Introduction: Navigating the Global Market for dental implant glue

Navigating the global market for dental implant glue is increasingly crucial for B2B buyers in today’s dynamic dental industry. As the demand for dental implants rises, so does the necessity for high-quality adhesives that ensure longevity and reliability in dental procedures. Dental implant glue is a pivotal component that not only enhances the stability of dental fixtures but also directly impacts patient outcomes and satisfaction.

This comprehensive guide serves as an essential resource for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, including regions like Egypt and Vietnam. It covers a wide array of topics, including the various types of dental implant adhesives, the materials used in their formulation, and critical manufacturing and quality control processes. Additionally, we delve into supplier insights, cost considerations, and market trends to equip buyers with the knowledge necessary for informed sourcing decisions.

By understanding the nuances of dental implant glue, buyers can navigate supplier landscapes more effectively, assess product quality, and ultimately make choices that enhance operational efficiency and patient care. This guide empowers businesses to not only meet regulatory standards but also to stay competitive in a rapidly evolving market landscape. With the right information at hand, B2B buyers can confidently select the adhesives that best meet their specific needs and those of their clients.

Understanding dental implant glue Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resin-Based Adhesives | High bond strength, quick curing time | Dental clinics, laboratories | Pros: Strong adhesion, versatile; Cons: Can be more expensive than other options. |

| Cement-Based Adhesives | Easy to apply, good for temporary solutions | Orthodontics, temporary restorations | Pros: Cost-effective, user-friendly; Cons: Lower bond strength compared to resin. |

| Biocompatible Adhesives | Non-toxic, suitable for sensitive patients | Implantology, restorative dentistry | Pros: Safe for patients, minimal irritation; Cons: May have limited application range. |

| Glass Ionomer Cements | Fluoride-releasing, good for moisture control | Pediatric dentistry, preventive care | Pros: Antimicrobial properties, tooth-friendly; Cons: Weaker bond strength over time. |

| Self-Adhesive Cements | No need for separate bonding agents, easy use | General dentistry, prosthodontics | Pros: Simplifies procedure, time-saving; Cons: May not provide the strongest bond for all applications. |

Resin-Based Adhesives

Resin-based adhesives are renowned for their high bond strength and quick curing times, making them ideal for permanent dental implants. They are suitable for various applications, including dental clinics and laboratories where durability is essential. When considering resin-based adhesives, buyers should note their versatility and strong adhesion but also acknowledge that they may come at a higher price point compared to other adhesive types.

Cement-Based Adhesives

Cement-based adhesives are particularly favored for their ease of application and effectiveness in temporary solutions. Commonly used in orthodontics and temporary restorations, these adhesives offer a cost-effective option for practices looking to manage expenses without sacrificing quality. However, buyers should be aware that while they are user-friendly, they may exhibit lower bond strength than resin-based options, which could be a consideration for long-term applications.

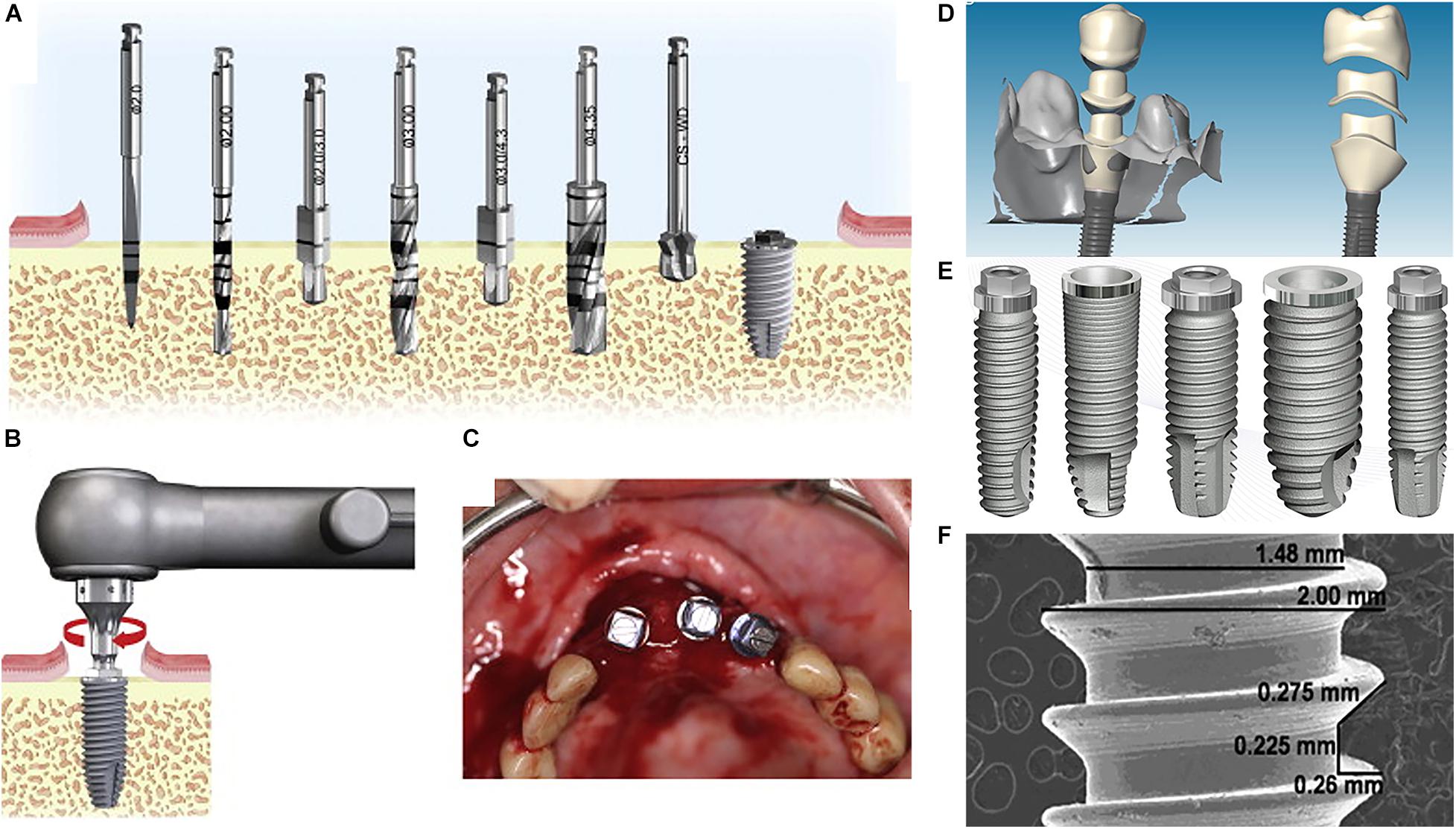

Illustrative Image (Source: Google Search)

Biocompatible Adhesives

Biocompatible adhesives are designed for patients with sensitive conditions or allergies, ensuring non-toxic interactions. These adhesives are primarily used in implantology and restorative dentistry where patient safety is paramount. When purchasing biocompatible adhesives, businesses should evaluate the safety profile and irritation potential; however, the range of applications may be somewhat limited, necessitating careful selection based on specific needs.

Glass Ionomer Cements

Glass ionomer cements are unique due to their fluoride-releasing properties and ability to manage moisture during application. They are widely used in pediatric dentistry and preventive care, providing an antimicrobial effect beneficial for young patients. While they are tooth-friendly and promote health, buyers should consider that their bond strength may weaken over time, which could impact long-term restorations.

Self-Adhesive Cements

Self-adhesive cements offer a streamlined application process, eliminating the need for separate bonding agents. This makes them particularly appealing in general dentistry and prosthodontics, where time efficiency is crucial. While they simplify procedures and save time, buyers should assess whether they meet the necessary bond strength for specific applications, as they may not be suitable for all scenarios, particularly those requiring maximum adhesion.

Related Video: Implant Supported Dentures

Key Industrial Applications of dental implant glue

| Industry/Sector | Specific Application of dental implant glue | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Secure attachment of dental implants | Enhances patient satisfaction and retention through reliable procedures | Quality certifications (ISO, CE), material biocompatibility, and ease of use |

| Dental Laboratories | Bonding components in dental prosthetics | Improves the longevity and functionality of dental restorations | Compatibility with various materials, curing time, and viscosity |

| Dental Equipment Manufacturers | Production of dental implant systems | Streamlines manufacturing processes and reduces production costs | Supply chain reliability, bulk purchasing options, and technical support |

| Oral Surgery Centers | Temporary fixation during surgical procedures | Increases surgical efficiency and patient safety | Regulatory compliance, adhesive strength, and ease of application |

| Research Institutions | Development of innovative dental materials and techniques | Facilitates advancements in dental technology and treatment options | Access to research data, cost-effectiveness, and customization capabilities |

Detailed Applications of Dental Implant Glue

Dental Clinics

In dental clinics, dental implant glue is essential for securing implants to the jawbone or other dental structures. This adhesive ensures that implants remain stable during the healing process, minimizing the risk of failure. For international buyers, especially in regions such as Africa and South America, it is crucial to source adhesives that meet local regulatory standards and are proven to be biocompatible. Additionally, factors like ease of application and the ability to bond with various implant materials should be prioritized to ensure successful outcomes.

Dental Laboratories

Dental laboratories utilize dental implant glue to bond various components of dental prosthetics, such as crowns and bridges, to the underlying implants. This application is critical for enhancing the durability and performance of dental restorations. Buyers in Europe and the Middle East should focus on adhesives that offer quick curing times and compatibility with different dental materials, as this can significantly impact production timelines and quality. Consistent supply and technical support from manufacturers can also enhance operational efficiency.

Dental Equipment Manufacturers

Manufacturers of dental equipment incorporate dental implant glue in the production of implant systems. The glue helps in assembling parts of dental implants securely, which is vital for ensuring product reliability and safety. B2B buyers from regions like Europe should consider sourcing adhesives that provide bulk purchasing options and technical assistance, as these factors can streamline manufacturing processes and reduce costs. Regulatory compliance is also essential to meet the stringent standards in the dental industry.

Oral Surgery Centers

In oral surgery centers, dental implant glue is used for temporary fixation during complex surgical procedures. This application allows for adjustments to be made during surgery without compromising the integrity of the implant. For international buyers, sourcing adhesives with strong bonding capabilities and compliance with safety regulations is critical. Additionally, the adhesive should be easy to apply and remove, ensuring a smooth surgical experience and enhanced patient safety.

Research Institutions

Research institutions leverage dental implant glue in the development of innovative dental materials and techniques. The glue is often used in experimental setups to test new implant designs or materials. For B2B buyers in this sector, it is important to source adhesives that offer customization options and access to comprehensive research data. Cost-effectiveness is also a key consideration, particularly for institutions operating with limited budgets. The ability to collaborate with suppliers on product development can further enhance research outcomes.

Strategic Material Selection Guide for dental implant glue

When selecting materials for dental implant glue, it’s crucial to consider several factors, including performance properties, cost, and regulatory compliance. Below, we analyze four common materials used in dental implant adhesives, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Epoxy Resins

Key Properties:

Epoxy resins are known for their excellent adhesion, chemical resistance, and mechanical strength. They can withstand high temperatures and pressures, making them suitable for various dental applications.

Pros & Cons:

The durability of epoxy resins is one of their most significant advantages, as they provide long-lasting bonds. However, they can be more expensive than other options and may involve complex manufacturing processes. Their rigidity can also limit their suitability for applications requiring flexibility.

Impact on Application:

Epoxy resins are compatible with a wide range of dental materials, including metals and ceramics. However, their curing process can be sensitive to environmental conditions, which may affect application in regions with extreme climates.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM D5767 for adhesives. In regions like Europe and the Middle East, certifications may be required to meet local health regulations.

2. Polyurethane Adhesives

Key Properties:

Polyurethane adhesives offer excellent flexibility, impact resistance, and adhesion to various substrates. They can also perform well under a range of temperatures and humidity levels.

Pros & Cons:

The key advantage of polyurethane adhesives is their versatility and ability to bond dissimilar materials effectively. However, they can be more challenging to handle due to their moisture sensitivity and longer curing times. Additionally, they may not be as chemically resistant as epoxy resins.

Impact on Application:

These adhesives are particularly effective in applications where movement or stress is expected, such as in implant-supported prosthetics. Their flexibility can enhance the longevity of the bond in dynamic environments.

Considerations for International Buyers:

Buyers should be aware of the varying regulations regarding polyurethane use in dental applications across different regions. Compliance with standards such as ISO 13485 is essential for manufacturers targeting the European market.

3. Cyanoacrylate Adhesives

Key Properties:

Cyanoacrylate adhesives, commonly known as superglues, cure rapidly and provide strong bonds. They are effective in bonding a variety of materials, including metals and plastics.

Pros & Cons:

The rapid curing time is a significant advantage, allowing for quick application and turnaround. However, cyanoacrylates can be brittle and may not withstand high-stress environments, making them less suitable for load-bearing applications.

Impact on Application:

These adhesives are often used for temporary fixes or in situations where speed is essential. They may not be ideal for permanent dental implants due to their limited durability under stress.

Considerations for International Buyers:

Cyanoacrylate adhesives may face stricter regulations in certain markets due to their chemical composition. Buyers should ensure compliance with local regulations, such as those set by the FDA in the United States or CE marking in Europe.

4. Silicone Adhesives

Key Properties:

Silicone adhesives are known for their flexibility, temperature resistance, and good adhesion to various substrates. They are also resistant to moisture and UV light.

Pros & Cons:

The flexibility of silicone adhesives makes them ideal for applications requiring movement, reducing the risk of bond failure. However, they may not provide as strong a bond as epoxy or polyurethane adhesives and can be more expensive.

Impact on Application:

Silicone adhesives are particularly useful in applications where thermal expansion and contraction are factors, such as in dental implants exposed to varying temperatures.

Considerations for International Buyers:

Buyers should be aware of the specific standards governing silicone adhesives in their regions, such as ASTM D4496. Ensuring that the product meets local compliance requirements is crucial for market entry.

Summary Table

| Material | Typical Use Case for dental implant glue | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Epoxy Resins | Permanent bonding of dental implants | Excellent durability and adhesion | High cost and complex processing | High |

| Polyurethane Adhesives | Flexible bonding in prosthetics | Versatile and impact-resistant | Moisture sensitivity and longer cure | Medium |

| Cyanoacrylate Adhesives | Temporary fixes and quick applications | Rapid curing time | Brittle and limited durability | Low |

| Silicone Adhesives | Flexible bonding in variable conditions | Excellent flexibility and resistance | Weaker bond strength | Medium |

This guide provides a comprehensive overview of the materials used in dental implant glue, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implant glue

The manufacturing process of dental implant glue is intricate and requires strict adherence to quality assurance standards. Understanding these processes is crucial for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. Below is a detailed overview of the typical manufacturing stages, quality control measures, and actionable insights for verifying supplier quality.

Manufacturing Process of Dental Implant Glue

-

Material Preparation

– The first stage involves sourcing high-quality raw materials, typically including polymers, adhesives, and fillers. It is essential to select materials that meet biocompatibility standards to ensure safety and effectiveness in dental applications.

– Suppliers should provide certificates of analysis (CoA) for each batch of raw materials, confirming compliance with relevant standards such as ISO 10993 for biocompatibility. -

Forming

– In this stage, raw materials are processed to create the adhesive formulation. Techniques such as mixing, stirring, and heating are employed to achieve a uniform consistency.

– Advanced methods like high-shear mixing may be utilized to ensure proper dispersion of components, which enhances the adhesive properties. Buyers should inquire about the specific equipment and technologies used in the mixing process. -

Assembly

– After forming, the adhesive is packaged into suitable containers or dispensing systems. This is crucial for maintaining product integrity and ease of use in clinical settings.

– Automated filling machines are often used to minimize contamination and ensure consistent dosing. Buyers should assess the automation level of their suppliers’ assembly lines, as this impacts product reliability. -

Finishing

– The final stage involves labeling, packaging, and conducting a thorough inspection of the finished product. This includes checking for any defects in packaging that could compromise product safety.

– Proper labeling must comply with regulatory requirements, including product information, usage instructions, and safety warnings. B2B buyers should verify that suppliers follow local and international labeling standards.

Quality Control (QC) Measures

Quality assurance is critical in the manufacturing of dental implant glue. Here are the key QC measures and international standards relevant to this industry:

- International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) that can enhance customer satisfaction by ensuring consistent product quality.

-

ISO 13485: Specifically focused on medical devices, this standard ensures that manufacturers consistently meet regulatory requirements and maintain effective QMS.

-

Industry-Specific Certifications

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

-

FDA Approval: For products marketed in the United States, compliance with FDA regulations is essential for safety and efficacy.

-

QC Checkpoints

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Buyers should ensure that suppliers maintain rigorous IQC procedures to prevent defects.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues early. Techniques such as statistical process control (SPC) can be beneficial.

- Final Quality Control (FQC): This final inspection assesses the finished product against predefined specifications. Buyers can request FQC reports to verify compliance with quality standards.

Common Testing Methods

To ensure the quality and performance of dental implant glue, various testing methods are utilized:

- Viscosity Testing: Measures the flow characteristics of the adhesive, which is critical for application.

- Tensile Strength Testing: Assesses the adhesive’s bonding strength, ensuring it can withstand the forces encountered in clinical use.

- Biocompatibility Testing: Evaluates the safety of the adhesive when in contact with biological tissues, adhering to ISO 10993 standards.

- Shelf Life Testing: Determines the stability and efficacy of the adhesive over time, ensuring that the product remains safe for use until its expiration date.

Verifying Supplier Quality

B2B buyers must take proactive steps to verify the quality control practices of their suppliers:

- Conduct Audits: Regular on-site audits can provide insights into the supplier’s manufacturing processes, quality control measures, and compliance with international standards. Buyers should establish an audit schedule based on the criticality of the product.

- Request Documentation: Buyers should ask for quality assurance documentation, including IQC, IPQC, and FQC reports. This documentation serves as evidence of the supplier’s commitment to quality.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can conduct thorough evaluations of the manufacturing facility and its processes.

- Understand Regulatory Nuances: Different regions have varying regulations and standards. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local requirements and ensure that suppliers meet these standards.

Conclusion

By gaining a thorough understanding of the manufacturing processes and quality assurance practices for dental implant glue, international B2B buyers can make informed decisions that ensure product safety and efficacy. Prioritizing suppliers with robust quality management systems and certifications will not only enhance product reliability but also build trust in the buyer-supplier relationship.

Comprehensive Cost and Pricing Analysis for dental implant glue Sourcing

When sourcing dental implant glue, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The costs associated with dental implant adhesives typically comprise several components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins. Each of these elements can significantly impact the overall price of the adhesive, and being aware of these factors can aid in effective negotiation and sourcing strategies.

Cost Components

-

Materials: The choice of raw materials is one of the most significant cost determinants. High-quality polymers and additives used in dental adhesives can vary widely in price. Buyers should evaluate the materials used to ensure they meet the necessary regulatory standards and performance expectations.

-

Labor: Labor costs encompass the wages paid to workers involved in production, packaging, and quality assurance. In regions with higher labor costs, such as parts of Europe, buyers may encounter higher prices for adhesives sourced from these areas. Conversely, sourcing from regions with lower labor costs may provide cost savings.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can subsequently lower the price of the final product.

-

Tooling: The initial investment in tooling for production can be significant, especially for customized products. Buyers should consider whether they require off-the-shelf solutions or bespoke formulations, as custom tooling can escalate costs.

-

Quality Control (QC): Rigorous quality assurance processes are essential in the dental industry. Suppliers that implement stringent QC measures may charge higher prices, but this can be justified by the enhanced reliability and performance of the product.

-

Logistics: Transportation costs can vary based on the distance between the supplier and the buyer, as well as the chosen shipping method. Incoterms (International Commercial Terms) play a crucial role in determining who bears these costs, which can influence pricing.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary significantly between suppliers and regions, influenced by market competition and demand.

Price Influencers

Several factors influence the pricing of dental implant glue:

-

Volume/MOQ: Bulk orders can lead to significant cost savings. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to benefit from lower unit prices.

-

Specifications/Customization: Customized adhesives tailored to specific applications often come at a premium. Buyers should assess whether standard products can meet their requirements to avoid unnecessary costs.

-

Materials and Quality Certifications: Products that meet international quality standards (e.g., ISO, CE) may be priced higher due to the assurance of quality and compliance. Buyers should weigh the importance of these certifications against potential savings from non-certified products.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers with a track record of quality and service may charge more but offer better support and reliability.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing and be prepared to negotiate based on order volume and long-term partnership potential. Establishing a good relationship can lead to better terms and conditions.

-

Cost-Efficiency: Always consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, storage, and potential wastage. This holistic view can aid in making more informed purchasing decisions.

-

Pricing Nuances: International buyers should be mindful of currency fluctuations and import duties, which can impact overall costs. Understanding local market conditions in regions like Africa, South America, the Middle East, and Europe can provide leverage in negotiations.

-

Disclaimer on Indicative Prices: Prices can vary significantly based on the factors discussed. Buyers should seek quotes from multiple suppliers and consider the context of their specific needs before making purchasing decisions.

By understanding these cost components and pricing influencers, international B2B buyers can optimize their sourcing strategies for dental implant glue, ensuring they achieve both quality and cost-effectiveness.

Essential Technical Properties and Trade Terminology for dental implant glue

Key Technical Properties of Dental Implant Glue

When sourcing dental implant glue, international B2B buyers should focus on several essential technical properties that influence performance and compatibility with dental applications. Understanding these properties helps ensure the selection of high-quality materials suitable for various implant scenarios.

-

Material Composition

– Dental implant adhesives are typically composed of biocompatible materials such as methacrylate or epoxy resins. The choice of material affects the adhesive’s strength, curing time, and compatibility with dental implants. For buyers, verifying the material composition is crucial to ensuring safety and efficacy in dental procedures. -

Tensile Strength

– This property measures the adhesive’s resistance to being pulled apart. A higher tensile strength indicates a stronger bond, which is essential for the stability of dental implants. Buyers must evaluate tensile strength data to ensure that the glue can withstand the mechanical forces experienced in the oral environment. -

Curing Time

– Curing time refers to the duration required for the adhesive to reach its optimal bonding strength. Fast-curing adhesives are beneficial in clinical settings for reducing patient chair time. Understanding this property helps buyers select products that align with workflow efficiency and patient care standards. -

Viscosity

– Viscosity indicates the thickness of the adhesive. Low-viscosity adhesives flow easily into gaps, providing better coverage and penetration, while high-viscosity products offer more control during application. Buyers should consider the intended use of the glue when assessing viscosity to ensure it meets specific application needs. -

Shelf Life

– The shelf life of dental implant glue is a critical factor for inventory management. A longer shelf life reduces waste and ensures that products remain effective over time. Buyers should inquire about the shelf life to make informed purchasing decisions and maintain optimal stock levels. -

Biocompatibility

– This property assesses how well the adhesive interacts with biological tissues. Biocompatibility is paramount in dental applications to prevent adverse reactions. Buyers must ensure that the adhesives meet relevant regulatory standards for biocompatibility to ensure patient safety.

Common Trade Terminology in Dental Implant Glue Sourcing

Understanding industry terminology is vital for effective communication and negotiation in the B2B market for dental implant glue. Here are several key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– An OEM produces parts or products that are used in another company’s end product. In dental glue sourcing, buyers might work with OEMs to ensure that the adhesive meets specific requirements for compatibility with their dental implants. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest amount of product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels and avoid overstocking or understocking issues. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers use RFQs to compare costs and conditions from multiple suppliers, ensuring they secure the best deal. -

Incoterms

– Incoterms are international commercial terms that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with their orders. -

CE Marking

– CE marking indicates that a product complies with European health, safety, and environmental protection standards. For buyers in Europe, ensuring that dental implant glue has CE marking is crucial for regulatory compliance. -

TDS (Technical Data Sheet)

– A TDS provides detailed information about a product’s properties, applications, and handling instructions. Buyers should always request TDS to ensure they understand the technical specifications and usage guidelines of the dental implant glue.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing dental implant glue, ultimately enhancing their procurement strategy and ensuring product efficacy in dental practices.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implant glue Sector

Market Overview & Key Trends

The dental implant glue sector is witnessing significant growth, driven by an increasing demand for dental procedures and advancements in adhesive technologies. Globally, the market is projected to expand as more dental professionals adopt innovative materials that enhance patient outcomes. Key trends include the rise of biocompatible adhesives that integrate seamlessly with human tissues, ensuring better stability and reducing the risk of allergic reactions. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the shift towards digital dentistry, which facilitates improved precision in implant procedures and the use of smart adhesive systems that provide real-time feedback during application.

Emerging technologies such as 3D printing and CAD/CAM systems are revolutionizing the dental implant landscape, enabling the production of customized solutions that meet specific patient needs. Buyers should also consider the impact of regulatory changes and the need for compliance with international standards, such as ISO certifications, which are crucial for market entry in various regions. Understanding these dynamics will empower international buyers to make informed sourcing decisions that align with market demands and technological advancements.

Sustainability & Ethical Sourcing in B2B

As environmental concerns gain prominence, sustainability in the dental implant glue sector is becoming increasingly vital. The production and disposal of dental adhesives can have significant environmental impacts, making it essential for B2B buyers to prioritize eco-friendly materials. This includes sourcing adhesives that utilize bio-based components or those certified by recognized standards such as ISO 14001 for environmental management.

Illustrative Image (Source: Google Search)

Ethical sourcing practices are equally important, as buyers should ensure their suppliers maintain transparent supply chains and adhere to fair labor practices. Certifications such as OEKO-TEX or Green Seal can help buyers identify products that meet stringent environmental and ethical standards. By opting for sustainable and ethically sourced materials, businesses not only enhance their brand reputation but also contribute to a healthier planet and society. Implementing these practices can be a competitive advantage in markets that increasingly value corporate responsibility.

Brief Evolution/History

The evolution of dental implant glue can be traced back to the early developments in dental adhesives during the mid-20th century. Initially, simple cyanoacrylate formulations were used, but advancements in chemistry and material science have led to the creation of more sophisticated adhesives that offer superior bonding strength and biocompatibility. The introduction of resin-based adhesives in the late 1990s marked a significant turning point, allowing for better integration with dental implants and reducing failure rates.

Today, the market is characterized by a wide array of products designed to cater to diverse needs, including temporary and permanent adhesives, each formulated to withstand the unique challenges posed by oral environments. This evolution reflects the ongoing innovation in dental materials, paving the way for enhanced patient care and outcomes. As international B2B buyers navigate this landscape, understanding the historical context can inform their sourcing strategies and help identify reputable suppliers.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of dental implant glue

-

What should I consider when vetting suppliers of dental implant glue?

When vetting suppliers, prioritize their certifications and compliance with international standards, such as ISO 13485 and CE marking for European markets. Request samples to assess product quality and consistency. Additionally, check their production capabilities and experience in the dental industry. Engaging with references from other clients can provide insights into their reliability and service levels. It’s also beneficial to evaluate their financial stability to ensure they can meet long-term supply commitments. -

Can dental implant glue be customized for specific applications?

Many suppliers offer customization options to meet specific needs, such as varying viscosities or curing times. Engage with potential suppliers early in the sourcing process to discuss your specific requirements. Ensure that they have the technical capability and flexibility to adapt their products while adhering to regulatory standards. A collaborative approach can lead to better product performance and satisfaction in your applications. -

What are typical minimum order quantities (MOQs) and lead times for dental implant glue?

MOQs can vary significantly between suppliers, typically ranging from 100 to 1,000 units depending on the product type and customization level. Lead times usually span from 2 to 6 weeks, influenced by production schedules and your order volume. For larger orders, negotiating better terms might be possible, including reduced MOQs or faster lead times. It’s advisable to discuss these details upfront to avoid disruptions in your supply chain. -

What payment terms should I expect when sourcing dental implant glue internationally?

Payment terms can vary by supplier and region. Common practices include upfront payments, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods that offer buyer protection. It’s crucial to establish clear terms in your purchase agreement to mitigate risks associated with currency fluctuations or international trade regulations. Always clarify who bears the costs of duties and taxes. -

How can I ensure quality assurance and certifications of dental implant glue?

Request documentation of quality assurance processes and certifications from potential suppliers. Look for compliance with ISO standards, as well as any relevant local regulations that apply in your target market. Conducting third-party audits or inspections can also provide additional assurance of product quality. Building a relationship with suppliers who prioritize quality will help mitigate the risk of receiving subpar products. -

What logistics considerations should I keep in mind when importing dental implant glue?

Logistics play a vital role in international sourcing. Understand the shipping terms (Incoterms) and ensure they are clearly defined in your contract. Consider the best shipping methods based on cost and delivery time. Additionally, be aware of import regulations in your country, including customs duties and import permits. Collaborating with experienced freight forwarders can streamline the logistics process and reduce potential delays. -

How should I handle disputes with suppliers of dental implant glue?

Establish clear communication channels and dispute resolution processes in your contracts. If issues arise, document all interactions and agreements to facilitate resolution. Engage in discussions to understand the supplier’s perspective and seek mutually beneficial solutions. If necessary, involve a neutral third party for mediation. It’s also wise to include arbitration clauses in contracts to resolve disputes efficiently without resorting to litigation. -

What are the common trends in dental implant glue that I should be aware of?

Stay informed about advancements in adhesive technology, such as the development of bio-compatible materials and faster curing times. Sustainability is also becoming a significant trend, with increasing demand for eco-friendly products. Regulatory changes may impact formulation standards, so keep abreast of updates from relevant authorities. Networking with industry peers and attending trade shows can provide insights into emerging trends and innovations in the dental adhesive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implant glue

Strategic sourcing in the dental implant glue market is pivotal for international B2B buyers aiming to enhance their product offerings and operational efficiency. As the demand for high-quality dental adhesives continues to rise, understanding key suppliers, manufacturing processes, and regulatory requirements is essential. By leveraging strategic sourcing practices, buyers can ensure they select reliable partners who provide innovative, effective, and compliant products.

Key Takeaways:

– Quality Assurance: Prioritize suppliers who adhere to international standards, such as ISO 13485, to guarantee product safety and efficacy.

– Market Trends: Stay informed about technological advancements in dental adhesives, such as bioactive formulations and improved bonding properties, which can significantly impact treatment outcomes.

– Cost Efficiency: Evaluate total cost of ownership rather than just upfront prices, ensuring long-term value through quality and reliability.

Looking ahead, the dental adhesive landscape will likely evolve with new innovations and regulatory changes. Buyers in regions like Africa, South America, the Middle East, and Europe should proactively engage with suppliers, attend industry exhibitions, and participate in forums to stay at the forefront of these developments. Now is the time to strengthen your sourcing strategies and align with partners who can drive your success in this competitive market.