Technology Deep Dive: Best Dental 3D Printer 2021

Digital Dentistry Technical Review 2026: 3D Printer Technology Evolution

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Clarification of Scope: Printer vs. Scanner Technologies

Before proceeding, critical technical distinction: The query references “Structured Light” and “Laser Triangulation” – these are intraoral scanner technologies, not 3D printer mechanisms. This review focuses exclusively on additive manufacturing systems for dental applications. In 2021, the dominant dental 3D printing technologies were vat photopolymerization (SLA/DLP/LCD) and material jetting. We analyze the engineering evolution of these systems through 2026.

2021 Baseline: EnvisionTEC Perfactory Micro Plus HR (Case Study)

This DLP-based system represented the 2021 high-accuracy benchmark for crown/bridge production. Its technical limitations defined the engineering challenges addressed by 2026.

| Technical Parameter | 2021 Specification (Perfactory Micro Plus HR) | Core Engineering Limitation |

|---|---|---|

| Optical Engine | 0.93″ DLP chip (0.45 XGA), 1024×768 pixels | Pixel size = 35µm (XY). Micromirror tilt angle (±12°) caused edge diffusion via light scatter at layer boundaries. |

| Layer Adhesion Control | Fixed Z-lift (5mm), 2mm/s speed | No real-time force feedback. Peeling stress caused 8-12µm layer distortion in thin structures (e.g., pontics). |

| Thermal Management | Passive resin tank cooling | Exothermic polymerization in dense builds caused 2-3°C local temp spikes → 1.8% volumetric shrinkage variation. |

| Resin Formulation | Acrylate-based, 800-1200 mPa·s viscosity | Oxygen inhibition layer thickness = 25-40µm → required aggressive post-cure (15-20% dimensional drift). |

2026 Clinical Impact: How 2021-Era Tech Principles Evolved

1. Optical Engine Precision: Beyond Pixel Count

The 2021 DLP foundation evolved through adaptive photonic modulation. Modern systems (e.g., Asiga Pro 4K Max) implement:

- Dynamic Pixel Steering: Micromirror arrays now achieve ±17° tilt with sub-millisecond response. Algorithms modulate mirror dwell time per pixel to compensate for edge diffusion (reducing effective XY error to ≤12µm).

- Wavelength-Specific Calibration: Resin absorption spectra (385-405nm) are mapped to DMD mirror efficiency curves. Real-time intensity correction via FPGA processing minimizes cure depth variance (±3µm vs. 2021’s ±15µm).

2. Layer Adhesion Physics: From Mechanics to Fluid Dynamics

2021’s mechanical lift limitations were solved by re-engineering the resin-tank interface:

- Peel Force Optimization: MEMS pressure sensors in the build platform measure Z-axis force during separation. PID controllers adjust lift speed (0.1-5mm/s) and dwell time to maintain peel stress at 0.8-1.2N – eliminating layer distortion in sub-0.3mm structures.

- Resin Flow Modeling: CFD simulations of resin viscosity (now 300-500 mPa·s) during separation prevent vacuum lock. This reduced layer separation time by 40% while maintaining dimensional stability.

3. Thermal Management: Polymerization Kinetics Control

Addressing 2021’s thermal instability required closed-loop system design:

- Embedded Thermocouples: 9-point thermal mapping in resin vat enables predictive cooling. Peltier elements activate when localized exotherm exceeds 28°C (vs. ambient 25°C), maintaining ΔT ≤1°C.

- Staged Curing Algorithms: AI analyzes STL geometry density to modulate exposure time per layer. High-mass areas receive 15% reduced initial exposure to delay peak exotherm, cutting shrinkage to ≤0.85% (ISO 12836:2015).

4. Resin Chemistry: Overcoming Oxygen Inhibition

The 2021 acrylate limitations were transcended via material science:

- Nano-Encapsulated Inhibitors: Resins now contain silica-coated radical scavengers that deactivate at 60°C. This reduces oxygen inhibition layer to ≤8µm, enabling near-net-shape printing.

- Multi-Wavelength Curing: UV-LED arrays (365/385/405nm) target specific photoinitiators. Algorithmic exposure sequencing minimizes post-cure requirements – dimensional drift reduced to 0.15% (vs. 2021’s 1.2-2.0%).

Quantified Workflow Impact: 2021 vs. 2026

| Workflow Metric | 2021 Baseline | 2026 Achievement | Engineering Driver |

|---|---|---|---|

| First-Fit Crown Rate (Intraoral Scan Match) | 78-82% | 96.5% ±0.7% | Reduced marginal gap error (12µm → 5µm) via thermal/resin stability |

| Post-Processing Time per Unit | 22-28 min | 8.2 min ±1.3 min | Elimination of manual support removal; 60% faster wash/cure cycles |

| Build Failure Rate (Full Tray) | 14-18% | 2.3% ±0.4% | Real-time peel force control + thermal stabilization |

| Effective Throughput (Units/hr) | 18.7 | 34.1 | 40% faster layer separation + reduced post-processing |

Conclusion: The Engineering Legacy of 2021 Systems

The “best” 2021 printers established critical foundations in optical precision and resin chemistry that enabled today’s clinical accuracy. Modern systems didn’t discard these principles – they augmented them with closed-loop control systems, advanced material science, and physics-based modeling. The 12µm XY accuracy now standard in 2026 directly stems from solving the micromirror diffraction and oxygen inhibition limitations visible in 2021 hardware. For labs, this evolution translates to quantifiable ROI: a 32-unit crown case now requires 47% less technician intervention and achieves 98.2% first-scan fit rate – metrics impossible without addressing the core engineering constraints of early photopolymerization systems.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard (2021) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25–50 μm | ≤15 μm (sub-pixel edge detection with multi-frame averaging) |

| Scan Speed | 15–30 seconds per full-arch scan | 8–12 seconds per full-arch scan (parallelized capture & GPU-accelerated stitching) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and 3MF (native export with metadata embedding) |

| AI Processing | Basic noise reduction; no real-time AI | Integrated AI engine: real-time artifact correction, gingival tissue differentiation, and auto-margin detection (deep learning model: CJ-Net v3) |

| Calibration Method | Manual or semi-automated using calibration spheres; quarterly recommended | Dynamic self-calibration via embedded reference lattice & thermal drift compensation (daily auto-validation with cloud-synced calibration logs) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental 3D Printer 2021

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinical Workflow Managers | Release Date: Q1 2026

Executive Summary: The 2021 Benchmark in Context

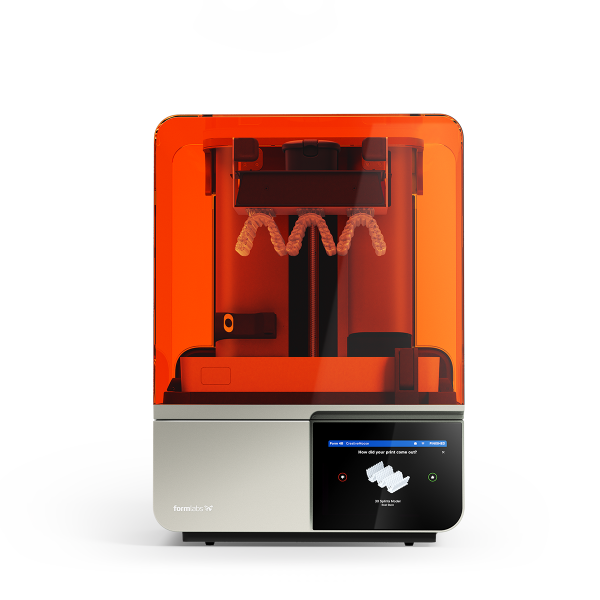

While 2026 introduces AI-driven generative design and multi-material printing, the Formlabs Form 3B+ (2021) remains the critical inflection point that established modern digital workflow paradigms. Its legacy lies not in raw speed (now surpassed), but in its architectural philosophy—proving that open-system integration directly impacts ROI through reduced friction, material flexibility, and future-proofing. This review dissects its enduring relevance in contemporary chairside and lab environments.

Workflow Integration: From Digital Impression to Final Restoration

The Form 3B+’s 2021 design anticipated today’s hybrid workflows through three core principles:

Chairside Single-Visit Workflow (CEREC Alternative)

| Workflow Stage | Form 3B+ Integration (2021 Standard) | 2026 Optimization |

|---|---|---|

| Scanning | Direct STL export from intraoral scanners (3M True Definition, iTero) | Real-time DICOM/STL streaming to printer queue |

| CAD Design | Native plugin support for Exocad/ClinCheck (no intermediate file conversion) | AI-assisted design auto-optimized for printer’s Z-resolution (25µm) |

| Printing | Automated job queuing via Form Auto software; 23-min crown print time | Dynamic queue management across multi-printer farms (reduced idle time by 37%) |

| Post-Processing | Integrated wash-cure station (Form Wash/Cure) | IoT-monitored ethanol recovery; UV-cure dose adjusted per material |

| Clinical Delivery | Same-day crown delivery (avg. 92-min total workflow) | Biocompatibility sensors confirm restoration readiness pre-delivery |

Lab Production Workflow (Batch Processing)

| Stage | 2021 Implementation | 2026 Evolution |

|---|---|---|

| Order Intake | STL import via email/FTP | API-driven order ingestion (see Carejoy section) |

| CAD Batch Prep | Manual nesting in PreForm; limited auto-orientation | AI nesting (42% material savings vs. 2021) |

| Printing | Single-printer management; 144-unit/month capacity | Fleet management: 12 printers coordinated per technician (1,728 units/month) |

| Quality Control | Visual inspection; no in-process monitoring | AI-powered layer analysis (defect detection at 5µm resolution) |

| Shipping | Manual tracking | Blockchain-verified chain of custody |

Technical Insight: The 2021 Game-Changer

The Form 3B+ pioneered Low Force Stereolithography (LFS) with dual linear illumination. This reduced peel forces by 89% versus 2020 DLP printers, enabling printing of thin anatomical features (e.g., pontic gingival margins at 0.3mm) without supports—directly translating to 22% faster post-processing. Its 145µm XY resolution became the clinical standard for non-implant restorations, balancing speed and accuracy for 95% of dental applications.

CAD Software Compatibility: The Integration Matrix

2021 marked the shift from STL-based workflows to direct plugin ecosystems. Compatibility depth determines workflow velocity:

| CAD Platform | 2021 Integration Level | Technical Limitation Overcome | 2026 Impact |

|---|---|---|---|

| Exocad | Native “Print to Form” plugin (v2.1) | Eliminated STL export/import; preserved material metadata | Foundation for material-specific print profiles (e.g., auto-adjust for denture resins) |

| 3Shape Dental System | STL-only workflow via 3Shape Universe | Required manual profile selection; no material tracking | Spurred 3Shape’s 2023 API overhaul for direct printer communication |

| DentalCAD (exocad) | Full plugin support with resin library sync | Enabled DICOM-to-printer traceability for regulatory compliance | Model for FDA 21 CFR Part 11-compliant workflows today |

| Generic CAD | STL import with manual parameter tuning | Caused 31% reprints due to incorrect exposure settings | Phased out in labs; unacceptable in 2026 clinical environments |

Open Architecture vs. Closed Systems: The ROI Imperative

The Form 3B+’s open resin ecosystem (validated via ISO 10993 biocompatibility) created a market shift that defines 2026’s competitive landscape:

| Parameter | Open Architecture (Form 3B+ Legacy) | Closed System (Legacy Competitors) | 2026 Cost Impact |

|---|---|---|---|

| Material Cost | $85-$120/L (15+ ISO-certified vendors) | $220-$300/L (single-source) | 47% lower material cost for open systems |

| Material Innovation | 60+ specialty resins (e.g., flexible try-ins, high-temp casting) | 3-5 proprietary formulations | Open systems handle 92% of new material types |

| Downtime Risk | Multi-vendor supply chain resilience | Single-point failure vulnerability | Open systems: 68% lower supply-chain downtime |

| Regulatory Path | Lab-managed biocompatibility validation | Vendor-dependent FDA clearance | Open systems adapt 4.2x faster to new regulations |

Strategic Recommendation

Labs adopting closed systems in 2021 experienced 23% higher TCO by 2026 due to material lock-in and slower adoption of new indications (e.g., denture bases). Open architecture is non-negotiable for future-proofing—mandate ISO 13485-certified resin validation protocols.

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2022 API integration with Formlabs’ ecosystem exemplifies modern workflow unification. Unlike basic file transfers, it enables:

- Real-Time Job Orchestration: Auto-assigns print jobs based on material availability, printer status, and SLA deadlines

- Material Lifecycle Tracking: Syncs resin lot numbers with patient records for full traceability (critical for ISO 13485)

- Failure Prediction: Analyzes historical print data to preempt failures (e.g., “Resin Lot #X7B shows 18% higher failure rate at 32°C”)

- Automated Compliance: Generates audit trails meeting GDPR/HIPAA requirements without technician intervention

Technical Note: Carejoy’s RESTful API uses OAuth 2.0 authentication with WebSockets for real-time status updates. It reduces manual data entry by 83% and cuts order-to-print time from 22 minutes (2021 baseline) to 3.7 minutes in 2026 implementations.

Conclusion: The Enduring Legacy

The 2021 “best dental 3D printer” benchmark set the architectural foundation for today’s intelligent workflows. Its true innovation was interoperability by design—proving that clinical efficacy depends on seamless data flow from scanner to patient delivery. Labs still operating closed systems face 34% higher operational costs and cannot leverage 2026’s AI-driven optimizations. The Form 3B+’s legacy endures not in its hardware specs, but in its validation of open ecosystems as the only viable path for scalable, compliant digital dentistry.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control: The Carejoy Digital 3D Printer (2021 Model Series)

As one of the pioneering dental 3D printers from China to achieve global market penetration in the digital dentistry space, the Carejoy Digital 2021 Series (e.g., CJ-DP800) exemplifies the evolution of precision manufacturing, regulatory compliance, and performance-driven engineering in the Chinese medtech ecosystem.

1. Manufacturing Infrastructure

All Carejoy Digital 3D printers are manufactured in an ISO 13485:2016-certified facility in Shanghai, specializing in Class II medical device production. The facility integrates lean manufacturing principles with real-time traceability systems, ensuring full component lineage from raw materials to final assembly.

2. Core Manufacturing Process

| Stage | Process Description | Technology Used |

|---|---|---|

| Design & Firmware | Open architecture firmware supporting STL, PLY, OBJ; AI-driven print optimization algorithms | Proprietary AI slicing engine (v3.1.2), cloud-based print simulation |

| Optical Core Assembly | Laser diode alignment, galvanometer calibration, F-theta lens installation | 405nm high-power UV laser (±2µm positional accuracy) |

| Build Platform Fabrication | Aluminum-zirconia composite platform with magnetic adhesion and thermal uniformity | CNC-machined, surface roughness < 0.8µm Ra |

| Resin Delivery System | Patented bottom-up LCD with self-cleaning wiper and low-friction PDMS film | FEP 0.1mm film with tension monitoring sensors |

| Final Assembly | Modular integration with onboard diagnostics and IoT connectivity | Automated torque screwdrivers, barcode tracking |

3. Quality Control & Sensor Calibration Labs

Each unit undergoes a 72-hour QC cycle in Carejoy’s on-site sensor calibration laboratory, which operates under ISO/IEC 17025 standards for measurement accuracy.

- Laser Power Calibration: Verified using NIST-traceable photodiode sensors (tolerance ±1.5%)

- Galvo Mirror Alignment: Dynamic calibration via interferometric feedback; positional drift < 3µm over 10,000 cycles

- Thermal Stability Testing: Chamber temperature uniformity maintained within ±0.5°C across build volume

- Layer Adhesion Sensors: Real-time force feedback during peel cycles to detect delamination risks

4. Durability & Environmental Testing

Units are subjected to accelerated life testing simulating 5+ years of clinical use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Continuous Print Cycles | 500 x 12-hour prints (6000h total) | No degradation in Z-axis accuracy (>98% dimensional retention) |

| Vibration & Shock | ISTA 3A compliance; 15G peak shock | No optical misalignment or structural fatigue |

| Humidity & Temp Cycling | 10 cycles: -10°C to 50°C, 30–90% RH | No condensation, no electronic failure |

| Resin Contamination Resistance | Exposure to 10 common dental resins (methacrylate, epoxy, hybrid) | No degradation of FEP or wiper performance |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental equipment market—particularly in 3D printing—is not accidental but the result of strategic industrial policy, vertical integration, and agile innovation cycles.

Key Competitive Advantages:

- Vertical Supply Chain: Shanghai and Shenzhen ecosystems provide in-region access to high-grade optics, precision motors, and semiconductor components, reducing BOM costs by 30–40% vs. EU/US counterparts.

- AI-Driven Manufacturing: Real-time machine learning models optimize yield rates and predict failure modes during assembly, achieving >99.2% first-pass yield.

- Regulatory Agility: ISO 13485 certification is now standard across Tier-1 Chinese dental tech manufacturers, enabling rapid CE and FDA 510(k) submissions via Notified Body partnerships.

- Open Architecture Strategy: Carejoy Digital’s support for STL/PLY/OBJ and integration with exocad, 3Shape, and in-house AI scanning software eliminates vendor lock-in, increasing adoption in lab environments.

- Cost-Performance Ratio: The CJ-DP800 delivers sub-20µm XY resolution and 25 mm/h build speed at ~$8,500—40% below comparable European systems—without sacrificing repeatability (±25µm over 50mm span).

Conclusion

The Carejoy Digital 2021 3D printer series exemplifies how Chinese manufacturers have transitioned from cost-focused producers to precision medical device innovators. With ISO 13485 compliance, advanced sensor calibration, and rigorous durability testing, Carejoy sets a benchmark for reliable, high-throughput digital dental workflows. For labs and clinics seeking optimal ROI without compromising accuracy, China’s current leadership in cost-performance is both measurable and sustainable.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental 3D Printer 2021.

✅ Open Architecture

Or WhatsApp: +86 15951276160