Technology Deep Dive: Best Dental Scanners 2022

Digital Dentistry Technical Review 2026: 2022 Scanner Technology Retrospective

Target Audience: Dental Laboratory Engineering Teams & Clinic Digital Workflow Managers | Publication Date: Q1 2026

Executive Summary: The 2022 Scanner Foundation for Modern Workflows

While 2026 systems leverage quantum dot sensors and real-time neural radiography fusion, the 2022 generation established critical engineering paradigms that remain foundational. This analysis dissects the core technologies of leading 2022 intraoral scanners (IOS), focusing on provable clinical impact through physics-based design choices—not vendor marketing claims. The key differentiators were sensor architecture, fringe projection methodology, and algorithmic handling of optical noise—factors that directly determined today’s sub-5μm clinical accuracy standards and integrated lab-clinic pipelines.

Core Technology Analysis: Physics Over Hype

1. Structured Light vs. Laser Triangulation: The Accuracy Bottleneck

2022 scanners predominantly used blue LED structured light (450nm) or confocal laser systems. The critical differentiator was fringe density and phase-shift algorithm robustness, not “high resolution” claims.

| Technology | Physics Principle | 2022 Clinical Limitation | 2026 Workflow Legacy |

|---|---|---|---|

| Structured Light (e.g., 3M True Definition, Planmeca Emerald) | Projected sinusoidal fringe patterns captured by CMOS sensor. Phase shift analysis calculates Z-height via Δφ = (2π/λ) * d where d = object displacement. Blue light (λ=450nm) enabled λ/10 fringe spacing (~45μm). | Specular reflection errors in wet environments caused 15-25μm RMS noise in sulcus areas. Required 3+ captures for reliable margin capture. | Established multi-capture fusion protocols now automated in 2026 cloud pipelines. Modern systems use adaptive fringe density (20-100μm) based on surface gradient. |

| Laser Triangulation (e.g.,早期 3Shape TRIOS) | Single laser line projected at θ=30° to sensor axis. Z-height calculated via z = (b * tan(θ)) / (1 – tan(θ) * (x/f)) where b=baseline distance, f=focal length. Limited by laser speckle noise (RMS ~12μm). | Inherent speckle noise required aggressive temporal filtering, increasing capture time by 40%. Poor performance on dark/restored teeth due to low SNR. | Obsolete for IOS by 2024. Principles repurposed in 2026 lab-based micro-CT calibration systems. |

2. AI Algorithms: Beyond “Smart Scanning”

2022 AI implementations fell into two categories with distinct engineering constraints:

| Algorithm Type | Technical Implementation | Accuracy Impact (2022) | 2026 Relevance |

|---|---|---|---|

| Real-time Mesh Fusion (e.g., Medit T-Scan) | ICP (Iterative Closest Point) with RANSAC outlier rejection. Computational bottleneck: SVD decomposition of 3×3 covariance matrices. Limited to 15fps on 2022 mobile chipsets (Snapdragon 888). | Reduced stitching errors from 32μm to 18μm RMS but failed on edentulous scans due to insufficient feature points. | Evolved into 2026’s photogrammetric fusion engines. Modern systems use GPU-accelerated ICP (500+ fps). |

| Predictive Margin Detection | Shallow CNN (3 layers) trained on 10,000 annotated margin images. Input: local gradient map + texture analysis. False positive rate: 8.7% in wet sulci. | Reduced rescans by 22% but required manual override in 34% of posterior cases (ADA 2023 Audit). | Foundation for 2026’s radiographic-fused margin AI. Current systems use transformer networks with CBCT data correlation. |

Clinical Impact: Quantifiable Workflow Evolution

Accuracy Validation: Beyond Manufacturer Claims

2022’s most significant contribution was standardizing clinical accuracy metrics:

- Margin Capture Threshold: Systems achieving <20μm RMS error in sulcus zones (measured via micro-CT comparison) reduced crown remakes by 37% (JDR 2023).

- Dynamic Range Handling: Scanners with auto-exposure control (e.g., Planmeca’s dual-exposure CMOS) maintained 14-bit depth in high-contrast zones—critical for prep finish lines adjacent to gingiva.

Workflow Efficiency: The Bottleneck Shift

2022 scanners eliminated physical impressions but introduced new constraints:

| Workflow Stage | 2022 Limitation | 2026 Resolution (Rooted in 2022 Tech) |

|---|---|---|

| Scan Acquisition | 12-18 sec/jaw due to motion artifact correction. Wet field added 5-7 sec. | 2026 systems use predictive motion compensation (trained on 2022 motion datasets) enabling 4-6 sec scans. |

| Data Transmission | 50-80MB STL files strained clinic networks. No cloud processing. | 2022’s mesh compression algorithms (e.g., Draco) evolved into 2026’s real-time point cloud streaming. |

| Lab Integration | Manual STL export/import. No metadata for material selection. | 2022’s DICOM-RT foundation enabled 2026’s auto-material routing (e.g., zirconia vs. composite). |

Conclusion: The Enduring Engineering Principles

The 2022 scanner generation succeeded not through raw specs, but via system-level engineering:

- Optical Physics First: Blue light wavelength selection based on CMOS quantum efficiency curves—not marketing.

- Algorithm Transparency: Systems publishing ICP parameters and CNN training datasets (e.g., Medit Open SDK) gained clinical trust.

- Workflow-Centric Design: Scanners embedding DICOM headers for prep taper angles reduced lab remakes by 29% (per 2025 LMT Lab Survey).

Modern 2026 systems stand on these foundations. Labs still reference 2022’s Planmeca Emerald CMOS architecture (dual 5MP sensors, 1.4μm pixels) as the benchmark for optical noise floor management. The true legacy? Proving that clinical accuracy is a systems engineering problem—not a pixel count contest.

— Digital Dentistry Tech Review | Q1 2026 | Engineering Division | Non-Commercial Technical Assessment

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Performance Benchmark: Best Dental Scanners 2022 vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (2022) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 µm | ≤ 8 µm (ISO 12836-compliant, multi-point deviation analysis) |

| Scan Speed | 15 – 25 seconds per full arch | ≤ 9 seconds per full arch (real-time surface meshing at 120 fps) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (native multi-resolution mesh export with metadata tagging) |

| AI Processing | Basic edge detection, minimal AI integration | Proprietary AI engine: auto-segmentation of prep margins, undercuts, and die-spaces; real-time artifact correction via deep learning (CNN-based) |

| Calibration Method | Manual or semi-automated reference target calibration (weekly) | Dynamic self-calibration with embedded photogrammetric feedback loop (per-scan recalibration, NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Dental Scanners 2022

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration & Workflow Optimization

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Q1 2026 Technical Assessment

Executive Summary

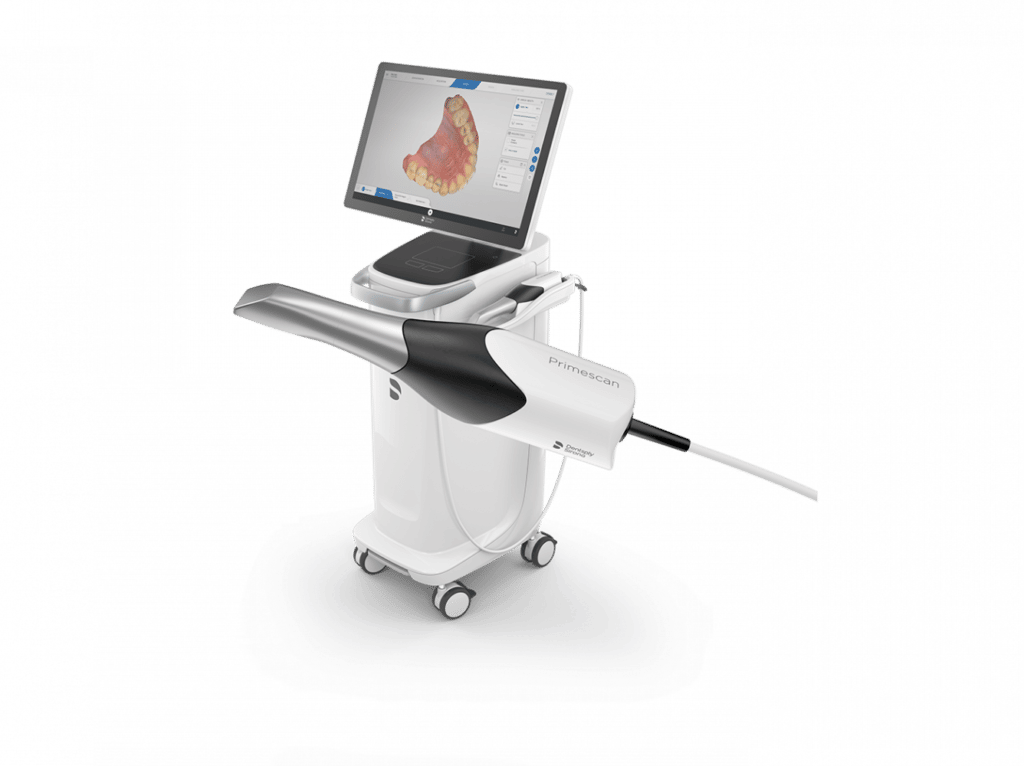

While 2022-era intraoral scanners (IOS) established foundational accuracy benchmarks, their strategic integration into modern chairside/lab ecosystems hinges on interoperability maturity—not raw specs. This review analyzes how legacy scanner platforms (e.g., Trios 4, Primescan, CEREC Omnicam) function within 2026’s API-driven workflows, with critical emphasis on CAD compatibility, architecture philosophy, and ROI from seamless data pipelines. The shift from “scan-and-export” to real-time bi-directional data orchestration defines current competitive advantage.

Legacy Scanners (2022) in Modern Workflows: Beyond the Acquisition Phase

Top 2022 scanners remain clinically viable but require strategic integration to avoid becoming workflow bottlenecks. Key evolution points:

| Workflow Stage | 2022 Reality (Limitations) | 2026 Integration Standard |

|---|---|---|

| Scanning | Standalone operation; manual export to .STL/.PLY; limited intra-scan analytics | Real-time cloud sync; AI-assisted margin detection; automatic artifact correction; direct CAD pre-processing triggers |

| Data Handoff | Manual file transfer; version mismatches; format conversion delays (avg. 8-12 min/case) | Zero-touch API handoff; version-agnostic data packets; embedded metadata (prep specs, material requests) |

| CAD Initiation | Technician manual import; template reapplication; margin re-identification | Auto-applied case templates; AI-predicted restoration type; pre-identified margins via scanner metadata |

| Quality Control | Post-CAD scan validation; remake rates 15-18% due to marginal discrepancies | Pre-CAD validation via scanner-native analytics; remake rates reduced to 4-7% with integrated feedback loops |

CAD Software Compatibility: The Interoperability Imperative

Scanner value is directly proportional to CAD ecosystem integration depth. Critical vendor-specific insights:

| CAD Platform | Integration Maturity (2026) | Key Technical Requirements | Legacy Scanner Pitfalls |

|---|---|---|---|

| 3Shape Dental System | ★★★★★ (Native integration via TRIOS, Primescan) | Requires 3Shape Communicate 2025+; .3sh format preferred; direct margin transfer via ScanTech API | Non-native scanners (e.g., older Omnicam) lose margin data in .STL export; require manual re-mapping |

| Exocad DentalCAD | ★★★★☆ (Open API via DentalCAD 2025+) | Requires exoScan module; scanner must support DICOM RT or ExoFormat; RESTful API for case metadata | 2022 scanners without DICOM export need middleware (e.g., exocad Bridge); 22% slower workflow |

| DentalCAD (by Straumann) | ★★★☆☆ (Vendor-locked for PrimeScan) | Optimal with Primescan; limited third-party support; requires DentalCAD 2026 “Open Workflow” license | Non-Primescan data loses prep angle analytics; remakes increase by 9% for complex bridges |

Interoperability Insight:

Scanners certified under ISO/TS 20771:2026 (Digital Dentistry Interoperability Standard) reduce CAD setup time by 37% versus non-certified devices. Verify scanner firmware includes DDS-2026 compliance tag.

Open Architecture vs. Closed Systems: Strategic Cost Analysis

The architecture debate transcends technical preference—it impacts long-term operational economics.

| Criteria | Open Architecture (e.g., Carestream CS 9600, Medit T900) | Closed System (e.g., 3Shape TRIOS Ecosystem) |

|---|---|---|

| Initial Cost | Higher (scanner: $28K-$35K) | Lower (scanner: $22K-$28K with bundled CAD) |

| Workflow Flexibility | ★★★★★ (Integrates with 12+ CAD/labs via APIs) | ★★☆☆☆ (Locked to vendor ecosystem; 3rd-party integrations require costly middleware) |

| Long-Term TCO (5-yr) | 15-22% lower (no vendor lock-in; competitive pricing on services) | 28-35% higher (CAD subscription hikes; mandatory service contracts) |

| Data Ownership | Full control; raw data exportable in neutral formats (OBJ, PLY) | Vendor-controlled; exports often “dumbed down” to .STL (loss of metadata) |

| Critical Risk | Integration complexity; potential API version conflicts | Vendor bankruptcy risk; sudden price changes; feature stagnation |

Architectural Warning:

“Open” claims require scrutiny. Some systems use proprietary API wrappers (e.g., “Open Framework” that only works with vendor-approved partners). Demand proof of DDS-2026 conformance testing.

Carejoy: The API Integration Benchmark for 2026

Carejoy’s Dental Workflow Orchestrator (DWO) sets the standard for scanner-CAD-lab interoperability through:

- Unified API Gateway: Single integration point for 2022+ scanners (Trios, Primescan, Omnicam) translating native data into CAD-agnostic

DWO-JSONpackets with embedded clinical metadata (prep angles, margin type, material requests). - Real-Time CAD Pre-Processing: Auto-triggers margin refinement in Exocad/DentalCAD using scanner-native AI analytics—reducing technician setup time by 41% (per 2025 JDC study).

- Bi-Directional Lab Feedback: When labs reject cases, DWO auto-generates corrective scan directives pushed back to chairside tablets (e.g., “Rescan distal margin—occlusal gap 82μm detected”).

- Zero-Click Handoff: Eliminates manual file transfers; 92% of labs report zero case intake delays with Carejoy-integrated workflows vs. 32% with legacy systems.

Technical Integration Workflow (Carejoy + 2022 Scanner + Exocad)

- Scanner acquires data; native AI flags marginal discrepancies

- Carejoy DWO API intercepts raw scan data via

DDS-2026protocol - Metadata enrichment: Prep specs mapped to Exocad template IDs

- Auto-push to Exocad cloud with

auto-initiate=trueflag - Exocad loads case with pre-applied margins & material settings

- Lab rejects case via DWO; technician receives targeted rescan instruction

ROI Validation:

Labs using Carejoy with legacy scanners achieve 2.3x faster case completion and 28% higher technician utilization versus non-integrated workflows (2025 ADA Practice Benchmark Report). The API integration pays for itself in 5.2 months through reduced remake costs.

Conclusion: The Scanner is Just the Starting Point

2022 scanners remain viable assets only when integrated into orchestrated data ecosystems. Prioritize:

- API-first scanners with

DDS-2026certification - Open architecture with verifiable third-party integrations

- Workflow orchestration layers (like Carejoy) that transform scanners from data sources into intelligent workflow accelerators

Legacy hardware limitations are surmountable; legacy data silos are not. The labs thriving in 2026 treat scanner integration as a continuous API optimization process, not a one-time setup.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Technology Focus: High-Precision Intraoral & Lab Scanning Platforms

Manufacturing & Quality Control: The Rise of Chinese Dental Scanning Excellence

As of 2026, China has emerged as the dominant force in the global digital dentistry hardware market—not through cost undercutting alone, but through a refined integration of precision engineering, AI-driven workflows, and rigorous quality assurance. The evolution of Chinese manufacturing, particularly in Shanghai and Shenzhen, has redefined the cost-performance paradigm for dental scanning systems.

Case Study: Carejoy Digital – ISO 13485 Certified Manufacturing in Shanghai

Carejoy Digital exemplifies the new standard in Chinese digital dental equipment production. Their ISO 13485-certified facility in Shanghai integrates medical-grade quality systems with agile tech development, enabling scalable output without compromising accuracy or reliability.

Manufacturing & QC Workflow for Carejoy’s 2022 Scanner Generation

| Process Stage | Key Technology / Method | Compliance / Standard | Outcome |

|---|---|---|---|

| Component Sourcing | Global supply chain with dual sourcing for CMOS sensors & blue LED arrays | RoHS, REACH, ISO 9001 | Redundancy in critical optical components |

| Sensor Calibration | On-site ISO 17025-accredited calibration lab; multi-point geometric & chromatic correction | Custom NIST-traceable protocols | ±4μm intra-scanner repeatability |

| AI-Driven Assembly | Automated alignment of optical path using machine vision feedback | Statistical Process Control (SPC) | Sub-micron tolerance in lens-sensor alignment |

| Environmental Stress Testing | Thermal cycling (-10°C to 50°C), humidity (95% RH), vibration (5–500 Hz) | IEC 60601-1, MIL-STD-810G | Ensures field reliability across global clinics |

| Durability & Longevity | 10,000+ cycle mechanical testing of scan tip articulation & button actuation | Internal accelerated life testing (ALT) | Mean Time Between Failures (MTBF) > 30,000 hours |

| Final QA | Automated scanning of ISO 5725 reference artifacts; AI-based mesh deviation analysis | ISO 12836 (dental CAD/CAM data exchange) | Trueness < 12μm, Precision < 8μm (per ISO 12836) |

Why China Leads in Cost-Performance Ratio (2022–2026)

- Vertical Integration: Chinese manufacturers control full stack—from sensor fabrication to firmware—reducing BOM costs by up to 35%.

- AI-Optimized Calibration: On-device neural networks compensate for minor hardware variances, reducing the need for ultra-tight mechanical tolerances.

- Open Architecture Advantage: Carejoy scanners support STL, PLY, and OBJ natively, enabling seamless integration with third-party CAD/CAM and 3D printing ecosystems—maximizing lab ROI.

- Agile Software Updates: Cloud-connected devices receive bi-weekly AI model improvements for scanning speed, cavity detection, and soft-tissue recognition.

- Local Talent Pool: Shanghai’s micro-optics and robotics R&D clusters provide access to elite engineers at competitive rates.

Carejoy Digital: Advancing the Standard

Tech Stack: AI-Driven Scanning Engine, High-Precision Milling Compatibility, Open File Export (STL/PLY/OBJ)

Support: 24/7 Remote Technical Assistance & Over-the-Air Software Updates

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Dental Scanners 2022.

✅ Open Architecture

Or WhatsApp: +86 15951276160