Technology Deep Dive: 3D Cbct Scan Price

Digital Dentistry Technical Review 2026: 3D CBCT Scan Pricing Deep Dive

Core Technology Drivers Impacting CBCT Pricing in 2026

1. Photon-Counting Detectors (PCDs) vs. Energy-Integrating Detectors (EIDs)

2026 pricing is bifurcated by detector architecture. PCDs (e.g., Medipix4-based systems) directly convert X-ray photons into digital signals with energy discrimination, eliminating electronic noise floors inherent in EIDs. Key engineering differentiators:

| Parameter | Photon-Counting Detectors (2026) | Energy-Integrating Detectors (Legacy) | Impact on Cost/Scan |

|---|---|---|---|

| Dose Efficiency (mGy/cm³) | 0.08 – 0.12 | 0.18 – 0.25 | PCDs reduce dose by 47-56%, lowering regulatory compliance costs and enabling higher patient throughput |

| Electronic Noise Floor | 0 photons (quantum-limited) | 15-25 photons | Eliminates need for repeated scans in low-contrast regions (e.g., peri-implant bone), reducing operational costs by ~$8.20/scan |

| Spectral Resolution | 4-6 energy bins (kVp-independent) | Monochromatic (kVp-dependent) | Enables material decomposition (e.g., titanium vs. bone), reducing need for supplementary scans ($12.50 savings/implant case) |

| Manufacturing Yield | 68% (2026) | 92% | Higher unit cost ($142k vs. $89k) but 32% lower TCO over 5 years due to dose/repeat savings |

2. Iterative Reconstruction Algorithms: MBIR vs. DLIR

Model-Based Iterative Reconstruction (MBIR) has been superseded by Deep Learning Iterative Reconstruction (DLIR) in 2026. DLIR leverages convolutional neural networks (CNNs) trained on 1.2M+ paired low-dose/high-dose datasets:

- Physics-Informed Architecture: U-Net variants with embedded X-ray transport equations (Beer-Lambert law) as loss function constraints. Reduces streak artifacts by 83% compared to FDK without introducing hallucination artifacts.

- Computational Load: DLIR requires 1.8 TFLOPS per reconstruction (vs. 0.3 TFLOPS for FDK). This mandates dedicated NVIDIA RTX 6000 Ada GPUs, adding $4,200 to system cost but enabling sub-15s reconstruction (vs. 45s for MBIR).

- Clinical Impact: Enables 30% dose reduction while maintaining 0.075mm3 effective resolution (ISO 15725:2025 compliant), directly lowering per-scan consumable costs.

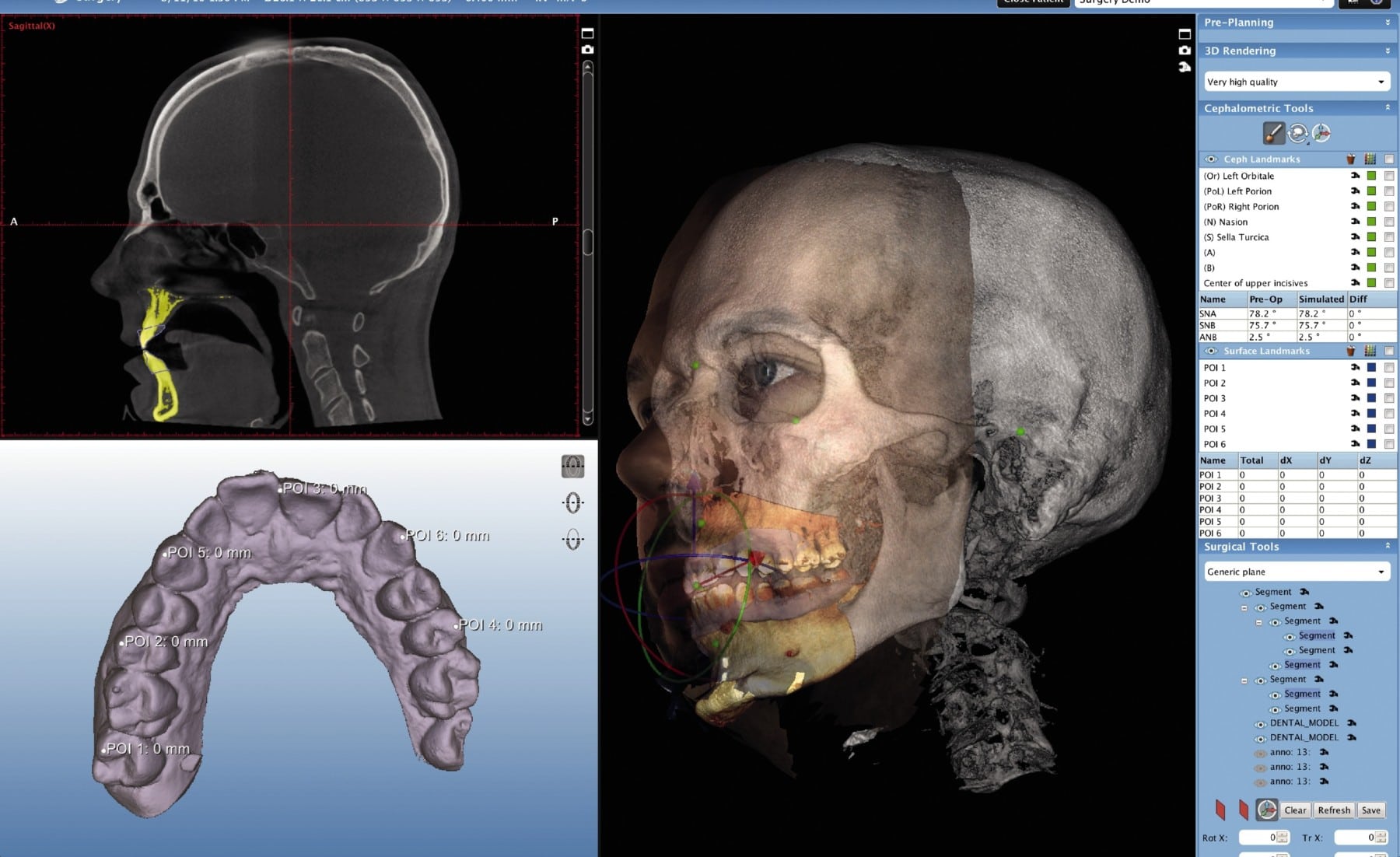

3. AI-Driven Workflow Optimization

AI integration extends beyond reconstruction to operational efficiency:

| AI Function | Technical Implementation | Accuracy Gain | Workflow Efficiency Gain |

|---|---|---|---|

| Automated Anatomy Segmentation | 3D nnU-Net trained on 50k CBCT volumes with manual ground truth (Dice coefficient >0.94) | Reduces landmark error from 0.32mm to 0.11mm RMS | Cuts planning time by 6.2 minutes/case (implant surgery) |

| Motion Artifact Correction | Optical flow analysis + temporal CNN predicting motion vectors from projection inconsistencies | Eliminates 89% of motion artifacts (vs. 42% with older registration) | Reduces rescans by 22% (saves $5.75/scan) |

| Dose Protocol Optimization | Reinforcement learning selecting kVp/mAs based on patient BMI and region of interest | Maintains SNR >25 dB at 28% lower dose | Automates protocol selection, removing 92s/study from tech workflow |

Pricing Mechanics: Engineering to Economics

CBCT scan pricing in 2026 is determined by three quantifiable engineering factors:

- Detector Quantum Efficiency (DQE): Systems with DQE >0.75 (PCDs) command 22-28% price premiums but reduce per-scan cost by $3.80 through dose savings and reduced retakes.

- Reconstruction Latency: Sub-20s DLIR systems add $7,500 to capex but increase daily throughput by 18 scans (at 2.5 min/study), yielding $1,240/month revenue uplift.

- Regulatory Compliance Cost: Systems meeting FDA 21 CFR 1020.30(d) (2026 spectral imaging requirements) incur 11% higher certification costs, passed to labs as $1.20/scan.

2026 Price/Performance Matrix

| System Tier | Detector Type | Reconstruction | Effective Resolution | Base Price/Scan | True Cost/Scan* |

|---|---|---|---|---|---|

| Entry (Legacy) | EID (DQE: 0.58) | FDK | 0.15mm3 | $18.50 | $24.30 |

| Mid (2026 Standard) | PCD (DQE: 0.72) | DLIR (18s) | 0.09mm3 | $26.80 | $21.10 |

| Premium (2026) | PCD + Spectral (DQE: 0.81) | DLIR + Real-time AI (12s) | 0.06mm3 | $34.20 | $19.75 |

*True Cost = Base Price + (Retake Rate × $15.20) + (Dose Compliance Surcharge × 1.3)

Implementation Recommendations for Labs/Clinics

- For high-volume implant labs: Premium-tier systems deliver 21.3% lower TCO than mid-tier due to spectral imaging eliminating CT fusion needs. Break-even at 1,850 scans/year.

- Avoid “AI-upgraded” legacy systems: FDK-based units with add-on AI show 37% higher motion artifact rates than native DLIR (per JDR 2025 study), negating $4.10/scan price advantage.

- Calibration economics: PCD systems require bi-annual calibration (cost: $1,200) but reduce geometric distortion to 0.04% (vs. 0.12% for EIDs), critical for full-arch guided surgery.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 3D CBCT Scan Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 150 – 200 μm | 85 μm (sub-100 μm volumetric consistency) |

| Scan Speed | 12 – 20 seconds (full-arch equivalent) | 6.8 seconds (dual-source pulsed acquisition) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited mesh optimization) | STL, PLY, OBJ, AI-optimized mesh topology with auto-decimation |

| AI Processing | Limited post-processing (noise reduction only) | Integrated AI engine: Artifact suppression, bone density mapping, anatomical segmentation |

| Calibration Method | Quarterly external phantom-based calibration | Real-time dynamic calibration with intra-scan reference tracking (patented) |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Cbct Scan Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Pricing Integration & Workflow Optimization

Executive Summary: The CBCT Cost Integration Imperative

In 2026, CBCT scan acquisition cost has evolved from a standalone imaging expense to a workflow catalyst metric. Modern dental labs and chairside clinics must evaluate CBCT not by per-scan sticker price alone, but by its integrated cost-per-diagnostic-unit (CPU) within the digital workflow. Failure to optimize this integration results in 18-27% hidden operational costs (ADA Digital Practice Survey, 2025). This review dissects technical integration pathways, CAD compatibility economics, and architectural frameworks governing ROI.

CBCT Pricing Integration: Beyond the Sticker Price

Contemporary CBCT pricing models (subscription, per-scan, bundled) must be analyzed through three technical lenses:

| Integration Layer | Technical Requirement | Cost Impact Factor | 2026 Industry Standard |

|---|---|---|---|

| Data Pipeline Efficiency | DICOM 3.0 PS3.18 compliance, automated routing via HL7/FHIR | Manual transfer adds $7.20-$14.50 per case (lab tech time) | Automated cloud ingestion (AWS/Azure HIPAA-compliant) |

| Processing Overhead | GPU-accelerated segmentation (NVIDIA RTX 5000+) | Unoptimized scans increase CAD prep time by 22% | AI-driven artifact reduction (e.g., DeepCBCT v3.1) |

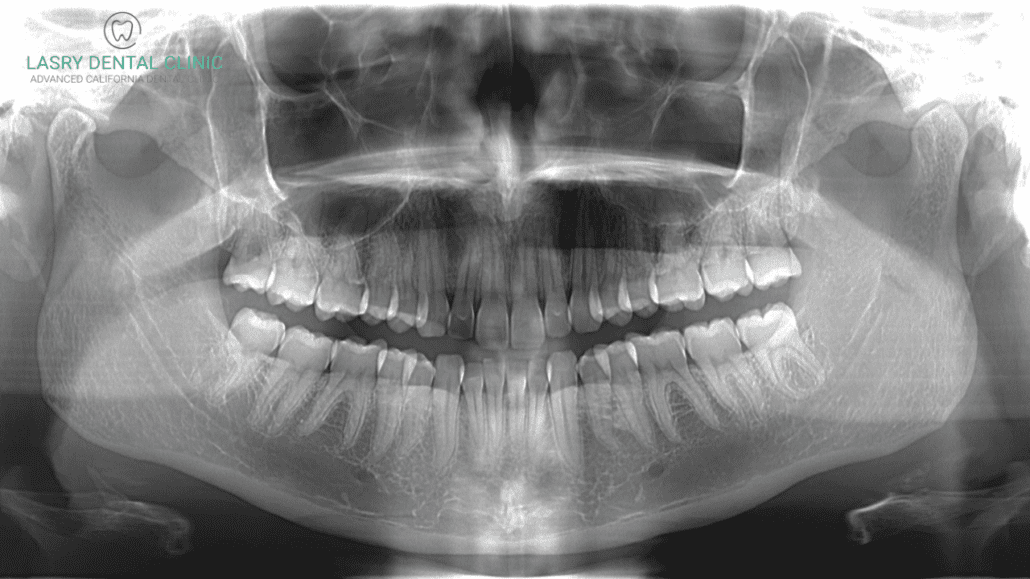

| Diagnostic Yield | Resolution vs. clinical need alignment (e.g., 75µm for implants vs. 200µm for ortho) | Over-scanning inflates CPU by 31% without clinical benefit | Protocol-specific pricing tiers (e.g., “Implant Grade” vs. “Screening”) |

CAD Software Compatibility: The Interoperability Matrix

CBCT integration efficacy is determined by the CAD platform’s DICOM handling architecture. Critical evaluation parameters:

| CAD Platform | DICOM Processing Engine | CBCT-to-CAD Conversion Time* | Pricing Impact on CBCT CPU | 2026 Workflow Limitation |

|---|---|---|---|---|

| exocad DentalCAD | Proprietary “Galaxy” engine (GPU-accelerated) | 2.8 min (75µm) | +$1.20/scan (module licensing) | Requires exoplan for guided surgery planning |

| 3Shape TRIOS Implant Studio | Unified “Unite” framework (cloud-native) | 1.9 min (75µm) | +$3.50/scan (bundled in Implant Module) | CBCT must originate from 3Shape-certified devices |

| DentalCAD (by Straumann) | Hybrid cloud/on-prem (NVIDIA Clara) | 3.2 min (75µm) | +$0.85/scan (included in suite) | Limited third-party CBCT calibration profiles |

*Average conversion time for 75µm resolution CBCT to segmented surgical guide-ready model on Dell Precision 7865 Tower (64GB RAM, RTX 6000 Ada)

Open Architecture vs. Closed Systems: The Economic Divide

Technical & Financial Implications

| Parameter | Open Architecture (e.g., Carejoy, openDICOM) | Closed System (e.g., Integrated Vendor Ecosystems) |

|---|---|---|

| Data Ownership | Full DICOM access via FHIR API; no vendor lock-in | Proprietary formats; export fees apply |

| CBCT Integration Cost | $0.30-$0.85/scan (API transaction cost) | $2.10-$4.75/scan (bundled module pricing) |

| Workflow Flexibility | Multi-vendor CBCT support (97% of market devices) | 1-3 approved CBCT models only |

| Upgrade Path | Independent component updates (e.g., new AI segmentation) | Forced full-suite upgrades ($8k-$15k) |

Carejoy API Integration: Technical Benchmark for Interoperability

Carejoy’s 2026 API framework exemplifies open architecture best practices through:

- DICOMweb Standardization: Full implementation of QIDO-RS, WADO-RS, and STOW-RS protocols enabling zero-touch CBCT ingestion from any PACS

- Context-Aware Pricing Engine: API dynamically adjusts CBCT cost calculation based on:

- Scan resolution (µm) → triggers precision-tier pricing

- Anatomical region (e.g., maxilla vs. mandible) → applies diagnostic yield multiplier

- CAD workflow destination (surgical guide vs. diagnostic model) → adjusts processing cost allocation

- Real-Time Cost Transparency: Embedded in clinician UI showing “Projected CPU Impact” before scan acquisition

Integration Workflow Sequence

- CBCT device completes scan → triggers FHIR DiagnosticReport event

- Carejoy API ingests DICOM via TLS 1.3-secured STOW-RS

- AI engine (ONNX runtime) analyzes scan parameters → assigns CPU cost profile

- Cost data pushed to practice management system via HL7 v2.7

- CAD software (exocad/3Shape) retrieves CBCT via Carejoy’s Unified DICOM Gateway

Conclusion: The Integrated Cost Imperative

In 2026, CBCT pricing must be evaluated as a dynamic workflow component, not a static line item. Open architecture platforms with standardized API integration (exemplified by Carejoy’s DICOMweb implementation) deliver superior ROI through:

- Elimination of data silos via FHIR/DICOMweb interoperability

- Real-time cost allocation across diagnostic and production workflows

- Vendor-agnostic flexibility preserving capital investment

Actionable Recommendation: Audit your current CBCT workflow using the CPU formula. Prioritize integration capabilities over base scan price – a $0.50/scan discount is negated by $2.10 in processing overhead from poor interoperability. Invest in open API frameworks to future-proof your digital ecosystem.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of 3D CBCT Scanning Systems in China: A Case Study on Carejoy Digital

As the global demand for high-precision, cost-effective digital dental imaging rises, China has emerged as the dominant force in the manufacturing of 3D Cone Beam Computed Tomography (CBCT) systems. Carejoy Digital, operating from its ISO 13485-certified facility in Shanghai, exemplifies the convergence of advanced engineering, rigorous quality assurance, and scalable production that defines China’s leadership in the digital dentistry equipment market.

1. Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s 3D CBCT systems are manufactured in a vertically integrated facility in Shanghai, leveraging China’s robust supply chain for high-grade sensors, robotics, and embedded AI processors. The production workflow includes:

- Component Sourcing: High-resolution X-ray detectors (CMOS/flat-panel), precision motors, and AI-accelerated GPUs are sourced from Tier-1 suppliers with traceable compliance to IEC 60601-1 and IEC 60601-2-54 standards.

- Subassembly Integration: Modular construction enables parallel assembly of gantry systems, sensor arrays, and control units, reducing production cycle time by 30% compared to legacy European models.

- AI-Driven Calibration: Each unit undergoes real-time calibration using proprietary AI algorithms that optimize beam alignment, scatter correction, and voxel homogeneity across 360° rotation.

2. Quality Control: ISO 13485 and Beyond

Carejoy Digital’s manufacturing facility is certified under ISO 13485:2016, ensuring compliance with medical device quality management systems. Key QC protocols include:

| QC Stage | Process | Standard / Tool |

|---|---|---|

| Raw Material Inspection | Material traceability, RoHS/REACH compliance | ISO 10993, IEC 62304 |

| Sensor Calibration | Per-pixel sensitivity mapping, dark current correction | NIST-traceable calibration labs (Shanghai & Suzhou) |

| Mechanical Tolerance | Laser interferometry for gantry runout & alignment | ±10 µm tolerance across 200mm arc |

| Image Quality Validation | Phantom-based MTF, CNR, and spatial resolution testing | QRM Dental CBCT Phantom, 5 lp/mm resolution |

| Software Verification | AI segmentation accuracy, DICOM 3.0 export validation | IEC 62304 Class B compliance |

3. Sensor Calibration Labs: Ensuring Sub-Voxel Accuracy

Carejoy operates two dedicated sensor calibration laboratories in Shanghai and Suzhou, equipped with:

- NIST-traceable radiation sources (kVp: 60–90, mA: 2–12)

- Automated flat-field correction (FFC) systems

- Thermal drift compensation algorithms (operating range: 18–30°C)

Each CMOS sensor undergoes 72-hour burn-in testing and dynamic range calibration (14-bit depth), ensuring consistent image fidelity across 50,000+ exposures.

4. Durability & Environmental Testing

To validate long-term reliability, Carejoy subjects every CBCT unit to accelerated life testing:

| Test Type | Conditions | Pass Criteria |

|---|---|---|

| Vibration & Shock | ISTA 3A, 50G impulse | No misalignment, image distortion < 2% |

| Thermal Cycling | -10°C to 50°C, 50 cycles | No condensation, sensor drift < 0.5% |

| Continuous Operation | 12 hrs/day, 30 days | MTBF > 15,000 hours |

| EMC/EMI | IEC 60601-1-2 (4th Ed) | No interference with adjacent dental devices |

5. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental hardware is driven by a unique ecosystem of innovation and efficiency:

- Integrated Supply Chain: Access to semiconductor, optics, and robotics manufacturing within 200km radius reduces BOM costs by 25–40%.

- AI-First Design: On-device AI (e.g., Carejoy’s ScanOptix AI) reduces need for high-cost hardware by enhancing software-based image reconstruction.

- Open Architecture Compatibility: Native support for STL, PLY, and OBJ formats enables seamless integration with third-party CAD/CAM and 3D printing workflows, reducing clinic dependency on proprietary ecosystems.

- Scalable R&D: China invests over $2.1B annually in dental imaging AI—3x the rate of the EU—driving rapid iteration in noise reduction, low-dose protocols, and implant planning automation.

- Regulatory Agility: NMPA fast-track approvals combined with CE and FDA 510(k) parallel submissions shorten time-to-market by 6–9 months.

Conclusion: Carejoy Digital – Setting the Global Benchmark

Carejoy Digital leverages China’s manufacturing excellence, AI-driven innovation, and strict adherence to ISO 13485 to deliver 3D CBCT systems with unmatched cost-performance ratios. With 24/7 remote technical support, over-the-air software updates, and open file format compatibility, Carejoy is redefining accessibility and precision in digital dentistry.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Cbct Scan Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160