Introduction: Navigating the Global Market for zimmer biomet dental implants

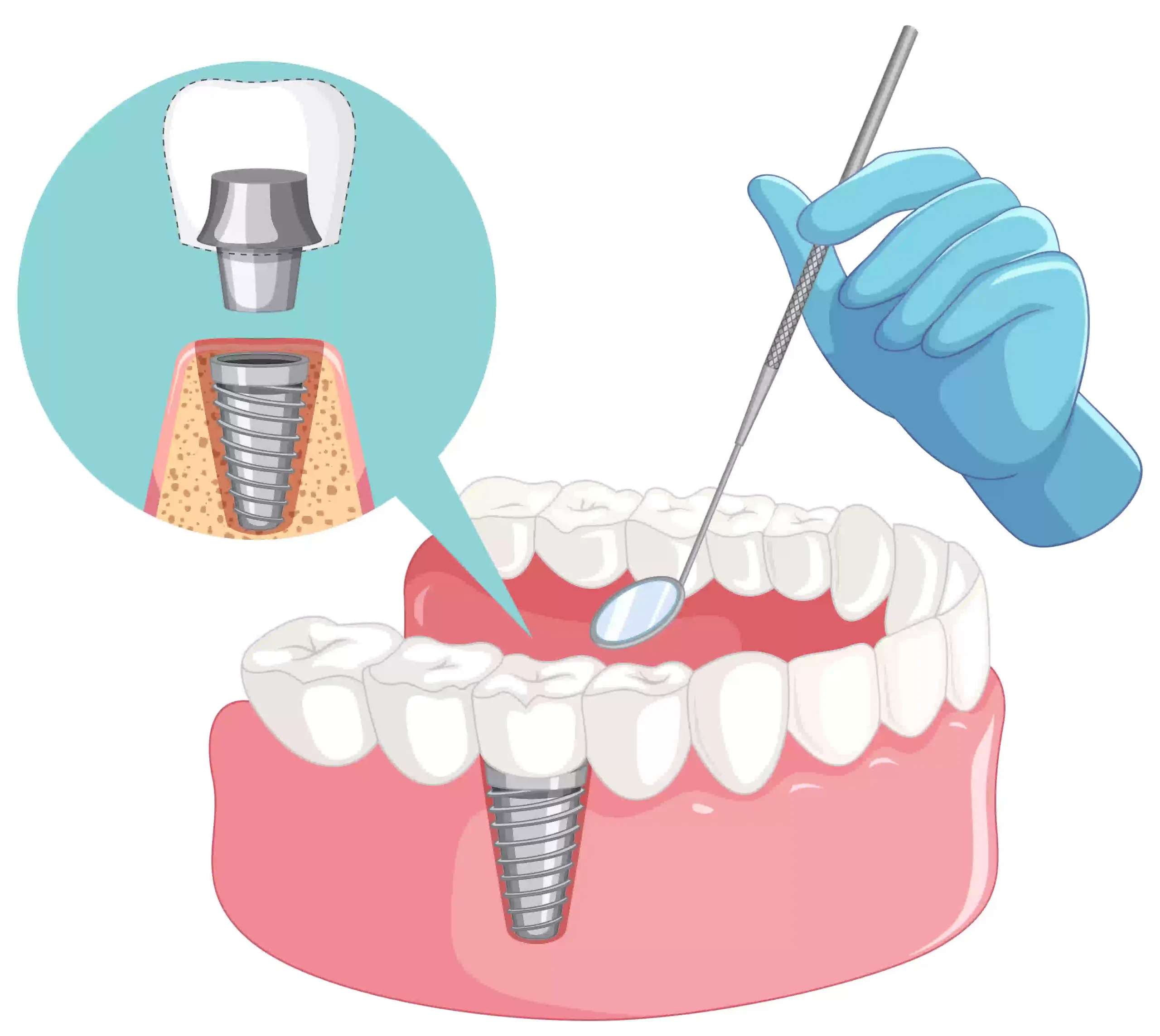

Navigating the global market for dental implants can be a complex endeavor, especially for B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. Zimmer Biomet dental implants stand out as a leading choice in the industry, known for their innovation, quality, and reliability. These implants are not only designed to enhance patient outcomes but also to meet the growing demands of dental professionals across different markets.

This comprehensive guide will delve into the various aspects of Zimmer Biomet dental implants, covering the types of implants, materials used, manufacturing and quality control processes, and insights into suppliers. Additionally, we will explore the cost implications, market trends, and address frequently asked questions to empower buyers in making informed sourcing decisions.

Understanding the intricacies of Zimmer Biomet’s offerings enables international B2B buyers to align their procurement strategies with the latest advancements in dental technology. This guide aims to equip you with actionable insights and critical knowledge to navigate the competitive landscape effectively, ensuring that you can provide the best solutions to your clients while maximizing your investment. Whether you are in France, South Africa, or anywhere in between, this resource is your key to unlocking the potential of Zimmer Biomet dental implants in your market.

Understanding zimmer biomet dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T3 Ex Hex Parallel Walled Implant | Features a hexagonal connection for stable prosthetic retention | General restorative dentistry | Pros: Excellent stability; Cons: May require specialized tools for placement. |

| T3 Ex Hex Tapered Implant | Tapered design enhances primary stability in soft bone | Implantology in challenging anatomical sites | Pros: Ideal for immediate placement; Cons: Higher cost due to advanced design. |

| Tapered Screw-Vent Implant | Versatile with a wide range of abutment compatibility | Full-arch restorations and single-tooth solutions | Pros: High adaptability; Cons: Learning curve for new practitioners. |

| Trabecular Metal Implant | Porous structure mimicking natural bone for enhanced osseointegration | Complex cases with significant bone loss | Pros: Promotes bone growth; Cons: Limited availability in some regions. |

| TSX Implant | Offers a unique surface treatment for improved integration | Diverse applications from single implants to bridges | Pros: Proven track record; Cons: Requires precise surgical technique. |

T3 Ex Hex Parallel Walled Implant

The T3 Ex Hex Parallel Walled Implant is characterized by its hexagonal connection, providing enhanced stability for prosthetic devices. This implant is particularly suitable for general restorative dentistry, where reliability in the prosthetic attachment is crucial. B2B buyers should consider the specialized tools required for placement, which can increase initial investment but ultimately lead to higher patient satisfaction due to the stability it offers.

T3 Ex Hex Tapered Implant

Designed with a tapered shape, the T3 Ex Hex Tapered Implant excels in achieving primary stability, especially in soft bone conditions. It is ideal for implantology in challenging anatomical sites, making it a preferred choice for immediate placements. Buyers should weigh the benefits of its advanced design against the higher costs, as the investment can lead to better outcomes in complex cases.

Illustrative Image (Source: Google Search)

Tapered Screw-Vent Implant

The Tapered Screw-Vent Implant is known for its versatility and compatibility with a broad range of abutments, making it suitable for full-arch restorations as well as single-tooth solutions. This adaptability is crucial for dental practices looking to streamline their inventory. However, practitioners may face a learning curve when first using this implant, which could affect initial cases.

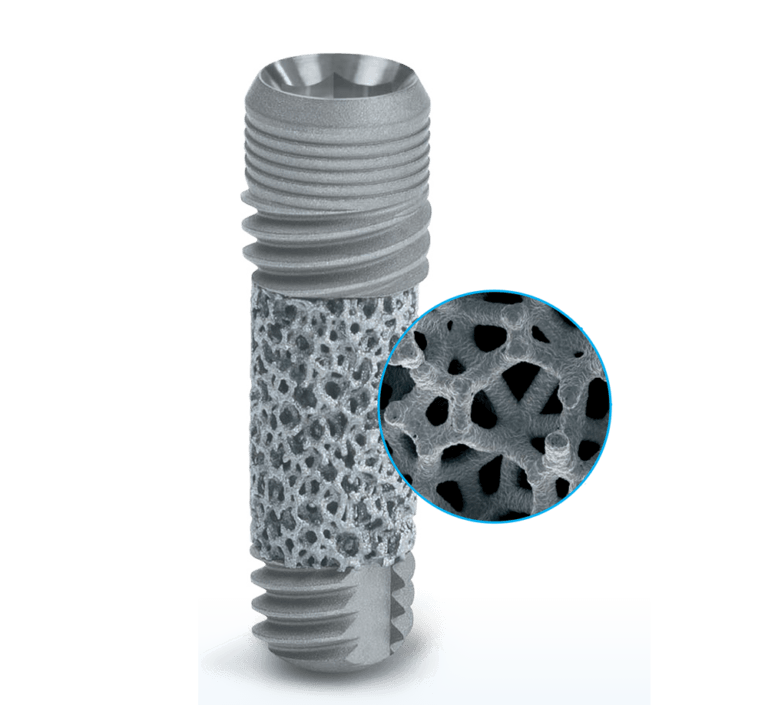

Trabecular Metal Implant

The Trabecular Metal Implant features a porous structure that mimics natural bone, promoting enhanced osseointegration. This implant is particularly beneficial for complex cases involving significant bone loss, providing a solution where traditional implants may fail. Buyers should consider its availability, as it may not be accessible in all regions, potentially limiting its use.

TSX Implant

The TSX Implant is distinguished by its unique surface treatment, which enhances integration with the surrounding bone. Its proven track record makes it suitable for a wide range of applications, from single implants to bridges. However, the precise surgical technique required for successful placement means that it is best suited for experienced practitioners, which can be a consideration for B2B buyers looking to maintain high standards in their practices.

Related Video: Zimmer Biomet T3® Implants*

Key Industrial Applications of zimmer biomet dental implants

| Industry/Sector | Specific Application of Zimmer Biomet Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Replacement of missing teeth through single or multiple implantations. | Enhances patient satisfaction and retention, leading to increased referrals. | Quality assurance, local regulatory compliance, and implant longevity. |

| Oral Surgery | Use in complex surgical procedures, including zygomatic implants. | Provides solutions for patients with significant bone loss, expanding service offerings. | Surgical expertise, compatibility with existing surgical tools, and patient safety protocols. |

| Prosthodontics | Integration with prosthetic solutions for full-arch restorations. | Streamlines workflow and improves outcomes, attracting higher-value cases. | Availability of compatible prosthetics, training for staff, and inventory management. |

| Dental Education & Training | Hands-on training for dental professionals using Zimmer Biomet products. | Improves skill sets of practitioners, leading to better patient outcomes and clinic reputation. | Access to training materials, certification programs, and local partnerships with educational institutions. |

| Research & Development | Clinical trials and studies on implant efficacy and innovation. | Contributes to product improvements and market competitiveness. | Ethical compliance, funding for trials, and collaboration with academic institutions. |

Detailed Applications

Dental Clinics

Zimmer Biomet dental implants are widely utilized in dental clinics for the replacement of missing teeth. This application not only restores function but also enhances aesthetic appeal, crucial for patient satisfaction. Clinics benefit from increased patient retention and referrals when they offer high-quality implant solutions. For international buyers, it is essential to consider local regulatory compliance and the quality assurance of the implants to ensure longevity and reliability.

Oral Surgery

In oral surgery, Zimmer Biomet implants are instrumental in complex procedures, particularly zygomatic implants for patients with severe bone loss. This application allows surgeons to provide solutions that were previously unavailable, thus expanding their service offerings. International buyers should focus on the expertise required for these surgeries, ensuring compatibility with existing surgical tools and adherence to patient safety protocols.

Prosthodontics

Prosthodontists leverage Zimmer Biomet implants for full-arch restorations, integrating them with prosthetic solutions. This application streamlines the workflow and significantly improves patient outcomes, attracting higher-value cases to practices. Buyers in this sector should prioritize the availability of compatible prosthetics and invest in staff training to maximize the benefits of these advanced solutions.

Dental Education & Training

Zimmer Biomet also plays a vital role in dental education by providing hands-on training for dental professionals. This application enhances the skill sets of practitioners, leading to improved patient outcomes and bolstered clinic reputations. For international buyers, it is crucial to access comprehensive training materials and certification programs, as well as to establish partnerships with local educational institutions to foster talent development.

Research & Development

Finally, Zimmer Biomet implants are utilized in research and clinical trials aimed at studying implant efficacy and innovation. This application not only contributes to product improvements but also enhances market competitiveness. Buyers in this sector must ensure ethical compliance, secure funding for trials, and foster collaborations with academic institutions to drive forward-thinking research initiatives.

Strategic Material Selection Guide for zimmer biomet dental implants

When selecting materials for Zimmer Biomet dental implants, understanding the properties, advantages, and limitations of each material is crucial for international B2B buyers. This guide analyzes four common materials used in these implants: Titanium, Zirconia, PEEK (Polyether Ether Ketone), and Trabecular Metal. Each material has its unique characteristics that impact performance, cost, and suitability for various applications.

Titanium

Key Properties:

Titanium is renowned for its exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. It can withstand a wide range of temperatures and pressures, making it suitable for various environments.

Pros & Cons:

The durability of titanium is one of its primary advantages, as it can endure significant mechanical stress without deformation. However, the manufacturing process can be complex and costly, which may affect the overall pricing of implants.

Impact on Application:

Titanium implants are compatible with various dental procedures and are widely accepted in the market due to their proven track record. They are particularly effective in environments where high mechanical loads are expected.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloys used in medical devices. Additionally, understanding local regulations in regions like Europe and South Africa is essential for market entry.

Zirconia

Key Properties:

Zirconia is a ceramic material known for its aesthetic appeal and high fracture toughness. It offers excellent resistance to wear and is less abrasive compared to metals.

Pros & Cons:

The primary advantage of zirconia is its tooth-like appearance, making it ideal for anterior implants where aesthetics are critical. However, it is generally less durable than titanium and can be more susceptible to chipping under high stress.

Impact on Application:

Zirconia is particularly suited for cosmetic applications where the visual outcome is paramount. It is less compatible with high-load scenarios, making it less suitable for posterior implants.

Considerations for International Buyers:

Buyers in Europe may prefer zirconia due to aesthetic preferences, but they should be aware of its limitations in load-bearing applications. Compliance with standards such as ISO 6872 is crucial.

PEEK (Polyether Ether Ketone)

Key Properties:

PEEK is a high-performance polymer that offers excellent chemical resistance and mechanical properties. It is lightweight and can withstand high temperatures, making it suitable for various dental applications.

Pros & Cons:

The key advantage of PEEK is its flexibility and adaptability in different environments. However, it is generally less durable than titanium and may not be suitable for high-stress applications.

Impact on Application:

PEEK is often used in implant abutments and temporary restorations due to its ease of processing and customization. It is not recommended for primary load-bearing implants.

Considerations for International Buyers:

International buyers should consider the regulatory landscape surrounding polymer implants, particularly in regions like the Middle East, where standards may vary. Compliance with ASTM F2026 is essential.

Trabecular Metal

Key Properties:

Trabecular Metal is a highly porous material that mimics the structure of natural bone. It offers excellent biological integration and load distribution.

Pros & Cons:

The primary advantage of Trabecular Metal is its ability to support bone ingrowth, enhancing implant stability. However, its manufacturing process can be complex and may lead to higher costs.

Impact on Application:

This material is particularly beneficial in areas where bone density is compromised, as it promotes osseointegration. It is suitable for both dental and orthopedic applications.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM F1586 for porous metal implants. Understanding the local market dynamics in regions like South America is crucial for successful adoption.

Summary Table

| Material | Typical Use Case for Zimmer Biomet Dental Implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Load-bearing dental implants | Exceptional strength and durability | High manufacturing complexity | High |

| Zirconia | Aesthetic anterior implants | Excellent aesthetics | Less durable under high stress | Medium |

| PEEK | Implant abutments and temporary restorations | Lightweight and flexible | Generally less durable than metals | Medium |

| Trabecular Metal | Implants in compromised bone density areas | Promotes bone ingrowth | Higher manufacturing costs | High |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in Zimmer Biomet dental implants, enabling informed purchasing decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for zimmer biomet dental implants

Zimmer Biomet dental implants are manufactured through a meticulous process that ensures high-quality products, which is crucial for B2B buyers in the dental industry. Understanding the manufacturing processes and quality assurance protocols is essential for buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This section provides an in-depth look into the stages of manufacturing and the quality control measures that underpin Zimmer Biomet’s reputation for excellence.

Manufacturing Processes

The manufacturing of Zimmer Biomet dental implants involves several key stages, each designed to ensure precision and reliability.

1. Material Preparation

The process begins with the selection of high-quality materials, primarily titanium and its alloys, due to their biocompatibility and strength. Zimmer Biomet adheres to strict sourcing standards to ensure that all materials meet international specifications. The preparation involves:

Illustrative Image (Source: Google Search)

- Material Testing: Ensuring that the raw materials are free from contaminants and meet the required mechanical properties.

- Certification: Sourcing materials from suppliers who can provide certifications such as ISO 13485, which indicates compliance with quality management systems specific to medical devices.

2. Forming

After preparing the materials, the next step is forming them into the desired shapes. This stage includes:

- Machining: Utilizing CNC (Computer Numerical Control) machines to achieve precise dimensions and tolerances. This technology allows for the production of complex geometries that enhance the implant’s integration with bone.

- Surface Treatment: Applying techniques such as sandblasting, acid etching, or anodization to improve the surface characteristics, promoting osseointegration.

3. Assembly

In this phase, various components of the dental implants are assembled. This can include the implant body, abutments, and other related components. Key activities include:

- Component Verification: Each part is checked for accuracy and compatibility with other components before assembly.

- Clean Room Environment: The assembly is performed in a controlled environment to prevent contamination, adhering to cleanroom standards.

4. Finishing

The final stage of manufacturing involves finishing processes to ensure the implants are ready for sterilization and distribution. This includes:

- Polishing: Enhancing the aesthetic and functional qualities of the implants.

- Packaging: Utilizing sterile packaging to maintain the integrity of the implants until they reach the end user.

Quality Assurance

Quality assurance is integral to the production of Zimmer Biomet dental implants, ensuring that every product meets stringent international standards.

Relevant International Standards

Zimmer Biomet complies with several international standards to maintain quality, including:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that the company consistently provides products that meet customer and regulatory requirements.

- ISO 13485: Specific to medical devices, this standard emphasizes the importance of maintaining a quality management system throughout the product lifecycle.

- CE Marking: For products marketed in Europe, CE marking demonstrates compliance with health, safety, and environmental protection standards.

- API (Active Pharmaceutical Ingredients): Compliance with API standards ensures that any materials used in the implants are of pharmaceutical-grade quality.

Quality Control Checkpoints

Zimmer Biomet employs multiple quality control checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are rigorously tested upon arrival to verify their compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive testing of finished products, including mechanical testing, surface analysis, and sterilization validation.

Common Testing Methods

To ensure the implants meet the necessary standards, several testing methods are employed:

- Mechanical Testing: Assessing the strength and durability of the implants under various conditions.

- Biocompatibility Testing: Ensuring that materials used do not provoke adverse reactions in the body.

- Sterility Testing: Confirming that the final products are free from microbial contamination.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps to ensure robust quality assurance:

- Conduct Audits: Request to perform onsite audits of the manufacturing facilities to assess compliance with quality standards.

- Review Quality Reports: Ask suppliers for quality control reports that detail their testing methodologies, results, and compliance with international standards.

- Third-party Inspections: Consider employing third-party inspection services to independently verify the quality of the implants prior to purchase.

Navigating Quality Control Nuances

International B2B buyers should be aware of specific nuances related to quality control in different regions. For instance:

- Regulatory Variations: Different countries may have varying regulatory requirements for medical devices. Buyers should familiarize themselves with local regulations in their respective markets to ensure compliance.

- Cultural Considerations: Understanding the cultural nuances related to quality expectations and business practices can enhance negotiation and partnership effectiveness.

In conclusion, Zimmer Biomet’s manufacturing processes and stringent quality assurance protocols are designed to ensure that their dental implants meet the highest standards of safety and efficacy. By understanding these processes, international B2B buyers can make informed decisions, ensuring that they select a reliable supplier that aligns with their quality expectations.

Comprehensive Cost and Pricing Analysis for zimmer biomet dental implants Sourcing

When sourcing Zimmer Biomet dental implants, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the key cost components, pricing influencers, and actionable buyer tips to optimize procurement strategies.

Cost Components

-

Materials: The primary materials used in Zimmer Biomet implants include titanium and zirconia, known for their biocompatibility and strength. Prices can vary significantly based on material quality and the latest advancements in implant technology.

-

Labor: Labor costs encompass skilled technicians involved in the manufacturing and assembly processes. Given the specialized nature of dental implants, labor costs can be substantial, particularly in regions with higher wage standards.

-

Manufacturing Overhead: This includes costs associated with facility operations, utilities, and administrative expenses. Manufacturers often pass on a portion of these overhead costs to buyers.

-

Tooling: The design and maintenance of tools used in the production of dental implants also contribute to the overall cost. Custom tooling for specialized implant designs can increase initial procurement expenses.

-

Quality Control (QC): Rigorous QC measures are essential in the dental industry to ensure the safety and efficacy of implants. The costs associated with testing and compliance with regulatory standards can add to the price.

-

Logistics: Shipping and handling costs can vary based on the geographic location of the buyer. International shipping, customs duties, and insurance are critical factors to consider in the total cost.

-

Margin: Suppliers typically include a profit margin that can vary depending on market competition and demand. Understanding the typical margins within the industry can aid in negotiation.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts, reducing the per-unit price. Establishing a reliable demand forecast can enable buyers to negotiate better terms.

-

Specifications/Customization: Customized implants tailored to specific clinical needs may incur additional costs. Buyers should weigh the necessity of customization against potential price increases.

-

Quality/Certifications: Implants that meet higher quality standards or possess specific certifications (e.g., ISO, CE) may command premium pricing. Buyers should assess the value these certifications bring to their practice.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more due to their perceived value.

-

Incoterms: Understanding Incoterms is crucial for determining responsibilities related to shipping, insurance, and customs clearance. These factors can significantly impact the final cost structure.

Buyer Tips

-

Negotiation: Engage in discussions about pricing and terms with suppliers. Leverage order volume and long-term partnership potential to negotiate favorable conditions.

-

Cost-Efficiency: Evaluate the total cost of ownership, not just the purchase price. Consider factors like warranty, after-sales support, and potential for future business.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, prices may differ in Europe compared to Africa or South America due to local market dynamics and economic conditions.

-

Research and Compare: Conduct thorough market research and compare prices and offerings from multiple suppliers. This can provide leverage during negotiations and help identify the best value.

-

Stay Informed on Trends: The dental implant market is evolving with new technologies and materials. Staying updated on industry trends can provide insights into future pricing shifts.

Disclaimer

Prices are indicative and may vary based on market conditions, supplier negotiations, and specific order details. It is advisable for buyers to conduct due diligence and seek tailored quotes based on their unique requirements.

Spotlight on Potential zimmer biomet dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘zimmer biomet dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for zimmer biomet dental implants

Key Technical Properties of Zimmer Biomet Dental Implants

Understanding the technical specifications of Zimmer Biomet dental implants is crucial for international B2B buyers. Here are some essential properties to consider:

-

Material Composition: Zimmer Biomet implants are primarily made from Titanium and Titanium Alloys. These materials are chosen for their biocompatibility, strength, and resistance to corrosion. For buyers, selecting implants with high-quality materials ensures durability and reduces the risk of implant failure.

-

Surface Treatment: The implants feature advanced surface treatments, such as Sandblasting and Acid Etching. This enhances osseointegration, which is the process of bone fusing with the implant. A better surface treatment can lead to faster healing and improved stability, making it an important factor for dental professionals when choosing implants.

-

Implant Geometry: Zimmer Biomet offers various implant shapes, including Tapered and Straight designs. The geometry affects the implant’s primary stability and loading characteristics. Buyers should consider the specific needs of their patients, as different geometries may be more suitable for certain clinical scenarios.

-

Connection Type: The connection types available, such as Hexagonal and Internal Connections, influence the ease of abutment placement and the overall implant stability. Understanding these connections helps buyers ensure compatibility with their existing systems and prosthetics.

-

Length and Diameter Options: Zimmer Biomet implants come in various lengths and diameters, allowing for customization based on patient anatomy and clinical requirements. This versatility is essential for dental practices aiming to address a wide range of implant cases.

-

Load Capacity: Each implant is designed to withstand specific loads, which is critical for long-term success. Knowing the load capacity helps dental professionals select the right implant for their patients’ needs, ensuring functionality and longevity.

Industry Trade Terminology

Familiarizing yourself with common trade terms can greatly enhance communication and negotiation in the dental implant market:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another company’s brand. In the context of dental implants, understanding OEM relationships can help buyers ensure they are sourcing high-quality products from reputable manufacturers.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory effectively and to negotiate better pricing terms.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request pricing information from suppliers for specific products. This is a critical step for B2B buyers to ensure they get competitive pricing and understand the supplier’s terms.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers mitigate risks and understand their obligations during the import/export process.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for managing patient appointments and ensuring timely delivery of dental implants.

-

Warranty: A warranty provides assurance regarding the quality and durability of the implants. Knowing the warranty terms can help buyers assess the long-term value and reliability of their purchases.

By grasping these technical properties and trade terminologies, B2B buyers from diverse regions can make informed decisions that enhance their procurement strategies and improve patient outcomes in dental practices.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the zimmer biomet dental implants Sector

Market Overview & Key Trends

The dental implants market, particularly for Zimmer Biomet, is experiencing robust growth driven by several global factors. Increasing aging populations, rising prevalence of dental diseases, and advancements in dental technologies are propelling the demand for dental implants. For international B2B buyers, understanding these dynamics is crucial, especially in regions like Africa, South America, the Middle East, and Europe.

Emerging trends include the integration of digital solutions and artificial intelligence in implant planning and placement, enhancing precision and reducing procedural time. Additionally, the move toward minimally invasive techniques is reshaping sourcing strategies, as buyers seek implants that offer both quality and ease of use. Buyers should also note the growing importance of comprehensive product portfolios that include compatible prosthetics and biomaterials, which are essential for a complete dental solution.

Sourcing trends are shifting towards suppliers who can provide innovative and reliable products backed by strong customer support and training. This is particularly relevant for markets in Africa and South America, where the infrastructure may be developing, necessitating robust partnerships with suppliers like Zimmer Biomet that can offer training and support.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a significant consideration for B2B buyers in the dental implant sector. The environmental impact of dental manufacturing processes has come under scrutiny, making it essential for companies like Zimmer Biomet to implement sustainable practices. This includes utilizing eco-friendly materials and minimizing waste during production.

Buyers should prioritize suppliers who emphasize ethical sourcing practices and transparency in their supply chains. Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials can indicate a commitment to sustainability. Zimmer Biomet has initiatives aimed at reducing its carbon footprint and enhancing resource efficiency, which can resonate with buyers focused on sustainability.

Moreover, as regulatory frameworks around environmental standards tighten globally, aligning with suppliers who adhere to these standards will not only mitigate risks but also enhance brand reputation. Buyers can leverage this focus on sustainability to appeal to their own customers, who are increasingly making purchasing decisions based on environmental considerations.

Brief Evolution/History

Founded in 1927, Zimmer Biomet has evolved from a small American company to a global leader in musculoskeletal healthcare, including dental implants. The company’s long history has been marked by continuous innovation, such as the introduction of advanced implant designs and digital solutions for enhanced patient outcomes.

Over the decades, Zimmer Biomet has expanded its product offerings, now providing a comprehensive range of dental implants that cater to diverse clinical needs. This evolution reflects a commitment to addressing the complexities of dental restoration and implantology, making it a reliable partner for B2B buyers seeking quality and innovation in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of zimmer biomet dental implants

-

What should I consider when vetting Zimmer Biomet suppliers?

When vetting suppliers for Zimmer Biomet dental implants, prioritize their certifications and compliance with international standards such as ISO 13485 and CE marking. Assess their operational history, client testimonials, and geographical distribution to ensure they can support your market needs. Additionally, inquire about their quality assurance processes, including how they handle recalls and product safety. Establishing direct communication with the supplier can also provide insights into their reliability and responsiveness. -

Can Zimmer Biomet dental implants be customized for specific needs?

Yes, Zimmer Biomet offers a range of customizable dental implants tailored to meet specific clinical requirements. Engage with your supplier to discuss customization options, including implant dimensions, surface treatments, and specific abutment designs. It’s essential to communicate your needs clearly and ensure that the supplier can accommodate these requests without compromising on quality or lead times. -

What are the typical minimum order quantities (MOQ) and lead times for Zimmer Biomet implants?

MOQs for Zimmer Biomet dental implants can vary based on the product line and supplier agreements. Generally, expect an MOQ ranging from 10 to 50 units. Lead times can range from 2 to 6 weeks, depending on the customization and availability of the implants. It’s advisable to discuss these details upfront with your supplier to plan your inventory and avoid potential stockouts. -

What payment terms are typically offered for international purchases?

Payment terms for Zimmer Biomet dental implants can vary by supplier and region. Common arrangements include upfront payments, letters of credit, or net 30/60 days terms, depending on your relationship with the supplier. Always negotiate clear payment terms in your contract to mitigate risks associated with currency fluctuations and ensure compliance with local regulations.

-

How can I verify the quality assurance certifications of Zimmer Biomet products?

To verify the quality assurance certifications of Zimmer Biomet products, request copies of relevant certificates such as ISO 13485, CE marking, and any other applicable regulatory approvals. Suppliers should provide documentation that demonstrates compliance with international quality standards. Additionally, consider conducting third-party audits or assessments for added assurance regarding product quality. -

What logistics considerations should I keep in mind when sourcing Zimmer Biomet implants?

When sourcing Zimmer Biomet implants, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs in your country. Opt for suppliers that offer comprehensive logistics support, including tracking systems and timely delivery guarantees. Understanding the import/export processes specific to your region will also help mitigate delays and ensure compliance with local laws. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes with suppliers, maintain clear documentation of all transactions and communications. Establish a formal dispute resolution process within your contract, outlining steps for mediation or arbitration. Open communication is key; address issues promptly and professionally. If necessary, involve legal counsel familiar with international trade laws to navigate complex disputes effectively. -

How do I ensure compliance with local regulations when using Zimmer Biomet implants?

Ensure compliance with local regulations by familiarizing yourself with the medical device regulations in your country. This may include obtaining necessary licenses, adhering to import/export restrictions, and ensuring that all products meet national safety standards. Collaborate closely with your supplier to stay updated on regulatory changes and ensure that all documentation, including product certifications, is accurate and readily available for inspection.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zimmer biomet dental implants

In conclusion, strategic sourcing of Zimmer Biomet dental implants presents a compelling opportunity for international B2B buyers. The comprehensive product range—including various bone level and tissue level implants—ensures that healthcare providers can meet diverse patient needs effectively. As Zimmer Biomet continues to innovate and expand its footprint globally, buyers can leverage their established reputation for quality and reliability to enhance their own service offerings.

Key Takeaways:

– Diverse Product Portfolio: Zimmer Biomet’s implants cater to a wide range of clinical situations, allowing buyers to address specific patient requirements.

– Global Reach: With distribution in over 100 countries, Zimmer Biomet provides international buyers with robust supply chain options, ensuring timely access to products.

– Commitment to Innovation: Continuous investment in R&D highlights the company’s dedication to improving patient outcomes through advanced technologies.

As markets in Africa, South America, the Middle East, and Europe grow, the demand for high-quality dental solutions will increase. Now is the time for B2B buyers to engage with Zimmer Biomet, fostering partnerships that will lead to better patient care and business growth. Embrace the future of dental implant solutions today.