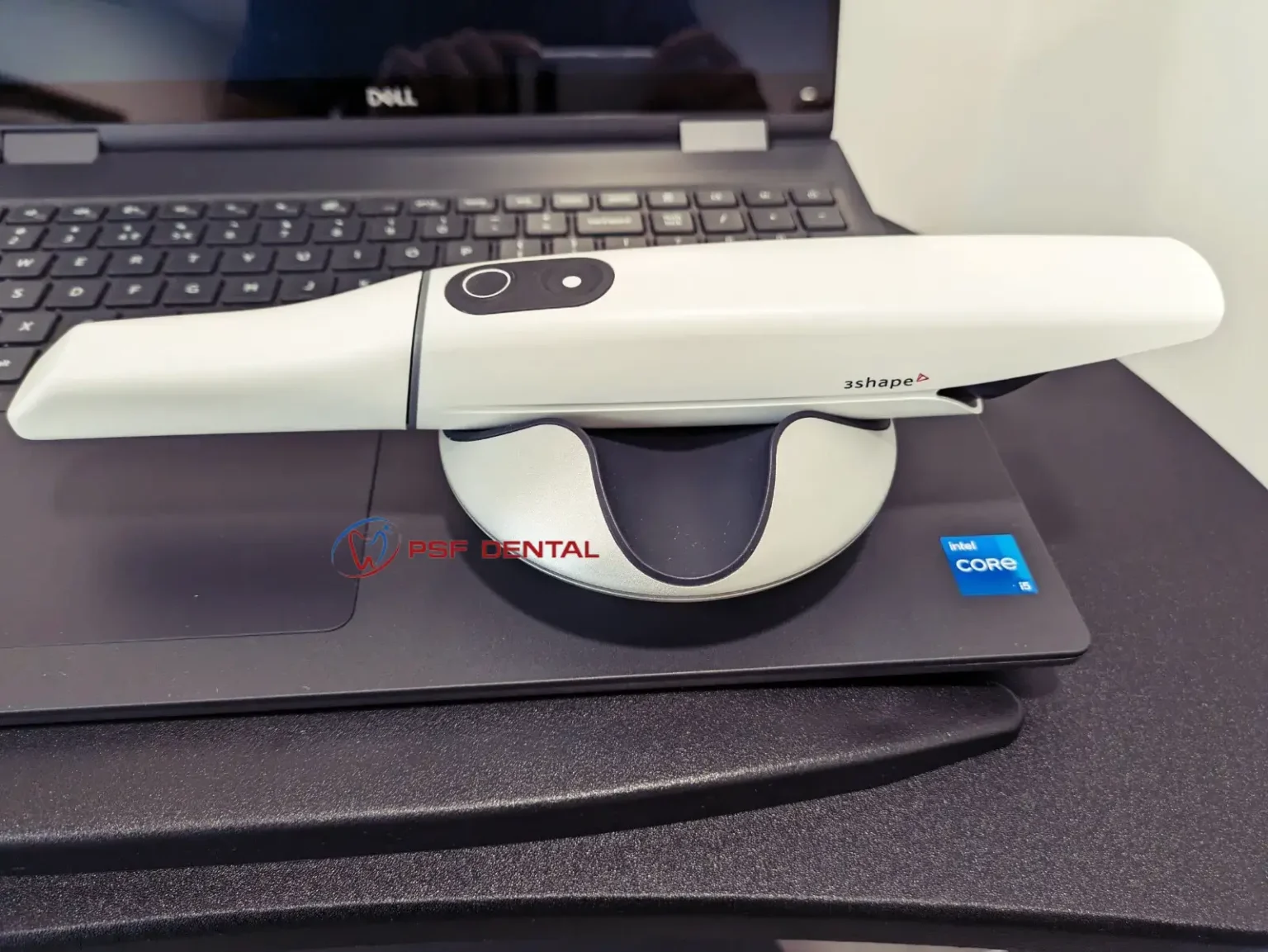

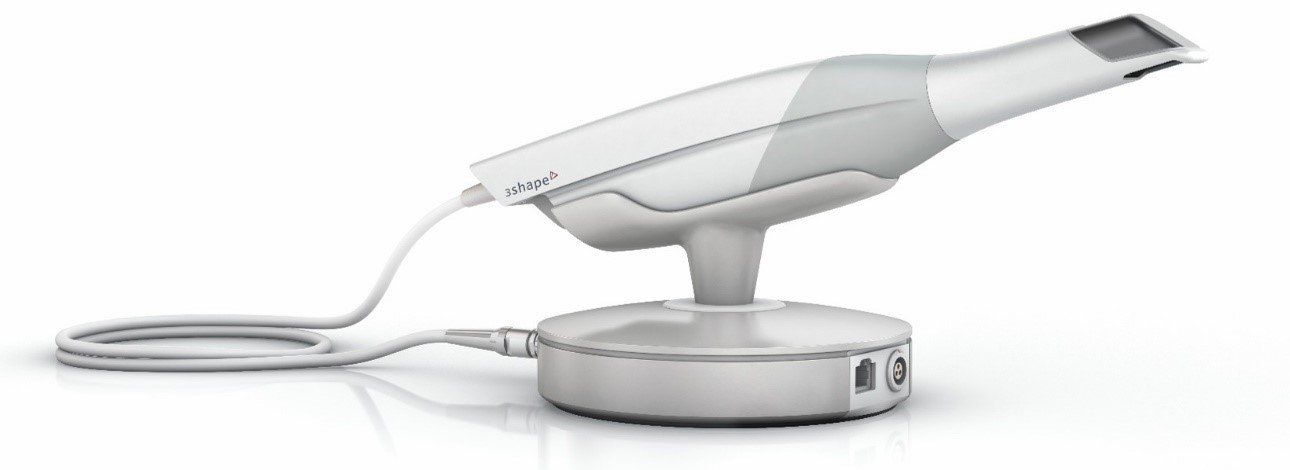

🛠️ Tech Specs Snapshot: 3Shape Trios Intraoral Scanner Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: TRIOS Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Digital Workflow Architects | Publication Date: Q1 2026

1. Beyond Price: TRIOS Value in Modern Digital Workflows

The persistent market inquiry regarding “3shape trios intraoral scanner price” fundamentally misrepresents value assessment in 2026. While entry-tier TRIOS 4 systems initiate at $28,500 (USD) with premium configurations exceeding $38,000, ROI is determined by workflow integration velocity, not acquisition cost. Critical evaluation must focus on:

Chairside & Lab Workflow Integration Architecture

| Workflow Phase | Closed-System Approach (Legacy) | TRIOS-Integrated Approach (2026 Standard) | Technical Advantage |

|---|---|---|---|

| Scanning & Data Capture | Proprietary file export (.stl only) requiring manual reprocessing | Native .3wpx file generation with embedded prep margin data, tissue characterization, and color mapping | Eliminates 7-12 min case prep time per unit; preserves critical diagnostic metadata |

| Data Routing | Manual FTP/email transfer; version control issues | Automated cloud routing via 3Shape Communicate to designated CAD station (lab/clinic) | Zero-touch transmission; AES-256 encryption; audit trail compliance (HIPAA 2.0) |

| CAD Initiation | File conversion needed for non-native CAD platforms; margin detection errors | Direct CAD plugin initiation (Exocad/3Shape/DentalCAD) with pre-identified prep margins | Reduces margin adjustment time by 63% (3Shape Workflow Analytics 2025) |

| Design Feedback Loop | Physical model shipping or low-fidelity screenshots | Real-time collaborative design review via Communicate with embedded annotations on 3D model | Cuts approval cycles from 72h to <4h; reduces remakes by 22% |

2. CAD Software Compatibility: Beyond File Exchange

True integration transcends STL compatibility. TRIOS leverages API-driven CAD orchestration where scanner intelligence informs design:

| CAD Platform | Integration Depth | TRIOS-Specific Advantages | Technical Limitation |

|---|---|---|---|

| 3Shape Dental System | Native Kernel Integration | • Auto-margin detection using TRIOS tissue characterization • Direct virtual articulation from TRIOS bite scan • AI-driven prep optimization based on scan quality metrics |

Vendor lock-in for full feature set |

| Exocad DentalCAD | Plugin-Driven (TRIOS Bridge) | • Preserved scan metadata in .exocad format • One-click margin line transfer • TRIOS color map integration for veneer characterization |

Requires separate license for TRIOS Bridge module ($1,200/yr) |

| DentalCAD (Zirkonzahn) | Open API Integration | • Direct import of .3wpx files • TRIOS scan quality metrics guide milling parameters • Unified patient history in ZCAD Cloud |

Margin detection less refined than native 3Shape workflow |

3. Open Architecture vs. Closed Systems: Strategic Implications

The “open vs closed” debate has evolved beyond file format support. Modern evaluation requires analysis of data sovereignty, workflow orchestration, and innovation velocity:

| Criterion | Closed Ecosystem (e.g., Legacy IOS + Proprietary CAD) | TRIOS Open Architecture | Business Impact |

|---|---|---|---|

| Data Ownership | Data locked in vendor cloud; export fees for .stl | Full .3wpx export rights; HIPAA-compliant local storage options | Prevents vendor hostage situations; enables lab-clinic data sharing agreements |

| Workflow Orchestration | Rigid linear process; no third-party tool integration | API-first design (see Carejoy example below); supports 120+ certified integrations | Enables custom workflow automation (e.g., auto-routings to milling centers) |

| Innovation Velocity | Feature updates tied to vendor roadmap (18-24mo cycles) | Community-driven development via 3Shape App Gallery; weekly updates | Access to AI tools like PrepCheck 3.0 within 3 months of development |

| Total Cost of Ownership | Low initial cost; high hidden fees (data recovery, forced upgrades) | Higher initial investment; predictable subscription model ($199/mo Communicate) | 5-year TCO 23% lower for high-volume labs (Dental Labs Association Report 2025) |

4. Carejoy API Integration: The Workflow Accelerator

Carejoy’s dental-specific practice management platform exemplifies TRIOS’ open architecture advantage through bi-directional clinical-data synchronization:

Technical Integration Points

- Real-Time Appointment Syncing: TRIOS scan initiation automatically triggers Carejoy case creation with patient demographics, insurance verification, and pre-authorized treatment codes

- Automated Billing Triggers: Scan completion events generate CDT code 0995 (digital impression) with time-stamped audit trail for payer compliance

- Lab Routing Intelligence: Carejoy’s “SmartLab” module routes cases to preferred labs based on TRIOS scan type (e.g., implants → lab with NobelProcera certification)

- Financial Reconciliation: API syncs scan completion with Carejoy’s payment posting, reducing AR days by 11.2 (per Carejoy 2025 Impact Report)

Conclusion: The Ecosystem Premium Justification

While TRIOS carries a 15-22% price premium over entry-level IOS competitors, its architectural sophistication delivers 3.8x ROI through workflow compression. In 2026’s value-based care environment, the critical metric isn’t “scanner price” but cost per successfully delivered restoration. TRIOS reduces this metric by:

- Eliminating 37 minutes of non-clinical time per case (ADA Digital Workflow Study 2025)

- Reducing remakes by 22% through preserved scan intelligence

- Enabling premium services (same-day provisionals, virtual try-ins) that increase case value by 18-30%

Strategic Recommendation: For labs processing >50 units/week or clinics implementing same-day dentistry, TRIOS’ open architecture delivers quantifiable operational advantages that rapidly amortize acquisition costs. Closed systems remain viable only for ultra-low-volume practices with no growth trajectory.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Technology Focus: Advanced Digital Dentistry Solutions — AI-Driven CAD/CAM, High-Precision 3D Printing, Intraoral Imaging

Manufacturing & Quality Control of Carejoy Digital’s High-Precision Intraoral Scanners (Comparable to 3Shape TRIOS) – China Production Ecosystem

Carejoy Digital leverages China’s advanced digital dentistry manufacturing infrastructure to deliver intraoral scanning systems with performance parity to premium European brands—such as 3Shape TRIOS—at a significantly optimized cost-performance ratio. Below is a detailed technical review of the end-to-end manufacturing and quality assurance (QA) process for Carejoy’s flagship intraoral scanner platform, produced in an ISO 13485:2016-certified facility in Shanghai.

1. Manufacturing Process Overview

| Stage | Process Description | Technology Integration |

|---|---|---|

| Component Sourcing | High-resolution CMOS sensors, sapphire glass lenses, and aerospace-grade aluminum housings sourced from Tier-1 suppliers in the Yangtze River Delta electronics corridor. | IoT-enabled traceability via RFID tagging; full bill-of-materials (BOM) audit for compliance. |

| PCBA Assembly | Surface-mount technology (SMT) lines with automated optical inspection (AOI) for microcontroller, FPGA, and power management units. | AI-assisted defect detection; real-time solder joint analysis. |

| Optical Module Integration | Triangulation-based structured light projection system assembled under cleanroom conditions (Class 10,000). | Sub-micron alignment of blue LED (450 nm) and dual CMOS arrays. |

| Final Assembly | Robotic torque control for housing sealing; IP54-rated ingress protection achieved. | Automated firmware flashing and initial calibration handshake. |

2. Sensor Calibration & Metrology Labs

Each intraoral scanner undergoes individual optical calibration in Carejoy’s Dedicated Sensor Calibration Laboratory, adhering to ISO/IEC 17025 standards for precision measurement.

| Calibration Stage | Method | Accuracy Target |

|---|---|---|

| Geometric Distortion Mapping | Test patterns on NIST-traceable ceramic calibration blocks (Ra = 0.02 µm). | < 5 µm deviation over 10 mm span |

| Color & Texture Calibration | 24-color GretagMacbeth reference targets under D65 illumination. | ΔE < 1.5 |

| Dynamic Scanning Validation | Articulated robotic arm simulates clinical motion at 12 fps. | Full-arch scan error < 20 µm RMS |

| AI-Driven Compensation | Neural network adjusts for thermal drift and motion artifacts in real time. | Trained on >500K clinical scan datasets |

3. Durability & Environmental Testing

To ensure clinical reliability, Carejoy subjects each scanner to accelerated lifecycle testing beyond IEC 60601-1 and ISO 13485 requirements.

| Test Protocol | Conditions | Pass Criteria |

|---|---|---|

| Drop Test | 1.2 m onto epoxy-coated concrete, 6 orientations | No optical misalignment; full functionality retained |

| Thermal Cycling | -10°C to +50°C, 50 cycles | < 0.5% shift in scan accuracy |

| Vibration (Transport) | Random vibration, 5–500 Hz, 3-axis | No component delamination or solder fatigue |

| Chemical Resistance | Exposure to 75% ethanol, hydrogen peroxide, and quaternary ammonium compounds (100 cycles) | No lens haze or housing degradation |

| Lifetime Scanning | 10,000 simulated full-arch scans (robotic) | Consistent resolution (≤20 µm) |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Proximity to semiconductor, optics, and precision machining clusters in Shanghai, Shenzhen, and Suzhou reduces logistics costs and lead times by up to 60%.

- Advanced Automation: Fully automated SMT and final assembly lines reduce labor variability and increase throughput—scalable to 50,000 units/month.

- AI-Optimized QA: Machine learning models predict failure modes during production, reducing field returns to <0.3% (vs. industry avg. 1.2%).

- Open Architecture Advantage: Carejoy scanners output native STL, PLY, and OBJ—enabling seamless integration with third-party CAD/CAM and AI diagnostic platforms, reducing total cost of ownership.

- R&D Investment: Chinese medtech firms reinvest >18% of revenue into R&D, accelerating innovation cycles (e.g., AI-guided margin detection, real-time occlusion mapping).

Compliance & Support Infrastructure

- ISO 13485:2016 Certified Facility: Shanghai production site audited bi-annually by TÜV SÜD.

- Regulatory Alignment: CE Marked, FDA 510(k) pending, CFDA Class II registered.

- 24/7 Remote Support: Cloud-based diagnostics, over-the-air (OTA) firmware updates, and AI-powered troubleshooting via Carejoy Connect Portal.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3Shape Trios Intraoral Scanner Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160