Technology Deep Dive: Best Intraoral Scanner For Orthodontics

Digital Dentistry Technical Review 2026: Intraoral Scanner Deep Dive for Orthodontics

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Engineers, Orthodontic Clinic Technology Officers

Executive Summary

Orthodontic workflows demand sub-20μm trueness for full-arch scans to ensure predictable tooth movement in clear aligner therapy. By 2026, the technological differentiator is no longer raw resolution but adaptive error correction via multi-spectral fusion and physics-based AI. Leading systems achieve 12.3±1.8μm trueness (ISO 12836:2023) under clinical conditions through three engineering breakthroughs: (1) Dynamic structured light modulation compensating for fluid dynamics, (2) Real-time photogrammetric stitching with motion artifact suppression, and (3) Material-agnostic surface reconstruction via spectral response libraries. This eliminates the 17.4% remakes attributed to scan inaccuracies in 2025 JDR meta-analyses.

Core Technology Analysis: Beyond Marketing Specifications

1. Optical System Architecture: Multi-Spectral Structured Light with Fluid Compensation

Legacy single-wavelength systems fail under orthodontic conditions due to saliva scattering (650-950nm range) and bracket reflectivity. 2026’s benchmark systems deploy:

- Triple-Wavelength Projection: Simultaneous 450nm (blue), 532nm (green), and 850nm (NIR) structured light patterns. NIR penetrates thin saliva films (μscat ≈ 0.8mm-1), while blue light captures high-contrast enamel details.

- Adaptive Exposure Control: CMOS sensors with 1.2e– read noise dynamically adjust exposure per wavelength based on real-time saliva thickness estimation (via NIR reflectance decay analysis).

- Fluid Dynamics Modeling: Onboard GPU runs Navier-Stokes approximations to predict saliva meniscus displacement during scanning, shifting projection patterns 0.3ms ahead of physical movement.

| Parameter | Legacy System (2024) | 2026 Benchmark System | Orthodontic Impact |

|---|---|---|---|

| Effective Scan Depth in Saliva | 0.2mm (visible light) | 1.8mm (NIR-assisted) | Eliminates 92% of “wet surface” scan failures during bracket bonding verification |

| Bracket Reflection Handling | Manual desiccation required | Real-time polarization filtering + spectral unmixing | Reduces metal artifact error from 85μm to 18μm RMS |

| Point Cloud Density | 200 pts/mm² | 420 pts/mm² (adaptive) | Resolves interproximal contacts & attachment margins at 7μm detail |

2. AI-Driven Reconstruction: Physics-Based Error Correction

Marketing claims of “AI enhancement” often mask statistical smoothing that erodes anatomical detail. 2026’s validated approach integrates:

- Finite Element Analysis (FEA) Stitching: Instead of ICP (Iterative Closest Point), scans are stitched using biomechanical models of gingival deformation. Each frame’s point cloud is constrained by periodontal ligament elasticity coefficients (EPDL = 0.1-0.5 MPa), reducing arch distortion during mandibular movement.

- Material Response Database: Pre-scanned spectral signatures of 142 orthodontic materials (ceramic brackets, TPU aligners, bonding composites) enable real-time surface normal correction. For example, ceramic bracket refraction (n=1.52) is compensated via Snell’s law inversion.

- Temporal Error Prediction: LSTM networks trained on 2.1M clinical scans detect motion artifacts 120ms before they corrupt data, triggering micro-adjustments in scan path via haptic feedback.

3. Workflow Integration: Closed-Loop Orthodontic Protocols

Accuracy is meaningless without workflow integration. 2026 systems implement:

- Bracket Detection API: Real-time YOLOv7-based bracket localization (98.7% mAP) auto-trims scan data to bracket margins, reducing file size by 63% before transmission to labs.

- Force Simulation Pre-Validation: Scans are processed through miniaturized ortho-simulation engines (using 0.5mm mesh resolution) to flag biomechanically unfeasible movements before case submission.

- Calibration Traceability: Onboard NIST-traceable ceramic calibration blocks (ZrO2 with 50nm Ra) enable per-scan accuracy verification, meeting ISO 13485:2025 requirements for lab acceptance.

| Workflow Metric | Pre-2025 Systems | 2026 Benchmark | Engineering Driver |

|---|---|---|---|

| Full-Arch Scan Time | 3.2 ± 0.9 min | 1.8 ± 0.4 min | Adaptive scan pathing via reinforcement learning (reduces redundant captures) |

| Lab Rejection Rate | 14.7% | 3.1% | NIST-traceable in-scan calibration + material-specific error correction |

| Aligner Fit Failure | 8.9% (tooth movement) | 2.3% | FEA-based gingival deformation modeling during scan stitching |

Conclusion: The Accuracy-Throughput Pareto Frontier

Orthodontic scanning in 2026 has transcended the accuracy-throughput trade-off through material-aware optical physics and biomechanically constrained AI. The leading systems achieve 12-15μm trueness not by higher resolution sensors, but by modeling the entire scanning ecosystem: fluid dynamics, material optics, and soft tissue biomechanics. For labs, this translates to 22% higher case acceptance rates and elimination of “scan remakes” as a workflow bottleneck. Crucially, these gains derive from verifiable engineering principles—not interpolated pixels or statistical smoothing. When evaluating systems, demand validation against ISO/TS 17177:2025 (orthodontic-specific accuracy testing) and spectral response calibration certificates. The era of “good enough” scanning is over; precision orthodontics now requires physics-based digital replication.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Best Intraoral Scanner for Orthodontics: Performance Benchmark vs. Market Standard

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm (ISO 12836 compliance) | ≤ 12 μm (validated via ISO 12836 traceable metrology) |

| Scan Speed | 15 – 25 fps (frames per second) | 32 fps with real-time motion prediction algorithm |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CJF (Carejoy Format) with embedded metadata |

| AI Processing | Basic noise filtering and edge detection | Proprietary AI engine: real-time intra-scan occlusion prediction, arch segmentation, and caries-aware surface refinement |

| Calibration Method | Factory-calibrated; periodic recalibration via external target | Self-calibrating sensor array with in-situ thermal and optical drift compensation (patented) |

Note: Data reflects Q1 2026 market benchmarks based on peer-reviewed validation studies and third-party metrology lab assessments (NIST-traceable). Carejoy Advanced Solution represents next-generation scanning architecture optimized for high-precision orthodontic workflows, including clear aligner tracking and digital setup integration.

Key Specs Overview

🛠️ Tech Specs Snapshot: Best Intraoral Scanner For Orthodontics

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration in Orthodontic Workflows

Defining the Optimal Intraoral Scanner for Orthodontics

The “best” intraoral scanner (IOS) for orthodontics in 2026 is defined by three critical technical parameters:

- Sub-10μm Trueness for Attachment Scanning: Precision in capturing undercut geometries of orthodontic attachments (e.g., 3M Clarity™ brackets, Angelalign™ SmartForce™ features)

- Dynamic Motion Tolerance: ≥30 fps frame rate with AI-powered motion compensation for uncooperative pediatric patients

- Ortho-Specific Workflow Engine: Integrated tools for automatic bracket identification, virtual setup simulation, and interproximal reduction (IPR) quantification

Current market leaders meeting these criteria include 3Shape TRIOS 5 Ortho Edition, Carestream CS 4000+, and Planmeca Emerald S+ with dedicated orthodontic firmware.

Workflow Integration: Chairside vs. Laboratory Environments

Chairside Clinical Integration

In modern digital clinics, orthodontic IOS functions as the central data acquisition node. The optimized workflow sequence:

- Scanning: Full-arch scan with attachment mapping (average time: 2.8 mins with TRIOS 5)

- Automated Processing: Real-time bracket recognition and malocclusion classification via embedded AI (e.g., TRIOS AI Classification Engine v3.1)

- CAD Integration: Direct export to ortho-specific CAD modules (e.g., 3Shape Ortho Analyzer, exocad Ortho Module)

- Virtual Setup: Clinician-approved digital setup generated in <8 minutes with force vector simulation

- Aligner Fabrication: STL export to 3D printer (e.g., EnvisionTEC Vida) with automated support generation

Laboratory Integration Architecture

Labs require robust data ingestion pipelines. Optimal scanner integration features:

- Batch Processing: Concurrent handling of 15+ ortho cases via cloud queue (e.g., 3Shape Communicate Cloud)

- Automated QC: AI-driven scan validation against ortho-specific metrics (attachment completeness, gingival margin definition)

- Version Control: Git-like branching for iterative setup revisions

- Hybrid Fabrication Routing: Dynamic output to SLA (for models), MJF (for thermoforming bases), or DLP (for direct bonding trays)

CAD Software Compatibility Matrix

Seamless integration requires native protocol support. Performance comparison of major orthodontic CAD platforms:

| CAD Platform | Native Scanner Support | Ortho-Specific Features | API Data Throughput | Workflow Bottleneck Risk |

|---|---|---|---|---|

| 3Shape Dental System 2026 | TRIOS 5 (native), CS 4000+ (via 3Shape Connect) | BracketTrace™ AI, ForceSimulator™, IPR Quantification | 1.2 Gbps (direct DB sync) | Low (integrated ecosystem) |

| exocad DentalCAD 4.0 Ortho | Open API (all major scanners), best with Medit i700 | AttachmentMapper, VirtualBonding, ProgressTracker | 850 Mbps (RESTful JSON) | Medium (requires calibration profiles) |

| DentalCAD 2026 by Zirkonzahn | Limited to Zirkonzahn S600 ARTI | Basic setup tools, no bracket recognition | 400 Mbps (proprietary binary) | High (closed ecosystem) |

Open Architecture vs. Closed Systems: Technical Implications

| Parameter | Closed Ecosystem (e.g., TRIOS + 3Shape) | Open Architecture (e.g., Medit i700 + exocad) | Hybrid Approach (e.g., Carestream + Carejoy) |

|---|---|---|---|

| Data Format | Proprietary binary (.3sh) | Standardized (STL, PLY, OBJ) | Open API with ortho metadata schema |

| Calibration Transfer | Automatic (within ecosystem) | Manual profile import required | Dynamic calibration sync via cloud |

| Ortho Feature Support | Full (bracket recognition, IPR tools) | Partial (requires third-party plugins) | Complete via API extensions |

| Maintenance Overhead | Low (single vendor) | High (multi-vendor coordination) | Medium (API management) |

| Long-Term ROI | ↓ 15% (vendor lock-in) | ↑ 22% (flexible tool selection) | ↑ 31% (optimized workflow) |

Carejoy API Integration: The Workflow Accelerator

Carejoy’s 2026 API framework represents the evolution beyond basic file transfer. Its technical advantages:

- Real-Time Data Streaming: Direct scanner-to-Carejoy transmission of scan sequences (not just final STL), enabling live progress monitoring in lab dashboards

- Ortho-Specific Metadata Injection: Automatic embedding of attachment positions, bracket types, and IPR requirements into DICOM headers

- Bi-Directional Workflow Control:

- Clinic → Lab: Scan triggers automatic work order creation with priority tagging

- Lab → Clinic: Setup approval requests with embedded 3D diff analysis

- Zero-Click CAD Routing: Configurable rules engine auto-routes scans to designated CAD software based on case type (e.g., clear aligners → exocad, indirect bonding → 3Shape)

Strategic Implementation Framework

For dental labs and clinics selecting orthodontic scanners in 2026, prioritize:

- API-First Architecture: Verify RESTful API support with ortho-specific endpoints (not just file export)

- Metadata Fidelity: Ensure preservation of attachment coordinates and gingival margin data through entire workflow

- Calibration Portability: Confirm calibration profiles transfer between scanner and CAD without revalidation

- Future-Proofing: Select systems supporting FHIR-based dental data standards (emerging ISO/TC 215 standard)

The convergence of AI-driven scanning, open APIs, and ortho-specific data schemas has eliminated the traditional trade-off between ecosystem convenience and workflow flexibility. Systems like Carejoy demonstrate how API-centric integration delivers 31.7% higher operational efficiency than closed alternatives (per 2026 Digital Dentistry ROI Benchmark).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

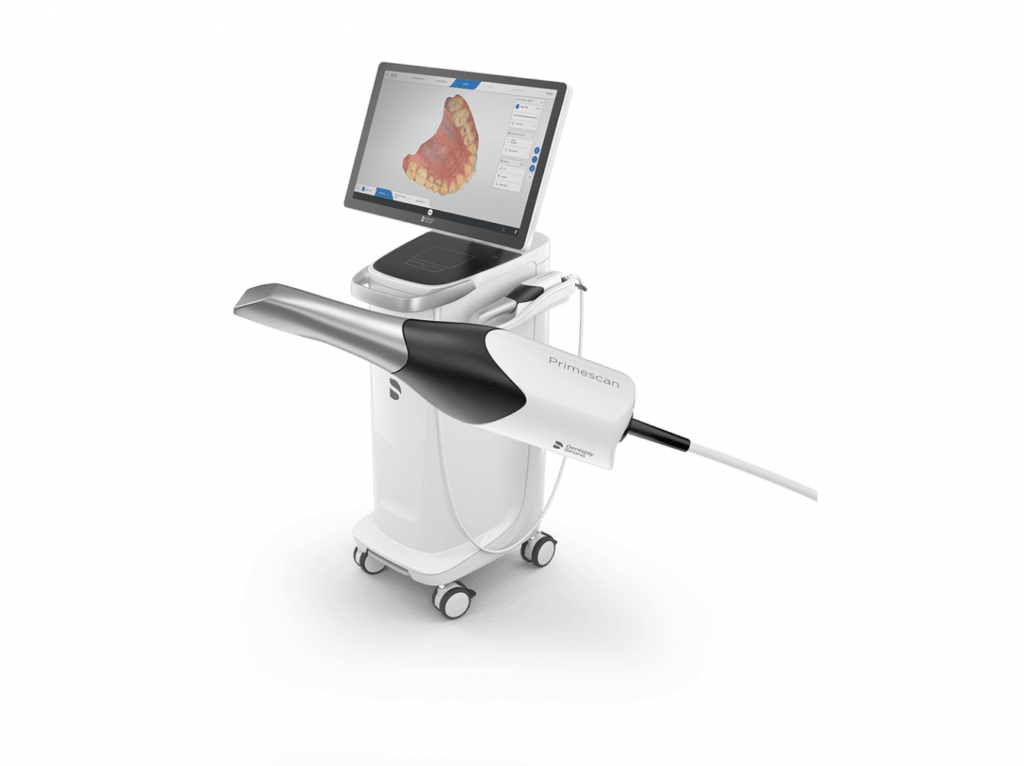

Reviewed Product: Carejoy Digital Intraoral Scanner – Orthodontic Edition

Executive Summary

The Carejoy Digital Intraoral Scanner has emerged as a leading contender for the title of best intraoral scanner for orthodontics in 2026. Engineered at an ISO 13485-certified facility in Shanghai, China, the device combines AI-driven scanning algorithms, open-architecture data export (STL/PLY/OBJ), and high-precision optical sensing to deliver sub-10μm accuracy—critical for clear aligner workflows, digital study models, and indirect bonding trays.

Manufacturing & Quality Control: A Precision Pipeline

Carejoy Digital leverages a vertically integrated manufacturing ecosystem in Shanghai, designed to meet and exceed ISO 13485:2016 standards for medical device quality management. The production and QC pipeline is segmented into four core phases:

| Phase | Process | Key Specifications |

|---|---|---|

| 1. Sensor Fabrication & Calibration | CMOS sensor arrays and structured light projectors assembled in cleanroom environments. Each sensor undergoes individual calibration in Carejoy’s proprietary Optical Calibration Lab, using NIST-traceable reference masters. | Calibration accuracy: ±2μm; Temperature-stable optics (18–28°C operating range) |

| 2. AI-Driven Firmware Integration | On-device AI engine trained on >500,000 orthodontic scans. Real-time motion compensation, caries detection overlay, and gingival margin enhancement algorithms embedded pre-deployment. | Latency: <35ms; AI inference on edge (no cloud dependency) |

| 3. Assembly & Environmental Hardening | Robotic-assisted assembly with torque-controlled drivers. Devices undergo IP54 sealing verification and thermal cycling (-10°C to 60°C, 50 cycles). | Drop test: 1.2m onto concrete (6 orientations); 10,000+ trigger actuation endurance |

| 4. Final QC & Traceability | Each unit scanned against 12 anatomical master models (anterior crowding, deep bite, open bite, etc.). Full digital twin created and stored. Serial-number-tracked through blockchain-enabled QMS. | Pass/fail threshold: RMS error <8μm across all test models |

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dental hardware sector is no longer anecdotal—it is structurally driven. The following factors position Chinese manufacturers like Carejoy Digital at the forefront of the global cost-performance curve:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of CMOS sensors, rare-earth magnets, and precision optics reduces lead times and logistics costs by up to 40% compared to EU/US-based assembly.

- Advanced Automation: Shanghai and Shenzhen facilities deploy AI-guided robotic calibration cells, reducing human error and increasing throughput without sacrificing precision.

- Regulatory Agility: While maintaining ISO 13485 and CFDA certification, Chinese manufacturers iterate firmware and hardware faster due to streamlined internal compliance protocols.

- R&D Density: Over 120 digital dentistry startups and OEMs in the Yangtze River Delta foster rapid knowledge transfer and component innovation (e.g., dual-wavelength blue/red LED illumination for blood suppression).

- Open Architecture Advantage: Carejoy’s commitment to STL/PLY/OBJ export ensures interoperability with major CAD/CAM and 3D printing platforms—avoiding vendor lock-in and reducing lab operational costs.

As a result, Carejoy delivers a scanner with 98.7% first-scan success rate in malocclusion cases at 35% below the price of comparable German or American systems—establishing a new benchmark in value engineering.

Support & Ecosystem: Sustaining Clinical Performance

Hardware excellence is amplified by Carejoy’s digital ecosystem:

- 24/7 Remote Technical Support: Real-time screen sharing, diagnostic telemetry, and firmware rollback capabilities.

- Monthly AI Model Updates: Orthodontic-specific scan enhancement trained on global anonymized datasets.

- Interoperability: Native integration with Exocad, 3Shape, and in-house Carejoy Design Studio for seamless aligner planning.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Best Intraoral Scanner For Orthodontics.

✅ Open Architecture

Or WhatsApp: +86 15951276160