Introduction: Navigating the Global Market for types of dental implants materials

Dental implants have revolutionized restorative dentistry, offering a reliable solution for replacing missing teeth. The choice of materials used in these implants is critical, as it directly affects their functionality, durability, and biocompatibility. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the landscape of dental implant materials is essential for making informed purchasing decisions.

This guide provides a comprehensive overview of the various types of dental implants and their associated materials. It explores the critical aspects of manufacturing processes and quality control measures, ensuring that buyers can source products that meet stringent safety and efficacy standards. Additionally, it highlights key suppliers in the global market, offering insights into cost considerations and market trends that can impact procurement strategies.

By delving into frequently asked questions, this guide empowers B2B buyers with the knowledge to navigate the complexities of sourcing dental implant materials. Whether you are looking to enhance your product offerings or ensure compliance with local regulations, this resource serves as a vital tool in making educated decisions that align with your business goals. Equip yourself with the insights necessary to thrive in the competitive dental implant market and meet the evolving needs of your clientele.

Understanding types of dental implants materials Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Implants | High strength, lightweight, excellent biocompatibility | Dental clinics, oral surgeries | Pros: Durable, proven track record. Cons: Higher cost. |

| Zirconia Implants | Aesthetic appeal, metal-free, good biocompatibility | Cosmetic dentistry, aesthetic practices | Pros: Natural appearance, less allergic reactions. Cons: Less strength than titanium. |

| Ceramic Implants | Non-metallic, bioactive properties | Specialty clinics, holistic practices | Pros: Biocompatible, promotes bone integration. Cons: Fragile, limited applications. |

| PEEK Implants | Polymer-based, flexible, and radiolucent | Advanced implantology, research settings | Pros: Lightweight, good stress distribution. Cons: Lower mechanical strength. |

| Composite Implants | Combination of materials for enhanced properties | Custom implant solutions, specific cases | Pros: Tailored properties, versatile. Cons: Complexity in manufacturing. |

Titanium Implants

Titanium implants are the most widely used type due to their exceptional strength and biocompatibility. They can withstand the forces of mastication and integrate well with bone, making them suitable for a variety of dental applications, including single-tooth replacements and full arch restorations. For B2B buyers, the proven track record of titanium implants is a significant advantage; however, they often come at a higher price point, which is an important consideration for budget-conscious practices.

Zirconia Implants

Zirconia implants are increasingly popular in aesthetic dentistry due to their tooth-like appearance and metal-free composition. They offer excellent biocompatibility and are less likely to cause allergic reactions, making them a suitable choice for patients with metal sensitivities. B2B buyers should consider the aesthetic benefits when sourcing these implants, although it’s essential to note that they may not provide the same level of strength as titanium options, which can limit their application in certain cases.

Ceramic Implants

Ceramic implants are non-metallic and possess bioactive properties that promote bone integration. They are particularly suited for patients seeking holistic or metal-free options. The biocompatibility and aesthetic qualities make them appealing for cosmetic procedures. However, B2B buyers should be aware that ceramic implants can be fragile and may not be appropriate for all clinical situations, necessitating careful patient selection and application.

PEEK Implants

PEEK (Polyether ether ketone) implants are polymer-based and offer unique advantages, such as being lightweight and radiolucent. They provide flexibility, which can aid in stress distribution during biting. These implants are particularly useful in advanced implantology and research settings. Buyers should consider the specific mechanical properties of PEEK, as they may not match the strength of titanium, potentially limiting their use in load-bearing applications.

Composite Implants

Composite implants combine various materials to enhance their properties, allowing for tailored solutions to meet specific clinical needs. This versatility can be beneficial for practices that require customized implant solutions. However, the complexity involved in manufacturing composite implants can lead to higher costs and longer lead times, which are critical factors for B2B buyers to consider when planning their inventory and procurement strategies.

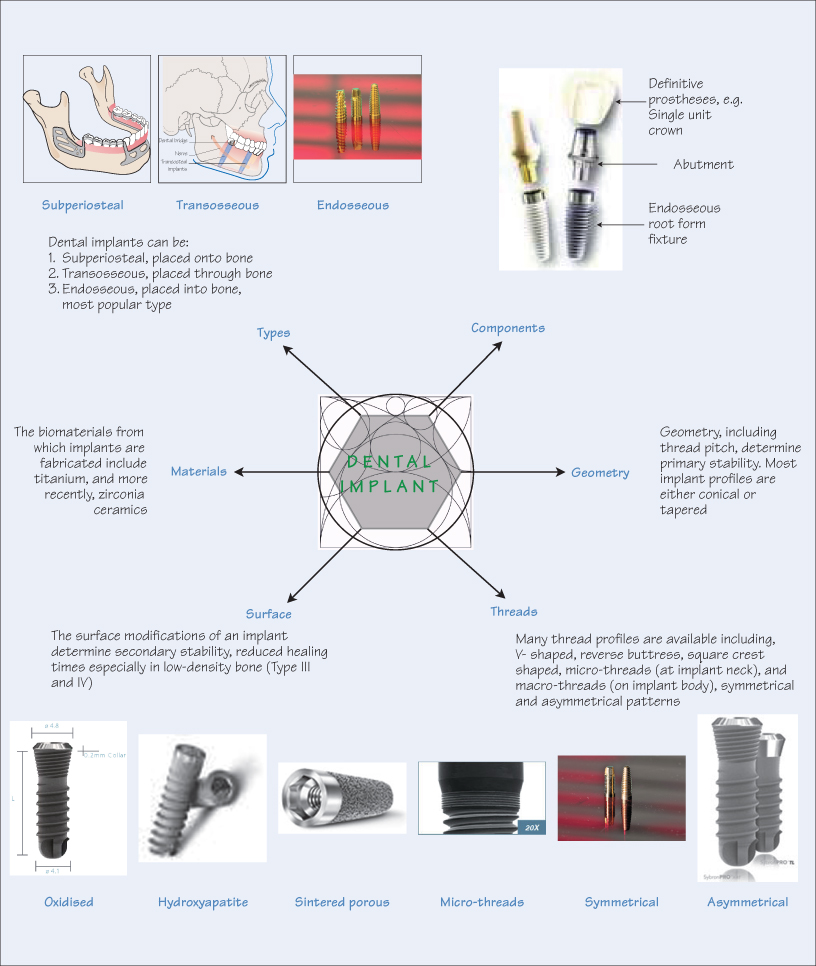

Related Video: 3 Types of Dental Implants and Surface treatments explained!

Key Industrial Applications of types of dental implants materials

| Industry/Sector | Specific Application of types of dental implants materials | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Healthcare | Production of titanium and zirconia dental implants | High biocompatibility and durability, leading to better patient outcomes | Ensure compliance with international health regulations and standards |

| Dental Laboratories | Custom implant fabrication using additive manufacturing | Rapid prototyping and tailored solutions for specific patient needs | Access to advanced manufacturing technologies and skilled technicians |

| Orthodontics and Prosthodontics | Use of hybrid materials for implant-supported dentures | Enhanced aesthetics and functionality, improving patient satisfaction | Sourcing materials that meet both aesthetic and functional requirements |

| Research and Development | Material testing and innovation in implant technology | Staying ahead of market trends and improving product offerings | Collaboration with academic institutions and research grants |

| Dental Equipment Manufacturing | Integration of dental implants into surgical tools and devices | Streamlined surgical procedures and improved operational efficiency | Quality assurance in material sourcing and adherence to manufacturing standards |

Applications in Detail

Dental Healthcare

In the dental healthcare sector, titanium and zirconia are the primary materials used for dental implants. Their high biocompatibility ensures that they integrate well with bone, reducing the risk of rejection and complications. B2B buyers from regions such as Africa and South America should prioritize suppliers who comply with international health regulations, such as ISO standards, to ensure the safety and efficacy of implants.

Dental Laboratories

Dental laboratories increasingly leverage additive manufacturing technologies to create custom dental implants tailored to individual patient anatomies. This approach allows for rapid prototyping and the production of complex designs that traditional methods cannot achieve. Buyers must consider sourcing advanced 3D printing technologies and skilled technicians to ensure high-quality output and meet the specific needs of dental professionals in their regions.

Orthodontics and Prosthodontics

The use of hybrid materials in implant-supported dentures is gaining traction in orthodontics and prosthodontics. These materials offer a balance of aesthetics and functionality, enhancing the visual appeal of dental solutions while ensuring durability under masticatory forces. International buyers should focus on sourcing materials that not only meet aesthetic demands but also comply with local regulations to ensure patient safety.

Research and Development

Within the realm of research and development, the focus is on testing new materials and technologies to improve dental implants. Companies engaged in R&D can gain a competitive edge by innovating and adapting to emerging trends. Collaborating with academic institutions or securing research grants can provide access to cutting-edge insights and technology, which is vital for maintaining relevance in the dental market.

Dental Equipment Manufacturing

In the dental equipment manufacturing sector, integrating high-quality dental implants into surgical tools and devices can significantly streamline surgical procedures. This integration enhances operational efficiency and improves patient outcomes. Buyers in this space should ensure that their material sourcing aligns with strict manufacturing standards to maintain product quality and safety.

Strategic Material Selection Guide for types of dental implants materials

When selecting materials for dental implants, it is crucial for B2B buyers to understand the properties, advantages, disadvantages, and specific applications of each material. Here, we analyze four common materials used in dental implants: Titanium, Zirconia, Stainless Steel, and Polyether Ether Ketone (PEEK).

Titanium

Key Properties: Titanium is known for its excellent biocompatibility, corrosion resistance, and high strength-to-weight ratio. It can withstand the harsh oral environment, including exposure to saliva and varying pH levels.

Pros & Cons: Titanium implants are durable and have a long history of successful use in dentistry. They are relatively easy to manufacture, but the cost can be high compared to other materials. Additionally, while titanium is strong, it can be prone to wear over time, especially under heavy masticatory forces.

Impact on Application: Titanium is compatible with bone integration, making it ideal for load-bearing applications. Its properties allow for osseointegration, which is critical for the longevity of dental implants.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloys. In regions like Europe and the Middle East, CE marking is essential for market entry.

Zirconia

Key Properties: Zirconia is a ceramic material known for its aesthetic appeal and high strength. It offers good resistance to wear and corrosion, making it suitable for long-term dental applications.

Pros & Cons: The primary advantage of zirconia is its tooth-like appearance, which makes it a preferred choice for visible areas. However, zirconia implants can be more brittle than titanium, leading to potential fracture under excessive force. Manufacturing zirconia implants can also be more complex and costly.

Impact on Application: Zirconia is particularly effective in anterior restorations where aesthetics are paramount. Its non-metallic nature makes it suitable for patients with metal allergies.

Considerations for International Buyers: Compliance with ISO 6872 and other relevant standards is necessary. Buyers in Europe should also consider the implications of the EU Medical Device Regulation (MDR) on zirconia products.

Stainless Steel

Key Properties: Stainless steel is a durable material known for its corrosion resistance and mechanical strength. It is often used in temporary dental implants or in pediatric dentistry.

Pros & Cons: The cost of stainless steel is relatively low, making it an economical choice for temporary solutions. However, it lacks the aesthetic qualities of titanium and zirconia and can corrode over time, especially in the oral environment.

Impact on Application: Stainless steel is suitable for short-term applications where cost is a significant factor. It is not recommended for permanent implants due to potential corrosion and aesthetic issues.

Considerations for International Buyers: Buyers should verify compliance with ASTM F138 and other relevant standards. In regions like Africa and South America, the lower cost may be appealing, but long-term implications must be considered.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer that offers excellent mechanical properties, chemical resistance, and biocompatibility. It is lightweight and can be customized for various applications.

Pros & Cons: PEEK’s flexibility and strength make it suitable for specific implant designs. However, it is less commonly used than metal implants, and its long-term performance in load-bearing applications is still under study. The cost of PEEK can also be higher than traditional materials.

Impact on Application: PEEK is particularly useful in cases where flexibility and shock absorption are needed. Its aesthetic properties are also beneficial for specific applications.

Considerations for International Buyers: Buyers should ensure compliance with ISO 10993 for biocompatibility. PEEK implants may require specific regulatory approvals in regions like Europe and the Middle East.

Summary Table

| Material | Typical Use Case for types of dental implants materials | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Load-bearing dental implants | Excellent biocompatibility | High cost, potential wear | High |

| Zirconia | Anterior restorations | Aesthetic appeal | Brittle, complex manufacturing | Med |

| Stainless Steel | Temporary implants | Low cost | Corrosion risk, poor aesthetics | Low |

| PEEK | Flexible implant designs | Lightweight, customizable | Higher cost, long-term performance uncertain | Med |

This guide provides a comprehensive overview of the materials available for dental implants, enabling B2B buyers to make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of dental implants materials

Manufacturing dental implants involves a series of intricate processes and stringent quality assurance measures. Understanding these stages can significantly enhance the purchasing decisions for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. Below is an overview of the typical manufacturing processes, quality control standards, and actionable insights for international buyers.

Manufacturing Processes for Dental Implants

-

Material Preparation

– The manufacturing process begins with selecting suitable materials, which are typically titanium, zirconia, or other biocompatible alloys.

– Key Techniques:- Powder Metallurgy: For titanium implants, titanium powder is often used, which undergoes a process of compaction and sintering.

- Additive Manufacturing: Techniques such as 3D printing are increasingly being utilized to create complex geometries that enhance osseointegration.

-

Forming

– Once the materials are prepared, the next stage involves shaping them into the desired implant form.

– Key Techniques:- CNC Machining: Computer Numerical Control (CNC) machines precisely cut and shape the implant components.

- Casting: This method is used for creating specific geometrical designs, particularly in zirconia implants.

-

Assembly

– After individual components are formed, they are assembled into a complete dental implant system.

– This may involve incorporating various parts, such as abutments and screws, which need to fit together securely to ensure stability and functionality. -

Finishing

– The final stage of manufacturing includes surface treatment processes to enhance the implant’s properties.

– Key Techniques:- Surface Coating: Techniques like sandblasting or acid etching are employed to increase surface roughness, which promotes better bone integration.

- Polishing: This process improves the aesthetic quality and reduces the risk of bacterial colonization.

Quality Assurance in Dental Implant Manufacturing

Quality assurance is critical in the dental implant industry, ensuring that products are safe, effective, and compliant with international standards.

-

International Standards

– ISO 9001: This general quality management standard ensures that organizations consistently meet customer and regulatory requirements.

– ISO 13485: Specifically tailored for medical devices, this standard focuses on the quality management systems that govern the design and manufacturing of dental implants.

– CE Marking: For European markets, obtaining a CE mark is essential, indicating that the product meets EU safety, health, and environmental protection requirements. -

Industry-Specific Standards

– FDA Regulations (USA): In the United States, dental implants must comply with FDA regulations, including the 510(k) premarket submission.

– MDSAP: The Medical Device Single Audit Program allows for a single audit to satisfy multiple regulatory requirements across different countries. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial phase checks raw materials against specifications before they enter the manufacturing process.

– In-Process Quality Control (IPQC): Ongoing inspections during manufacturing ensure that processes remain within acceptable limits.

– Final Quality Control (FQC): After assembly, each implant undergoes rigorous testing to verify that it meets all specifications and quality standards. -

Common Testing Methods

– Mechanical Testing: Includes tensile strength and fatigue testing to ensure the implants can withstand chewing forces.

– Biocompatibility Testing: This assesses how the implant interacts with biological systems, crucial for patient safety.

– Sterilization Validation: Ensures that the final product is free from contaminants, often verified through methods like ethylene oxide sterilization or gamma irradiation.

Verification of Supplier Quality Control

For B2B buyers, ensuring the quality of dental implants involves several verification strategies:

-

Audits

– Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and adherence to quality standards.

– Buyers should look for suppliers that are transparent about their quality management systems and willing to share audit results. -

Reports

– Requesting quality assurance reports, including IQC, IPQC, and FQC data, can offer additional assurance that the implants meet required standards. -

Third-Party Inspection

– Engaging third-party inspection services can help verify that the manufacturing processes and final products comply with international standards.

– This is especially important for buyers in regions with less stringent regulatory environments, such as parts of Africa and South America.

Navigating Quality Control Nuances

B2B buyers must be aware of the nuances in quality control across different regions:

- Africa: Regulatory frameworks may vary significantly; hence, it’s essential to verify local compliance and quality standards.

- South America: Understanding the specific requirements for each country, including ANVISA in Brazil, can streamline the import process.

- Middle East: Countries like Saudi Arabia have distinct regulations, necessitating a thorough understanding of local standards.

- Europe: European buyers should prioritize CE marking and compliance with EU regulations to ensure market access.

By comprehensively understanding the manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions that enhance the safety and efficacy of dental implants in their markets. Ensuring robust quality control not only protects patients but also reinforces the credibility of businesses operating within the dental implant sector.

Related Video: DENTAL IMPLANTS : TYPES, SURFACE TREATMENTS, why TITANIUM is used for making implants?

Comprehensive Cost and Pricing Analysis for types of dental implants materials Sourcing

When sourcing dental implant materials, international B2B buyers must navigate a complex cost structure and pricing model that can vary significantly based on multiple factors. Understanding these elements can lead to more informed purchasing decisions, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The cost of raw materials is one of the most significant factors in dental implant pricing. Common materials include titanium, zirconia, and polyether ether ketone (PEEK). The choice of material not only affects the price but also impacts the implant’s biocompatibility and longevity.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality control, and assembly. Regions with higher labor costs may see increased pricing, while countries with lower labor costs can offer more competitive rates.

-

Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, thus lowering overall prices.

-

Tooling: The initial setup for manufacturing dental implants requires specialized tooling. These costs can be substantial but are typically amortized over high-volume production runs.

-

Quality Control (QC): Ensuring that dental implants meet regulatory standards is crucial. The costs associated with quality assurance processes can vary significantly based on the certifications required (e.g., ISO 13485, CE marking).

-

Logistics: Shipping and handling costs are particularly important for international buyers. Variations in transport modes (air vs. sea), customs duties, and insurance can significantly affect the total cost.

-

Margin: Suppliers typically mark up their costs to maintain profitability. This margin can vary based on the supplier’s brand reputation, market demand, and competition.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can influence pricing. Higher volumes often lead to reduced per-unit costs, making bulk purchasing more economical.

-

Specifications/Customization: Custom implants tailored to specific needs can drive up costs. Buyers should weigh the necessity of customization against standard options.

-

Quality/Certifications: Implants that meet higher quality standards or possess certifications may command higher prices. Buyers must assess whether these certifications align with their market requirements.

-

Supplier Factors: The supplier’s location, reputation, and service level can impact pricing. Local suppliers may offer lower shipping costs but may not have the same range of materials as international options.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining responsibilities in shipping, insurance, and customs duties, all of which can affect the overall cost.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms with suppliers. Discussing volume discounts or long-term contracts can yield favorable pricing.

-

Cost-Efficiency: Evaluate suppliers based on total cost rather than just upfront prices. Consider logistics, warranty options, and after-sales support in your calculations.

-

Total Cost of Ownership (TCO): Understand that the initial purchase price is only part of the equation. Assess the long-term implications of your choice, including durability, potential replacement costs, and patient outcomes.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe may face unique challenges, including fluctuating currency rates and varying import tariffs. Ensure you factor these elements into your budget.

Disclaimer

Prices can vary widely based on specifications, market conditions, and supplier negotiations. This analysis provides indicative pricing and cost structures that should be validated with current market data and supplier quotes.

Essential Technical Properties and Trade Terminology for types of dental implants materials

Understanding the technical properties and trade terminology associated with dental implant materials is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances the ability to communicate effectively with suppliers and manufacturers.

Illustrative Image (Source: Google Search)

Essential Technical Properties

-

Material Grade

– Definition: Refers to the classification of materials based on their chemical composition and mechanical properties.

– B2B Importance: Different grades of titanium, for instance, are commonly used in dental implants, with Grade 4 being a standard for its strength and biocompatibility. Buyers must ensure they select the appropriate grade to meet specific clinical needs. -

Biocompatibility

– Definition: The ability of a material to perform with an appropriate host response when applied in a medical context.

– B2B Importance: Since dental implants are placed in the oral cavity, they must not elicit adverse reactions. Understanding biocompatibility helps buyers assess the safety of materials and comply with health regulations in different regions. -

Tensile Strength

– Definition: The maximum amount of tensile (pulling) stress a material can withstand before failure.

– B2B Importance: Implants must endure the forces generated during chewing. A higher tensile strength indicates a more durable product, which is critical for long-term success. Buyers should inquire about this property when sourcing implants. -

Surface Roughness

– Definition: A measure of the texture of a surface, typically quantified by the average roughness (Ra) value.

– B2B Importance: The surface texture of dental implants significantly influences osseointegration (the process by which bone fuses to the implant). Buyers should look for implants with optimized surface roughness to enhance stability and longevity. -

Porosity

– Definition: The presence of tiny holes or voids within a material, which can affect its mechanical properties and biological performance.

– B2B Importance: Controlled porosity can improve the integration of the implant with bone. Buyers should understand the implications of porosity when selecting materials, as it can influence healing and stability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– B2B Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure the quality of dental implants sourced from manufacturers. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Knowing the MOQ is essential for budgeting and inventory management. Buyers from regions with varying demand should negotiate MOQs that align with their purchasing capacity. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products.

– B2B Importance: An effective RFQ process allows buyers to compare offers from multiple suppliers, ensuring they secure the best pricing and terms for dental implant materials. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law.

– B2B Importance: Familiarity with Incoterms helps buyers understand their responsibilities regarding shipping, insurance, and tariffs, which is crucial for smooth cross-border transactions. -

Lead Time

– Definition: The amount of time that passes from the initiation of a process until its completion, particularly in production and delivery.

– B2B Importance: Buyers must consider lead time in their planning to ensure timely availability of dental implants for their operations, particularly in markets with high demand.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement processes, ensuring they source high-quality dental implant materials that meet both regulatory and clinical standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of dental implants materials Sector

Market Overview & Key Trends

The dental implants materials market is experiencing robust growth driven by rising global awareness of oral health and advancements in dental technology. Key drivers include an aging population, increasing disposable income in emerging markets, and the rising prevalence of dental diseases. In regions like Africa and South America, where oral health services are expanding, there is significant demand for affordable yet high-quality dental implants.

Emerging trends in B2B sourcing include the adoption of additive manufacturing (3D printing), which allows for customizable implants tailored to individual patient anatomy, enhancing patient outcomes. This technology is gaining traction due to its potential to reduce manufacturing costs and lead times, making it an attractive option for international buyers. Additionally, digital workflows in implantology are streamlining the processes from diagnosis to treatment planning, improving efficiency and accuracy.

International buyers, particularly from Europe, are increasingly focusing on supplier reliability and compliance with stringent regulations such as ISO standards and CE marking. The dynamics of the market also reflect a shift towards value-based purchasing, where cost-effectiveness is balanced with quality and innovation. Buyers are encouraged to engage with suppliers who demonstrate a commitment to continuous improvement and technological advancements in implant design and materials.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the sourcing of dental implant materials. The environmental impact of traditional manufacturing processes and the disposal of medical waste necessitate a shift towards more sustainable practices. International buyers are increasingly prioritizing suppliers who adopt eco-friendly manufacturing techniques and utilize biodegradable or recyclable materials in their products.

The importance of ethical supply chains cannot be overstated, especially in regions where labor practices may vary. Buyers should conduct due diligence to ensure that their suppliers adhere to fair labor practices and environmental regulations. Green certifications, such as ISO 14001 for environmental management, serve as indicators of a supplier’s commitment to sustainable practices. Utilizing materials with certifications like the Forest Stewardship Council (FSC) or Global Organic Textile Standard (GOTS) can also enhance a buyer’s credibility and marketability.

Incorporating sustainability into the procurement strategy not only meets regulatory expectations but also aligns with the growing consumer demand for responsible sourcing. This approach fosters brand loyalty and can lead to increased market share among environmentally conscious consumers.

Brief Evolution/History

The development of dental implants has evolved significantly since their inception over fifty years ago. Initially, materials such as stainless steel were commonly used; however, the introduction of titanium revolutionized the industry due to its superior biocompatibility and strength. Over the years, innovations such as ceramic implants and coated implants have emerged, offering aesthetic advantages and enhanced osseointegration.

Today, the focus is shifting towards not only improving the functionality and aesthetics of implants but also ensuring that the materials used are sustainable and ethically sourced. This evolution is crucial for B2B buyers who must navigate a landscape increasingly driven by consumer expectations for quality, safety, and environmental responsibility.

Frequently Asked Questions (FAQs) for B2B Buyers of types of dental implants materials

-

What criteria should I use to vet suppliers of dental implant materials?

When vetting suppliers, consider their certifications (such as ISO 13485 for medical devices), production capacity, and experience in the dental industry. Request product samples to assess quality, and check their compliance with international regulations like CE marking for Europe or FDA approval for the U.S. Additionally, gather references from existing clients to evaluate their reliability and service levels. Engaging in trade shows or industry forums can also provide insights into potential suppliers’ reputations. -

Can I customize dental implant materials according to my specifications?

Many suppliers offer customization options to meet specific requirements such as material type, dimensions, and surface treatments. It’s essential to communicate your needs clearly and verify the supplier’s capability to accommodate these specifications. Discuss potential design modifications during initial negotiations and inquire about any additional costs or lead times associated with customization. Establishing a collaborative relationship can facilitate smoother customization processes.

Illustrative Image (Source: Google Search)

-

What are the typical minimum order quantities (MOQs) and lead times for dental implant materials?

MOQs can vary significantly based on the supplier and the type of materials ordered. Commonly, MOQs for dental implants range from 50 to 500 units, depending on the complexity and customization of the order. Lead times typically range from 4 to 12 weeks, influenced by the production process and material availability. Always clarify these details upfront to ensure they align with your inventory and operational requirements. -

What payment terms should I expect when sourcing dental implant materials internationally?

Payment terms can differ by supplier and may include options such as advance payment, letters of credit, or net 30/60 terms. It’s advisable to negotiate favorable terms that minimize financial risk while ensuring supplier commitment. Be aware of currency exchange implications and consider using escrow services for larger transactions to protect both parties. Establishing clear payment schedules in your contract can help prevent disputes later on. -

How can I ensure quality assurance and compliance with certifications for dental implant materials?

Request detailed documentation of quality assurance processes from your suppliers, including their testing protocols and certifications. Suppliers should provide certificates of compliance for materials used in dental implants, confirming adherence to relevant standards. Consider conducting audits or inspections at the supplier’s facility if possible, or hiring third-party inspection services to verify quality before shipment. This diligence is crucial to maintaining high standards in your products. -

What logistics considerations should I keep in mind when importing dental implant materials?

Effective logistics management is vital for timely delivery and cost control. Assess shipping methods (air vs. sea) based on urgency and budget, and consider the implications of customs duties and tariffs in your calculations. Collaborate closely with your suppliers to ensure proper documentation is provided for customs clearance. It’s beneficial to partner with a logistics provider experienced in medical device shipping to navigate regulatory requirements smoothly. -

How should I handle disputes with suppliers regarding dental implant materials?

To minimize disputes, establish clear terms and conditions in your contract, including quality standards, delivery timelines, and payment terms. In the event of a disagreement, communicate openly with the supplier to understand their perspective and seek a mutually agreeable solution. If resolution is not possible, consider mediation or arbitration as outlined in your contract. Maintaining a professional relationship and documenting all communications can aid in resolving disputes effectively. -

What are the key regulatory considerations when sourcing dental implant materials for international markets?

Each region has its own regulatory framework for medical devices. For example, in Europe, compliance with the Medical Device Regulation (MDR) is essential, while in the U.S., the FDA’s approval process must be followed. Familiarize yourself with local regulations in your target markets, including labeling requirements and post-market surveillance. Engaging with suppliers knowledgeable about these regulations can streamline the compliance process and mitigate risks associated with market entry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of dental implants materials

In summary, strategic sourcing in the dental implant materials sector is pivotal for international buyers aiming to enhance their product offerings while optimizing costs. The diverse range of materials, including titanium, zirconia, and polymer composites, each presents unique advantages and challenges. By carefully evaluating the functionality, biocompatibility, and aesthetic appeal of these materials, buyers can make informed decisions that align with their market demands.

Key Takeaways:

– Evaluate Material Properties: Understand the mechanical and biological properties of different implant materials to select the most suitable options.

– Regulatory Compliance: Ensure that sourcing partners comply with local and international regulations, enhancing the safety and efficacy of dental implants.

– Innovative Manufacturing Techniques: Consider suppliers that utilize additive manufacturing technologies, which can offer customization and potentially lower costs.

Looking ahead, the dental implant industry is poised for growth, driven by advancements in material science and manufacturing techniques. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should actively engage with suppliers to leverage these innovations. By fostering strategic partnerships and staying abreast of market trends, businesses can position themselves competitively in this evolving landscape.