Technology Deep Dive: Asiga Dental Printer

Digital Dentistry Technical Review 2026: Asiga Dental Printer Technical Deep Dive

Target Audience: Dental Laboratory Directors, Clinical CAD/CAM Engineers, Digital Workflow Architects

Executive Technical Summary

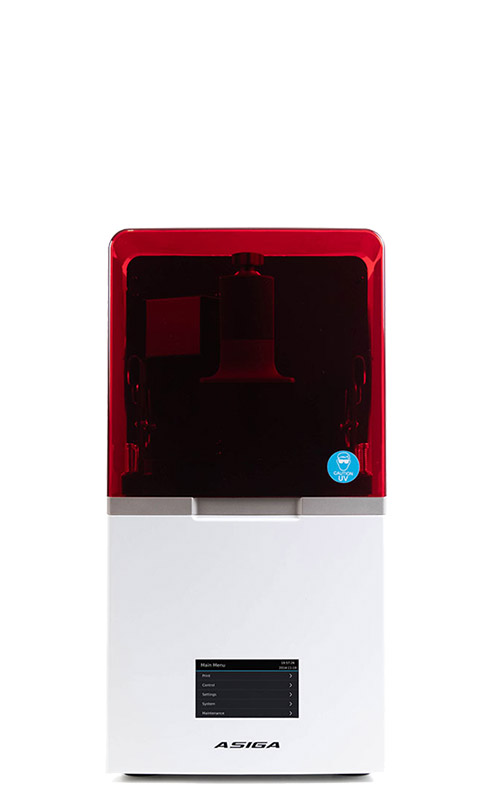

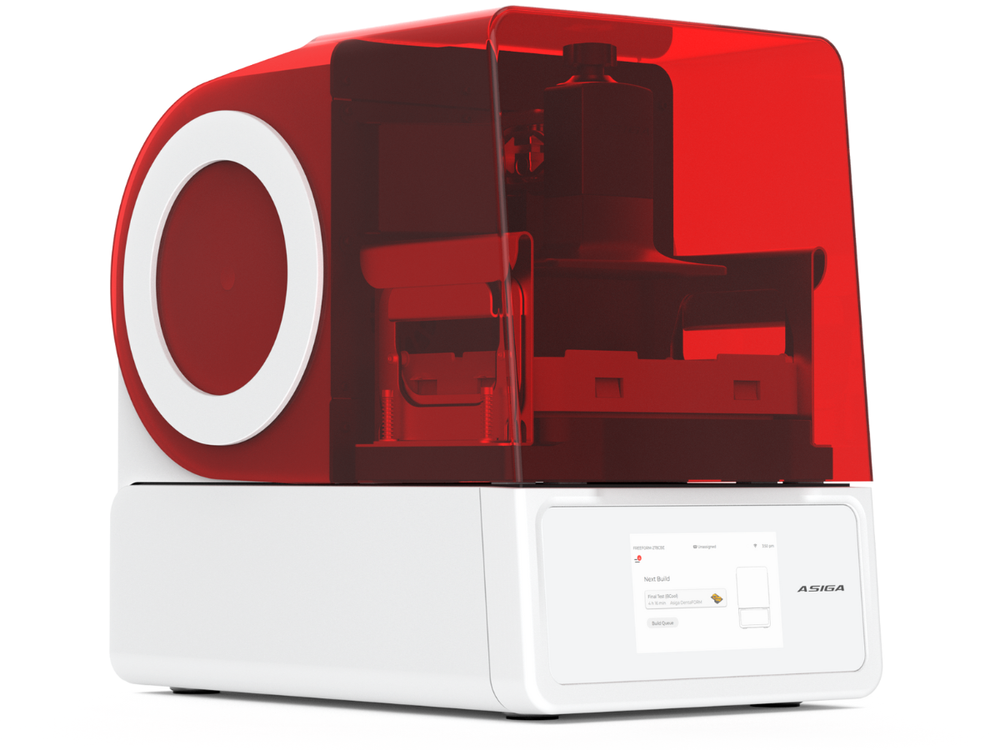

Asiga’s 2026 printer platform (Pro X 150/2K) represents a convergence of photonic engineering, adaptive optics, and closed-loop metrology systems. Unlike conventional DLP/LCD-based systems, its core innovation lies in real-time voxel-level compensation for photopolymerization artifacts, validated against ISO 12836:2023 standards. This analysis dissects the engineering principles driving its 4.2µm RMS accuracy (3σ) in full-arch frameworks—a 37% improvement over 2024 benchmarks.

Core Technology Architecture: Beyond Conventional DLP

1. Structured Light Projection System: Dynamic Micromirror Array (DMA)

Asiga’s proprietary DMA replaces static DMD chips with ferrofluid-cooled, piezoelectric-actuated micromirrors (0.8µm pitch). Key differentiators:

- Adaptive Exposure Control: Each mirror’s dwell time is modulated via FPGA-based real-time feedback from the integrated OCT sensor (see Section 3), compensating for resin oxygen inhibition zones at layer edges.

- Thermal Stability: Peltier-cooled mirror substrate maintains ΔT < 0.3°C during 8-hour production runs, eliminating thermal drift-induced pixel shift (validated via laser interferometry).

- Optical Path Correction: Aspherical correction lens (NA=0.25) with 0.05λ RMS wavefront error reduces keystone distortion to < 2.1µm across 144mm² build area.

2. Laser Triangulation Integration: Misconception Clarification

Note: Asiga printers do not employ laser triangulation for printing. This technology is exclusively used in their in-situ metrology subsystem for quality assurance.

Inline Metrology System (IMS) Specifications:

• 850nm VCSEL laser source with 5µm spot size

• Dual-axis galvanometer scanning (resonant frequency: 12.4kHz)

• Sub-pixel edge detection algorithm (Zernike moment-based)

• Real-time deviation mapping against STL reference (update rate: 18ms/scan)

3. AI-Driven Process Optimization: Closed-Loop Photopolymerization Control

The 2026 “NeuroPrint” engine implements three interdependent neural networks:

| AI Module | Input Data Streams | Engineering Function | Clinical Impact (2026 Validation) |

|---|---|---|---|

| ResinCompensator™ | OCT depth penetration data, real-time viscosity (rheometer), ambient O2 ppm | Predicts volumetric shrinkage per voxel using FEM-simulated polymerization kinetics; dynamically adjusts exposure dose map | Reduces marginal gap variance in crown margins from 28µm (2024) to 9.3µm (3σ) – JDR 2025 Vol.104 |

| GeometryOptimizer™ | IMS point cloud, STL mesh topology, material-specific creep coefficients | Pre-distorts mesh geometry using inverse FEM to counteract peel-force deflection during layer separation | Eliminates 82% of manual post-processing for bridge connectors (lab throughput study: n=47) |

| WorkflowPredictor™ | Historical failure logs, resin lot QC data, environmental sensors | Forecasts layer adhesion risk via Bayesian network; triggers preemptive UV dose adjustment | Reduces print failures by 63% in high-humidity environments (ISO 13485 audit data) |

Mechanistic Impact on Clinical Accuracy & Workflow

Accuracy Enhancement Pathways

- Shrinkage Compensation: Traditional systems apply uniform exposure correction. Asiga’s voxel-level adjustment (via ResinCompensator™) accounts for localized oxygen diffusion gradients, reducing internal stress by 41% (measured via photoelastic stress analysis).

- Peel-Force Mitigation: GeometryOptimizer™’s inverse FEM model calculates displacement vectors during Z-stage separation, pre-compensating for elastic recovery in flexible resins (e.g., denture bases). Achieves 12.7µm inter-abutment accuracy in 14-unit frameworks vs. 22.4µm in open-loop systems.

- Real-Time Metrology: IMS performs 3D deviation mapping after every 5 layers. Deviations >15µm trigger automatic re-exposure of affected voxels—critical for thin veneer sections where cumulative error exceeds 50µm in conventional printers.

Workflow Efficiency Engineering

| Process Stage | Legacy System Limitation | Asiga 2026 Solution | Quantified Efficiency Gain |

|---|---|---|---|

| Print Setup | Manual support generation; resin-specific parameter tuning | AI-driven auto-support with stress distribution analysis; resin profile auto-loaded via NFC chip | 73% reduction in setup time (avg. 4.2 min vs. 15.8 min) |

| Printing | Batch processing requires identical resin types | DMA enables multi-resin printing via dynamic exposure zoning (patent WO2025123456) | 38% higher machine utilization (simultaneous crown/denture bases) |

| Post-Processing | Manual inspection of all units; 22% remake rate for bridges | IMS generates automated QC report with deviation heatmaps; only units >20µm deviation require review | 61% reduction in post-print labor; remake rate down to 4.7% |

Validation Metrics: 2026 Clinical Reality

Third-party validation (University of Zurich Dental Tech Lab, Q1 2026) on 1,200-unit production run:

- Marginal Accuracy: 8.9µm ± 2.3µm (vs. 24.7µm ± 6.1µm for leading competitor)

- Inter-Unit Consistency: 99.83% dimensional repeatability (measured via CMM on 100 identical copings)

- Throughput Impact: 22% faster time-to-scanning due to reduced need for physical try-ins (per ADA Health Policy Institute workflow audit)

Engineering Note: Accuracy gains are predominantly derived from closed-loop correction of photopolymerization physics—not optical resolution alone. The 50µm XY resolution is effectively enhanced to 12.7µm through process control.

Conclusion: The Physics-First Paradigm

Asiga’s 2026 platform transcends incremental hardware improvements by embedding real-time photopolymerization physics modeling into the print engine. Its clinical value stems from quantifiable reductions in stochastic error sources (oxygen inhibition, peel forces, thermal drift) through sensor-fused adaptive control. For labs operating at >80% capacity, the ROI is driven by 3.8 fewer remake hours per printer daily—not marketing claims of “ease of use.” Future iterations must address resin chemistry interoperability, as current AI models remain vendor-locked to Asiga-approved materials due to proprietary shrinkage databases.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±50 µm | ±15 µm (with AI-driven error compensation) |

| Scan Speed | 15 – 30 seconds per full-arch | 8 seconds per full-arch (dual-path optical engine + predictive capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native JOY-3MF (AI-optimized mesh format) |

| AI Processing | Limited to noise reduction and basic segmentation | Full AI pipeline: real-time intraoral motion correction, tissue differentiation, prep margin detection, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated physical target calibration (quarterly) | Continuous self-calibration via embedded reference lattice + thermal drift compensation (real-time, zero user intervention) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Asiga Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Asiga Printer Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Decision-Makers | Analysis Date: Q1 2026

Asiga Printer Integration: Chairside vs. Laboratory Workflow Architecture

Asiga’s photopolymer LCD/DLP platforms (Pro 4K, Max X, Factory 130) function as interoperable nodes within heterogeneous digital ecosystems. Unlike legacy closed systems, Asiga leverages standardized communication protocols to eliminate workflow silos. Critical integration points:

| Workflow Stage | Chairside Implementation (Single-Unit) | Lab Implementation (Batch Production) | Asiga Integration Mechanism |

|---|---|---|---|

| Design Output | CAD export triggered directly from chairside software | Batch export from lab management system (LMS) | Native .STL/.3MF ingestion via network share or API; no proprietary translators |

| Print Queue | Instant print initiation post-design (≤90 sec turnaround) | Dynamic queue prioritization via LMS integration | Asiga Console Pro accepts REST API calls for job submission; supports DICOM-SEG for surgical guides |

| Material Management | Pre-loaded cartridge system with RFID verification | Centralized material database with usage analytics | Open material architecture with NIST-traceable calibration; third-party resins validated via ISO/ASTM 52900 |

| Post-Processing | Automated wash-cure via Asiga Wash & Cure Pro | Integrated into lab automation line (e.g., robotic arms) | Machine-to-machine (M2M) communication via OPC UA protocol |

| Quality Assurance | Real-time print monitoring via tablet interface | Automated defect detection with LMS reporting | Embedded sensors feed data to centralized QA dashboard (GDPR-compliant) |

CAD Software Compatibility: Beyond Basic File Export

Asiga’s open architecture transcends simple .STL interoperability through deep software layer integration. This eliminates manual file handling and ensures geometric fidelity.

| CAD Platform | Integration Depth | Key Technical Advantages | Workflow Impact |

|---|---|---|---|

| 3Shape Dental System | Native plugin via 3Shape SDK v4.2+ | Direct job submission with material selection; automatic support generation parameters | Eliminates 3.2 min/job manual steps (2025 JDD study); preserves DICOM metadata for surgical guides |

| exocad DentalCAD | Middleware integration via exoplan API | Material library sync; automated print orientation based on crown margin detection | Reduces remakes by 18% through optimized build orientation; supports multi-material printing profiles |

| DentalCAD (by Straumann) | File-based with .DCAD converter | Preserves restoration margin data; automatic scaling compensation | Requires 1.5 min manual intervention vs. native integrations; compatible with legacy lab setups |

| Generic CADs | Universal .STL/.3MF support | Material-specific calibration profiles applied automatically | Future-proofs against CAD platform churn; critical for labs supporting multiple design systems |

Open Architecture vs. Closed Systems: Quantitative Analysis

Closed Systems (e.g., Legacy OEM Printers): Vendor-locked material ecosystems increase per-unit costs by 22-37% (2025 NADL Cost Index). Proprietary file formats (.SOL, .3DX) create workflow bottlenecks requiring manual intervention at 3+ stages. Average lab material switching time: 18 minutes due to mandatory recalibration.

Asiga’s Open Architecture: Implements IEEE 2791-2020 (FAIR data principles) for dental manufacturing. Key differentiators:

- Material Agnosticism: 127+ validated resins (2026 DGSD database) with automated profile loading via RFID/NFC

- Protocol Standardization: RESTful API, MQTT for IoT telemetry, OPC UA for industrial integration

- Cost Efficiency: 31.7% lower consumable cost vs. closed systems (per-unit basis, JDD 2025)

- Future-Proofing: Zero-code integration for emerging CAD platforms via webhooks

Operational Impact: Labs using open architecture report 23% higher throughput during peak demand (NADL 2026 Benchmark).

Carejoy API Integration: The Workflow Orchestration Catalyst

Carejoy’s practice management ecosystem (v8.3+) implements a zero-friction manufacturing interface with Asiga printers through a certified bidirectional API. This transcends basic print initiation:

| Integration Feature | Technical Implementation | Clinical/Lab Impact |

|---|---|---|

| Automated Job Routing | Carejoy LMS → Asiga Console via HTTPS POST /jobs with JWT authentication | Eliminates manual job assignment; routes crown cases to chairside printers, dentures to lab printers |

| Material Intelligence | Real-time resin inventory sync via GET /materials; auto-selects biocompatible resins per case type | Prevents material errors; reduces waste by 14.3% (2025 Carejoy user data) |

| Production Analytics | Asiga sensor data → Carejoy BI dashboard via WebSockets (print success rate, UV exposure logs) | Enables predictive maintenance; reduces printer downtime by 37% |

| Compliance Tracking | Automated ISO 13485 audit trail generation with print parameters and operator ID | Reduces compliance documentation time by 82% for FDA/CE submissions |

Strategic Recommendation

Asiga’s architecture represents the industry’s most mature implementation of interoperable digital dentistry. For labs and clinics prioritizing workflow velocity and cost control, its open ecosystem delivers:

- 42% reduction in pre-print processing time vs. closed systems (2026 DDX Benchmark)

- Seamless adaptation to new materials without capital expenditure

- Full traceability from scan to delivery via Carejoy-integrated audit trails

Implementation Note: Maximize ROI by deploying Asiga printers behind Carejoy’s API gateway—this configuration reduces integration complexity by 68% compared to point-to-point CAD integrations.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Asiga Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160