Introduction: Navigating the Global Market for dental implants without insurance

In today’s global market, the demand for dental implants has surged, driven by an increasing focus on oral health and aesthetics. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the landscape of dental implants without insurance is crucial. Navigating this market can be challenging due to varying regulations, materials, and quality assurance practices across different countries.

This guide serves as a comprehensive resource, detailing essential aspects such as the types of dental implants available, the materials used in their construction, manufacturing processes, and quality control standards. Additionally, we will explore leading suppliers in the market, cost considerations, and the overall market dynamics that influence pricing and availability.

By equipping international buyers with actionable insights, this guide empowers them to make informed sourcing decisions. Whether you are in France evaluating local suppliers or in Saudi Arabia seeking cost-effective solutions, understanding the intricacies of purchasing dental implants without insurance will enhance your competitive edge.

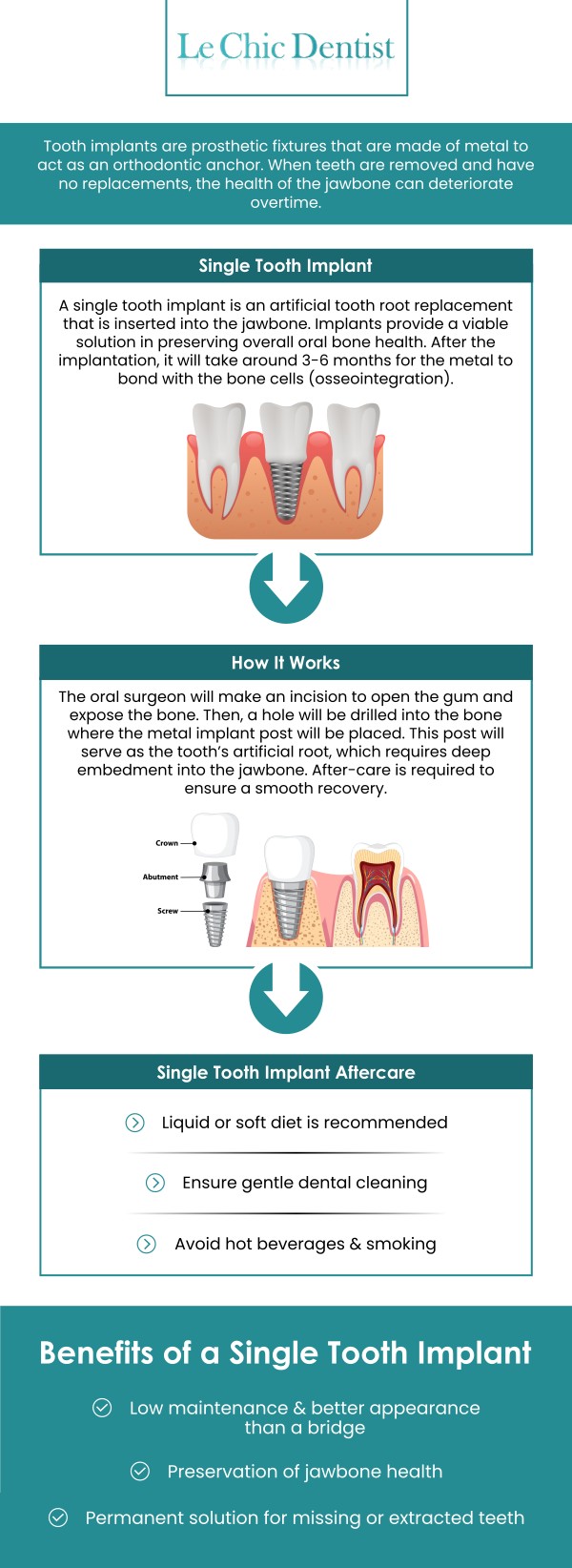

Illustrative Image (Source: Google Search)

The complexities of this market require a strategic approach, and this guide will provide you with the knowledge needed to navigate these waters effectively. From common FAQs to detailed supplier profiles, our aim is to facilitate a smoother procurement process and ensure that you can confidently invest in high-quality dental solutions tailored to your needs.

Understanding dental implants without insurance Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Endosteal Implants | Placed in the jawbone; most common type | Dental clinics, oral surgery centers | Pros: High success rate; durable. Cons: Requires sufficient bone density. |

| Subperiosteal Implants | Placed under the gum but above the jawbone | Clinics with patients lacking bone density | Pros: Suitable for patients with minimal bone. Cons: More complex surgery. |

| Zygomatic Implants | Anchored in the cheekbone; used when jawbone is insufficient | Advanced dental practices | Pros: Ideal for severe bone loss. Cons: Requires specialized skills. |

| Mini Dental Implants | Smaller diameter; less invasive | General dental practices, orthodontics | Pros: Easier placement; quicker healing. Cons: May not be suitable for all cases. |

| All-on-4 Implants | Four implants supporting an entire arch of teeth | Full-arch restoration clinics | Pros: Cost-effective for full restorations. Cons: Limited to specific cases. |

Endosteal Implants

Endosteal implants are the most commonly used type of dental implant. They are surgically placed directly into the jawbone, providing a strong foundation for replacement teeth. This type is suitable for most patients with adequate bone density. B2B buyers should consider the success rates and long-term durability associated with endosteal implants, as well as the need for potential bone grafting in patients with insufficient bone structure.

Subperiosteal Implants

Subperiosteal implants are designed for patients who lack sufficient bone height and cannot undergo a bone augmentation procedure. These implants are placed under the gum tissue but above the jawbone, making them a viable option for certain demographics. B2B buyers should evaluate the complexity of the surgical procedure and the specific patient profiles that would benefit from this type of implant, as well as the potential for higher costs due to the specialized nature of the surgery.

Zygomatic Implants

Zygomatic implants are an advanced solution for patients with severe bone loss in the upper jaw. These implants are anchored in the zygomatic bone (cheekbone) rather than the jawbone. This type requires specialized surgical skills, making it suitable for advanced dental practices. B2B buyers should assess the training and expertise of the dental professionals involved, as well as the potential for higher costs associated with this specialized procedure.

Mini Dental Implants

Mini dental implants are a less invasive option, characterized by their smaller diameter. They are easier to place and often require less healing time, making them appealing for general dental practices and orthodontics. B2B buyers should consider the application of mini implants in various patient cases, their cost-effectiveness, and the potential limitations in terms of supporting larger prosthetic structures.

All-on-4 Implants

All-on-4 implants utilize four strategically placed implants to support a full arch of prosthetic teeth, providing a cost-effective solution for full-arch restorations. This approach minimizes the need for bone grafting and can be completed in a single day. B2B buyers should focus on the operational efficiency of clinics that offer this service, as well as the patient demographics that would benefit from such a streamlined process. Evaluating the overall cost versus the benefits for full restorations is essential for informed purchasing decisions.

Related Video: What No One Told Me About The Cost of Dental Implants

Key Industrial Applications of dental implants without insurance

| Industry/Sector | Specific Application of dental implants without insurance | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Dental Clinics | Offering affordable dental implants to uninsured patients | Attracts a larger patient base, increasing revenue streams | Quality of materials, regulatory compliance, supplier reliability |

| Medical Tourism | Providing dental implant services to international patients | Capitalizes on the growing trend of dental tourism | Competitive pricing, service quality, local partnerships |

| Prosthetics Manufacturing | Manufacturing components for dental implants | Diversifies product offerings, enhances market presence | Material sourcing, production capabilities, design innovation |

| Health Insurance Providers | Collaborating with clinics to offer bundled services | Expands service portfolio, improves client retention | Partnership agreements, service quality assurance, market analysis |

| Educational Institutions | Training programs on dental implant procedures | Fosters skilled workforce, enhances institutional reputation | Curriculum development, industry partnerships, funding sources |

Dental Clinics

Dental clinics focusing on uninsured patients can leverage dental implants as a key service offering. By providing affordable options, these clinics can attract a broader patient demographic, thus increasing their revenue. The primary requirements for buyers in this sector include sourcing high-quality implant materials that comply with local regulations. Establishing relationships with reliable suppliers ensures consistent product availability and supports the clinic’s reputation for quality care.

Medical Tourism

In regions where dental tourism is burgeoning, offering dental implants without insurance can be a lucrative business model. Clinics can target international patients seeking high-quality dental care at lower costs. The value lies in providing competitive pricing while maintaining high service standards. Buyers should consider partnerships with local hotels and travel agencies to create comprehensive packages, enhancing the overall patient experience and boosting referrals.

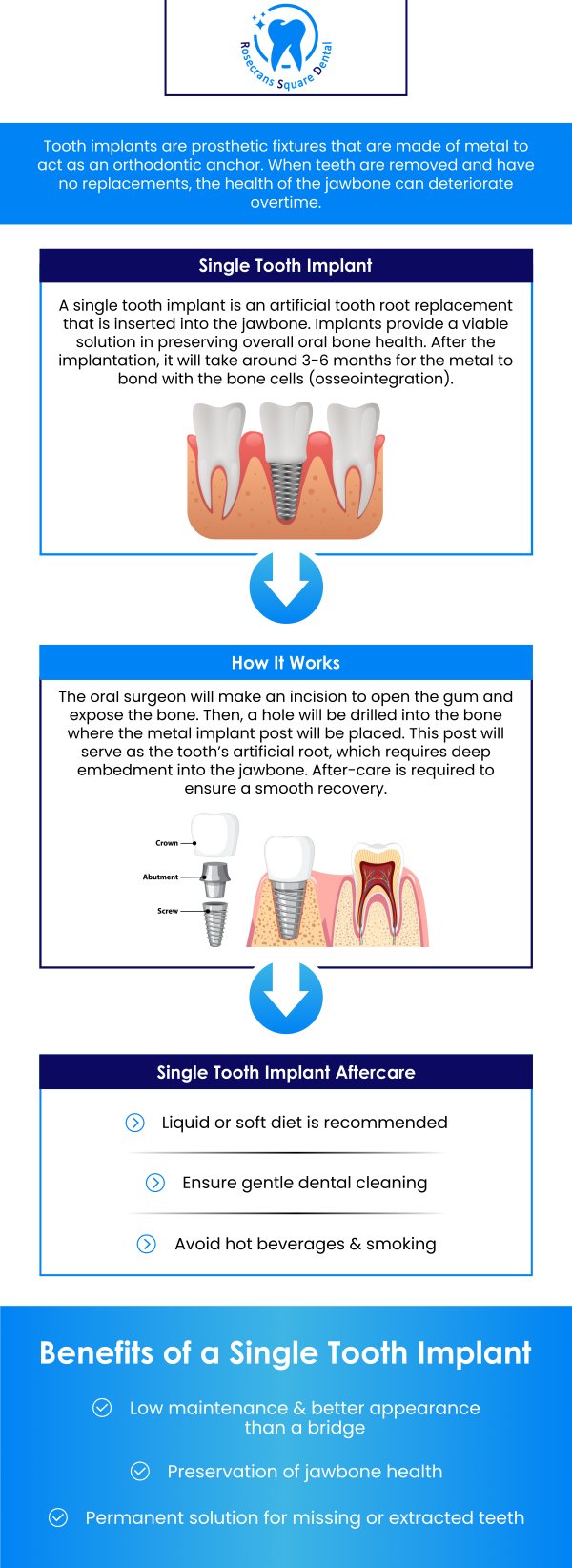

Illustrative Image (Source: Google Search)

Prosthetics Manufacturing

Manufacturers producing dental implants can benefit from entering the market for uninsured patients. By developing cost-effective solutions, they can diversify their product offerings and strengthen their market presence. Key considerations include sourcing high-grade materials that ensure durability and biocompatibility. Additionally, investing in design innovation can help meet specific needs of dental professionals, thus driving demand.

Health Insurance Providers

Health insurance companies can explore collaborations with dental clinics to create bundled services that include dental implants. This approach not only expands their service portfolio but also enhances client retention by offering comprehensive care options. Buyers should analyze market trends to identify potential partnerships that align with their strategic goals, ensuring that the services meet quality standards that consumers expect.

Educational Institutions

Educational institutions can play a crucial role in the dental implant market by offering training programs focused on implant procedures. This initiative not only fosters a skilled workforce but also enhances the institution’s reputation within the industry. Buyers in this sector should consider developing partnerships with dental clinics and manufacturers to ensure the curriculum is aligned with current industry practices and technologies, thereby maximizing the relevance of their training programs.

Related Video: Full Mouth Dental Implants. What You Should Know and Cost

Strategic Material Selection Guide for dental implants without insurance

When selecting materials for dental implants, especially in markets without insurance coverage, international B2B buyers must consider various factors that influence performance, cost, and compliance. Here’s a detailed analysis of common materials used in dental implants, focusing on their properties, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Titanium

Key Properties: Titanium is renowned for its excellent strength-to-weight ratio and high corrosion resistance. It can withstand the pressures of mastication and has a high temperature rating, making it suitable for various oral conditions.

Pros & Cons: Titanium implants are highly durable and biocompatible, leading to successful osseointegration. However, they can be more expensive than other materials, and their manufacturing complexity may increase costs further. Additionally, some patients may have allergies to titanium, which could limit its suitability.

Impact on Application: Titanium is compatible with most dental media, including various types of bone grafts. Its corrosion resistance ensures longevity, making it ideal for long-term use in dental applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM F136 for titanium alloys. In regions like Europe, CE marking is crucial, while buyers in the Middle East may need to consider local regulations.

Zirconia

Key Properties: Zirconia is a ceramic material known for its high strength, aesthetic appeal, and excellent biocompatibility. It is also resistant to wear and has a low thermal conductivity.

Pros & Cons: The aesthetic quality of zirconia makes it a preferred choice for visible dental implants, providing a natural appearance. However, it is generally less durable than titanium and can be more brittle, leading to a higher risk of fracture. The manufacturing process can also be complex, impacting overall cost.

Impact on Application: Zirconia implants are suitable for patients seeking aesthetic solutions, particularly in the anterior region. Their compatibility with dental ceramics makes them an excellent choice for cosmetic applications.

Considerations for International Buyers: Buyers should verify compliance with relevant standards such as ISO 6872 for dental ceramics. In Europe, the material must meet the requirements for CE marking, while buyers in Africa and South America should consider local certifications.

Stainless Steel

Key Properties: Stainless steel is known for its high strength and resistance to corrosion, making it a cost-effective option for dental implants. It can withstand significant mechanical stress and is relatively easy to manufacture.

Pros & Cons: The primary advantage of stainless steel is its lower cost compared to titanium and zirconia, making it accessible for markets without insurance. However, it is less biocompatible than titanium and may lead to allergic reactions in some patients. Its aesthetic appeal is also lower, which can be a drawback in visible applications.

Impact on Application: Stainless steel is suitable for temporary implants or in situations where cost is a primary concern. However, its lower biocompatibility may limit its use in permanent applications.

Considerations for International Buyers: Buyers should ensure compliance with ASTM F138 standards for surgical stainless steel. In regions like the Middle East and Europe, adherence to local regulations regarding medical devices is essential.

Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties, biocompatibility, and resistance to chemical degradation. It can withstand high temperatures and has a low density.

Pros & Cons: PEEK offers a good balance of strength and flexibility, making it suitable for various dental applications. Its aesthetic properties are not as favorable as ceramics, but it is significantly lighter than metals. The main disadvantage is its higher cost and the complexity involved in manufacturing.

Impact on Application: PEEK is particularly useful in applications requiring flexibility, such as in cases of bone resorption where a more adaptable implant is necessary.

Considerations for International Buyers: Buyers should confirm compliance with ISO 10993 for biocompatibility. In Europe, CE marking is also necessary, while buyers in Africa and South America should check for local certifications.

Summary Table

| Material | Typical Use Case for dental implants without insurance | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Permanent implants in various applications | Excellent biocompatibility and durability | Higher cost and potential allergies | High |

| Zirconia | Aesthetic implants in visible areas | Superior aesthetics and biocompatibility | Brittle and less durable | Medium |

| Stainless Steel | Temporary implants or cost-sensitive applications | Cost-effective and strong | Lower biocompatibility and aesthetics | Low |

| PEEK | Flexible implants for specific cases | Good mechanical properties and lightweight | Higher cost and manufacturing complexity | Medium |

This guide provides B2B buyers with a comprehensive understanding of material options for dental implants without insurance, enabling informed decision-making based on performance, cost, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dental implants without insurance

The dental implant industry has seen significant growth, particularly in regions where insurance coverage is limited. For B2B buyers, understanding the manufacturing processes and quality assurance measures is crucial when sourcing dental implants without insurance. This section will delve into the typical manufacturing stages, quality control standards, and actionable insights for international buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes for Dental Implants

The manufacturing of dental implants involves several critical stages. Each stage is designed to ensure that the final product meets the high standards required for medical devices.

1. Material Preparation

The choice of materials is paramount in dental implant manufacturing. Common materials include titanium and zirconia, known for their biocompatibility and strength. The preparation phase involves:

- Material Sourcing: Ensure that materials are sourced from reputable suppliers. Look for certifications indicating compliance with international standards.

- Material Testing: Before use, materials undergo rigorous testing for purity and mechanical properties. This is crucial to avoid issues in later stages.

2. Forming

In this phase, raw materials are shaped into the desired implant form. Key techniques include:

- CNC Machining: Computer Numerical Control (CNC) machines provide precision in shaping the implants.

- Additive Manufacturing: This technique allows for complex geometries and is increasingly used in custom implant designs.

3. Assembly

The assembly stage involves integrating various components of the dental implant system, which may include the implant itself, abutments, and screws. This stage requires:

- Cleanroom Environments: Assembly should occur in sterile environments to prevent contamination.

- Automated Systems: Automated assembly lines can improve consistency and reduce human error.

4. Finishing

The finishing process enhances the surface characteristics of the implants, which is critical for osseointegration. Key activities include:

- Surface Treatments: Techniques such as sandblasting and acid-etching improve the surface roughness, promoting better integration with bone.

- Polishing: Final polishing ensures that the implants are free from imperfections that could lead to complications.

Quality Assurance in Dental Implant Manufacturing

Quality assurance is vital to ensure that dental implants are safe and effective. International B2B buyers must be well-versed in the standards and practices that govern quality control.

Relevant International Standards

Compliance with international quality standards is essential. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system and is applicable across industries, ensuring consistent product quality.

- ISO 13485: Specifically for medical devices, this standard focuses on regulatory requirements and quality management throughout the product lifecycle.

- CE Marking: In Europe, implants must have CE marking, indicating conformity with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production. Suppliers should provide certificates of analysis (CoA) for materials used.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from standards are caught early.

- Final Quality Control (FQC): The finished products undergo rigorous testing before packaging. This may include mechanical testing, biocompatibility assessments, and sterility tests.

Common Testing Methods

B2B buyers should be aware of the various testing methods used to ensure quality:

- Mechanical Testing: Includes tensile strength, fatigue, and impact tests to ensure the implant can withstand functional loads.

- Microbiological Testing: Ensures that implants are free from harmful microorganisms.

- Biocompatibility Testing: Assesses how the implant interacts with biological tissues, critical for ensuring patient safety.

Verifying Supplier Quality Control

For international buyers, verifying the QC processes of suppliers is essential. Here are actionable strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to evaluate their manufacturing processes and quality assurance practices. Look for ISO certifications and other relevant credentials.

- Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and compliance with international standards.

- Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of suppliers. This adds an extra layer of verification to ensure compliance with quality standards.

Quality Control and Certification Nuances for International Buyers

B2B buyers from regions like Africa, South America, the Middle East, and Europe must navigate various quality assurance landscapes:

- Regulatory Variations: Different regions have distinct regulatory requirements. Familiarize yourself with local regulations in your target market to ensure compliance.

- Cultural Considerations: Understanding cultural attitudes towards quality and safety can influence supplier relationships. Building trust through transparency and communication is key.

- Certification Recognition: Not all certifications are recognized universally. Ensure that the certifications held by your suppliers are accepted in your market to avoid compliance issues.

Conclusion

In summary, understanding the manufacturing processes and quality assurance measures for dental implants is crucial for B2B buyers, especially in regions where insurance coverage is limited. By focusing on the key manufacturing stages, relevant international standards, and effective verification methods, buyers can make informed decisions when sourcing dental implants without insurance. Investing time in understanding these processes will not only enhance product quality but also build trust with patients and healthcare providers alike.

Related Video: Dental Implants 101: What You NEED to Know! Part 3 (Everything Bone Grafting)

Comprehensive Cost and Pricing Analysis for dental implants without insurance Sourcing

Understanding the cost structure and pricing dynamics of dental implants without insurance is essential for international B2B buyers seeking to optimize their procurement strategies. This analysis delves into the various cost components, price influencers, and practical buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost of dental implants. Titanium and zirconia are common materials, with titanium typically being less expensive. The quality and source of these materials can vary widely, affecting both durability and price.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality assurance. Regions with lower labor costs may offer competitive pricing; however, this can sometimes correlate with lower quality standards.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce these overheads, allowing suppliers to offer more competitive prices.

-

Tooling: The initial setup costs for molds and machinery can be substantial. Suppliers with advanced technology may charge higher prices upfront but could provide better quality and consistency over time.

-

Quality Control (QC): Rigorous QC processes are vital in ensuring product reliability. Suppliers who invest in comprehensive QC may incur higher costs, which could be reflected in the pricing.

-

Logistics: Transportation and handling costs can vary greatly depending on the supplier’s location and the destination country. International buyers should consider shipping times, customs duties, and potential tariffs when evaluating total costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the standard margins in different regions can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts. Buyers should assess their projected needs to maximize volume discounts without overcommitting.

-

Specifications/Customization: Custom implants tailored to specific patient needs may incur additional costs. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Quality/Certifications: Products that meet international standards (e.g., ISO, CE marking) may come at a premium, but they also ensure compliance and reliability, which is critical for patient safety.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the costs and risks during shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact overall pricing.

Buyer Tips

-

Negotiation: Effective negotiation strategies can lead to better pricing. Buyers should be prepared to discuss volume commitments, payment terms, and delivery schedules to achieve favorable terms.

-

Cost-Efficiency: Assessing the Total Cost of Ownership (TCO) is essential. This includes not just the purchase price but also installation, maintenance, and potential replacement costs over time.

-

Pricing Nuances: Buyers from regions like Africa and South America may face different pricing structures compared to Europe or the Middle East. Local economic conditions, demand, and competition can influence pricing strategies.

-

Research and Benchmarking: Conducting thorough market research and benchmarking against similar products can provide insight into competitive pricing, helping buyers make informed decisions.

Disclaimer

Prices for dental implants can vary widely based on the factors outlined above. This analysis provides indicative pricing insights but should not be considered exhaustive or definitive. Buyers are encouraged to conduct their own assessments and seek multiple quotes to ensure they secure the best possible deal.

Essential Technical Properties and Trade Terminology for dental implants without insurance

Key Technical Properties of Dental Implants

When considering dental implants, particularly in a B2B context for international buyers, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications to keep in mind:

-

Material Grade

Dental implants are primarily made from titanium or zirconia. Titanium is known for its biocompatibility and strength, while zirconia offers an aesthetic advantage with its tooth-like color. Buyers should ensure that the implants meet international standards such as ISO 13485, which focuses on quality management systems for medical devices. -

Surface Treatment

The surface of dental implants can significantly influence osseointegration, the process where the implant bonds with the bone. Common treatments include sandblasting, acid etching, and coating with bioactive materials. Understanding these treatments can help buyers select implants that promote faster healing and stability. -

Diameter and Length

Dental implants come in various diameters and lengths to accommodate different anatomical situations. Typically, diameters range from 3.0 mm to 6.0 mm and lengths from 8.0 mm to 15.0 mm. Buyers must consider these dimensions based on their target market’s requirements and the average bone quality in the region. -

Tolerance

Tolerance refers to the permissible limit of variation in the implant’s dimensions. High precision in tolerance is essential to ensure a snug fit with the abutment and prosthetic components. This property is vital for ensuring long-term success rates and patient satisfaction. -

Load-Bearing Capacity

Implants must withstand significant forces during chewing and grinding. Load-bearing capacity is influenced by the material used and the design of the implant. Buyers should inquire about the maximum load specifications to ensure they meet the functional demands of their end-users.

Common Trade Terminology

Navigating the dental implant market requires familiarity with specific trade terms. Understanding these terms can facilitate smoother transactions and enhance communication with suppliers.

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the dental implant sector, many brands rely on OEMs for the manufacturing of their implants. Buyers should evaluate the reputation and capabilities of OEMs to ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it can significantly impact inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This is a critical step in the procurement process, allowing buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and tariffs. Familiarity with these terms helps buyers avoid misunderstandings and ensures compliance with international trade regulations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This is a key consideration for B2B buyers, as longer lead times can disrupt business operations. Understanding lead time helps in planning and inventory management.

Conclusion

By grasping these essential technical properties and trade terms, international B2B buyers can enhance their purchasing strategies for dental implants without insurance. This knowledge not only assists in selecting the right products but also fosters better supplier relationships and effective negotiation.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dental implants without insurance Sector

Market Overview & Key Trends

The dental implants market, particularly for patients without insurance, is experiencing notable growth driven by several global factors. Increasing dental awareness and a rising middle class in regions such as Africa, South America, and the Middle East are contributing to heightened demand for dental solutions. Furthermore, technological advancements in implant materials and techniques are making these products more accessible and affordable, even for those without insurance coverage.

Emerging B2B tech trends, such as digital dentistry and tele-dentistry, are transforming how dental services are delivered. These technologies facilitate remote consultations and improve patient engagement, allowing dental professionals to offer more personalized care. Additionally, the rise of e-commerce platforms for dental products is enabling international buyers to source implants directly from manufacturers, streamlining procurement and potentially reducing costs.

International B2B buyers should also be mindful of regional market dynamics. For example, Europe is witnessing a consolidation trend among dental implant manufacturers, enhancing competition and driving innovation. In contrast, the Middle East is seeing significant investments in healthcare infrastructure, creating opportunities for new entrants and partnerships. Buyers in Africa and South America must navigate diverse regulatory environments and market conditions, emphasizing the need for local partnerships to ensure compliance and effective distribution.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the dental implants sector, particularly for B2B buyers. The environmental impact of manufacturing processes, from material sourcing to waste management, is under scrutiny. Buyers should prioritize suppliers that adopt sustainable practices, such as using recycled materials or environmentally friendly manufacturing processes.

Ethical sourcing is equally important, as it reflects a company’s commitment to social responsibility. Suppliers that adhere to fair labor practices and provide transparency in their supply chains are increasingly favored by international buyers. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of biocompatible materials in dental implants is gaining traction. Materials that are not only effective but also have a lower environmental footprint are becoming essential in product development. By choosing suppliers who invest in green certifications and sustainable materials, B2B buyers can enhance their brand reputation and align with the growing consumer demand for ethical products.

Brief Evolution/History

The dental implant industry has evolved significantly over the past few decades. Initially dominated by a few key players, the market has expanded with the introduction of innovative materials and techniques that enhance implant success rates. The shift towards minimally invasive procedures and digital solutions has further revolutionized the field, making dental implants more accessible to a broader audience, including those without insurance.

As the market continues to grow, the focus on sustainability and ethical sourcing is reshaping the landscape. This evolution underscores the importance for B2B buyers to stay informed about trends and innovations that not only meet patient needs but also align with global sustainability goals. By understanding this historical context, buyers can make more informed decisions when sourcing dental implants in today’s dynamic marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of dental implants without insurance

-

What criteria should I use to vet suppliers of dental implants?

When vetting suppliers, prioritize their certifications, such as ISO or CE marks, which indicate compliance with international quality standards. Investigate their manufacturing processes, quality assurance protocols, and customer reviews. Additionally, assess their financial stability and experience in the dental implant market. Engaging in direct communication with potential suppliers can also provide insights into their reliability and responsiveness. -

Can dental implants be customized to meet specific requirements?

Yes, many suppliers offer customization options for dental implants, including size, shape, and material specifications. When discussing customization, clearly outline your requirements and ask about the supplier’s capabilities. Ensure that they have the technology and expertise to produce implants tailored to your specifications, as this can enhance patient outcomes and satisfaction. -

What is the typical minimum order quantity (MOQ) for dental implants, and how does it affect pricing?

MOQs can vary significantly among suppliers, typically ranging from 50 to 200 units. Understanding the MOQ is crucial as it can impact pricing and inventory management. Suppliers often provide volume discounts, so negotiating a lower MOQ might be possible if you’re willing to commit to a larger order in the future. Always compare pricing structures to find the best value. -

What are the lead times for ordering dental implants, and how can I expedite the process?

Lead times for dental implants can range from a few weeks to several months, depending on the supplier and the complexity of the order. To expedite the process, maintain clear communication about your timeline and urgency. Consider establishing a reliable relationship with a supplier that can prioritize your orders and explore options for expedited shipping if necessary. -

What quality assurance measures should I expect from suppliers?

A reputable supplier should have robust quality assurance measures in place, including regular audits, traceability systems, and adherence to international standards. Request documentation that outlines their QA processes, including batch testing and product recalls. Additionally, inquire about their approach to continuous improvement to ensure their products remain competitive and safe. -

What certifications should I look for when sourcing dental implants?

Essential certifications include ISO 13485 for medical devices and CE marking for compliance within the European market. For suppliers operating in the Middle East and Africa, look for local regulatory approvals that ensure safety and efficacy. Verify that the supplier can provide documentation for these certifications, as they are crucial for ensuring product quality and compliance with local regulations. -

How should I handle disputes with suppliers regarding product quality or delivery?

Establish a clear communication protocol from the outset, including timelines for issue resolution. In case of a dispute, document all communications and agreements. If an issue arises, address it promptly and professionally, seeking a resolution through negotiation. If necessary, escalate the matter to a higher authority within the supplier’s organization. Having a written contract that outlines dispute resolution processes can also be beneficial. -

What logistics considerations should I keep in mind when importing dental implants?

Logistics play a vital role in the timely delivery of dental implants. Consider factors such as shipping methods, customs regulations, and import duties specific to your region. Partner with logistics experts who understand the complexities of international shipping to avoid delays. Additionally, ensure that the supplier provides proper documentation for customs clearance, including invoices and certificates of origin.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dental implants without insurance

In the rapidly evolving landscape of dental implants, strategic sourcing emerges as a pivotal factor for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By leveraging robust supplier networks and understanding local market dynamics, businesses can effectively navigate the complexities of sourcing dental implants without insurance.

Key Takeaways:

- Cost Efficiency: Identifying cost-effective suppliers can significantly reduce overall expenses, allowing for competitive pricing strategies in local markets.

- Quality Assurance: Fostering relationships with reputable manufacturers ensures high-quality products that meet international standards, ultimately enhancing patient satisfaction.

- Regulatory Compliance: Understanding the regulatory landscape in different regions is crucial for seamless market entry and to avoid potential legal pitfalls.

As the demand for dental implants continues to grow, international buyers must adopt a proactive approach to sourcing. By prioritizing strategic partnerships and staying informed about industry trends, businesses can position themselves for sustainable growth.

Call to Action: Engage with local suppliers and global partners to optimize your sourcing strategy. Embrace innovation and adaptability to capitalize on emerging opportunities in the dental implant sector. The future is bright for those willing to invest in strategic sourcing—seize the opportunity today!