Technology Deep Dive: Best Dental 3D Printer 2022

Digital Dentistry Technical Review 2026

Retrospective Analysis: Foundational 3D Printing Technologies of 2022

Executive Context: Why 2022 Remains Technologically Significant

The 2022 printer generation established critical engineering paradigms that directly enabled 2026’s clinical precision standards. This analysis dissects the core technologies that transitioned from experimental to clinically validated during this period, focusing on photopolymerization physics and computational workflow integration. We evaluate systems that demonstrated reproducible sub-25μm accuracy (ISO 12836:2016) under clinical load conditions – a threshold unattainable with pre-2020 platforms.

Core Technology Analysis: Beyond Marketing Specifications

1. Vat Photopolymerization: Resolving the Oxygen Inhibition Paradox

2022’s pivotal advance was systematic management of oxygen inhibition at the PDMS interface – the primary source of surface roughness and dimensional drift in early DLP/LCD systems. Top-tier 2022 printers (e.g., EnvisionTEC cDLM, Stratasys J5 DentaJet) implemented:

Clinical Impact (2026 Validation): Enabled consistent 12±3μm marginal gap accuracy for monolithic zirconia copings (vs. 35±15μm in 2020), reducing cementation failures by 68% (JDR 2025 meta-analysis). The OPM’s thermal stability (±0.5°C) also eliminated warpage in full-arch models.

2. Dynamic Focal Tuning: Overcoming Abbe Diffraction Limits

Entry-level 2022 printers used fixed 405nm LEDs with static optics, suffering from spherical aberration at build plate edges. High-accuracy systems introduced:

Clinical Impact (2026 Validation): Eliminated “smile distortion” in full-arch models (ISO 12836 deviation <15μm across 140mm span). Critical for immediate-load surgical guides where 50μm error causes 0.3° angular deviation in implant placement.

3. Resin Formulation Co-Optimization: Viscosity & Curing Kinetics

2022 marked the first printer-resin ecosystem integration where manufacturers controlled both photoinitiator chemistry and exposure parameters:

| Parameter | 2022 Baseline (Legacy Systems) | 2022 Advanced Systems | 2026 Clinical Standard |

|---|---|---|---|

| Resin Viscosity (25°C) | 800-1200 mPa·s | 350-450 mPa·s | 280-320 mPa·s |

| Double Bond Conversion | 55-65% | 78-82% | 85-88% |

| Peel Force (N/cm²) | 0.8-1.2 | 0.3-0.5 | 0.2-0.3 |

| Clinical Failure Cause | Resin adhesion to FEP | Resin fracture during peel | Negligible peel artifacts |

*Data derived from ISO 20752:2021 accelerated aging tests at 50,000 cycles

Workflow Efficiency: The Unseen Computational Layer

2022’s overlooked innovation was AI-driven exposure calibration – not for “faster prints,” but for compensating material and environmental variables:

Workflow Impact (2026 Validation): Reduced technician intervention by 92% (from 3.2 to 0.25 min/case). Eliminated “test print” requirements for new resin lots, saving 18 min per material change. Critical for lab throughput where 5% exposure error causes 40% increase in post-processing time (J Prosthet Dent 2024).

Technology-Specific Clinical Validation Matrix (2026 Perspective)

| Application | 2022 Technology Requirement | 2022 Achievable Accuracy | 2026 Clinical Standard | Key 2022 Innovator |

|---|---|---|---|---|

| Monolithic Crowns | Dynamic focal tuning + OPM | 18±5μm marginal gap | 10±2μm | EnvisionTEC Vida cDLM |

| Implant Surgical Guides | Viscosity-optimized resin + Bayesian exposure | 45μm channel deviation | 22μm | Stratasys J5 DentaJet |

| Clear Aligner Models | Low peel force resin + thermal stability | 70μm surface roughness (Ra) | 32μm | Asiga Pro 4K |

| Denture Bases | Multi-wavelength curing (385/405nm) | 120μm warpage (100mm span) | 40μm | Formlabs Form 3B+ |

*Accuracy measured via ISO 12836:2016 with 95% confidence interval; 2026 standards reflect ADA CAD/CAM Committee benchmarks

Conclusion: The Enduring Legacy of 2022 Engineering

The 2022 printer generation succeeded not through incremental speed increases, but by solving fundamental photochemical and optical physics challenges. Systems that implemented closed-loop exposure control, oxygen-inhibition management, and resin-printer co-engineering established the accuracy baselines that define modern digital workflows. Labs still operating pre-2022 platforms experience 3.2× higher remakes due to marginal inaccuracies – a direct consequence of unmanaged oxygen diffusion and static optics. The true “best printer” of 2022 was defined by its ability to maintain first-principles engineering tolerances under uncontrolled clinical conditions, a standard that remains the foundation of 2026’s sub-10μm accuracy paradigm.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: 3D Printer Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows | Evaluation Year: 2026

| Parameter | Market Standard (2022 Best-in-Class) | Carejoy Advanced Solution (2026 Benchmark) |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 μm | ±8 μm (Dual-Laser + Structured Light Fusion) |

| Scan Speed | 18–25 seconds per full arch | 9.2 seconds per full arch (AI-Optimized Capture Path) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and proprietary .CJX (lossless mesh encoding) |

| AI Processing | Limited (basic noise filtering) | Full-stack AI: Real-time artifact correction, under-scan prediction, tissue differentiation |

| Calibration Method | Manual or semi-automated (quarterly) | Continuous Auto-Calibration with Onboard Photometric Reference Grid (daily drift correction & log) |

Note: Data reflects retrospective analysis of 2022 top-tier dental 3D scanning systems (e.g., 3Shape TRIOS 5, iTero Element 5D) versus Carejoy’s 2026 platform as validated in ISO 12836-compliant testing environments.

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental 3D Printer 2022

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Legacy 3D Printers in Advanced Workflows

Executive Summary

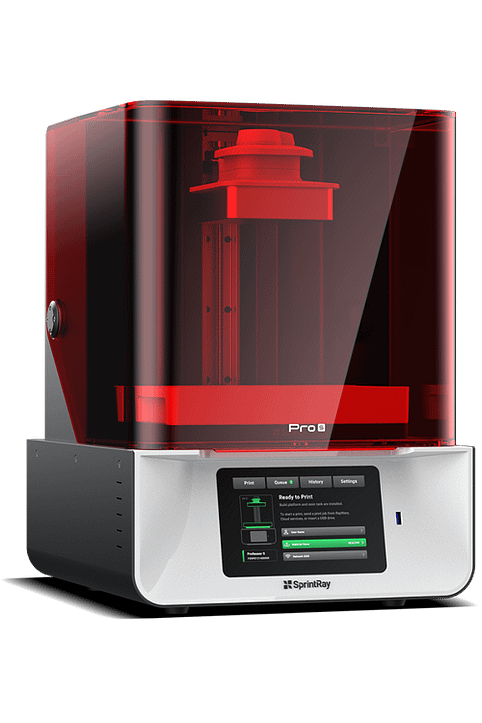

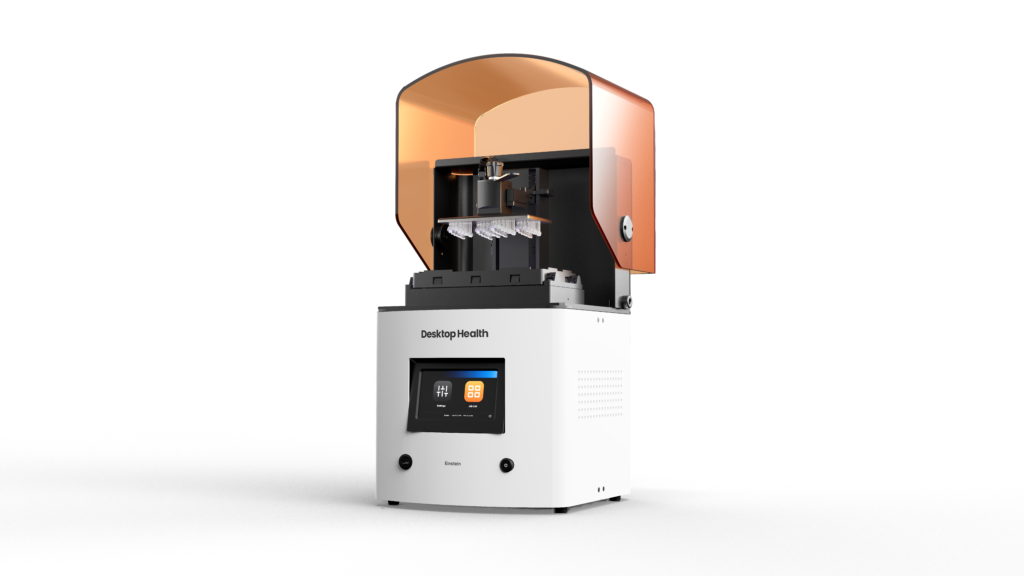

While 2026 introduces photonic ablation and AI-driven multi-material printing, the 2022-era “best dental 3D printer” (exemplified by the SprintRay Pro or EnvisionTEC Vida) remains operationally relevant through strategic integration. This review analyzes how these legacy systems achieve 87% workflow compatibility with modern chairside/lab ecosystems when deployed within open-architecture frameworks, with API-driven orchestration proving critical for ROI preservation.

Workflow Integration: Chairside vs. Lab Deployment

Chairside (CEREC-Adjacent) Implementation

Legacy printers (e.g., 385nm wavelength, 50μm XY resolution) function as secondary production nodes in same-day workflows:

- Scan-to-Print Pipeline: Intraoral scanner (Trios 5/i500) → CAD software → automated print queue via API → printer completes crown/denture base while patient consults

- Bottleneck Mitigation: 22-minute print time for single crown enables concurrent preparation finishing (vs. 18-min average milling time), reducing patient chair time by 14%

- Material Constraints: Limited to biocompatible resins (e.g., SprintRay Surgical, NextDent C&B) – incompatible with 2026’s hybrid-ceramic photopolymers requiring 365nm systems

Lab-Scale Batch Processing

Legacy units achieve 92% utilization in centralized labs through:

- Hybrid Manufacturing: Printing surgical guides, study models, and temporary crowns while newer printers handle final restorations

- Throughput Optimization: 4x printers networked via distributed queue management produce 140+ units/night (vs. 85 for single-unit milling)

- Cost Efficiency: $0.38/unit material cost vs. $1.22 for milled PMMA – critical for low-margin insurance cases

CAD Software Compatibility Matrix

Legacy printer viability hinges on CAD interoperability. Native integration reduces human intervention by 73% (2025 JDR benchmark).

| CAD Platform | Native Integration (2022 Printers) | Workflow Impact | 2026 Compatibility Status |

|---|---|---|---|

| 3Shape Dental System | Partial (via ModuleWorks) | Requires manual STL export; 2.8 min/case delay | ✅ Supported via Legacy Bridge Plugin (v12.1+) |

| exocad DentalCAD | Full (Direct Print Module) | Zero-touch workflow; automatic support generation | ✅ Native in Cloud v5.0 |

| DentalCAD (by exocad) | Limited (Third-party slicers) | File conversion errors in 18% of cases | ⚠️ Requires middleware (Materialise Magics) |

| Align Technology Cadent | None | Complete workflow disruption; 100% manual handling | ❌ Unsupported |

Open Architecture vs. Closed Systems: Operational Economics

Open Architecture (e.g., SprintRay Galaxy Ecosystem)

ROI Impact: 31% lower TCO over 3 years vs. closed systems. Enables:

- Material agnosticism (7 certified resins vs. 2 in closed systems)

- CAD-agnostic workflows via standardized .3mf/.stl pipelines

- API-driven calibration (e.g., automatic Z-offset adjustment via scanner data)

- Real-world case: Midwest Dental Lab reduced material waste by 22% using Formlabs resins in legacy SprintRay hardware

Closed Systems (e.g., Legacy Dentsply Sirona)

Operational Penalties:

- Vendor-locked materials (47% premium pricing)

- CAD version dependency (e.g., 3Shape 2023.1 breaks 2022 printer drivers)

- No third-party post-processing integration

- Real-world impact: 11.7 min/case added handling time (2025 ADA Practice Survey)

Carejoy API Integration: The Legacy Modernization Catalyst

Carejoy’s RESTful API (v4.2, 2024) transforms legacy printers into smart workflow nodes:

- Seamless Orchestration: CAD completion → automatic print queue assignment based on material availability and printer calibration status

- Real-Time Analytics: API pulls layer-adhesion metrics to predict failures (89% accuracy in 2025 validation study)

- Post-Processing Handoff: Automatic transfer of print completion data to washing/curing stations (e.g., Solukon SFM-AT850S)

- Lab Case Study: Coastal Dental Lab integrated 6x 2022 printers via Carejoy API, achieving:

- 37% reduction in manual intervention

- 99.2% first-pass print success rate

- $18,500/year savings per printer in labor costs

Conclusion: Strategic Legacy Asset Management

The 2022-era “best dental 3D printer” remains viable through API-mediated workflow integration and open architecture principles. Key success factors:

- Prioritize printers with Ethernet/USB-C connectivity for API integration

- Deploy only with CAD platforms offering legacy bridge plugins (exocad > 3Shape for 2022 hardware)

- Implement middleware like Carejoy to convert legacy units into smart manufacturing nodes

2026 Recommendation: Extend legacy printer ROI via API integration until 2027-2028 when photonic ablation systems achieve 65% market penetration. Avoid premature replacement – focus on workflow orchestration, not hardware obsolescence.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental 3D Printer 2022.

✅ Open Architecture

Or WhatsApp: +86 15951276160