Introduction: Navigating the Global Market for dental implant material

In today’s global marketplace, the demand for high-quality dental implant materials is surging, driven by an increasing focus on dental health and aesthetics. For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of dental implant materials is crucial for making informed sourcing decisions. The choice of materials not only impacts the success of dental procedures but also influences patient satisfaction and clinic reputation.

This comprehensive guide aims to equip international buyers with the insights needed to navigate this complex landscape. It covers a wide range of topics including the various types of dental implant materials, their manufacturing processes, and stringent quality control measures that ensure reliability and safety. Additionally, we will provide an overview of leading suppliers and their offerings, alongside an analysis of cost structures and market trends that can affect purchasing decisions.

By delving into frequently asked questions, this guide will address common concerns and highlight best practices in sourcing dental implant materials. Ultimately, it serves as a vital resource for businesses looking to enhance their procurement strategies, minimize risks, and capitalize on opportunities in the global dental market. Empowering yourself with this knowledge will not only streamline your purchasing process but also position your business for success in an increasingly competitive environment.

Understanding dental implant material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Implants | Highly biocompatible, strong, and lightweight | General dentistry, oral surgery | Pros: Excellent durability; Cons: Higher cost |

| Zirconia Implants | Ceramic-based, aesthetic appeal, metal-free | Cosmetic dentistry, sensitive patients | Pros: Natural appearance; Cons: Less durable than titanium |

| Polymer Implants | Flexible, lightweight, and customizable | Temporary solutions, pediatric dentistry | Pros: Cost-effective; Cons: Limited longevity |

| Hybrid Implants | Combination of materials for enhanced performance | Advanced restorative procedures | Pros: Tailored properties; Cons: Complexity in sourcing |

| Resorbable Implants | Biodegradable, designed for temporary use | Short-term applications, research | Pros: No removal needed; Cons: Limited applications |

Titanium Implants

Titanium implants are the gold standard in dental implant technology due to their exceptional biocompatibility and mechanical strength. They are commonly used in general dentistry and oral surgery, making them a reliable choice for B2B buyers looking to invest in durable solutions. Buyers should consider the higher cost of titanium implants, but their longevity and reliability often justify the investment, especially in markets demanding high-quality dental care.

Zirconia Implants

Zirconia implants are a ceramic alternative to traditional titanium implants, offering aesthetic advantages due to their tooth-like appearance. They are particularly suitable for cosmetic dentistry and patients with metal sensitivities. B2B buyers should weigh the benefits of aesthetics against the potential for lower durability compared to titanium. The growing demand for metal-free options in regions like Europe and North America makes zirconia a compelling choice for innovative dental practices.

Polymer Implants

Polymer implants are lightweight and flexible, making them an attractive option for temporary solutions and pediatric dentistry. Their customizable nature allows for tailored applications, which can be beneficial for practices focusing on cost-effective solutions. However, B2B buyers should be aware of their limited longevity and consider the specific use case, particularly in markets where budget constraints are a primary concern.

Hybrid Implants

Hybrid implants combine different materials to optimize performance, catering to advanced restorative procedures. This versatility allows dental practitioners to address a range of patient needs effectively. For B2B buyers, the complexity in sourcing these specialized implants can be a challenge. However, the tailored properties of hybrid implants can significantly enhance patient outcomes, making them a worthwhile investment for innovative dental practices.

Resorbable Implants

Resorbable implants are designed for temporary applications, as they biodegrade over time, eliminating the need for removal. This characteristic makes them ideal for short-term treatments and research settings. While they may not suit all dental applications, their growing popularity in specific markets could present unique opportunities for B2B buyers focused on innovative solutions. Understanding the limitations and potential applications of resorbable implants is crucial for making informed purchasing decisions.

Related Video: Dental Implant Materials: What’s Best?

Key Industrial Applications of dental implant material

| Industry/Sector | Specific Application of dental implant material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Use of titanium and zirconia implants | Enhanced patient outcomes and satisfaction | Certification of materials, biocompatibility, and sourcing from reliable suppliers |

| Dental Laboratories | Fabrication of custom prosthetics | Increased precision in restorations | Quality control processes, advanced manufacturing capabilities, and lead times |

| Orthopedic Surgeons | Application in maxillofacial surgeries | Broadens treatment options for patients | Regulatory compliance, material certifications, and availability of various sizes |

| Medical Device Companies | Development of dental implant systems | Innovation in product offerings and market competitiveness | Research and development support, material sourcing, and intellectual property considerations |

| Educational Institutions | Training and research on implant materials | Advancement of dental education and practices | Partnerships with manufacturers for material supply, research funding, and access to new technologies |

Dental Clinics

Dental clinics utilize dental implant materials primarily for the placement of titanium or zirconia implants. These materials are favored for their biocompatibility and strength, providing a stable foundation for dental prosthetics. Clinics benefit from enhanced patient outcomes as these implants can significantly improve oral function and aesthetics. International buyers should ensure that the materials sourced meet stringent quality standards and certifications to minimize complications and ensure patient safety.

Dental Laboratories

Dental laboratories rely on high-quality dental implant materials to fabricate custom prosthetics such as crowns, bridges, and dentures. The precision offered by advanced materials leads to better-fitting restorations, which ultimately increases patient satisfaction and reduces remakes. Buyers in this sector should prioritize suppliers with robust quality control processes and advanced manufacturing capabilities to ensure consistent and reliable products.

Orthopedic Surgeons

In the realm of maxillofacial surgery, orthopedic surgeons employ dental implant materials to address complex dental issues, including jaw reconstruction and dental rehabilitation. The use of advanced materials allows for a wider range of treatment options, improving patient care. B2B buyers in this sector must consider the regulatory compliance of the materials and the availability of various sizes to cater to specific patient needs.

Medical Device Companies

Medical device companies are increasingly focusing on the development of innovative dental implant systems using advanced materials. The integration of new technologies and materials can enhance the functionality and performance of these implants, making them more appealing in a competitive market. Companies should engage with suppliers that offer comprehensive research and development support, as well as reliable material sourcing to drive innovation.

Educational Institutions

Educational institutions utilize dental implant materials for training and research purposes, facilitating the development of future dental professionals. Access to high-quality materials is crucial for effective hands-on training and advancing research in implant technology. Collaborations with manufacturers for material supply and research funding can greatly enhance educational programs and contribute to the evolution of dental practices.

Strategic Material Selection Guide for dental implant material

When selecting materials for dental implants, international B2B buyers must consider various factors that influence the performance, durability, and overall success of the implants. Below, we analyze four common materials used in dental implants: titanium, zirconia, stainless steel, and PEEK (Polyether Ether Ketone). Each material has distinct properties, advantages, and limitations that can significantly impact application and compliance with international standards.

Titanium

Key Properties: Titanium is renowned for its excellent biocompatibility, high strength-to-weight ratio, and corrosion resistance. It can withstand the physiological conditions in the oral cavity, including temperature fluctuations and mechanical stress.

Pros & Cons: Titanium implants are highly durable and have a long track record of successful integration with bone (osseointegration). However, they can be relatively expensive, and the manufacturing process may involve complex techniques like machining or additive manufacturing.

Impact on Application: Titanium is compatible with various media, including saline solutions and oral fluids, making it suitable for long-term use in dental applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with standards such as ASTM F136 for titanium alloys. The availability of titanium implants may vary, so sourcing from reputable manufacturers is crucial.

Zirconia

Key Properties: Zirconia is a ceramic material known for its aesthetic appeal, high strength, and excellent wear resistance. It also exhibits good biocompatibility and is less prone to corrosion.

Pros & Cons: The primary advantage of zirconia implants is their tooth-like appearance, which is particularly appealing for anterior teeth. However, they can be more brittle than titanium, making them less suitable for high-stress applications. Additionally, zirconia implants may have a higher upfront cost.

Impact on Application: Zirconia is compatible with oral fluids and has been shown to resist plaque accumulation, which can enhance long-term outcomes.

Considerations for International Buyers: Compliance with ISO 6872 standards is essential for zirconia implants. Buyers should also consider the local market’s acceptance of zirconia versus titanium, as preferences may vary by region.

Stainless Steel

Key Properties: Stainless steel is an alloy known for its strength, ductility, and resistance to corrosion. It is often used in temporary implants or as a component in hybrid systems.

Pros & Cons: Stainless steel is cost-effective and easy to manufacture, making it a popular choice for temporary solutions. However, it lacks the long-term biocompatibility of titanium and zirconia and may corrode over time, which can lead to complications.

Impact on Application: While stainless steel is suitable for temporary applications, its compatibility with oral fluids is limited compared to titanium and zirconia.

Considerations for International Buyers: Buyers should ensure compliance with ASTM F138 for stainless steel used in surgical implants. The cost-effectiveness of stainless steel may appeal to markets in Africa and South America, where budget constraints are common.

PEEK (Polyether Ether Ketone)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties, chemical resistance, and biocompatibility. It can withstand high temperatures and is often used in applications requiring flexibility.

Pros & Cons: PEEK implants offer a lightweight alternative to metal implants and can be manufactured with lower complexity. However, they may not provide the same level of osseointegration as titanium, which can limit their use in certain applications.

Impact on Application: PEEK is compatible with various biological environments and can be used in conjunction with other materials to enhance performance.

Considerations for International Buyers: Compliance with ISO 10993 for biocompatibility is crucial for PEEK implants. Buyers should also consider the regulatory landscape in their respective regions, as acceptance of polymer-based implants may vary.

Summary Table

| Material | Typical Use Case for dental implant material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent dental implants | Excellent osseointegration | Higher manufacturing complexity | High |

| Zirconia | Aesthetic anterior implants | Tooth-like appearance | Brittle, higher upfront cost | Medium |

| Stainless Steel | Temporary implants or hybrid systems | Cost-effective, easy to manufacture | Limited long-term biocompatibility | Low |

| PEEK | Flexible or hybrid implants | Lightweight, lower manufacturing complexity | Limited osseointegration | Medium |

This guide provides a structured approach to selecting dental implant materials, emphasizing the importance of understanding the specific needs and regulatory requirements of international markets. By considering these factors, B2B buyers can make informed decisions that align with their business objectives and customer expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implant material

Dental implants are a critical component in restorative dentistry, and their manufacturing process is vital to ensuring their safety and efficacy. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of manufacturing and quality assurance is essential for making informed procurement decisions.

Manufacturing Processes for Dental Implant Material

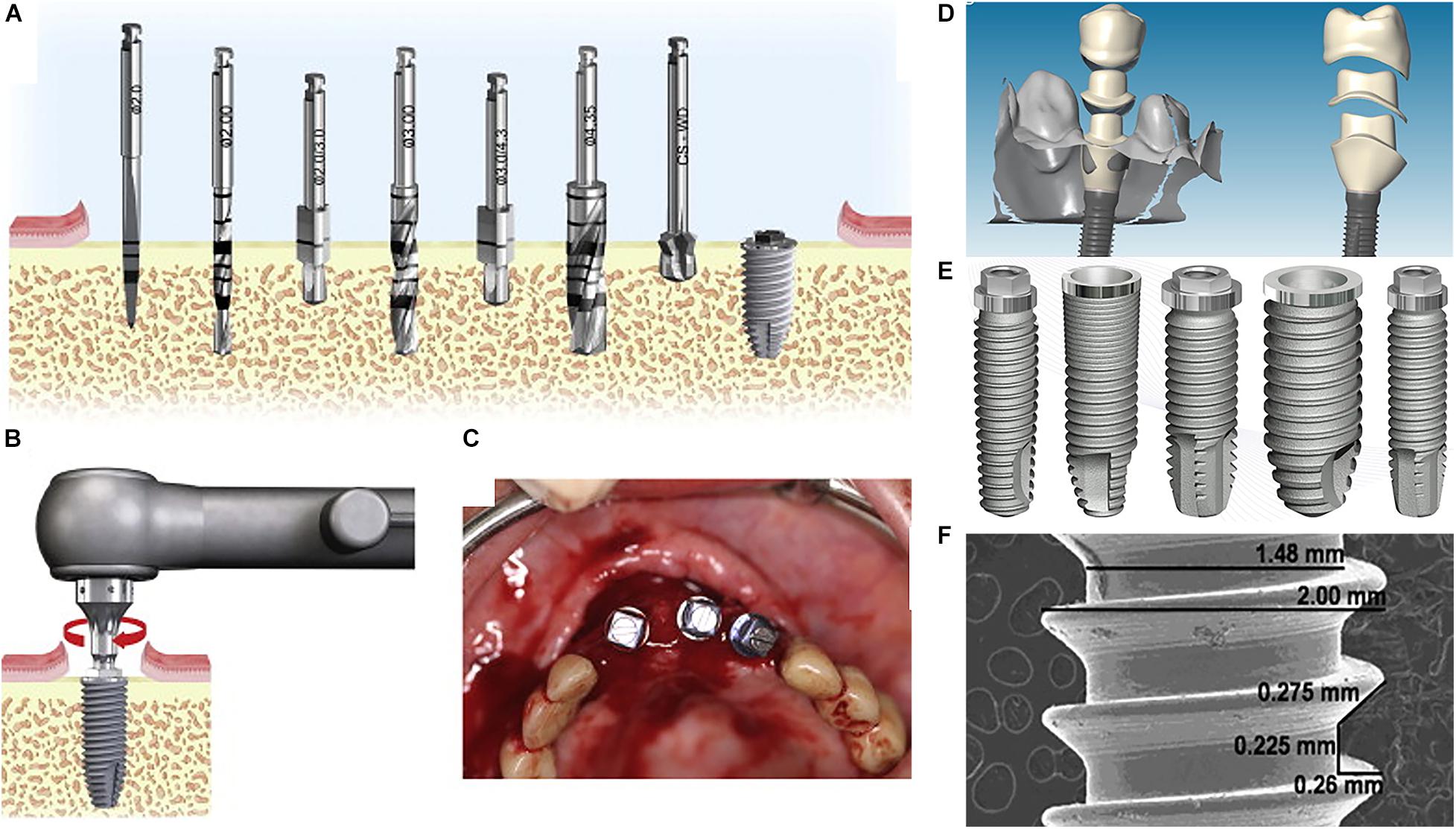

The manufacturing of dental implant materials typically involves several key stages:

1. Material Preparation

The first stage involves selecting high-quality raw materials, which are often titanium or zirconia due to their biocompatibility and strength. The materials undergo rigorous purification processes to remove impurities that could affect performance.

Key Techniques:

– Powder Metallurgy: Involves the mixing of metal powders, compacting them into a desired shape, and then sintering at high temperatures to achieve solidification.

– CNC Machining: Computer Numerical Control (CNC) machines are used to precisely shape the implant components, ensuring high dimensional accuracy.

2. Forming

After preparation, the next step is forming the dental implants. This can be done through various methods depending on the design specifications.

Key Techniques:

– Injection Molding: Used for creating complex shapes by injecting molten material into a mold.

– Casting: Suitable for simpler designs where the material is poured into a mold and allowed to solidify.

3. Assembly

In cases where implants consist of multiple components, assembly is the next step. This can include the integration of abutments or other attachments.

Key Techniques:

– Laser Welding: Provides a strong bond between components while minimizing thermal distortion.

– Screw-Fitting: Ensures secure attachment of various parts with precision.

4. Finishing

The final stage involves surface treatments to enhance the implants’ properties and ensure compatibility with biological tissues.

Key Techniques:

– Sandblasting: Increases surface roughness, promoting osseointegration.

– Anodizing: Used to enhance corrosion resistance and improve biocompatibility.

Quality Assurance (QA) in Dental Implant Manufacturing

Quality assurance is integral to the manufacturing of dental implants. International standards and industry-specific certifications play a crucial role in ensuring that products are safe and effective.

Relevant International Standards

- ISO 9001: This standard ensures that the manufacturing process meets quality management requirements.

- ISO 13485: Specifically for medical devices, this standard ensures that manufacturers comply with regulatory requirements.

- CE Marking: Required in Europe, indicating that the product meets EU safety, health, and environmental protection standards.

Industry-Specific Certifications

- API (American Petroleum Institute): While primarily related to the oil industry, some aspects of API standards can apply to manufacturing processes.

- FDA Approval: In the U.S., dental implants must be approved by the Food and Drug Administration, ensuring safety and efficacy.

Quality Control Checkpoints

Quality control (QC) is essential at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials before production begins to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify any deviations in real-time.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify compliance with quality standards before shipment.

Common Testing Methods

B2B buyers should be aware of the testing methods used to ensure the quality of dental implants:

- Mechanical Testing: Evaluates the strength and durability of the material under various conditions.

- Biocompatibility Testing: Assesses the material’s interaction with biological systems, ensuring safety for patients.

- Sterility Testing: Ensures that the implants are free from pathogens that could cause infections.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from regions with varying regulatory environments, verifying a supplier’s QC processes is critical. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insight into the supplier’s manufacturing practices and compliance with international standards.

-

Request Quality Reports: Suppliers should provide documentation of their QC processes, including test results and compliance certifications.

-

Engage Third-Party Inspectors: Utilizing independent inspectors can help validate the quality and safety of the products being procured.

Quality Control and Certification Nuances

Navigating QC and certification can be complex for international buyers. Here are some nuances to consider:

-

Regional Regulations: Buyers must be aware of local regulations that may differ from international standards. For instance, while CE marking is essential in Europe, other regions may have different requirements.

-

Language Barriers: Documentation may not always be available in English. Buyers should ensure they have access to translated quality reports and certifications.

-

Cultural Differences: Understanding the business practices and quality expectations in different regions can facilitate smoother negotiations and partnerships.

Conclusion

For B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe, a thorough understanding of the manufacturing processes and quality assurance protocols for dental implant materials is crucial. By focusing on these aspects, buyers can ensure they procure high-quality, reliable products that meet the needs of their markets and patients.

Related Video: SMART Quality Control for Manufacturing

Comprehensive Cost and Pricing Analysis for dental implant material Sourcing

Understanding the cost structure and pricing dynamics of dental implant material sourcing is crucial for international B2B buyers. This analysis will provide insight into the various cost components, influential pricing factors, and practical tips for negotiation and procurement, particularly tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components of Dental Implant Materials

-

Materials: The choice of materials significantly impacts the overall cost. Titanium and zirconia are the most commonly used materials in dental implants. Titanium, while more cost-effective, may have higher long-term benefits due to its biocompatibility. Consider sourcing from regions with established supply chains to reduce material costs.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the quality of workmanship. Skilled labor is crucial in ensuring the precision required for dental implants.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Manufacturers in regions with high overhead may pass these costs onto buyers, so understanding the manufacturing environment can inform sourcing decisions.

-

Tooling: The initial setup costs for manufacturing dental implants can be substantial. Tooling costs should be factored into the price, especially for custom or specialized implants. Buyers should inquire about tooling amortization to gauge the potential for lower prices on repeat orders.

-

Quality Control (QC): Rigorous QC processes are essential in the dental industry to meet regulatory standards. High-quality QC can increase manufacturing costs, but it ensures the reliability and safety of the products. Buyers should prioritize suppliers who demonstrate robust QC measures.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling play a significant role in the total cost. Consider the distance from the supplier and the complexity of the logistics involved, including customs clearance, tariffs, and insurance.

-

Margin: Supplier margins vary widely based on market positioning and competition. Understanding the market landscape can help buyers negotiate better pricing by leveraging supplier competition.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Establishing a long-term relationship with suppliers can also lead to favorable pricing on larger orders.

-

Specifications and Customization: Customized implants may incur additional costs due to design and production complexity. Standardized products typically offer better pricing, so evaluate whether customization is necessary for your needs.

-

Materials and Quality Certifications: The presence of certifications (e.g., ISO, CE) adds value and can justify higher prices. However, be cautious of suppliers who cannot provide such certifications, as they may compromise quality.

-

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers with a track record of quality and compliance may command higher prices but often provide greater assurance in product performance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is vital for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping and insurance, impacting the overall cost structure.

Buyer Tips

-

Negotiation Strategies: Buyers should approach negotiations with a clear understanding of their needs and market conditions. Leverage competitive offers to negotiate better terms and pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential replacement costs. This broader perspective can lead to more informed sourcing decisions.

-

Pricing Nuances: Be aware of regional pricing differences. For example, while European suppliers may offer higher quality, they may also come with higher price tags. Conversely, suppliers from Africa and South America may provide more competitive pricing but may require additional scrutiny regarding quality.

Disclaimer

Prices for dental implant materials can fluctuate due to market conditions, exchange rates, and changes in supply chain dynamics. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential dental implant material Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dental implant material’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dental implant material

Key Technical Properties of Dental Implant Materials

When sourcing dental implant materials, understanding their technical properties is crucial for ensuring quality, compatibility, and performance. Here are some essential specifications:

-

Material Grade

– Definition: This refers to the classification of materials based on their composition and mechanical properties. Common grades for dental implants include titanium alloys (e.g., Ti-6Al-4V) and zirconia.

– Importance: Selecting the appropriate material grade is vital for ensuring biocompatibility and mechanical strength. Higher-grade materials typically offer better resistance to corrosion and wear, which is essential in dental applications. -

Tensile Strength

– Definition: Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure.

– Importance: A higher tensile strength in dental implants translates to better durability and longevity. For B2B buyers, understanding tensile strength helps in evaluating the reliability of the implant under functional loads. -

Surface Roughness

– Definition: This is a measure of the texture of a surface, quantified by the average roughness (Ra) value. Implant surfaces can be smooth or treated for enhanced osseointegration.

– Importance: The surface roughness affects the biological response of the implant in the body. Implants with optimized surface roughness promote better bone integration, which is critical for long-term success. -

Porosity

– Definition: Porosity refers to the percentage of void spaces in a material, affecting its mechanical properties and biological performance.

– Importance: Controlled porosity can enhance the bone-implant interface, facilitating osseointegration. Buyers should consider porosity levels to ensure the implant meets specific clinical requirements. -

Fatigue Strength

– Definition: This property indicates the material’s ability to withstand repeated loading and unloading cycles without failure.

– Importance: High fatigue strength is crucial for dental implants that will experience cyclical forces from chewing. Understanding this property helps buyers select implants that will maintain integrity over time.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers who adhere to high manufacturing standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory planning, especially for smaller practices or startups. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: Submitting a well-structured RFQ can streamline the procurement process, ensuring that buyers receive competitive pricing and terms. -

Incoterms (International Commercial Terms)

– Definition: These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management, which is crucial in international trade. -

Lead Time

– Definition: Lead time is the amount of time it takes from placing an order to receiving the product.

– Importance: Understanding lead times aids in planning and inventory management, ensuring that dental practices have the necessary materials when needed.

By grasping these technical properties and terminology, B2B buyers in the dental implant market can make informed decisions, fostering successful partnerships and ensuring optimal outcomes for their practices.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implant material Sector

Market Overview & Key Trends

The dental implant material sector is experiencing robust growth, driven by increasing demand for dental procedures, advancements in technology, and a rising emphasis on aesthetics and functionality. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The global market is projected to expand significantly, with a CAGR of around 7-8% over the next five years, influenced by the aging population and a surge in dental tourism.

Emerging trends such as digital dentistry, 3D printing, and bioactive materials are transforming the sourcing landscape. Digital technologies streamline production and enhance customization, allowing for tailored solutions that meet specific regional market needs. Moreover, 3D printing is revolutionizing the way dental implants are produced, enabling rapid prototyping and reducing lead times, which is particularly advantageous for B2B buyers requiring quick turnaround times.

International buyers should also be aware of the increasing integration of Artificial Intelligence (AI) in the supply chain, which optimizes inventory management and demand forecasting. Additionally, the rise of e-commerce platforms tailored for dental products facilitates easier access to global suppliers, enabling buyers in regions like South Africa and Kenya to source high-quality materials efficiently.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a key consideration in the dental implant material sector. The environmental impact of sourcing and production processes is under scrutiny, prompting many companies to adopt sustainable practices. For B2B buyers, this means prioritizing suppliers who utilize eco-friendly materials and processes. Look for certifications such as ISO 14001, which indicates effective environmental management systems, or materials that meet the requirements for green certifications.

Ethical sourcing is equally important; buyers should ensure that their supply chains are transparent and socially responsible. This includes verifying that suppliers adhere to fair labor practices and sustainable extraction methods. A commitment to ethical sourcing not only enhances brand reputation but also meets the growing consumer demand for responsible products.

Furthermore, as regulations around sustainability tighten globally, being proactive in sourcing sustainable materials can offer a competitive edge. Buyers should engage with suppliers who are innovating in this space, such as those developing biodegradable or recyclable dental implant materials, aligning with the broader goals of sustainability in healthcare.

Brief Evolution/History

The evolution of dental implant materials dates back to the mid-20th century, with the introduction of titanium as a suitable material due to its biocompatibility and strength. Over the decades, advancements have led to the development of various materials, including ceramics and polymers, aimed at improving aesthetics and functionality. The shift towards minimally invasive procedures and the integration of technology in implantology have further transformed the market.

Today, the focus is not only on the physical properties of materials but also on their environmental and ethical implications. As B2B buyers navigate this landscape, understanding the historical context helps in appreciating current innovations and making informed sourcing decisions. Engaging with suppliers who are at the forefront of these developments can provide significant advantages in meeting market demands effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of dental implant material

-

What criteria should I use to vet suppliers of dental implant materials?

When vetting suppliers, consider their industry experience, certifications, and reputation. Look for suppliers that hold relevant certifications such as ISO 13485, which indicates compliance with quality management systems for medical devices. Additionally, assess their product portfolio and customer reviews to gauge reliability. Request references from other international buyers to understand their service levels. It’s also prudent to verify their financial stability to ensure they can meet long-term supply commitments. -

Can I customize dental implant materials to meet specific needs?

Yes, many suppliers offer customization options for dental implant materials. This could include variations in size, shape, and material composition based on your requirements. When discussing customization, provide detailed specifications and ask about the supplier’s capabilities to meet those specifications. Additionally, inquire about the costs and lead times associated with customization, as these can vary significantly among suppliers. -

What are typical minimum order quantities (MOQ) and lead times for dental implant materials?

Minimum order quantities can vary widely based on the supplier and the type of dental implant materials. Generally, MOQs can range from 100 to 1,000 units. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. Always clarify these terms upfront and consider negotiating them based on your purchasing volume or establishing a long-term relationship. -

What payment terms should I expect when sourcing dental implant materials?

Payment terms can differ between suppliers, but common practices include upfront deposits (often 30-50%) and the balance upon delivery or before shipment. Ensure to discuss and agree on payment methods, which may include letters of credit, wire transfers, or payment through online platforms. Be cautious with suppliers that demand full payment upfront without a solid track record, as this can increase financial risk. -

How important are quality assurance certifications for dental implant materials?

Quality assurance certifications are crucial in the dental implant sector as they ensure that materials meet stringent safety and efficacy standards. Look for suppliers that are certified by recognized bodies such as the FDA in the U.S. or CE marking in Europe. These certifications not only enhance product credibility but also reduce the risk of compliance issues in your target markets. Request copies of these certifications for your records. -

What logistical considerations should I keep in mind when importing dental implant materials?

Logistics plays a vital role in the procurement process. Consider factors such as shipping methods, customs regulations, and potential tariffs when importing dental implant materials. Work with suppliers that have experience in international shipping to ensure compliance with local regulations. Additionally, establish a clear timeline for delivery and discuss who will be responsible for handling customs clearance to avoid unexpected delays. -

How can I resolve disputes with suppliers effectively?

To resolve disputes, maintain clear communication and documentation throughout the procurement process. Establish a formal dispute resolution clause in your contract, outlining steps for mediation or arbitration should issues arise. If a dispute occurs, address it promptly and directly with the supplier. If necessary, involve third-party mediation services that specialize in international trade to facilitate a resolution. Maintaining a professional relationship can often help in resolving issues amicably. -

What should I do if the materials I receive do not meet my specifications?

If the materials received do not meet your specifications, first document the discrepancies with photographs and detailed descriptions. Contact the supplier immediately to discuss the issue and refer to your purchase agreement for guidance on returns or replacements. Many reputable suppliers have policies in place for handling such situations, but it’s essential to act quickly and maintain open lines of communication to facilitate a satisfactory resolution.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implant material

The strategic sourcing of dental implant materials is pivotal for B2B buyers looking to enhance their product offerings and maintain a competitive edge in the global marketplace. Key takeaways include the importance of establishing strong relationships with suppliers, understanding regional material regulations, and leveraging technological advancements in manufacturing processes. Buyers must prioritize quality and compliance, particularly when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Value of Strategic Sourcing

Investing in strategic sourcing not only reduces costs but also enhances supply chain resilience. By diversifying suppliers and fostering collaboration, businesses can mitigate risks associated with geopolitical tensions and market fluctuations. Additionally, embracing sustainability in sourcing practices can significantly improve brand reputation and customer loyalty.

Looking Ahead

As the dental implant market continues to evolve, international buyers should stay informed about emerging trends and innovations. Engaging in continuous market research and attending industry conferences can provide valuable insights. As you navigate this dynamic landscape, take proactive steps to align your sourcing strategies with your long-term business goals. The future is bright for those who adapt and innovate—seize the opportunities ahead to ensure your success in the dental implant material sector.