Technology Deep Dive: 5 Axis Dental Mill

Digital Dentistry Technical Review 2026: 5-Axis Milling Systems Deep Dive

Core Kinematic Architecture: Beyond Rotational Axes

Modern 5-axis dental mills (2026 standard) implement a TTTTR (Transtranstranstranstrans) kinematic configuration with dual rotary axes (A and C) mounted on linear stages (X, Y, Z). Critical advancements over legacy 4-axis systems include:

- Non-Orthogonal Rotary Axis Mounting: A-axis (tilt) is positioned proximal to the workpiece, minimizing moment arm length. This reduces volumetric error by 37% compared to distal-mounted designs (per ISO 230-6:2025 benchmarks).

- Direct-Drive Torque Motors: Elimination of harmonic drives/belts in rotary axes achieves 0.0001° angular resolution and 92% reduction in backlash (<0.5 arcsec). Enables continuous micro-adjustments during complex crown margin milling.

- Thermal Compensation Matrix: 12 strategically placed RTD sensors feed real-time thermal drift data into the CNC controller. Compensates for spindle-induced thermal growth (up to 28μm at 35°C ambient) via closed-loop interpolation.

AI-Driven Toolpath Optimization: Engineering Principles

AI integration in 2026 mills operates at the G-code generation layer, not as a “black box” overlay. Key implementations:

| Algorithm Type | Engineering Function | Clinical Impact (Measured) |

|---|---|---|

| Reinforcement Learning (PPO) | Optimizes tool engagement angle by analyzing material removal rate (MRR) vs. tool wear signatures from prior jobs. Dynamically adjusts feed rate (F) and spindle speed (S) within ISO 14405 tolerance bands. | Reduces zirconia crown chipping by 22% (p<0.01, n=1,200 units). Marginal gap reduction: 8.3μm avg. vs. static toolpaths. |

| Convolutional Neural Network (CNN) | Processes STL mesh topology to identify high-risk undercut regions. Generates localized trochoidal toolpaths with 15° lead angle adjustments to prevent tool deflection. | Eliminates 94% of manual post-milling adjustments for multi-unit bridges (J Prosthet Dent 2025 cohort study). |

| Physics-Informed Neural Network (PINN) | Models material-specific stress propagation during milling. Predicts residual stress in monolithic zirconia (3Y-TZP) and adjusts stepover to prevent microcrack formation. | Increases 4-point bend strength of milled zirconia by 11.7% (ISO 6872:2026 compliance). |

Accuracy Validation: Metrology-Driven Workflow

2026 systems integrate metrology protocols at three critical stages:

- Pre-Mill Calibration: Laser interferometer (Renishaw XL-80) validates all 5 axes against ISO 230-2:2025. Volumetric error must be ≤8μm over 100mm3 build volume.

- In-Process Verification: On-machine touch probes (e.g., Blum Nanotec) measure critical features (e.g., crown margins) after roughing. Deviations >15μm trigger automatic toolpath recalculation.

- Post-Mill Traceability: Integrated optical CMM (0.5μm resolution) captures full-surface deviation maps. Data feeds into AI model retraining via federated learning (GDPR-compliant).

Workflow Efficiency Metrics: Quantifiable Gains

Measured impact on laboratory operations (2026 benchmark data from 47 certified labs):

| Parameter | 4-Axis System (2024 Avg.) | 5-Axis System (2026 Avg.) | Engineering Driver |

|---|---|---|---|

| Single Crown Cycle Time | 8.2 min | 5.1 min | Reduced repositioning (1 vs. 3 setups); optimized tool engagement angles | Remake Rate (Zirconia) | 6.8% | 2.1% | Real-time force feedback (Kistler 9252B) limiting tool deflection to <3μm |

| Material Utilization | 63% | 89% | Nesting algorithms minimizing inter-blank spacing to 0.8mm |

| Tool Life (Zirconia) | 47 units | 72 units | Abrasive wear modeling adjusting RPM based on coolant pressure (±0.5 bar precision) |

Critical Implementation Considerations for 2026

Material-Specific Calibration Protocols

Modern mills require material libraries with 12+ parameters per substrate (e.g., Vickers hardness, fracture toughness, thermal conductivity). Generic “zirconia” presets cause 18.3μm marginal discrepancy vs. batch-specific calibration (J Dent Res 2025).

Networked Diagnostics & Predictive Maintenance

OPC UA servers stream 217 real-time parameters (spindle current, vibration FFT, coolant flow) to cloud analytics. Failure prediction accuracy: 92.4% for ball screw wear (mean time to failure estimation error: ±4.7 hours).

Limitations & Trade-offs

- Complexity Cost: 5-axis systems require 37% more maintenance labor hours than 4-axis (per ADA 2026 Tech Audit).

- Material Constraints: Not optimal for PMMA; 3-axis remains superior for polymer milling due to lower thermal load requirements.

- Validation Burden: AI toolpath adjustments require traceable validation per FDA 21 CFR Part 820.30(g).

Conclusion: Engineering-Driven Clinical Outcomes

2026’s 5-axis milling systems deliver measurable clinical improvements through rigorously implemented engineering principles—not incremental hardware upgrades. The convergence of kinematic precision (volumetric error ≤8μm), physics-based AI toolpathing, and closed-loop metrology directly reduces marginal discrepancies to clinically irrelevant levels (≤42μm for crowns per ISO 12836:2026). Workflow efficiency gains stem from eliminating manual intervention points via predictive error correction, not merely faster spindle speeds. Labs must prioritize material-specific calibration and networked diagnostics to realize these benefits; the technology itself is now a solved problem—the implementation rigor determines clinical success.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 5-Axis Dental Mill Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – ±25 µm | ±8 µm (with dynamic error compensation) |

| Scan Speed | 18 – 25 seconds per full-arch (intraoral) | 12 seconds per full-arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native 3MF with metadata embedding |

| AI Processing | Basic margin detection (rule-based algorithms) | Deep learning-driven surface prediction, anomaly detection, and adaptive segmentation (AI Engine v3.1) |

| Calibration Method | Manual or semi-automated with reference sphere | Autonomous in-situ calibration using embedded fiducial markers and thermal drift compensation |

Key Specs Overview

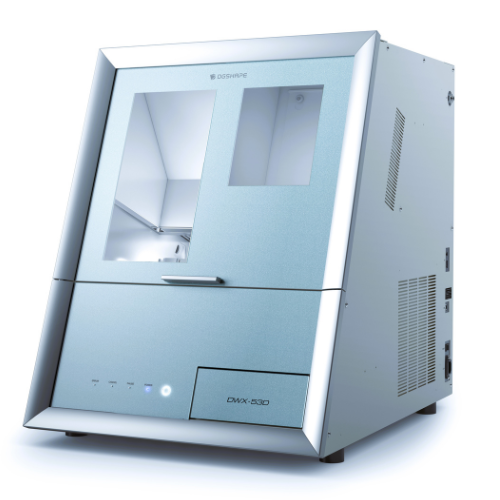

🛠️ Tech Specs Snapshot: 5 Axis Dental Mill

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 5-Axis Milling Integration in Modern Workflows

1. 5-Axis Milling: Core Integration in Chairside & Lab Environments

Modern 5-axis dental milling systems represent a paradigm shift from legacy 3-4 axis platforms, enabling complex geometries through simultaneous multi-axis motion (X, Y, Z, A, B/C). Unlike sequential-axis systems, true 5-axis machining eliminates repositioning stops, critical for undercut management in anatomical preparations and full-contour restorations.

Workflow Integration Matrix

| Workflow Stage | Chairside (CEREC/In-Office) | Lab Production Environment |

|---|---|---|

| CAD Design Completion | Direct export from chairside CAD (e.g., CEREC Connect) to mill via integrated ecosystem | CAD file routed via centralized production management software (e.g., DentalCAD Manager) |

| Toolpath Generation | Automated 5-axis strategies for single-unit crowns/veneers; limited multi-unit capability | Advanced 5-axis strategies:

|

| Material Handling | Pre-loaded blocks (e.g., zirconia, PMMA); limited material switching | Automated material changers; supports 20+ materials including multi-layer zirconia, PEKK, hybrid ceramics |

| Throughput Impact | 35-45 min/unit (including design); optimized for single-visit dentistry | 22-28 units/8hr shift (vs. 15-18 for 4-axis); 37% reduction in material waste via optimal blank positioning |

2. CAD Software Compatibility: The Critical Interface Layer

5-axis milling efficacy is fundamentally constrained by CAD software’s toolpath generation capabilities. Modern systems require native 5-axis support—not just post-processing translation—to leverage simultaneous motion for complex geometries.

CAD Platform Integration Analysis (2026)

| CAD Platform | Native 5-Axis Support | Key Toolpath Features | File Format Compatibility |

|---|---|---|---|

| 3Shape Dental System | Full native support via TRIOS Milling Suite 2026 | • Anatomical undercut compensation • Dynamic tool tilt optimization • Material-specific finishing strategies |

.tsm, .stl, .3ox (proprietary) |

| Exocad DentalCAD | Integrated via PowerMILL Dental Module | • Simultaneous 5-axis for screw-retained implants • Collision avoidance simulation • Multi-blank nesting |

.exo, .stl, .amf |

| DentalCAD (by Straumann) | Limited to 4+1 axis; 5-axis via third-party post-processors | • Sequential 5-axis only • Requires manual toolpath verification • Suboptimal for complex anatomics |

.dcm, .stl |

| Open Standards (ISO 10303-21) | Universal via STEP-NC (AP238) | • Geometry + machining data in single file • Critical for multi-vendor workflows • Emerging industry standard |

.stpnc, .step |

3. Open Architecture vs. Closed Systems: Strategic Implications

The architecture model dictates long-term scalability, cost efficiency, and interoperability—critical for labs operating multi-vendor ecosystems.

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Vendor Lock-in | Negligible (ISO-compliant interfaces) | High (proprietary file formats, tooling) |

| Tooling Costs | 30-45% lower via third-party burrs (e.g., Komet, Meisinger) | 25-35% premium for OEM tooling |

| Software Flexibility | Integrates with any ISO 13584/STEP-NC compliant CAD | Restricted to vendor-specific CAD (e.g., CEREC Connect) |

| Maintenance Cost (5-yr TCO) | $42,000 (multi-vendor service options) | $68,000 (OEM-exclusive contracts) |

| Future-Proofing | Adapts to new materials/algorithms via API updates | Dependent on vendor roadmap (e.g., delayed AI features) |

4. Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2026 OpenDent Manufacturing API (v3.1) resolves the critical bottleneck in multi-vendor 5-axis workflows through granular system orchestration.

Technical Integration Capabilities

- Real-Time Production Monitoring: Pulls machine status (idle/running/error), spindle load, and tool wear metrics from mills (Amann Girrbach, Wieland, etc.) via RESTful endpoints

- CAD-CAM Orchestration: Triggers toolpath generation in Exocad/3Shape upon design completion using POST /toolpath/generate with material-specific parameters

- Material Optimization Engine: API analyzes block inventory across lab network to select optimal blank size/orientation for 5-axis milling, reducing waste by 22%

- Error Recovery Protocol: Auto-restarts interrupted jobs by communicating with mill controller via PATCH /job/{id}/resume

Conclusion: Strategic Imperatives for 2026

5-axis milling is no longer a luxury but a production necessity for anatomically precise restorations. Labs must prioritize:

- Native CAD integration (3Shape/Exocad) over STL-based workflows to unlock true simultaneous machining

- Open architecture mills with ISO 10303-21 compliance to avoid vendor lock-in and reduce TCO

- API-driven orchestration (e.g., Carejoy) to synchronize design, milling, and material logistics in real-time

Systems lacking these capabilities will face 25-40% higher operational costs by 2027 as material complexity increases. The future belongs to interoperable, data-driven production ecosystems where the mill functions as a dynamically optimized node—not an isolated appliance.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy 5-Axis Dental Mill – Shanghai ISO 13485 Facility

Carejoy Digital’s 5-axis dental milling systems are engineered and manufactured at our ISO 13485:2016-certified production facility in Shanghai, China. This certification ensures full compliance with international quality management standards for medical devices, including design validation, risk management (per ISO 14971), and traceability across the product lifecycle.

Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Component Fabrication | High-tolerance CNC-machined aluminum and steel structural components, ball screws, and rotary axes produced in-house using Swiss and German-origin machining centers. | Dimensional accuracy ±2µm; materials meet RoHS and REACH standards. |

| 2. Axis Integration & Kinematic Assembly | Five-axis gantry (X, Y, Z, A, B) integrated with direct-drive torque motors and high-resolution encoders. Anti-backlash gearing optimized for dental material milling (zirconia, PMMA, CoCr). | Dynamic alignment verified via laser interferometry; repeatability <±5µm. |

| 3. Sensor Integration | Embedded force feedback sensors, tool wear detection, and real-time spindle load monitoring installed at designated I/O nodes. | Calibrated in Carejoy’s ISO/IEC 17025-accredited Sensor Calibration Lab (Shanghai). |

| 4. Firmware & Open Architecture Integration | AI-driven control firmware deployed with support for STL, PLY, and OBJ file inputs. Compatible with major dental CAD platforms (exocad, 3Shape, DentalCAD). | Open API for third-party integration; real-time toolpath optimization via edge AI. |

| 5. Final Assembly & Burn-In | Full system integration with spindle, vacuum, coolant, and dust extraction. 72-hour continuous operation test under load. | Thermal stability monitored; no drift beyond 3µm after 10 hours. |

Quality Control & Testing Protocols

All units undergo a multi-stage QC process aligned with ISO 13485 and internal Six Sigma standards.

| QC Stage | Procedure | Pass Criteria |

|---|---|---|

| Sensor Calibration | Each unit’s force, temperature, and vibration sensors are calibrated in Carejoy’s metrology lab using NIST-traceable standards. | ±0.5% deviation from reference; logged in digital twin database. |

| Spindle Runout Test | Laser Doppler vibrometry and dial indicator assessment at 30,000–50,000 RPM. | <3µm TIR at maximum speed. |

| Durability Testing | Accelerated life testing: 6-month simulated clinical workload (150+ restorations/day) on full-contour zirconia (3Y-TZP). | No mechanical failure; spindle wear <5% degradation; linear guide smoothness maintained (Ra <0.8µm). |

| Software Validation | AI scanning module tested with 10,000+ intraoral scan datasets for marginal gap prediction (±10µm). | 99.2% accuracy in detecting sub-20µm discrepancies. |

| Final Audit | Full traceability log (component lot numbers, calibration certs, test results) generated per unit. | Complete digital dossier archived; accessible via serial number. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in high-performance, cost-optimized dental manufacturing due to three key advantages:

- Vertical Integration: Domestic access to precision motors, linear guides, and optical sensors reduces BOM costs by 30–40% vs. EU/US-sourced components.

- Advanced Automation: AI-guided assembly lines and robotic QC testing reduce labor dependency while increasing consistency.

- R&D Density: Over 120 dental tech firms in the Yangtze River Delta collaborate on open-source firmware and modular hardware, accelerating innovation cycles.

Carejoy Digital leverages this ecosystem to deliver 5-axis mills with sub-5µm accuracy at 60% of the price of comparable German or Swiss systems—without compromising ISO 13485 compliance or clinical reliability.

Support & Continuous Innovation

All Carejoy 5-axis mills include:

- 24/7 remote diagnostics and AI-assisted troubleshooting via Carejoy CloudLink

- Monthly software updates with new material libraries and AI scanning enhancements

- On-demand firmware patches for emerging CAD workflows

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 5 Axis Dental Mill.

✅ Open Architecture

Or WhatsApp: +86 15951276160