Introduction: Navigating the Global Market for recovery from dental implants

In the rapidly evolving landscape of dental healthcare, the recovery process from dental implants stands as a pivotal component that directly influences patient satisfaction and long-term success. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their offerings, understanding the complexities of implant recovery becomes essential. This guide serves as a comprehensive resource, equipping stakeholders with critical insights into the various types of recovery products, the materials used, manufacturing quality control standards, and potential suppliers.

Why Focus on Recovery?

Successful recovery from dental implants is not merely a matter of patient comfort; it significantly impacts the overall effectiveness of the dental procedure. As demand for dental implants rises globally, so does the necessity for high-quality recovery solutions that meet diverse patient needs. This guide will delve into the multifaceted aspects of recovery, including product types ranging from pain management tools to advanced healing aids, ensuring that buyers can make informed decisions.

Empowering Informed Sourcing

By navigating through an in-depth analysis of costs, market trends, and frequently asked questions, this guide empowers B2B buyers to source effectively and strategically. Whether you’re a supplier in Turkey, a distributor in Italy, or a healthcare provider in South America, understanding the nuances of recovery from dental implants is crucial for maintaining competitive advantage and ensuring patient satisfaction. Embrace the opportunity to elevate your offerings and meet the increasing demand for quality dental care solutions.

Understanding recovery from dental implants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Immediate Loading Implants | Placed and loaded with a temporary crown on the same day. | Dental clinics focusing on quick turnaround. | Pros: Faster recovery, improved aesthetics. Cons: Higher failure rate if not properly managed. |

| Delayed Loading Implants | Implants placed and allowed to heal before loading. | Clinics prioritizing long-term success rates. | Pros: Lower risk of complications. Cons: Longer overall treatment time. |

| Mini Dental Implants | Smaller diameter implants, often used in narrow spaces. | Practices with patients needing less invasive options. | Pros: Less invasive, quicker recovery. Cons: May not support larger prosthetics. |

| Zygomatic Implants | Longer implants anchored in the cheekbone for severe bone loss. | Specialized clinics dealing with complex cases. | Pros: Suitable for patients with significant bone loss. Cons: Higher surgical complexity. |

| Bone-Grafting Recovery | Involves additional procedures to augment bone before implant placement. | Clinics with a focus on comprehensive rehabilitation. | Pros: Increases success rates for implants. Cons: Extended recovery period and costs. |

Immediate Loading Implants

Immediate loading implants are designed to be placed and loaded with a temporary crown on the same day of surgery. This method is ideal for dental clinics that focus on providing quick treatment solutions, enhancing patient satisfaction through immediate aesthetic results. However, B2B buyers should consider the higher risk of implant failure if not managed correctly, necessitating thorough training for the surgical team and careful patient selection.

Delayed Loading Implants

With delayed loading implants, the surgical procedure involves placing the implant and allowing it to heal before attaching the final prosthetic. This approach is favored by clinics that prioritize long-term success and stability of the implants. Buyers should be aware that while this method has a lower risk of complications, it requires a longer overall treatment timeline, which may affect patient flow and scheduling.

Mini Dental Implants

Mini dental implants are characterized by their smaller diameter, making them suitable for patients with limited bone structure or those seeking less invasive options. They are particularly beneficial for practices that aim to provide quick recovery solutions. However, buyers must weigh the advantages of a less invasive procedure against the limitation that mini implants may not support larger prosthetics, potentially leading to future patient dissatisfaction.

Zygomatic Implants

Zygomatic implants are longer implants that anchor into the cheekbone, making them suitable for patients with severe bone loss in the upper jaw. This type of implant is typically utilized in specialized clinics that handle complex cases and offer advanced solutions. While they provide a viable option for challenging scenarios, the surgical complexity is a significant consideration for buyers, necessitating skilled professionals and potentially higher costs.

Bone-Grafting Recovery

Bone-grafting recovery involves additional procedures to augment the bone before implant placement, making it a comprehensive solution for patients with inadequate bone density. Clinics that focus on thorough rehabilitation and long-term implant success often use this method. While it increases the likelihood of successful implant integration, buyers should be prepared for an extended recovery period and associated costs, which could impact patient satisfaction and clinic profitability.

Related Video: Recovery from your All on 4 Dental Implant Procedure | Post Operative Instructions

Key Industrial Applications of recovery from dental implants

| Industry/Sector | Specific Application of Recovery from Dental Implants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Post-operative care products for implant patients | Enhances patient satisfaction and recovery rates | Quality certifications, product efficacy, supplier reliability |

| Dental Laboratories | Custom implant manufacturing and recovery solutions | Streamlines production and reduces turnaround times | Material sourcing, technological capabilities, compliance with regulations |

| Pharmaceuticals | Development of pain management solutions post-implant | Increases patient adherence to treatment plans | Clinical data, regulatory approvals, market demand |

| Healthcare Equipment | Devices for monitoring recovery progress | Improves patient outcomes and operational efficiency | Compatibility with existing systems, technology updates, service support |

| Insurance Providers | Coverage policies for implant recovery procedures | Enhances service offerings and market competitiveness | Understanding regional healthcare laws, risk assessment models, cost structures |

Dental Clinics

In dental clinics, recovery from dental implants is crucial for ensuring patient satisfaction and optimal healing. Clinics often invest in post-operative care products, such as specialized mouth rinses or pain management medications, to facilitate a smoother recovery process. By offering these products, clinics can enhance their service portfolio, leading to higher patient retention rates. For international buyers, sourcing high-quality and clinically validated products is essential, particularly in regions where patient safety standards are paramount.

Dental Laboratories

Dental laboratories play a vital role in the recovery process by manufacturing custom implants that align with individual patient needs. The integration of recovery solutions into their offerings can streamline production, reduce turnaround times, and improve the overall quality of services. Buyers from regions like Europe and South America should focus on suppliers that provide advanced materials and technology to ensure compliance with local regulations while meeting the demands of the market.

Pharmaceuticals

Pharmaceutical companies are increasingly focusing on developing pain management solutions for patients recovering from dental implants. These products not only improve patient adherence to treatment but also contribute to better recovery outcomes. For B2B buyers in Africa and the Middle East, understanding local market dynamics and regulatory requirements is crucial when sourcing these pharmaceutical products. Additionally, having access to robust clinical data can enhance credibility and support marketing efforts.

Healthcare Equipment

In the healthcare equipment sector, devices that monitor recovery progress are becoming more prevalent. These devices assist in tracking patient outcomes and ensuring that any complications are addressed promptly. By investing in such technologies, businesses can improve operational efficiency and patient satisfaction. B2B buyers should consider compatibility with existing healthcare systems and the availability of service support when sourcing these advanced monitoring tools.

Insurance Providers

Insurance providers are increasingly recognizing the importance of offering coverage for implant recovery procedures. By including these services in their portfolios, they can enhance their competitiveness in the market. For international buyers, particularly in regions with varying healthcare laws, understanding the nuances of coverage policies and risk assessment models is critical. This knowledge can help insurance companies tailor their offerings to meet the specific needs of their client base, ultimately leading to better customer retention and satisfaction.

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Strategic Material Selection Guide for recovery from dental implants

When selecting materials for recovery from dental implants, it is crucial for B2B buyers to consider the properties, advantages, and limitations of various materials. This decision impacts not only the performance of the implants but also the overall patient experience and compliance with regional standards. Below, we analyze four common materials used in this context.

Titanium

Key Properties:

Titanium is renowned for its excellent corrosion resistance and high strength-to-weight ratio. It can withstand the physiological conditions of the human body, including varying temperatures and pressures, making it an ideal choice for dental implants.

Pros & Cons:

The primary advantage of titanium is its durability and biocompatibility, which minimizes the risk of rejection by the body. However, titanium can be relatively expensive, and its manufacturing process may involve complex techniques, which can drive up costs.

Impact on Application:

Titanium is compatible with various media, including saliva and blood, which is essential for dental applications. Its resistance to corrosion ensures longevity, reducing the need for replacements.

Considerations for International Buyers:

Buyers in regions like Africa, South America, and Europe should ensure compliance with ASTM and ISO standards for titanium implants. Additionally, understanding local regulations regarding biocompatibility is vital.

Zirconia

Key Properties:

Zirconia is a ceramic material known for its high strength and aesthetic appeal. It exhibits excellent fracture toughness and is resistant to wear and corrosion.

Pros & Cons:

Zirconia’s aesthetic properties make it a preferred choice for visible dental applications, as it closely resembles natural teeth. However, it may not be as durable as titanium under extreme conditions, and its manufacturing process can be more complex, affecting cost.

Impact on Application:

Zirconia is compatible with various dental adhesives and bonding agents, enhancing its application in restorative dentistry. However, its brittleness may limit its use in load-bearing situations.

Considerations for International Buyers:

Compliance with local and international standards, such as ISO and JIS, is essential for zirconia products. Buyers should also consider the availability of skilled labor for the complex manufacturing processes associated with zirconia.

PEEK (Polyether Ether Ketone)

Key Properties:

PEEK is a high-performance polymer known for its excellent mechanical properties and chemical resistance. It can withstand high temperatures and is also biocompatible.

Pros & Cons:

The key advantage of PEEK is its lightweight nature and flexibility, which can enhance patient comfort. However, its cost is typically higher than traditional materials, and the manufacturing process can be intricate.

Impact on Application:

PEEK is particularly useful in applications requiring flexibility and resistance to wear. It is compatible with various dental adhesives and can be used in conjunction with other materials.

Considerations for International Buyers:

B2B buyers should ensure that PEEK products meet local regulations and standards, particularly in regions with stringent medical device regulations. Understanding the supply chain for PEEK is also crucial, as sourcing can vary by region.

Stainless Steel

Key Properties:

Stainless steel is known for its high tensile strength and corrosion resistance. It is a cost-effective material that can withstand the rigors of dental applications.

Pros & Cons:

The main advantage of stainless steel is its affordability and durability, making it a popular choice for temporary implants and dental tools. However, it may not be as biocompatible as titanium or zirconia, which could lead to complications in some patients.

Impact on Application:

Stainless steel is suitable for various dental applications, including temporary implants. However, its potential for corrosion in certain environments may limit its long-term use.

Considerations for International Buyers:

Buyers should be aware of the specific grades of stainless steel that comply with ASTM and ISO standards. Additionally, understanding the local market for stainless steel implants is essential for effective sourcing.

Summary Table

| Material | Typical Use Case for recovery from dental implants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent biocompatibility | Higher cost and manufacturing complexity | High |

| Zirconia | Aesthetic dental restorations | Natural tooth-like appearance | Brittleness under load | Medium |

| PEEK | Flexible dental applications | Lightweight and comfortable | Higher cost and complex manufacturing | High |

| Stainless Steel | Temporary implants and dental tools | Cost-effective and durable | Potential corrosion and biocompatibility issues | Low |

This strategic material selection guide provides essential insights for B2B buyers in the dental implant recovery sector, facilitating informed decision-making tailored to regional needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for recovery from dental implants

Manufacturing Processes for Recovery from Dental Implants

The manufacturing of components used in dental implant recovery is a multi-faceted process that demands precision and adherence to stringent quality control measures. Understanding these processes can empower international B2B buyers to make informed purchasing decisions.

Key Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The choice of materials is crucial, as they must be biocompatible, durable, and capable of withstanding the oral environment. Common materials include titanium, zirconia, and various polymers.

– Material Testing: Before manufacturing begins, raw materials undergo rigorous testing to ensure they meet specified mechanical and chemical properties. This includes tensile strength tests and corrosion resistance assessments. -

Forming

– Casting and Machining: The forming process often involves casting or machining techniques to shape the materials into the desired components. For titanium implants, CNC (Computer Numerical Control) machining is prevalent due to its high precision.

– Additive Manufacturing: Emerging technologies like 3D printing are gaining traction in creating custom implants and abutments, allowing for tailored solutions that fit individual patient anatomies. -

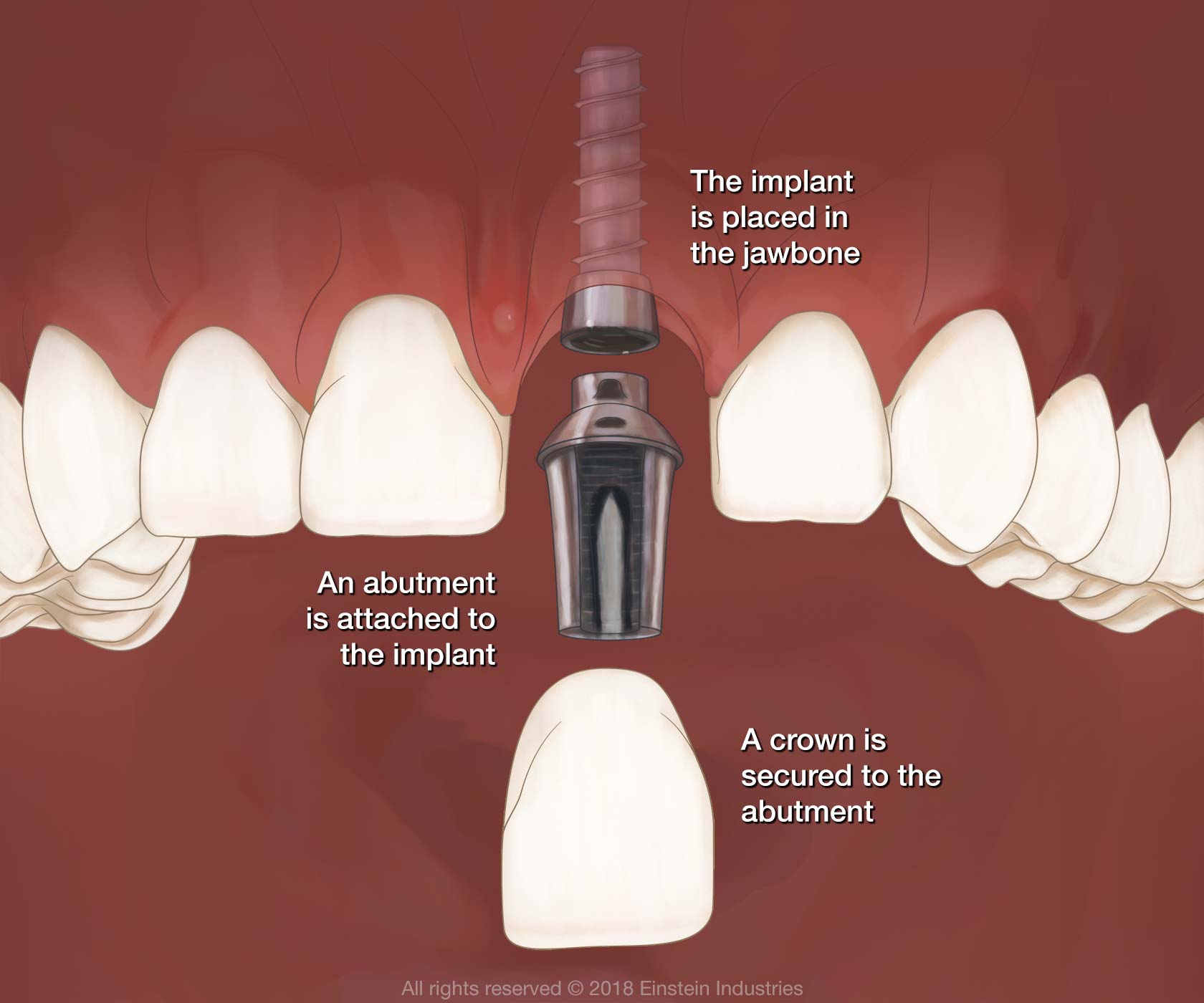

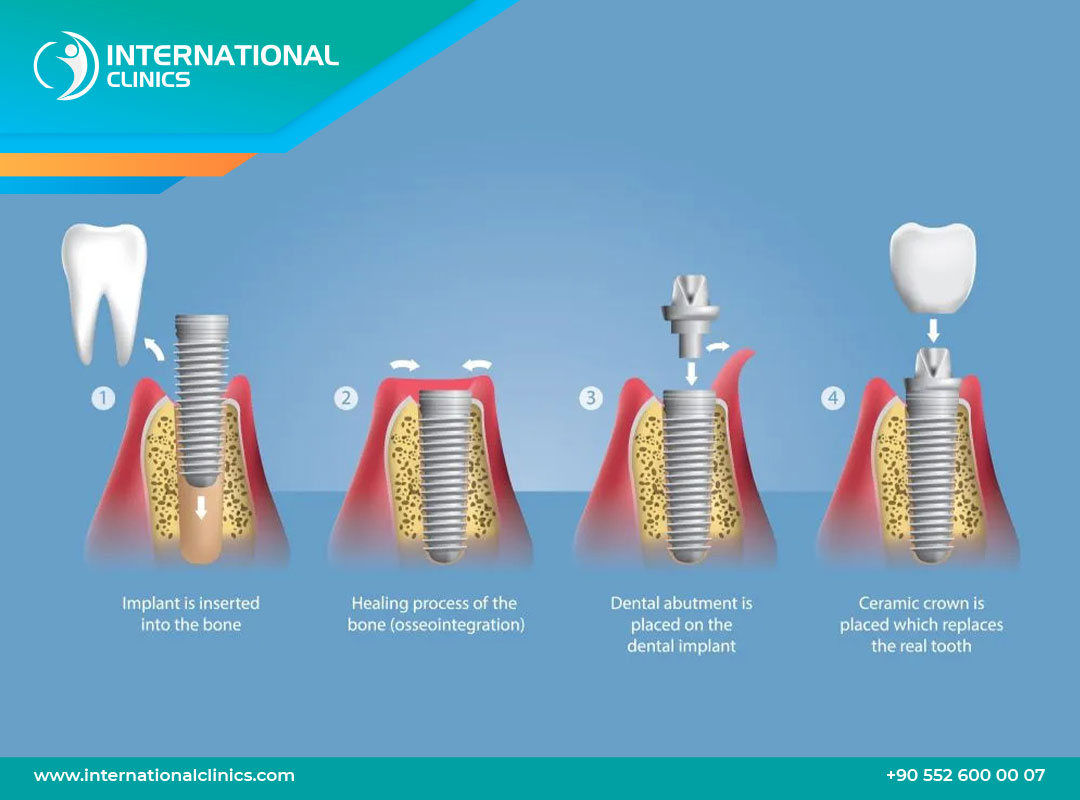

Assembly

– Integration of Components: This stage involves assembling various parts, such as the implant, abutments, and healing caps. Each component must fit precisely to ensure stability and facilitate recovery.

– Surface Treatments: Post-assembly, surface treatments (e.g., anodizing for titanium) enhance the implant’s osseointegration capabilities, promoting better bonding with bone tissue. -

Finishing

– Polishing and Coating: Final finishing techniques, such as polishing or applying bioactive coatings, improve the aesthetic and functional properties of the implants. These coatings can enhance biocompatibility and reduce the risk of infection.

– Packaging: The final products are packaged in sterile environments to maintain their integrity until they reach the healthcare provider.

Illustrative Image (Source: Google Search)

Quality Assurance in Dental Implant Manufacturing

Quality assurance (QA) is critical in ensuring that dental implants are safe, effective, and reliable. Buyers must be aware of various standards and checkpoints that govern this process.

International Standards

-

ISO 9001: This is a general quality management standard that applies to various industries, including medical devices. It emphasizes continuous improvement and customer satisfaction.

-

ISO 13485: Specifically for medical devices, this standard outlines the requirements for a quality management system that demonstrates the ability to provide medical devices and related services that consistently meet customer and regulatory requirements.

-

CE Marking: In Europe, products must comply with EU regulations and receive CE marking, indicating that they meet health, safety, and environmental protection standards.

-

API Standards: For materials used in dental implants, compliance with API (Active Pharmaceutical Ingredients) standards may be relevant, especially when implants are coated with drugs for enhanced recovery.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Ensures that raw materials meet predetermined specifications before they enter the manufacturing process.

- In-Process Quality Control (IPQC): Monitoring of the manufacturing process to identify any deviations from standards in real-time.

- Final Quality Control (FQC): Comprehensive testing of the finished products to verify they meet all applicable standards before distribution.

Common Testing Methods

- Mechanical Testing: Includes tensile, compression, and fatigue tests to ensure that the implant can withstand the forces of mastication.

- Biocompatibility Testing: Assessing the interaction of the implant materials with biological systems to ensure safety.

- Sterility Testing: Verifying that the implants are free from viable microorganisms to prevent infections post-surgery.

Verifying Supplier Quality Control

B2B buyers must establish robust verification processes to ensure that suppliers adhere to quality standards:

-

Supplier Audits: Conduct regular audits of suppliers to assess compliance with quality management systems and manufacturing processes. This can be done through on-site visits or remote audits using digital tools.

-

Documentation Review: Request access to quality management system documentation, including quality manuals, procedures, and records of previous audits.

-

Third-Party Inspections: Engage independent third-party organizations to conduct inspections and testing. This adds an additional layer of credibility to the quality assurance process.

-

Certification Verification: Ensure that suppliers provide valid certifications for ISO and CE compliance. Regularly check for updates or changes in status.

Navigating Quality Control Nuances for International Buyers

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Differences: Familiarize yourself with the regulatory requirements specific to your region. For instance, while the EU has stringent regulations, other regions may have different compliance standards.

-

Cultural Considerations: Be aware of cultural differences that may impact communication and negotiation with suppliers. Establish clear expectations and maintain open lines of communication to foster strong partnerships.

-

Supply Chain Transparency: Ensure that your suppliers maintain transparency throughout the supply chain. This can be critical in tracing the origins of materials and understanding the quality control measures implemented at each stage.

By understanding the manufacturing processes and quality assurance measures involved in the production of dental implants, international B2B buyers can make informed decisions that enhance their procurement strategies and ensure high-quality outcomes for their clients.

Related Video: Dental implants procedure video – restoration

Comprehensive Cost and Pricing Analysis for recovery from dental implants Sourcing

Understanding the Cost Structure for Dental Implant Recovery

When sourcing materials for recovery from dental implants, a comprehensive understanding of the cost structure is crucial for international B2B buyers. The costs associated with this process can be broken down into several key components:

-

Materials: The cost of high-quality materials is a significant factor in the overall expense. Biocompatible materials, such as titanium and zirconia, are often preferred for their durability and safety. The prices may vary based on the supplier’s location and raw material sourcing.

-

Labor: Skilled labor is essential in the production and assembly of dental implants. Labor costs can fluctuate significantly based on the region. For instance, labor in Europe may be more expensive compared to Africa or South America, influencing the total cost.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs, which is crucial for competitive pricing.

-

Tooling: Custom tooling may be necessary for specialized implants, which can add to the initial investment. It’s important to consider whether the tooling costs will be amortized over large production runs.

-

Quality Control (QC): Rigorous QC processes are necessary to ensure product safety and efficacy. The costs associated with QC can vary widely depending on the complexity of the product and the regulatory environment in the supplier’s country.

-

Logistics: Shipping and handling costs must be factored into the total cost, particularly for international shipments. Costs can vary based on the Incoterms used, the distance between supplier and buyer, and customs duties.

-

Margin: Suppliers will typically add a profit margin on top of their costs. Understanding the average margins in different regions can help buyers negotiate better deals.

Factors Influencing Pricing

Several price influencers can significantly impact the cost of sourcing dental implants:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should evaluate their needs and negotiate terms that provide cost savings at scale.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should assess whether customization is necessary or if standard products would suffice.

-

Quality and Certifications: Higher quality products often come at a premium. Certifications such as ISO or CE mark can also influence costs, as they require additional testing and compliance measures.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer companies may offer lower prices to gain market share.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. For example, DDP (Delivered Duty Paid) may include more upfront costs but simplify logistics.

Buyer Tips for Cost-Efficiency

To achieve cost-efficiency in sourcing dental implants, international buyers should consider the following strategies:

-

Negotiate Terms: Engage in discussions with suppliers to negotiate pricing, especially for bulk orders. Leverage market data to justify your position.

-

Total Cost of Ownership (TCO): Look beyond initial purchase prices and consider the TCO, which includes logistics, maintenance, and potential wastage. This approach can uncover more cost-effective options.

-

Research Regional Pricing Nuances: Be aware of regional pricing differences, particularly between continents. For instance, buyers from the Middle East may face different pricing structures compared to those in Europe.

-

Supplier Diversification: Avoid reliance on a single supplier. Diversifying your supplier base can help mitigate risks and potentially lead to better pricing.

-

Stay Informed on Market Trends: Keep abreast of changes in material costs, labor rates, and regulatory requirements in different regions to make informed purchasing decisions.

Disclaimer

Prices and costs discussed herein are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough due diligence and obtain multiple quotes before making sourcing decisions.

Spotlight on Potential recovery from dental implants Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘recovery from dental implants’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for recovery from dental implants

Key Technical Properties for Recovery from Dental Implants

When sourcing materials and components for dental implant recovery, understanding the technical properties is crucial for ensuring product quality and patient safety. Here are some essential specifications that international B2B buyers should consider:

-

Material Grade: The quality of materials used in dental implants significantly impacts their durability and biocompatibility. Common materials include titanium and zirconia. For titanium, grades 4 and 5 (Ti-6Al-4V) are widely recognized for their strength and corrosion resistance. Buyers should prioritize suppliers who provide clear certifications of material grade to ensure compliance with international standards.

-

Tensile Strength: This property refers to the maximum amount of tensile (stretching) stress a material can withstand before failure. For dental implants, a tensile strength of at least 800 MPa is recommended to ensure that the implant can endure the forces of chewing and other stresses. Understanding tensile strength helps buyers select reliable products that reduce the risk of implant fracture.

-

Surface Roughness: The texture of the implant surface can influence osseointegration—the process by which bone attaches to the implant. A surface roughness value between 1.5 to 3 micrometers is optimal, promoting better cell attachment and bone growth. Buyers should inquire about surface treatment processes, as these can greatly affect the healing outcomes.

-

Porosity: This refers to the presence of tiny holes or voids in the material, which can affect the implant’s integration with bone. An ideal porosity level allows for biological fluids to permeate while maintaining structural integrity. Buyers should evaluate the porosity specifications to ensure the implants are conducive to healing.

-

Fatigue Resistance: This property indicates how well a material can withstand cyclic loading over time. Dental implants must endure repeated stresses without failing. A fatigue strength rating of at least 300 MPa is generally expected. Understanding this property helps buyers make informed decisions about the longevity and reliability of the implants.

Common Trade Terms in Dental Implant Recovery

Familiarity with industry terminology is essential for smooth transactions and effective communication with suppliers. Here are some key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the OEM landscape can help buyers identify reputable manufacturers and ensure quality standards are met.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, especially for smaller businesses or new entrants in the market.

-

RFQ (Request for Quotation): An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. Including detailed specifications in an RFQ can lead to better pricing and terms, allowing buyers to compare offers effectively.

-

Incoterms (International Commercial Terms): These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs associated with their orders.

-

Lead Time: This refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and inventory management, particularly in regions where delivery may be affected by logistics challenges.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it under certain conditions. A comprehensive warranty can provide peace of mind to buyers, indicating the manufacturer’s confidence in their product quality.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance the quality of dental implant recovery solutions while ensuring compliance with industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the recovery from dental implants Sector

Market Overview & Key Trends

The recovery from dental implants sector is witnessing significant transformation driven by various global factors. One of the primary drivers is the increasing prevalence of dental conditions linked to aging populations, particularly in Europe and North America, which is spurring demand for effective recovery solutions. Emerging markets in Africa and South America are also experiencing growth due to rising disposable incomes and increased awareness of dental health.

Current and Emerging B2B Tech Trends:

1. Digital Dentistry: The integration of digital technologies, such as 3D printing and CAD/CAM systems, is revolutionizing the production of dental implants and recovery devices. This allows for more precise fittings and quicker turnaround times.

2. Telemedicine: The rise of telehealth services is enhancing patient monitoring and follow-up care post-implant surgery, creating opportunities for suppliers to provide related technology solutions.

3. Smart Materials: Innovations in biocompatible materials are improving the effectiveness of implants and recovery products, appealing to both healthcare providers and patients looking for longevity and comfort.

International B2B buyers should be aware of these trends as they navigate the sourcing landscape. Collaborating with suppliers who are at the forefront of these technologies can enhance product offerings and improve patient outcomes. Additionally, understanding regional preferences and regulatory requirements in countries like Turkey and Italy can facilitate smoother transactions and better market penetration.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly vital in the dental implants recovery sector. The environmental impact of dental materials and manufacturing processes is under scrutiny, leading to a push for greener alternatives. Ethical sourcing practices are not just a regulatory requirement; they are becoming a competitive differentiator in the marketplace.

Key Considerations for B2B Buyers:

– Environmental Certifications: Look for suppliers who provide products with recognized environmental certifications, such as ISO 14001 or those that comply with the EU’s Ecolabel standards. This ensures that the materials used in dental implants are sustainably sourced and have minimal environmental impact.

– Sustainable Materials: Prioritize suppliers who utilize bio-based or recycled materials in their products. Innovations such as biodegradable polymers can significantly reduce the ecological footprint of dental recovery products.

– Transparency in Supply Chains: Engage with companies that maintain clear and ethical supply chains. This includes regular audits and compliance with international labor standards, which not only helps in meeting regulatory requirements but also enhances brand reputation.

By focusing on sustainability, B2B buyers can contribute to a healthier planet while meeting the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The dental implants sector has evolved significantly since the first successful implant procedures in the 1960s. Initially dominated by metal materials, the industry has transitioned towards the use of advanced ceramics and biocompatible materials, enhancing patient outcomes and recovery times. The introduction of computer-assisted design and manufacturing (CAD/CAM) in the late 20th century marked a turning point, allowing for customized implants and better fitting. Today, the sector is not only focused on technological advancements but also on sustainability and ethical sourcing, reflecting a broader trend within the global B2B landscape towards responsible business practices. This evolution highlights the importance of adapting to market demands and consumer expectations, providing B2B buyers with opportunities to differentiate their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of recovery from dental implants

-

What criteria should I use to vet suppliers for dental implant recovery products?

When vetting suppliers, prioritize their experience in the dental industry and their track record with international buyers. Look for certifications such as ISO 13485 for quality management in medical devices. Additionally, consider their production capabilities, including technology used and workforce expertise. Request references from previous clients, particularly those in your target regions, to gauge reliability and product efficacy. A transparent communication process and willingness to accommodate customization requests are also key indicators of a reputable supplier. -

Can I customize dental implant recovery products to suit my market needs?

Yes, many suppliers offer customization options for dental implant recovery products, including variations in materials, sizes, and packaging. When discussing customization, be clear about your specific needs and market regulations. It’s beneficial to collaborate closely with suppliers during the design phase to ensure compliance with local standards in your region. Always request prototypes before finalizing orders to assess the product’s suitability for your target audience. -

What are the typical minimum order quantities (MOQs) and lead times for dental implant recovery products?

MOQs can vary significantly among suppliers, often depending on the product type and customization level. For standard products, MOQs might range from 50 to 500 units, while customized items may require larger orders. Lead times typically range from 4 to 12 weeks, depending on production schedules and shipping logistics. Discussing these parameters upfront can help manage expectations and facilitate better planning for your inventory and sales strategies.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely based on the supplier’s policies and the buyer’s negotiation. Common practices include advance payments, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods like PayPal or bank transfers to mitigate risks. Always clarify payment terms in the contract to avoid misunderstandings. Building a good relationship with your supplier may also allow for more favorable terms over time. -

How can I ensure quality assurance and compliance with certifications?

To ensure quality assurance, request documentation of the supplier’s compliance with international standards, such as CE marking in Europe or FDA approval in the U.S. Regular audits and inspections can also be part of your quality assurance strategy. Establish a quality control protocol that includes testing samples from each batch before distribution. Additionally, consider using third-party inspection services for added assurance, especially for large orders or new suppliers. -

What logistics considerations should I keep in mind when importing dental implant recovery products?

Logistics plays a critical role in the timely delivery of dental implant recovery products. Assess the supplier’s shipping capabilities, including preferred shipping methods, customs handling, and delivery timelines. Research local import regulations in your target market to avoid compliance issues. Partnering with experienced freight forwarders can streamline the import process, ensuring that products arrive safely and on time. Always factor in potential delays due to customs clearance or transportation disruptions. -

What should I do if I encounter a dispute with my supplier?

Disputes can arise over quality, delivery, or payment issues. The first step is to communicate directly with the supplier to resolve the matter amicably. Document all interactions and agreements for reference. If the issue remains unresolved, consider mediation or arbitration as outlined in your contract. Having a clear dispute resolution process in place can save time and resources. Additionally, establishing a good relationship with suppliers can often prevent disputes from escalating. -

How can I stay updated on trends and innovations in dental implant recovery products?

To stay informed on trends and innovations, subscribe to industry publications and join relevant professional associations. Attend trade shows and conferences, both in-person and virtually, to network with suppliers and industry experts. Online platforms like LinkedIn can also be valuable for connecting with thought leaders and following discussions on new technologies. Engaging in continuous education through webinars or courses can further enhance your understanding of the evolving landscape of dental implant recovery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for recovery from dental implants

In summary, the recovery process from dental implants presents a unique opportunity for international B2B buyers to enhance their sourcing strategies. Key takeaways include the importance of understanding regional market dynamics, the necessity of collaborating with reliable suppliers, and the value of maintaining high standards in product quality. By strategically sourcing dental implant materials and services, businesses can not only improve patient outcomes but also optimize their operational efficiency.

Strategic sourcing plays a crucial role in navigating the complexities of the dental implant market. By leveraging partnerships with reputable manufacturers and suppliers, companies can ensure access to innovative technologies and competitive pricing. Additionally, being aware of local regulations and industry standards in diverse markets such as Africa, South America, the Middle East, and Europe will empower buyers to make informed decisions that align with their business goals.

As we look to the future, it is essential for international B2B buyers to embrace adaptability and innovation in their sourcing strategies. By doing so, they can position themselves favorably in a rapidly evolving market and contribute to improved recovery outcomes for patients worldwide. Take action today—evaluate your sourcing strategies and strengthen your partnerships to capitalize on the growth opportunities in the dental implant sector.