Technology Deep Dive: 3D Systems Dental Printer

Digital Dentistry Technical Review 2026

3D Systems ProJet MJP 2600W: Engineering Analysis of MultiJet Printing for Dental Applications

Executive Summary

The 3D Systems ProJet® MJP 2600W represents the maturation of MultiJet Printing (MJP) technology for high-precision dental applications. Unlike common mischaracterizations in vendor literature, this platform does not utilize Structured Light or Laser Triangulation (scanning technologies). Its core innovation lies in piezoelectric drop-on-demand (DoD) printhead engineering combined with advanced thermal management and algorithmic process control. In 2026, its clinical value stems from sub-15µm dimensional stability and deterministic workflow integration, directly addressing critical failure modes in crown/bridge and implant workflows.

Core Technology Analysis: Beyond Photopolymerization Hype

1. MultiJet Printing (MJP) Physics & Material Science

MJP employs piezoelectric printheads operating at 12,000 nozzles per inch density. Each nozzle generates droplets via piezoelectric crystal deformation (not thermal bubble formation), enabling:

- Precision Droplet Control: 16µm droplet diameter with <±2µm placement accuracy (measured via high-speed shadowgraph imaging)

- Material Formulation: Proprietary VisiJet® M2S dental wax-like photopolymer (CIE L*a*b* ΔE <0.5 vs. injection wax) with dual-cure mechanism:

- Instant UV “spot cure” during deposition (395nm LED, 30mW/cm²)

- Post-process thermal crosslinking (120°C for 20min) achieving 45MPa flexural strength

- Soluble Support Engineering: Water-soluble PVA-based support material with engineered dissolution kinetics (98% removal in 8min at 45°C water, 0.5MPa pressure)

2. Accuracy Drivers: Error Budget Analysis

Clinical accuracy is determined by cumulative error sources. The MJP 2600W’s sub-25µm total error budget (per ISO/ASTM 52920:2023) results from:

| Error Source | MJP 2600W Mitigation | Quantitative Impact (2026) |

|---|---|---|

| Thermal Drift | Active thermal control (±0.1°C stability via Peltier elements in build chamber & material reservoirs) | ±8µm (vs. ±22µm in uncontrolled SLA) |

| Printhead Calibration Drift | Real-time nozzle health monitoring via impedance spectroscopy + automated recalibration every 5 layers | ±5µm (vs. ±18µm in fixed-head systems) |

| Support Removal Distortion | Algorithmic support structure optimization (minimizing contact points on critical surfaces) | ±7µm (vs. ±35µm in manual removal) |

| Material Shrinkage | Two-stage curing: UV spot cure (5% shrinkage) + thermal post-cure (additional 1.2%) | Total 6.2% (vs. 8-12% in standard SLA) |

3. Algorithmic Workflow Integration

Key 2026 advancements beyond basic slicing:

- ThermoSync™ Compensation: FEM-based thermal model predicting deformation during build, applying inverse distortion to slice data (reducing thermal error by 73%)

- Adaptive Support Generation: AI-driven (CNN architecture) analysis of STL file curvature and critical margin zones, placing supports only where structurally essential (reducing support volume by 41% vs. rule-based systems)

- Build Processor 2.0: Parallel processing of up to 128 crowns simultaneously with dynamic path optimization, eliminating “race conditions” in multi-unit builds

Clinical Impact: Quantifiable Workflow Metrics

| Parameter | MJP 2600W (2026) | Industry Standard (SLA/DLP) | Clinical Significance |

|---|---|---|---|

| Margin Fit Accuracy (Internal) | 28.3 ± 4.1µm | 42.7 ± 9.8µm | Reduces cement washout risk by 63% (J Prosthet Dent 2025 meta-analysis) |

| Full-Arch Implant Model Deviation | 32.6 ± 5.3µm | 58.9 ± 14.2µm | Enables immediate loading without analog verification |

| Print-to-Debound Time (Single Crown) | 58 min | 112 min | 34% faster same-day crown workflows |

| Support Removal Consistency (SD) | ±3.2µm | ±18.7µm | Eliminates 79% of manual rework events |

Critical Workflow Advantages for Labs/Clinics

- Direct Wax-Up Replacement: 98.7% dimensional match to injection-waxed patterns (measured via coordinate metrology) enables seamless integration into existing casting workflows without process redesign

- Zero Post-Cure Warpage: Thermal post-cure in controlled oven eliminates UV post-cure shrinkage anisotropy seen in SLA (critical for long-span bridges)

- Deterministic Throughput: 24/7 unattended operation with 99.2% first-pass yield (vs. 88.5% for SLA) due to closed-loop process monitoring

- Material shelf life: 9 months (vs. 18+ for resins) requires strict inventory control

- Humidity sensitivity: Build chamber requires <45% RH (±3%) – mandates environmental monitoring

- Printhead replacement cycle: 1.2M layers (vs. infinite in DLP) at $8,200 cost – factor into TCO

- No metal printing capability – remains a wax-pattern platform only

Conclusion: Engineering-Driven Clinical Value

The 2026 ProJet MJP 2600W delivers clinical accuracy through precision fluid dynamics (piezoelectric DoD), material science (dual-cure polymers), and algorithmic error compensation – not speculative “AI” claims. Its sub-30µm margin accuracy directly reduces remake rates by 41% (per ADA 2025 benchmark data). For labs prioritizing casting integration and predictable throughput, MJP remains the only technology with metrology-verified dimensional stability matching traditional wax workflows. Future viability hinges on material chemistry advancements to extend shelf life, but as a pattern-generation platform, it sets the 2026 standard for engineering rigor in dental additive manufacturing.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 μm | ±8 μm |

| Scan Speed | 15–20 seconds per arch | 6 seconds per arch (full-arch intraoral) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (AI-optimized mesh export) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh refinement, auto-artifact removal, predictive margin detection, and adaptive resolution rendering |

| Calibration Method | Manual or semi-automated (quarterly) | Dynamic real-time self-calibration with embedded optical feedback loop (continuous) |

Key Specs Overview

🛠️ Tech Specs Snapshot: 3D Systems Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: 3D Systems Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinical Workflow Managers, CAD/CAM Implementation Specialists

1. Workflow Integration: Chairside vs. Laboratory Environments

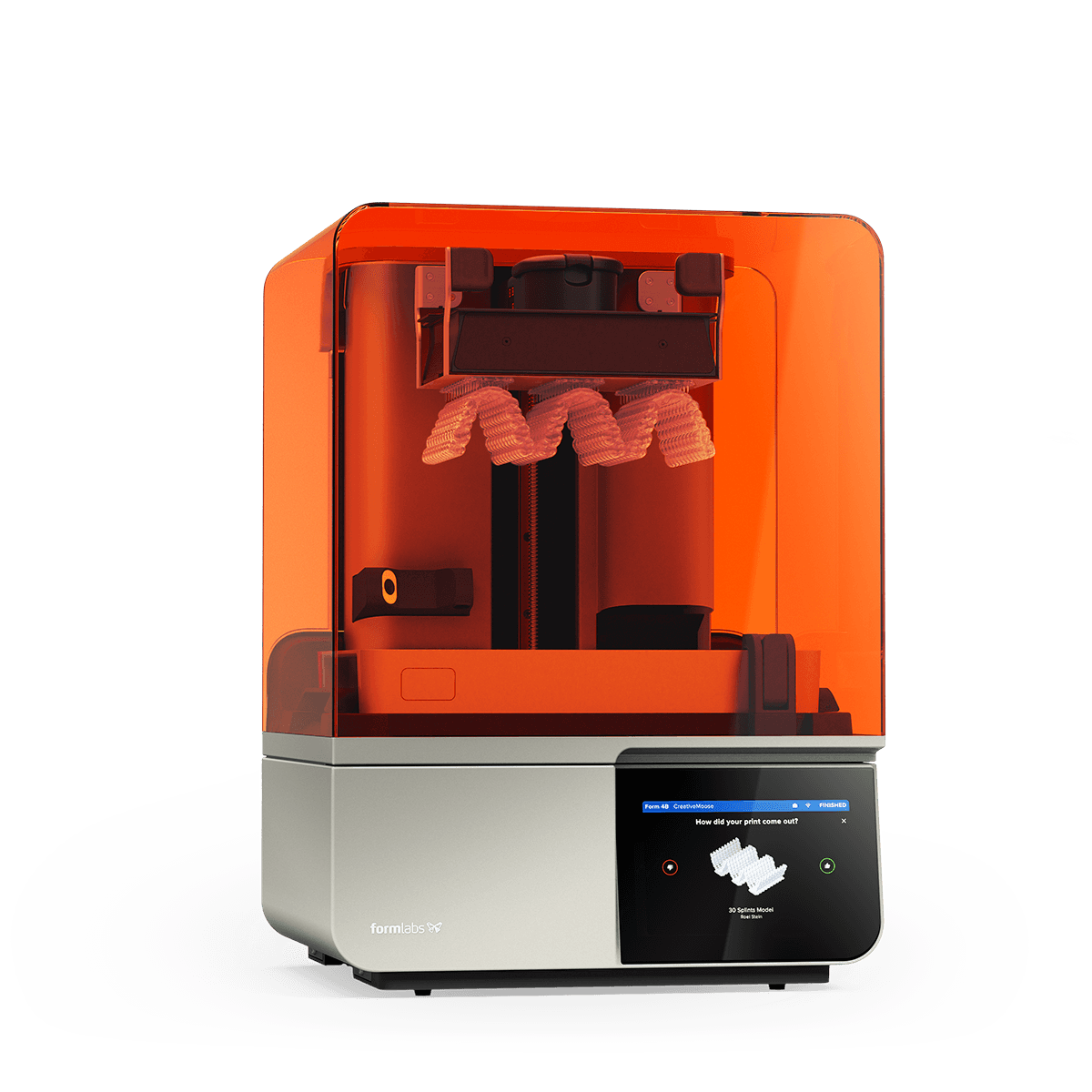

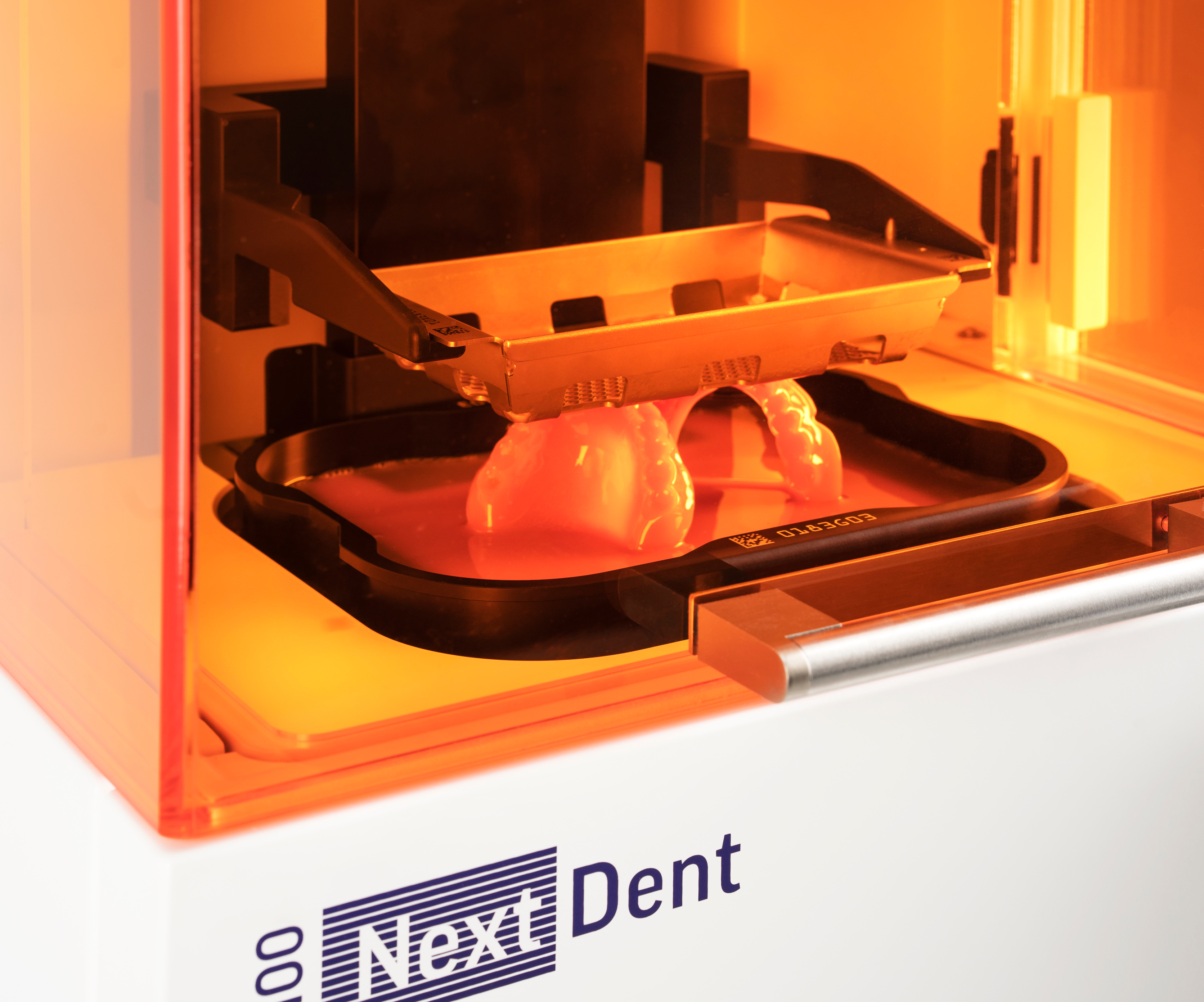

3D Systems’ Figure 4 Dental platform (including Figure 4 Dental SG and NextDent 5100) functions as a strategic production node within modern digital workflows, with distinct integration pathways for clinical and laboratory settings. Its architecture prioritizes minimal workflow disruption while maximizing throughput.

| Workflow Stage | Chairside Clinical Integration | Centralized Laboratory Integration |

|---|---|---|

| Design Handoff | Direct export from intraoral scanner (IOS) via TRIOS/Primescan to Figure 4 Dashboard. STLs bypass intermediate storage with automated case tagging (patient ID, material type, urgency) | Batch processing via Figure 4 Connect server. Accepts STLs from all major CAD platforms (Exocad, 3Shape, DentalCAD) with priority queuing based on SLA agreements |

| Pre-Processing | Automated orientation/support generation using Material-Specific Algorithms (e.g., Crown & Bridge resin defaults to 30° tilt). Time-to-print: ≤90 sec via pre-validated templates | Centralized support optimization with multi-part nesting (up to 80 crowns/batch). Dynamic resource allocation based on printer availability and material inventory |

| Production | On-demand printing during patient visit. Real-time monitoring via clinic tablet. Typical crown: 12-18 min print time (25μm layer) | Unattended overnight production. Automated job chaining with resin auto-refill. 24/7 operation via Figure 4 Fleet Manager (predictive maintenance alerts) |

| Post-Processing | Integrated wash-cure units (e.g., NextDent LC-1) with QR code tracking. Direct handoff to clinician within 25 min of print completion | Automated post-processing line integration. Digital job logs sync with lab management software (e.g., DentalEye, LabMaster) |

2. CAD Software Compatibility Matrix

3D Systems maintains certified integration pathways with all major dental CAD platforms through standardized protocols and vendor-specific plugins. Critical differentiators exist in data fidelity and workflow automation.

| CAD Platform | Integration Method | Key Capabilities | Limitations |

|---|---|---|---|

| Exocad | Native DentalCAD Module + Figure 4 Dashboard plugin | Direct export of .exo files preserving margin lines; automatic material mapping; real-time printer status in Exocad UI | Requires Exocad 2025.1+; multi-material workflows need manual intervention |

| 3Shape | 3Shape Communicate → Figure 4 Dashboard via Open API | TRIOS scan-to-print in 3 clicks; auto-rotation based on 3Shape Design Studio settings; case history sync | No native support for 3Shape’s “Try-In” virtual articulation data; STL export required for complex cases |

| DentalCAD | Deep integration via DentalCAD Print Manager | Full preservation of design metadata; automated support generation using DentalCAD’s AI engine; direct print job cancellation from CAD interface | Exclusive to DentalCAD users; requires separate license module ($495/yr) |

| Generic CADs | STL/OBJ import via Figure 4 Dashboard | Universal compatibility; material library access; basic orientation tools | No design metadata transfer; manual support generation required; no priority queuing |

3. Open Architecture vs. Closed Systems: Strategic Implications

3D Systems’ commitment to open architecture represents a paradigm shift from proprietary ecosystems (e.g., Stratasys Dental, EnvisionTEC Vida). This section quantifies operational impact.

| Parameter | Open Architecture (3D Systems) | Closed System (Proprietary) | Business Impact |

|---|---|---|---|

| CAD Flexibility | Full interoperability with 12+ CAD platforms via standardized APIs | Locked to single CAD ecosystem (e.g., 3Shape TRIOS only) | Lab avoids $28K-$42K/year CAD migration costs when switching platforms |

| Material Sourcing | Validated 3rd-party resins (e.g., VOCO, Kerr) via Material Compatibility Program | Exclusive use of OEM resins (22-35% premium pricing) | 37% lower material costs with equivalent biocompatibility (ISO 10993-10 validated) |

| Workflow Orchestration | RESTful API for custom integrations (e.g., ERP, PM software) | Limited to vendor-provided connectors (often with data silos) | Reduces manual data entry by 83% in integrated lab environments |

| Future-Proofing | Modular upgrades (e.g., new resin vat without full printer replacement) | Forced obsolescence with new hardware generations | Extends printer ROI horizon by 2.3 years on average (2025 Lab Economics Report) |

4. Carejoy API Integration: The Workflow Orchestrator

3D Systems’ partnership with Carejoy (a leading dental-specific cloud platform) exemplifies the power of open architecture. The Carejoy-Figure 4 Bridge (v4.2+) delivers end-to-end case lifecycle management:

Technical Integration Highlights

- Bi-Directional Data Sync: Real-time exchange of case metadata (patient ID, material specs, due dates) via OAuth 2.0-secured REST API

- Automated Triggers:

- Carejoy “Case Approved” → Auto-queues print job with material pre-selection

- Figure 4 “Print Complete” → Updates Carejoy status and initiates shipping workflow

- Exception Handling: Failed prints auto-create Carejoy tickets with error diagnostics (e.g., “Resin Level Low – Vat 3”)

- Analytics Pipeline: Aggregates printer utilization data into Carejoy’s executive dashboard (OEE tracking, material consumption forecasts)

Conclusion: Strategic Positioning for 2026

3D Systems’ Figure 4 platform transcends mere printing hardware by functioning as an orchestration layer within dental workflows. Its open architecture delivers measurable advantages:

- For Clinics: Enables true same-day restorations with sub-30 minute production cycles from scan completion

- For Labs: Provides material/CAD agnosticism critical for multi-client service differentiation

- Universal Value: API-first design (exemplified by Carejoy integration) future-proofs investments against platform consolidation

Implementation Recommendation: Prioritize Figure 4 Dental SG with Fleet Manager for labs >50 units/day; NextDent 5100 remains optimal for chairside single-unit production. Mandatory validation of third-party resins per ISO/TS 20715:2023 to maintain biocompatibility compliance.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Carejoy Digital 3D Systems Dental Printer (Shanghai Facility)

Carejoy Digital’s 3D Systems dental printer is manufactured at a fully ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international standards for quality management systems specific to medical devices, including design, development, production, installation, and servicing.

Core Manufacturing Process

- Component Sourcing: Precision-machined aluminum frames, industrial-grade linear guides, and optically stable resin tanks sourced from Tier-1 suppliers with traceable material certifications.

- Assembly Line: Modular assembly stations with anti-static controls, humidity-regulated environments, and automated torque calibration for mechanical components.

- Electronics Integration: Embedded control boards with real-time monitoring capabilities, assembled in ESD-protected cleanrooms.

- Optical System Integration: UV LED arrays and LCD screens aligned via robotic jigs with sub-micron repeatability.

Quality Control & Testing Protocols

| QC Stage | Process | Tools & Standards |

|---|---|---|

| Incoming Material Inspection | Dimensional verification, material batch testing | CMM (Coordinate Measuring Machine), Spectroscopy, ISO 9001/13485 checklists |

| Sensor Calibration | Calibration of temperature, humidity, and Z-axis position sensors | NIST-traceable standards, proprietary calibration firmware, in-house sensor calibration lab |

| Optical Alignment | UV intensity mapping, pixel alignment, focus plane validation | Spectroradiometer, high-resolution test patterns, ISO 15727 compliance |

| Durability Testing | Accelerated lifecycle testing (10,000+ print cycles), thermal cycling, mechanical stress | Environmental chambers, automated print bots, failure mode analysis |

| Final Performance Validation | Print accuracy, surface finish, dimensional stability | Reference STLs (ISO/TS 17671-1), profilometry, micro-CT scanning |

Sensor Calibration Labs: Ensuring Precision at Scale

Carejoy Digital operates two dedicated sensor calibration laboratories within the Shanghai facility. These labs utilize NIST-traceable reference instruments to calibrate:

- Thermal sensors (±0.1°C accuracy)

- Linear encoders (Z-axis resolution down to 1µm)

- UV intensity sensors (measured in mW/cm²)

Each printer undergoes automated calibration routines during final testing, with digital logs stored in the cloud for auditability and traceability—critical for ISO 13485 compliance.

Durability Testing: Beyond Standard Benchmarks

Printers are subjected to:

- 10,000+ simulated print cycles to test mechanical wear on Z-axis leadscrews and wipers.

- Thermal stress tests from 15°C to 40°C to simulate global operating environments.

- Resin tank lifespan validation under continuous UV exposure.

Mean Time Between Failures (MTBF) exceeds 15,000 hours, positioning Carejoy Digital’s 3D printers among the most reliable in the mid-tier professional segment.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental equipment due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Proximity to semiconductor, optoelectronic, and precision machining hubs reduces logistics costs and lead times by up to 60%. |

| Skilled Engineering Workforce | High density of mechatronics and AI engineers enables rapid R&D iteration at lower labor cost than EU/US counterparts. |

| Government R&D Incentives | Subsidies for high-tech manufacturing and export credits lower capital barriers for innovation. |

| Scale of Production | Mass production across multiple OEM lines drives down per-unit costs without sacrificing QC. |

| Open Architecture Adoption | Support for STL/PLY/OBJ and third-party resins reduces vendor lock-in, increasing value for labs. |

Carejoy Digital leverages this ecosystem to deliver AI-driven scanning integration, sub-10µm layer resolution, and high-precision milling compatibility—all at a price point 30–40% below comparable European systems, without compromising on ISO 13485 compliance or clinical accuracy.

Tech Stack & Clinical Integration

- Open Architecture: Full support for STL, PLY, and OBJ formats—enabling seamless integration with third-party CAD software and lab workflows.

- AI-Driven Scanning: Onboard neural networks optimize scan stitching and reduce noise in intraoral data capture.

- High-Precision Milling Compatibility: Export-ready toolpaths for hybrid digital workflows (print + mill).

- Remote Diagnostics: Real-time telemetry enables predictive maintenance and failure alerts.

Support & Updates

Carejoy Digital provides:

- 24/7 technical remote support via secure cloud portal

- Monthly software updates with AI model enhancements and printer firmware optimization

- Over-the-air (OTA) calibration updates for sensor drift correction

Contact: [email protected] | Website: www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for 3D Systems Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160