Introduction: Navigating the Global Market for dental implant images

In today’s competitive dental landscape, the demand for high-quality dental implant images has surged, driven by advancements in technology and an increasing emphasis on aesthetic outcomes. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing dental implant images is crucial. These images not only aid in showcasing products but also serve as essential tools for marketing, education, and patient consultations.

This guide offers a comprehensive exploration of the global market for dental implant images, covering various critical aspects. Buyers will gain insights into the types of dental implant images, including 2D and 3D formats, and the materials used in their production. We will delve into the manufacturing and quality control processes, ensuring that the images meet industry standards and expectations. Additionally, this guide will highlight reputable suppliers across different regions, providing valuable contacts for potential partnerships.

Understanding the cost structures associated with dental implant images is vital for budgeting and financial planning. Furthermore, we will analyze the current market trends to help buyers identify opportunities and challenges in their respective regions. Finally, a section dedicated to frequently asked questions (FAQs) will address common queries and concerns, empowering buyers to make informed decisions.

By leveraging the insights provided in this guide, international B2B buyers can confidently navigate the complexities of sourcing dental implant images, ultimately enhancing their competitive edge in a rapidly evolving market.

Understanding dental implant images Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2D Radiographs | Simple, cost-effective, and widely available. | General diagnostics and treatment planning. | Pros: Low cost, quick to obtain. Cons: Limited detail, may miss underlying issues. |

| 3D Cone Beam CT | Provides detailed 3D imaging of dental structures. | Complex implant planning and assessment. | Pros: High accuracy, comprehensive views. Cons: Higher cost, requires specialized equipment. |

| Intraoral Scans | Digital impressions capturing precise tooth anatomy. | Custom implant design and fitting. | Pros: Enhanced accuracy, immediate data capture. Cons: Equipment investment needed, learning curve. |

| Photographic Imaging | High-resolution images for aesthetic evaluation. | Marketing materials, case presentations. | Pros: Visual appeal, effective for patient education. Cons: Not diagnostic, requires good lighting and technique. |

| Digital Workflow Images | Integration of various digital imaging technologies. | Streamlined implant procedures and efficiency. | Pros: Cohesive data management, improved collaboration. Cons: Initial setup complexity, ongoing software costs. |

2D Radiographs

2D radiographs are the most traditional form of dental imaging, offering a straightforward view of the teeth and surrounding structures. They are particularly suitable for initial diagnostics and treatment planning, especially in regions where advanced imaging technology may not be readily available. For B2B buyers, the key consideration is the cost-effectiveness of these images, as they are significantly cheaper and quicker to produce. However, their limitations in detail can lead to missed diagnoses, making them less ideal for complex cases.

3D Cone Beam CT

3D Cone Beam Computed Tomography (CBCT) represents a significant advancement in dental imaging, providing detailed three-dimensional views of dental and facial structures. This type of imaging is invaluable for complex implant planning, allowing for precise assessments of bone density and anatomy. B2B buyers should consider the investment in CBCT technology, as it requires specialized equipment and training. The high accuracy and comprehensive views offered by CBCT can greatly enhance patient outcomes, making it a worthwhile investment for practices focused on advanced dental procedures.

Intraoral Scans

Intraoral scans are rapidly gaining traction in the dental industry, capturing digital impressions of the patient’s mouth with high precision. They are particularly beneficial for creating custom implants, as they provide immediate and accurate data for design and fitting. For B2B buyers, the initial investment in intraoral scanning technology can be significant, but the long-term benefits include enhanced accuracy and efficiency in the workflow. The learning curve associated with new technology must also be considered, as staff training is essential for optimal use.

Photographic Imaging

Photographic imaging involves capturing high-resolution images of dental work and patient cases, making it an effective tool for marketing and patient education. While not diagnostic, these images can be crucial for creating compelling marketing materials and case presentations. B2B buyers should assess the quality of photographic equipment and the expertise of staff in capturing images, as these factors can significantly impact the effectiveness of visual communication. The aesthetic appeal of photographic images can enhance a practice’s reputation, particularly in competitive markets.

Digital Workflow Images

Digital workflow images encompass a range of imaging technologies that integrate into a cohesive digital platform for managing dental procedures. This approach enhances the efficiency of implant processes and improves collaboration among dental professionals. For B2B buyers, the key considerations include the initial complexity of setup and the ongoing costs associated with software and digital tools. However, the benefits of streamlined data management and improved patient outcomes make digital workflows a compelling option for modern dental practices aiming for efficiency and precision.

Related Video: Step by Step Guide to Your Dental Implant Procedure

Key Industrial Applications of dental implant images

| Industry/Sector | Specific Application of dental implant images | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Treatment planning and simulation | Enhances patient outcomes through precise planning | Quality of imaging technology and software support |

| Dental Laboratories | Custom implant design and fabrication | Increases efficiency in production and accuracy | Compatibility with existing systems and materials |

| Educational Institutions | Training and skill development | Improves educational quality and clinical skills | Access to updated imaging technology and resources |

| Research Institutions | Clinical studies and product development | Drives innovation and evidence-based practices | Regulatory compliance and ethical considerations |

| Insurance Companies | Risk assessment and claims processing | Reduces fraudulent claims and improves risk management | Data accuracy and integration with existing systems |

Dental Clinics

In dental clinics, dental implant images are pivotal for treatment planning and simulation. These images allow practitioners to visualize the patient’s anatomy, ensuring that the implants are placed with precision. This not only enhances patient outcomes but also minimizes surgical complications. International buyers, especially from regions like Africa and South America, should ensure they procure high-resolution imaging systems that are compatible with their existing dental software and equipment.

Dental Laboratories

For dental laboratories, dental implant images facilitate the custom design and fabrication of implants. By utilizing these images, labs can create highly accurate and tailored implants that fit patients’ unique anatomical structures. This process significantly increases production efficiency and reduces the likelihood of errors. Buyers in the Middle East and Europe should prioritize sourcing imaging systems that can seamlessly integrate with CAD/CAM technologies to streamline workflows.

Educational Institutions

In educational settings, dental implant images are essential for training and skill development. They provide students with realistic simulations of implant procedures, enhancing their understanding and practical skills. This not only improves the quality of education but also prepares students for real-world clinical situations. Institutions in Africa and Europe should seek partnerships with suppliers that offer comprehensive training programs alongside their imaging technologies.

Research Institutions

Research institutions utilize dental implant images for clinical studies and product development. These images are crucial for gathering data and analyzing the effectiveness of new implant technologies, driving innovation in the dental field. For international buyers, especially in South America and the Middle East, it is vital to ensure that sourcing aligns with regulatory compliance and ethical standards to facilitate credible research outcomes.

Insurance Companies

For insurance companies, dental implant images play a crucial role in risk assessment and claims processing. By providing a clear visual record of dental procedures, these images help in reducing fraudulent claims and improving risk management strategies. Buyers from Europe and Africa should consider integrating imaging data into their existing claims management systems to enhance accuracy and efficiency in processing claims.

Related Video: Smyl Manatee – Dental Implant Procedure

Strategic Material Selection Guide for dental implant images

When selecting materials for dental implant images, it is crucial to consider their properties, advantages, disadvantages, and specific implications for international B2B buyers. Here, we analyze four common materials used in dental implant imaging: titanium, zirconia, PEEK (Polyether Ether Ketone), and stainless steel.

Titanium

Key Properties: Titanium is known for its excellent strength-to-weight ratio and corrosion resistance, making it ideal for long-term use in dental applications. It can withstand high temperatures and pressures, which is essential during sterilization processes.

Pros & Cons: The durability of titanium implants is a significant advantage, as they can last for many years without degradation. However, the manufacturing process can be complex and costly, which may increase the final product price. Additionally, while titanium is biocompatible, some patients may have allergic reactions, which could limit its suitability for certain individuals.

Impact on Application: Titanium is compatible with various imaging techniques, including X-rays and CT scans, making it a versatile choice for dental imaging.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM and ISO for medical devices. Awareness of local regulations regarding titanium use in dental applications is also essential.

Zirconia

Key Properties: Zirconia is a ceramic material known for its high strength and aesthetic appeal. It has excellent wear resistance and is highly biocompatible, making it suitable for dental applications.

Pros & Cons: The primary advantage of zirconia is its superior aesthetic properties, which closely mimic natural teeth. However, it is more brittle than titanium, which can lead to fractures under excessive stress. The manufacturing process for zirconia can also be more expensive due to the need for specialized equipment.

Impact on Application: Zirconia is particularly effective in aesthetic applications, where visual appearance is paramount. However, its compatibility with certain imaging modalities may be limited compared to metals.

Considerations for International Buyers: Buyers should be aware of the specific standards for ceramic materials in their regions, as regulations can vary significantly. Understanding the aesthetic preferences of local markets can also influence purchasing decisions.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties and resistance to chemicals and high temperatures. It is lightweight and has a good strength-to-weight ratio.

Pros & Cons: The main advantage of PEEK is its flexibility and resistance to wear, making it suitable for various dental applications. However, it is not as strong as titanium, which may limit its use in load-bearing situations. The cost of PEEK can also be relatively high compared to traditional materials.

Impact on Application: PEEK is compatible with various imaging techniques but may not provide the same level of detail as metal-based materials in certain applications.

Considerations for International Buyers: Buyers should verify compliance with relevant international standards for polymers in medical applications. Additionally, understanding the market demand for lightweight materials can help in making informed purchasing decisions.

Stainless Steel

Key Properties: Stainless steel is known for its corrosion resistance and strength. It is widely used in various medical applications due to its durability and cost-effectiveness.

Pros & Cons: The primary advantage of stainless steel is its affordability and availability. However, it is heavier than titanium and can be prone to corrosion if not properly treated. Additionally, its aesthetic appeal is lower compared to zirconia.

Impact on Application: Stainless steel is compatible with most imaging techniques, but its density can sometimes obscure finer details in imaging.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards such as ASTM or ISO. Understanding the local market’s price sensitivity can also guide purchasing decisions.

Summary Table

| Material | Typical Use Case for dental implant images | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Long-term dental implants | Excellent strength and durability | Potential allergic reactions | High |

| Zirconia | Aesthetic dental applications | Superior aesthetic properties | Brittle under stress | High |

| PEEK | Versatile dental applications | Lightweight and flexible | Less strength than metals | Med |

| Stainless Steel | General dental applications | Cost-effective and durable | Heavier and less aesthetic appeal | Low |

This guide provides actionable insights for international B2B buyers, helping them navigate the complexities of material selection for dental implant images while considering regional compliance and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implant images

Manufacturing Processes for Dental Implant Images

The production of dental implant images involves several critical manufacturing stages that ensure the final product meets the required quality standards. Understanding these processes is essential for B2B buyers looking to source reliable products.

1. Material Preparation

The manufacturing process begins with careful selection and preparation of materials. Dental implants are typically made from biocompatible materials such as titanium or zirconia. These materials are chosen for their strength, corrosion resistance, and compatibility with human tissue.

- Sourcing: International buyers should verify the origin and quality of raw materials, as different suppliers may use varying grades.

- Processing: The materials undergo treatments like sterilization and surface modification to enhance their properties. Buyers should inquire about the specific treatments used and their implications for product performance.

2. Forming

Forming is a critical stage where raw materials are shaped into the desired form. This can be achieved through various techniques, including:

- CNC Machining: This method allows for high precision and repeatability. It is widely used for creating intricate designs that meet specific dental requirements.

- Additive Manufacturing (3D Printing): An increasingly popular technique, especially for custom implants. It allows for more complex geometries and personalized solutions.

Buyers should assess the technology used by suppliers to ensure it aligns with their quality expectations. Advanced forming techniques can lead to better fit and function of the implants.

3. Assembly

Once individual components are formed, they are assembled. This stage may involve:

- Joining Techniques: Methods such as welding or adhesive bonding are used to create strong connections between parts.

- Inspection: Each assembly is often checked for alignment and integrity. Buyers should confirm that suppliers have robust inspection protocols in place.

4. Finishing

Finishing processes enhance the aesthetic and functional properties of dental implants. This may include:

- Surface Treatment: Techniques such as sandblasting or anodizing improve the surface texture, facilitating osseointegration.

- Polishing and Coating: These processes ensure a smooth finish, reducing the risk of irritation when implanted.

B2B buyers should inquire about the finishing techniques employed, as these can significantly impact the performance and longevity of the implants.

Quality Assurance in Manufacturing

Quality assurance (QA) is paramount in the dental implant industry, given the high stakes of patient health and safety. Buyers must understand the QA processes and standards that suppliers adhere to.

International Standards

Several international standards govern the manufacturing and quality control of dental implants:

- ISO 9001: This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

- ISO 13485: Specifically for medical devices, this standard outlines the requirements for a comprehensive quality management system, emphasizing risk management and design controls.

Additionally, industry-specific certifications such as CE marking (for European markets) and API certification (for specific regions) are crucial. Buyers should ensure that their suppliers hold relevant certifications, which not only verify compliance but also enhance trust in product quality.

Quality Control Checkpoints

Quality control (QC) involves several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to identify defects early.

- Final Quality Control (FQC): A thorough inspection of the final product before it is shipped, ensuring it meets all specifications.

B2B buyers should request documentation of these QC processes, including inspection reports and certificates of compliance.

Common Testing Methods

To ensure the reliability and safety of dental implants, various testing methods are employed, including:

- Mechanical Testing: Evaluates the strength, fatigue, and wear resistance of materials.

- Biocompatibility Testing: Assesses how the materials interact with biological systems, which is critical for patient safety.

- Sterility Testing: Ensures that the implants are free from microbial contamination.

Understanding these testing methods allows buyers to make informed decisions about the quality of the products they source.

Verifying Supplier Quality Control

International B2B buyers should adopt rigorous strategies to verify supplier quality control practices:

- Audits: Conducting on-site audits can provide direct insight into a supplier’s manufacturing and QC processes. Buyers should look for suppliers who welcome and facilitate audits.

- Documentation and Reports: Requesting detailed QC reports and certificates of compliance can help assess a supplier’s commitment to quality. Suppliers should maintain transparent documentation that outlines their QC procedures and results.

- Third-Party Inspection: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s capabilities and compliance with international standards.

QC and Certification Nuances for International Buyers

When sourcing dental implants from different regions, international buyers must be aware of specific nuances in QC and certification:

- Regional Regulations: Different countries may have unique regulatory requirements for medical devices. Buyers should familiarize themselves with local regulations in their target markets.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother communication and negotiation with suppliers.

- Supply Chain Reliability: Evaluating the entire supply chain, including logistics and distribution channels, is essential to ensure timely delivery and compliance with quality standards.

By being proactive in understanding manufacturing processes and quality assurance measures, B2B buyers can significantly enhance their sourcing strategies for dental implants, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Comprehensive Cost and Pricing Analysis for dental implant images Sourcing

When sourcing dental implant images, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will help you navigate the complexities of procurement while optimizing your budget and ensuring quality.

Cost Components

-

Materials: The primary cost driver in dental implant images is the quality of materials used. High-grade imaging materials, such as biocompatible plastics or metals, can significantly increase costs. Additionally, sourcing from reputable suppliers who adhere to international standards can further elevate material prices.

-

Labor: Labor costs encompass the workforce involved in the design and production of dental implant images. Regions with higher labor costs, like parts of Europe, may lead to higher overall prices. Conversely, sourcing from areas with lower labor costs, such as certain regions in South America or Africa, might offer cost advantages but could also affect quality.

-

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive prices. Buyers should inquire about the production efficiency of potential suppliers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs should be factored into the overall pricing structure, particularly for buyers looking for specific customization in their dental implant images.

-

Quality Control (QC): Rigorous QC processes ensure the reliability and safety of dental implant images. Suppliers that invest in robust QC measures may charge higher prices, but this investment is often justified by the reduction in defects and increased product reliability.

-

Logistics: Transportation and handling costs vary significantly based on distance, shipping methods, and Incoterms. Buyers must consider these logistics costs, especially for international shipments that may involve customs duties and longer lead times.

-

Margin: Suppliers typically add a profit margin to cover risks and ensure sustainability. This margin can vary widely based on market conditions and competition, influencing the final price offered to buyers.

Price Influencers

Several factors can influence pricing beyond the direct cost components:

-

Volume/MOQ (Minimum Order Quantity): Purchasing larger volumes often leads to discounts. Buyers should negotiate MOQ terms to achieve better pricing.

-

Specifications/Customization: Custom designs or specifications typically incur additional costs. Clearly defining requirements upfront can help avoid unexpected expenses.

-

Materials: The choice of materials significantly impacts pricing. Opting for standard materials may reduce costs compared to specialized or certified options.

-

Quality and Certifications: Products that meet specific regulatory certifications (e.g., ISO, CE marking) may come at a premium. Buyers should weigh the importance of certifications against cost.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more but offer enhanced service and product assurance.

-

Incoterms: Understanding Incoterms is essential for determining who bears the cost and responsibility for shipping. This can significantly impact the total cost structure.

Buyer Tips

-

Negotiation: Cultivate strong relationships with suppliers and engage in open negotiations to achieve favorable pricing. Be prepared to discuss volume discounts and payment terms.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the purchase price. Consider factors like durability, maintenance, and potential return on investment.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that may affect pricing. Leveraging local knowledge can lead to better sourcing decisions.

Disclaimer

Prices for dental implant images can vary significantly based on the factors outlined above. The information provided is indicative and should be used as a guideline for initial budgeting and planning. Always consult with suppliers for the most accurate and up-to-date pricing.

Spotlight on Potential dental implant images Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dental implant images’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dental implant images

Key Technical Properties for Dental Implant Images

Understanding the essential technical properties of dental implant images is crucial for B2B buyers in the dental industry. These properties not only influence product performance but also ensure compliance with industry standards. Here are several critical specifications to consider:

Illustrative Image (Source: Google Search)

-

Material Grade

Dental implants are typically made from titanium or zirconia, known for their biocompatibility and strength. The material grade affects durability and the implant’s ability to integrate with bone. Buyers should verify the material specifications to ensure they meet regulatory standards, as this can impact patient outcomes and brand reputation. -

Surface Texture

The surface of dental implants is engineered to enhance osseointegration, the process where bone fuses with the implant. Surface treatments such as sandblasting or acid-etching can increase the surface area and improve cell attachment. Understanding the surface characteristics is essential for buyers to select products that promote long-term stability and success rates. -

Dimension Tolerances

Precision in dimensions is vital for the fitting and function of dental implants. Tolerances refer to the allowable deviation from specified dimensions. High-precision tolerances are crucial for ensuring that implants fit correctly within the patient’s anatomy, thus minimizing complications. Buyers should request detailed specifications to ensure compatibility with existing dental systems. -

Load-Bearing Capacity

The load-bearing capacity of an implant determines its ability to withstand chewing forces. This property is influenced by the design and material used. Buyers should consider the expected functional loads in their specific markets when evaluating implant options, especially for high-demand cases. -

Radiopacity

Radiopacity is the property that allows dental implants to be visible on X-rays. Implants with appropriate radiopacity help dental professionals assess their position and integration with bone. Buyers should ensure that the products they procure possess adequate radiopacity for effective clinical evaluation.

Common Trade Terminology

Understanding industry jargon is essential for navigating the procurement process effectively. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the dental implant industry, buyers often source products from OEMs to ensure quality and compliance with industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their operational capacities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers for specific products. This process allows buyers to compare costs and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Familiarity with Incoterms helps buyers understand shipping costs and risks associated with international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. It is a critical factor for buyers who need to manage their inventory and ensure timely delivery of dental services. Understanding lead times can help buyers plan their operations more efficiently. -

Certification Standards

Certification standards, such as ISO or CE marking, indicate that products meet specific safety and quality requirements. Buyers should prioritize suppliers whose products comply with relevant certifications to ensure quality and reduce liability risks.

By understanding these essential technical properties and trade terms, B2B buyers can make informed decisions when procuring dental implant images, ensuring quality and compliance in their purchasing processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implant images Sector

Market Overview & Key Trends

The global dental implant images sector is witnessing significant transformations driven by technological advancements and evolving market dynamics. Key drivers include the growing prevalence of dental diseases and increasing aesthetic awareness among consumers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As urbanization and disposable incomes rise, B2B buyers must adapt to the changing landscape where demand for high-quality dental imaging solutions is surging.

Current trends show a shift towards digital solutions, with 3D imaging and CAD/CAM technologies becoming increasingly standard. B2B buyers should prioritize suppliers that offer advanced imaging software and hardware, as these technologies enhance precision and reduce treatment times. Furthermore, the integration of Artificial Intelligence (AI) in imaging solutions is revolutionizing diagnostic processes, enabling faster and more accurate assessments. Buyers should look for partners that are at the forefront of these innovations to remain competitive.

Emerging sourcing trends emphasize the importance of local partnerships and regional suppliers to mitigate risks associated with global supply chains. For buyers in Africa and South America, developing relationships with local manufacturers can lead to cost reductions and improved service delivery. Additionally, the rise of e-commerce platforms tailored for B2B transactions is making sourcing more accessible, allowing international buyers to easily compare products and services.

Sustainability & Ethical Sourcing in B2B

The dental implant images sector is increasingly scrutinized for its environmental impact, prompting B2B buyers to prioritize sustainability in their sourcing decisions. The manufacturing processes of dental implants can generate considerable waste and carbon emissions, making it imperative for buyers to engage with suppliers that demonstrate a commitment to reducing their environmental footprint.

Ethical sourcing has become paramount as consumers and businesses alike demand transparency in supply chains. Buyers should seek suppliers who adhere to sustainable practices, such as using recycled materials and minimizing resource consumption. Certifications like ISO 14001 for environmental management systems or the Forest Stewardship Council (FSC) for sustainable materials can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the adoption of ‘green’ materials in dental implants, such as biocompatible polymers and metals, is gaining traction. Buyers should actively inquire about the materials used in the imaging processes and the lifecycle impacts of these products. By prioritizing sustainability, B2B buyers not only enhance their corporate responsibility but also align with market trends that favor eco-friendly practices.

Brief Evolution/History

The dental implant images sector has evolved significantly over the past few decades. Initially dominated by traditional 2D imaging techniques, the field has transitioned towards sophisticated 3D imaging technologies that allow for more detailed visualization of dental structures. This evolution has been fueled by advancements in digital imaging and computer-aided design, which have improved diagnostic accuracy and treatment planning.

As the sector continues to mature, the integration of AI and machine learning is expected to further enhance imaging capabilities, providing unprecedented insights into patient care. For international B2B buyers, understanding this historical context is crucial for identifying reliable suppliers that can meet the growing demand for innovative dental imaging solutions. Embracing these advancements will not only improve service offerings but also position buyers as leaders in a competitive market.

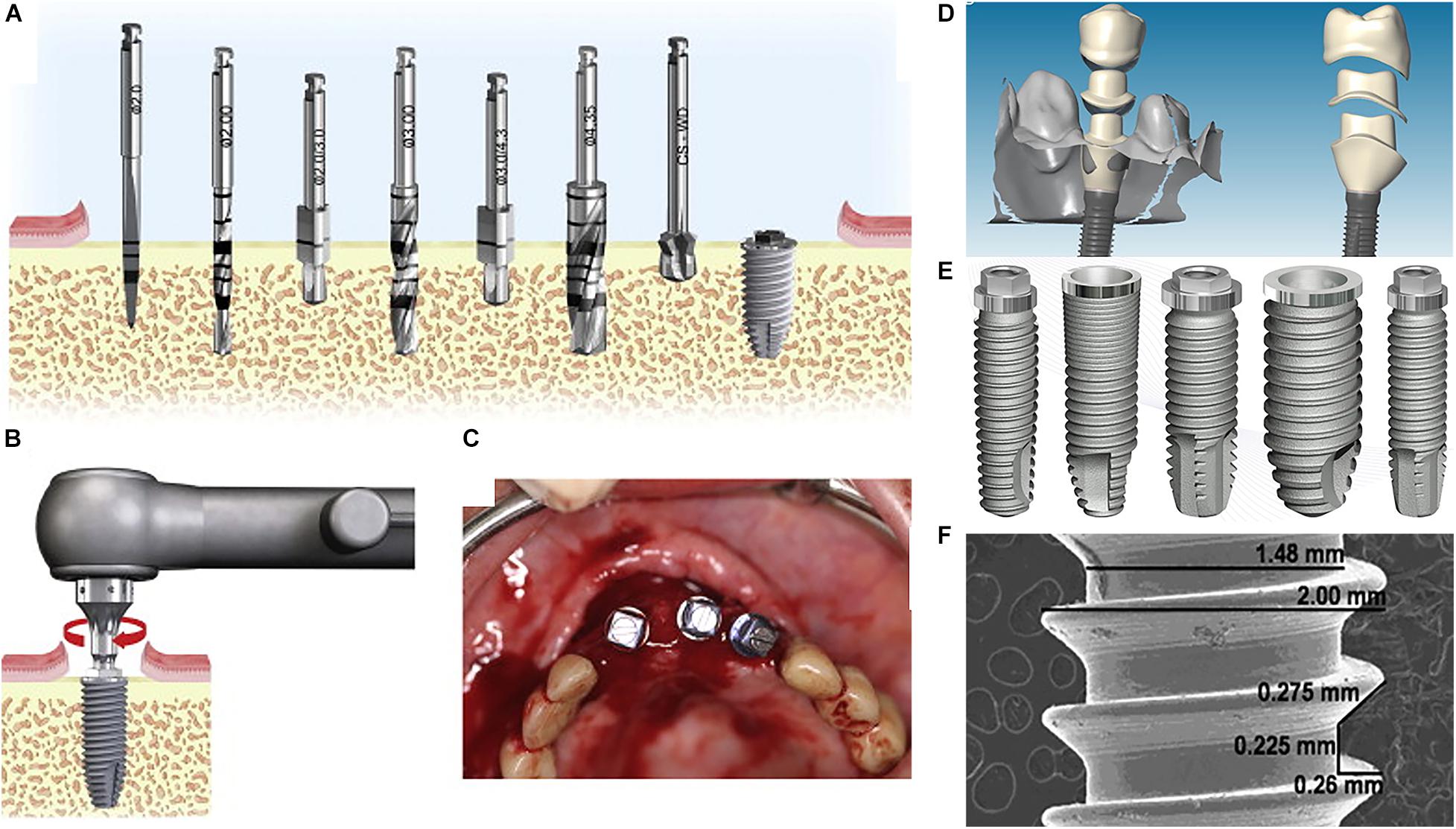

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Frequently Asked Questions (FAQs) for B2B Buyers of dental implant images

-

What should I consider when vetting suppliers for dental implant images?

When vetting suppliers, prioritize their reputation and experience in the dental implant industry. Check for certifications and compliance with international quality standards. Look for reviews and testimonials from previous clients to gauge their reliability. Also, consider their production capabilities, including technology used and customization options. It’s beneficial to engage in direct communication to assess their responsiveness and willingness to address your specific needs. -

Can I customize dental implant images to fit my specific needs?

Yes, many suppliers offer customization options for dental implant images. This can include alterations in design, material specifications, or branding elements. Discuss your requirements clearly with potential suppliers to ensure they can accommodate your needs. Request samples or prototypes to evaluate their capabilities. Customization can enhance your marketing efforts and align the product more closely with your brand identity. -

What are the typical minimum order quantities (MOQ) and lead times for dental implant images?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to several hundred units depending on the complexity of the images and customization requirements. Lead times also differ based on the supplier’s location and production capacity, often ranging from 2 to 12 weeks. Always clarify these details upfront to plan your inventory and avoid potential disruptions in your supply chain. -

What payment options are available for international B2B purchases of dental implant images?

International suppliers often accept various payment methods, including bank transfers, credit cards, and trade finance options. Some may also offer payment plans or letters of credit to facilitate larger orders. It’s essential to discuss payment terms early in the negotiation process to ensure they align with your financial practices and to establish trust with the supplier. -

How can I ensure quality assurance and certification for dental implant images?

Request documentation of quality assurance processes and certifications that comply with international standards, such as ISO or CE marking. Suppliers should be willing to share their quality control measures, including testing procedures and inspection reports. Consider conducting an on-site audit or asking for third-party inspection services to validate their claims, especially for high-volume orders. -

What logistics considerations should I keep in mind when sourcing dental implant images internationally?

Logistics is crucial in international sourcing. Evaluate the supplier’s shipping capabilities and experience with customs regulations in your country. Discuss shipping options, costs, and estimated delivery times. Ensure that your supplier provides proper documentation for customs clearance. Additionally, consider insurance options for your shipment to mitigate risks during transit. -

How can I handle disputes with suppliers effectively?

Establish clear communication channels from the outset to address issues promptly. Draft a comprehensive contract outlining terms and conditions, including dispute resolution procedures. If a dispute arises, engage in direct dialogue with the supplier to seek a resolution. If necessary, involve a neutral third party for mediation or arbitration to resolve conflicts without damaging the business relationship. -

What are the key trends in the dental implant image market I should be aware of?

Stay informed about technological advancements such as 3D imaging and digital workflow integrations that enhance the accuracy and efficiency of dental implants. Sustainability is also becoming a significant trend, with suppliers focusing on eco-friendly materials and production processes. Additionally, observe shifts in consumer preferences towards personalized dental solutions, which can inform your purchasing decisions and marketing strategies.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implant images

In conclusion, strategic sourcing of dental implant images presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging high-quality imaging solutions, businesses can enhance their product offerings, streamline operations, and improve patient outcomes. Key takeaways include the importance of collaborating with reputable suppliers who prioritize quality and innovation, as well as adopting technologies that facilitate efficient sourcing and distribution.

Buyers should also consider the regional nuances that affect sourcing decisions, such as regulatory requirements and market demand fluctuations. Establishing strong partnerships with local and international suppliers can lead to better pricing, improved service levels, and a competitive edge in the market.

Looking ahead, the demand for advanced dental implant imaging is expected to grow, driven by technological advancements and increasing consumer expectations. Now is the time for B2B buyers to invest in strategic sourcing practices that align with these trends. By doing so, they can position themselves for success and capitalize on the evolving landscape of dental implant solutions. Engage with trusted suppliers and explore innovative imaging technologies to ensure your business remains at the forefront of this dynamic industry.