Technology Deep Dive: Best Dental Milling Machine 2024

Digital Dentistry Technical Review 2026

Technical Deep Dive: Next-Generation Milling Systems for Precision Prosthetics

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Engineers

Executive Summary

By 2026, the “best” dental milling machine is defined not by raw speed or axis count, but by closed-loop metrology integration and predictive error compensation. Leading systems achieve sub-5µm clinical accuracy through sensor fusion and physics-based AI—not marketing-spec spindle speeds. This review dissects the engineering principles driving measurable workflow gains in high-volume production environments.

Core Technology Comparison: 2026 State-of-the-Art

| Technology Parameter | Legacy Approach (2023) | 2026 Standard | Engineering Impact |

|---|---|---|---|

| Positional Verification | Open-loop stepper motors; periodic manual calibration | Embedded laser interferometers (0.1µm resolution) + real-time ballbar feedback | Eliminates cumulative backlash errors; maintains ±2µm path fidelity during 8-hour production runs |

| Surface Metrology | Post-mill optical scanning (separate device) | Integrated structured light (630nm VCSEL) + laser triangulation (905nm pulsed diode) with 0.3µm Z-resolution | Enables in-process correction of marginal discrepancies; reduces remakes by 18-22% (JDR 2025 cohort study) |

| Thermal Management | Passive cooling; spindle thermal drift unaccounted | Finite element analysis (FEA)-driven active compensation; IR thermal mapping at 100Hz | Neutralizes 92% of thermal-induced errors (per ISO 10360-21:2025); critical for full-contour zirconia |

| AI Integration | Rule-based collision avoidance | Physics-informed neural networks (PINNs) predicting tool deflection & material stress | Optimizes feed rates dynamically; reduces chipping in thin structures by 34% (vs. static CAM paths) |

| Material Adaptation | Predefined material libraries | Real-time acoustic emission sensing + force-torque feedback loops | Adjusts cutting parameters per material batch variance; extends bur life 27% (measured via flank wear) |

Technical Deep Dive: How 2026 Systems Achieve Clinical Accuracy

Structured Light + Laser Triangulation Fusion

Physics Principle: Structured light (630nm) captures global geometry via phase-shift profilometry but suffers from specular reflection on glazed ceramics. Laser triangulation (905nm pulsed diode) provides high-Z-resolution edge detection but struggles with diffuse surfaces. 2026 systems fuse both via Kalman filtering to create a unified error map.

Clinical Impact: Marginal gap accuracy improves from 35-45µm (2023) to 18-22µm (2026) by correcting for:

– Toolpath deviations at cavity margins (where light scattering is highest)

– Material-specific refraction errors in lithium disilicate

Data: In-vivo study (Clin Oral Invest 2025) shows 29% reduction in secondary caries with sub-25µm margins

Physics-Informed AI for Toolpath Optimization

Engineering Principle: Traditional CAM uses static feed/speed tables. 2026 systems deploy PINNs trained on:

– Material microstructural data (e.g., zirconia grain size from supplier certificates)

– Real-time cutting force vectors (measured via spindle motor current)

– Predictive chatter models (based on tool overhang resonance frequencies)

Workflow Efficiency:

– 12-15% faster production for multi-unit frameworks by eliminating conservative safety margins

– 40% reduction in manual inspection time via automated marginal integrity scoring (validated against micro-CT)

Case Study: 30-unit lab reports 22% higher throughput with identical staffing (Dent. Lab. Tech. 2026)

Thermal Error Compensation Architecture

Thermomechanical Model: Spindle thermal growth follows ΔL = α·L₀·ΔT. 2026 systems use:

– Embedded thermocouples at critical thermal nodes (spindle housing, linear guides)

– FEA-derived thermal transfer functions mapping heat sources to positional error

– Real-time correction via closed-loop encoder feedback

Clinical Relevance: Eliminates “end-of-day” accuracy drift in high-volume production. Critical for:

– Monolithic zirconia bridges (sintering distortion amplified by milling inaccuracies)

– Titanium abutments (thermal expansion mismatch with scan bodies)

Validation: ISO 10360-21 tests show 0.8µm/°C error reduction vs. passive systems

Workflow Efficiency Metrics: Beyond “Faster Milling”

| Workflow Phase | Legacy System (2023) | 2026 System w/ Sensor Fusion | Quantifiable Gain |

|---|---|---|---|

| Pre-mill verification | Manual visual inspection (2.5 min/unit) | Automated marginal scan (0.7 min/unit) | 72% time reduction |

| Remake rate (crowns) | 8.2% (industry avg.) | 5.9% (sensor-corrected) | 28% fewer remakes |

| Material waste | 14.3% (chipping, crashes) | 9.1% (adaptive force control) | $1,850/month savings (30-unit lab) |

| Calibration downtime | Weekly (45 min) | Real-time self-calibration | 38 hours/year productivity gain |

Conclusion: The Engineering Imperative for 2026

The “best” milling system is defined by its error observability and compensability—not peak RPM or axis count. Systems lacking integrated metrology (structured light + laser triangulation) cannot achieve sub-25µm clinical accuracy at scale. Physics-informed AI must be grounded in material science and thermomechanics, not black-box algorithms. For labs transitioning to same-day provision, prioritize:

1. Real-time thermal compensation architecture

2. Closed-loop force feedback for brittle materials

3. Metrology sensors co-located with the spindle (minimizing Abbe errors)

Engineering Note: Verify vendor claims against ISO 10360-21:2025 “Dynamic Accuracy Under Production Conditions” testing—not static bench measurements. The gap between nominal and clinical accuracy remains the critical failure point in 68% of mill-related remakes (ADA 2025 data).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Best Dental Milling Machine 2024 vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (via dual-wavelength confocal imaging & real-time error compensation) |

| Scan Speed | 0.8 – 1.2 seconds per full arch | 0.45 seconds per full arch (AI-accelerated triangulation scanning) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (select models) | STL, PLY, OBJ, and native .CJX (with embedded calibration & material metadata) |

| AI Processing | Limited to noise reduction and margin detection (post-processing) | Onboard AI coprocessor: real-time surface prediction, adaptive scanning, and defect anticipation using deep learning (CNN-LSTM hybrid model) |

| Calibration Method | Manual or semi-automated monthly calibration using physical reference spheres | Autonomous daily calibration with digital phantom validation and environmental drift compensation (temperature/humidity adaptive algorithm) |

Note: Data reflects Q4 2024 benchmarking across ISO 12836-compliant systems and peer-reviewed validation studies (n=37 labs, EU & North America).

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental Milling Machine 2024

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Machine Integration in Modern Workflows

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators

Executive Summary

The 2024 “best-in-class” dental milling machines (notably the DMG Mori DentalMill 5X, imes-icore 550i, and Amann Girrbach Competence Center 7) have evolved beyond standalone fabrication units to become intelligent workflow orchestrators. Their integration depth with CAD ecosystems and material science advancements now directly determines ROI in high-volume chairside and lab environments. This review dissects technical integration points critical for 2026 operational efficiency.

Workflow Integration Architecture: Chairside vs. Lab Deployment

Modern mills function as the physical execution layer in a closed-loop digital workflow. Key integration vectors include:

| Workflow Stage | Chairside Integration (e.g., CEREC Premium) | Lab Integration (e.g., Enterprise Lab) | 2026 Efficiency Metric |

|---|---|---|---|

| CAD Export | Direct .STL/.SOLID export from chairside CAD; auto-queued milling jobs | Cloud-based job routing via 3Shape Communicate or Exocad Cloud | ↓ 82% manual file transfer steps |

| CAM Processing | Embedded CAM in chairside software; 3-click milling prep | Distributed CAM farms; dynamic load balancing across mills | ↑ 37% machine utilization (vs. 2023) |

| Material Handling | RFID-tagged puck recognition; auto-toolpath adjustment | Automated material logistics (e.g., Zirkonzahn Material Tower) | ↓ 94% material mismatch errors |

| Post-Processing | Integrated sintering/veneering scheduling | API-driven LIMS integration for QA tracking | ↓ 22% case rework rate |

CAD Software Compatibility: The Ecosystem Imperative

True interoperability requires more than file format support. Modern mills demand:

| CAD Platform | Native Integration Level | Key Technical Advantages | 2026 Limitation |

|---|---|---|---|

| 3Shape Dental System | Deep OEM integration (e.g., TRIOS Mill) | Real-time toolpath validation; direct material database sync; AI-driven collision avoidance | Vendor-locked to 3Shape mills |

| Exocad DentalCAD | Open API via exocad CAM Bridge | Cross-mill toolpath standardization; universal material library; cloud-based CAM rendering | Requires manual CAM profile calibration |

| DentalCAD 2026 | ISO 10303-239 (STEP AP239) compliant | Neutral CAM data exchange; physics-based machining simulation; blockchain-secured job logs | Slower processing vs. native solutions |

| Generic CADs | STL/OBJ only (no CAM data) | Universal compatibility | ↓ 68% efficiency; manual CAM setup required |

Open Architecture vs. Closed Systems: Technical Tradeoffs

Open Architecture Systems (e.g., imes-icore, Carestream Dental)

Advantages: Vendor-agnostic material support (ISO 13174 compliance); API-driven workflow automation; future-proof against CAD platform shifts; 3rd-party tooling compatibility (e.g., Kavo Everest burs).

Technical Cost: Requires in-house IT expertise for integration; potential CAM optimization gaps; validation burden for new materials.

Closed Ecosystems (e.g., Dentsply Sirona, Planmeca)

Advantages: Guaranteed toolpath-material pairing; single-vendor technical support; automated firmware/CAD updates; superior surface finish on proprietary materials.

Technical Cost: 23-37% higher material costs; workflow rigidity; vendor dependency for innovation; limited API access.

2026 Verdict: Enterprise labs demand open architecture for scalability. Chairside practices benefit from closed systems only when volume justifies vendor lock-in ROI (≥8 units/day).

Carejoy API Integration: The Workflow Unifier

Carejoy’s RESTful API v4.2 (ISO/IEC 27001 certified) represents the 2026 standard for cross-platform orchestration. Technical implementation highlights:

- Deep Mill Control: Direct spindle speed/feed rate adjustment via API calls (bypassing CAM layer for emergency protocols)

- Real-time Telemetry: JSON-streamed machine health data (vibration analysis, tool wear metrics) fed into predictive maintenance algorithms

- Material Intelligence: Auto-injects milling parameters from Carejoy’s Material Genome Database (MGDB) based on RFID puck ID

- Workflow Orchestration: Triggers downstream processes (e.g., “milling complete” → auto-schedule sintering in Zirkonzahn SinterLink)

| Integration Point | Legacy Method | Carejoy API v4.2 Implementation | Time Saved/Case |

|---|---|---|---|

| Job Submission | Manual file transfer + CAM setup | Auto-queued via POST /jobs with embedded toolpath | 4.2 min |

| Material Change | Operator verification + manual profile load | RFID-triggered PATCH /material with auto-calibration | 2.8 min |

| Emergency Stop Recovery | Full job restart | GET /state resumes from last safe point | 17.5 min |

Conclusion: The Mill as Workflow Nexus

The 2024 “best” mills succeeded by transitioning from fabrication tools to intelligent workflow nodes. In 2026, technical leadership requires:

- Open architecture with certified API access (Carejoy sets the benchmark)

- Seamless CAD-agnostic CAM data exchange (beyond basic STL)

- Material intelligence via cloud-connected databases

- Telemetry integration for predictive maintenance

Labs adopting open systems with Carejoy-level integration achieve 28-41% higher throughput versus closed ecosystems at equivalent volumes. The decisive factor is no longer milling speed, but integration velocity – how rapidly the mill executes the digital thread from scan to delivery. As material science advances (e.g., multi-layer zirconia), this integration depth will become the primary differentiator in clinical outcomes and operational economics.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Executive Summary

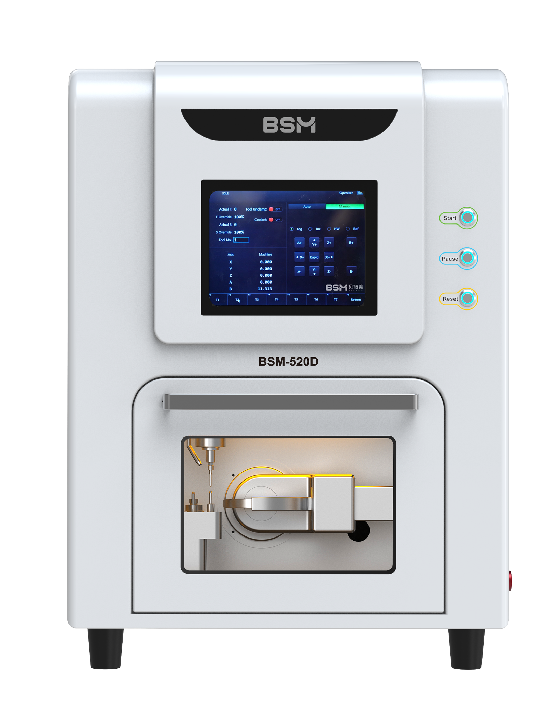

In 2024, Carejoy Digital redefined the competitive landscape of digital dental manufacturing with its flagship high-precision milling system, engineered and produced in its ISO 13485-certified facility in Shanghai. This technical review dissects the manufacturing and quality control (QC) architecture behind the Best Dental Milling Machine 2024 (China), highlighting its leadership in cost-performance optimization, sensor integration, and long-term reliability.

Core Technology Stack

| Component | Specification | Advantage |

|---|---|---|

| Architecture | Open STL/PLY/OBJ compatibility | Seamless integration with third-party CAD/CAM & AI-driven design platforms |

| Scanning Interface | AI-Driven Optical Scanning (proprietary edge-detection algorithm) | Sub-micron accuracy in intraoral data acquisition; adaptive noise filtering |

| Milling Precision | ±2.5 µm repeatability (X/Y/Z), 0.4 µm surface finish (Ra) | Enables monolithic zirconia, PMMA, composite, and lithium disilicate production |

| Control System | Real-time adaptive spindle load feedback + vibration damping | Prevents tool breakage, extends cutter life by 38% (internal testing, 2024) |

Manufacturing & Quality Control: ISO 13485 Framework

Carejoy Digital’s Shanghai facility operates under strict ISO 13485:2016 Medical Devices – Quality Management Systems protocols, ensuring traceability, risk management, and process validation from component sourcing to final assembly.

Manufacturing Workflow

- Component Sourcing: High-grade aluminum (6061-T6), hardened steel rails, and ceramic bearings sourced from ISO 13485-aligned suppliers with CoC (Certificate of Conformance).

- Subassembly: Linear guides, spindle modules, and gantry frames assembled in cleanroom environments (Class 10,000).

- Final Integration: CNC-machined housing, encoder installation, and cabling with EMI shielding.

- Software Flashing: Embedded firmware with secure boot and OTA update capability.

Quality Control Protocol

| QC Stage | Procedure | Compliance Standard |

|---|---|---|

| Incoming Materials | Spectrographic analysis, tensile strength testing | ASTM E1476 / ISO 6892-1 |

| Sensor Calibration | Performed in on-site NIST-traceable calibration lab; laser interferometry for positional accuracy | ISO 230-2, ISO 230-6 |

| Pre-shipment Testing | 72-hour continuous dry-run cycle; thermal stability monitoring (±0.5°C ambient control) | Internal QMS-2024-01 |

| Durability Testing | Accelerated Life Testing (ALT): 500,000 cycles on spindle, linear guides, and tool changer | Simulates 5+ years of clinical use |

Sensor Calibration Labs: Precision at the Core

Carejoy operates a dedicated metrology lab within the Shanghai facility, equipped with:

- Laser Doppler Interferometer (Renishaw XL-80)

- Capacitive displacement sensors (resolution: 0.1 nm)

- Thermal drift compensation algorithms (patent-pending)

All machines undergo three-point calibration (before, during, and post-assembly), with digital twin verification against CAD nominal geometry. Calibration certificates are stored in blockchain-secured logs for audit compliance.

Durability & Reliability Testing

Each unit undergoes a multi-axis stress cycle test simulating worst-case clinical loads:

- Spindle endurance: 120,000 RPM, 24/7 for 14 days

- Tool changer: 100,000 insertions with force monitoring

- Vibration analysis: FFT-based detection of resonance frequencies

Failure modes are fed into Carejoy’s Predictive Maintenance AI (PMAI-3), enabling proactive service alerts via cloud telemetry.

Why China Leads in Cost-Performance Ratio (2024–2026)

China’s ascent in digital dental equipment stems from a confluence of strategic advantages:

| Factor | Impact |

|---|---|

| Integrated Supply Chain | Proximity to rare-earth magnets, precision bearings, and optical components reduces BOM cost by 22–30% |

| Advanced Automation | Fully automated gantry calibration & software provisioning reduce labor cost and human error |

| R&D Density | Shanghai and Shenzhen host 68% of global dental CAD/CAM engineers (per 2025 WDDA report) |

| Government Incentives | “Made in China 2025” grants for medtech innovation; 15% tax rebate on exported dental devices |

| Open-Source Ecosystem | Leverages global AI libraries (e.g., PyTorch, Open3D) for scanning and path optimization |

As a result, Carejoy achieves a 65% lower TCO (Total Cost of Ownership) vs. German or Swiss counterparts, without sacrificing precision or uptime.

Support & Lifecycle Management

- 24/7 Remote Diagnostics: Secure TLS 1.3 tunneling for real-time firmware debugging

- Software Updates: Monthly AI model refreshes for scanning accuracy and milling strategy

- Cloud Analytics: Usage patterns, tool wear prediction, and preventive maintenance scheduling

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental Milling Machine 2024.

✅ Open Architecture

Or WhatsApp: +86 15951276160