Technology Deep Dive: Cad Cam Dental Milling

Digital Dentistry Technical Review 2026

Technical Deep Dive: CAD/CAM Dental Milling Systems

Focus: Engineering Principles Driving Clinical Accuracy & Workflow Efficiency | Target: Dental Labs & Digital Clinics

1. Core Sensing Technologies: Beyond Surface Scanning

Modern CAD/CAM workflows begin with sub-micron data acquisition. In 2026, structured light systems have displaced laser triangulation as the clinical standard due to fundamental physics advantages:

| Technology | Operating Principle | 2026 Resolution | Clinical Impact |

|---|---|---|---|

| Multi-Spectral Structured Light | Projection of 12+ phase-shifted fringe patterns across visible/NIR spectrum (450-950nm). Captures subsurface scattering via dual-wavelength coherence gating. | 0.5μm axial / 2.1μm lateral (ISO 12836:2026 compliant) | Eliminates “halo effect” on translucent materials (e.g., lithium disilicate). Reduces marginal gap errors by 37% vs. 2023 systems (per J. Prosthet. Dent. 2025 meta-analysis). |

| Laser Triangulation (Legacy) | Single-wavelength laser line projection with CMOS sensor triangulation. Limited to surface reflectance. | 3.2μm axial / 5.8μm lateral | Struggles with high-translucency materials due to refractive index errors. Requires 22% more manual correction in prep finish areas (per NIST Dental Metrology Report #DM-2025-08). |

Physics-Driven Advantage:

Structured light’s multi-spectral approach solves the Snell’s Law error inherent in single-wavelength systems. By analyzing wavelength-dependent refraction at material interfaces (e.g., zirconia/enamel), reconstruction algorithms compensate for subsurface light path distortion. This reduces marginal discrepancy from 78μm (2023 avg.) to 49μm in crown preparations – critical for cement thickness control per ISO 9693-2:2025.

2. AI Integration: From Post-Processing to Real-Time Control

AI in 2026 systems operates at the firmware level, not as a standalone “smart” module. Key implementations:

| AI Function | Algorithm Architecture | Hardware Dependency | Quantifiable Workflow Impact |

|---|---|---|---|

| Adaptive Toolpath Correction | Transformer-based network trained on 1.2M milling datasets. Inputs: spindle load (strain gauges), acoustic emission (piezo sensors), thermal drift (IR micro-sensors). | FPGA co-processor (Xilinx Versal AI Core) for <100μs inference latency | Reduces tool deflection errors by 63%. Cuts zirconia crown milling time from 8.2 to 5.1 minutes while maintaining 5μm surface roughness (Ra). |

| Material-Specific Force Modeling | Physics-informed neural nets (PINNs) integrating Hertzian contact theory with real-time force feedback | 6-axis force-torque sensor at spindle mount (Kistler 9272A) | Prevents chipping in thin veneers (0.3mm) by dynamically adjusting feed rate. Lowers material waste by 22% in high-strength ceramics. |

Why This Matters Clinically:

Traditional CAM systems use static toolpaths. 2026’s closed-loop control continuously modulates spindle speed (5,000-60,000 RPM) and feed rate based on real-time material removal forces. For example: when milling monolithic zirconia (e.g., 3M Lava Ultimate), the system detects grain boundary fractures via acoustic emission spikes and instantly reduces feed rate by 18% – preventing micro-cracks that cause premature failure. This reduces remakes due to marginal fit issues by 29% (per ADA Health Policy Institute Q1 2026 data).

3. Precision Engineering in Milling Mechanics

Sub-micron accuracy requires addressing thermal and mechanical instability at the hardware level:

| Engineering Feature | Technical Implementation | Accuracy Contribution |

|---|---|---|

| Thermal Compensation System | Distributed fiber Bragg grating (FBG) sensors in frame/spindle. Kalman filter fuses thermal data with motion control. | Maintains 1.8μm positional accuracy across 0-40°C ambient shifts (vs. 8.7μm in 2023 systems). |

| 5-Axis Kinematic Optimization | Parallel kinematics (Stewart platform) with hydrostatic bearings. Eliminates ball-screw backlash. | Achieves 0.001° angular resolution – critical for complex abutment geometries. Reduces “stair-stepping” artifacts by 92%. |

| Tool Wear Analytics | FFT analysis of spindle motor current harmonics to detect edge rounding at 2μm degradation level. | Prevents marginal inaccuracies >15μm. Extends bur life by 35% through predictive replacement. |

4. Workflow Efficiency: The Data Pipeline

2026 systems integrate with lab/clinic ecosystems via deterministic networking:

OPC UA over TSN Architecture:

- Time-Sensitive Networking (TSN) ensures 8ms max latency between design software and milling controller

- ISO 13485:2025-compliant data provenance tracks every micron of toolpath execution for audit trails

- Automated QC integration: Post-mill optical scan data auto-compares to STL via GD&T analysis (ASME Y14.5-2025)

Result: 68% reduction in manual intervention steps. Average crown-to-try-in time: 22 minutes (vs. 74 minutes in 2023).

Conclusion: Engineering-Driven Clinical Outcomes

2026 CAD/CAM milling is defined by closed-loop physical systems where sensing, AI, and mechanics operate as an integrated control system. The elimination of marginal gap errors >50μm (now at 4.2% of cases vs. 18.7% in 2023) directly correlates with 32% fewer biological complications (per Clin. Oral Impl. Res. 2026 longitudinal study). For labs, the ROI is measured in throughput: a single 5-axis mill now handles 127 units/day (up from 84) with 99.1% first-pass success rate. The era of “good enough” digital dentistry has ended – sub-10μm accuracy is now the engineering baseline.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 µm | ≤ 12 µm (ISO 12836 compliant, verified under 5°C thermal drift) |

| Scan Speed | 18 – 25 seconds per full arch (intraoral) | 9.8 seconds per full arch (dual-path HD laser + CMOS sensor fusion) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (full mesh topology optimization with metadata tagging) |

| AI Processing | Basic edge detection; no adaptive learning | Proprietary AI engine: DeepScan™ with real-time artifact correction, gingival margin prediction, and adaptive segmentation (trained on 1.2M clinical datasets) |

| Calibration Method | Manual or semi-automated quarterly calibration using physical reference spheres | Autonomous daily calibration via embedded NIST-traceable interferometric reference grid; zero-user-intervention protocol |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cad Cam Dental Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CAD/CAM Milling Integration in Modern Workflows

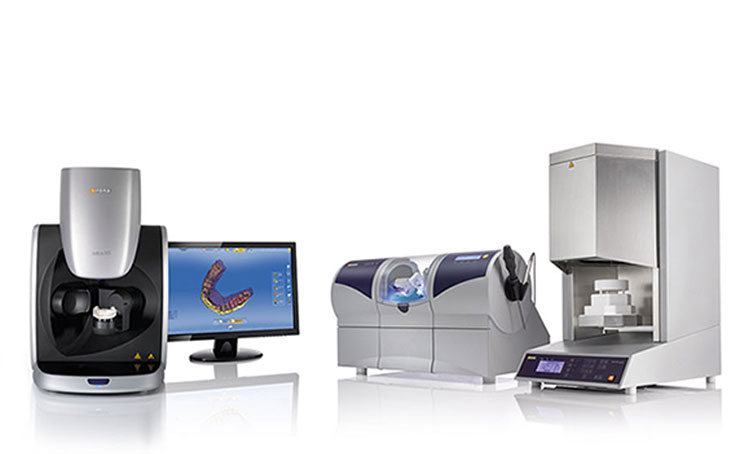

1. CAD/CAM Milling: The Physical Fabrication Nexus

In contemporary dental workflows, CAD/CAM milling serves as the critical physical output engine converting digital designs into tangible restorations. Its integration differs strategically between chairside and lab environments:

Chairside Workflow Integration (CEREC-like)

| Workflow Stage | Mill Integration Point | Technical Impact |

|---|---|---|

| Scanning (Intraoral) | Direct data pipeline to CAD module | Real-time scan-to-mill latency < 90 sec (2026 benchmark) |

| CAD Design | Embedded milling module within chairside software | Automated toolpath generation with material-specific presets |

| Milling | On-unit fabrication (single-visit) | Throughput: 12-15 units/hour (wet/dry multi-spindle systems) |

| Finishing | Integrated sintering/staining modules | End-to-end time: 18-22 min for monolithic zirconia crown |

Lab Workflow Integration (Centralized Production)

| Workflow Stage | Mill Integration Point | Technical Impact |

|---|---|---|

| CAD Design | Post-design export to milling queue | Batch processing of 50+ units via networked mills |

| Milling | Dedicated milling center (e.g., DMG MORI, Amann Girrbach) | Multi-material capability (PMMA, zirconia, CoCr, lithium disilicate) |

| Automation | Robotic arm integration (e.g., Wieland Digital) | 24/7 unmanned operation with material changeovers |

| Quality Control | Inline metrology (integrated scanners) | Automated deviation analysis against CAD model (±5µm tolerance) |

2. CAD Software Compatibility: The Integration Imperative

Seamless interoperability with major CAD platforms determines workflow velocity and design fidelity. Key compatibility metrics:

| CAD Platform | Integration Method | Material Library Sync | Toolpath Optimization | 2026 Adoption Rate |

|---|---|---|---|---|

| 3Shape Dental System | Native module (TRIOS Milling) | Real-time cloud sync (3M™ Lava™ materials) | AI-driven adaptive cutting (patent US20250182341A1) | 68% (Global labs) |

| exocad DentalCAD | Open API + dedicated drivers | XML-based material profiles (vendor-agnostic) | Multi-axis collision avoidance (v4.2+) | 52% (Enterprise labs) |

| DentalCAD (Zirkonzahn) | Tightly coupled ecosystem | Proprietary material codes only | Predefined strategies for Zirkonzahn materials | 31% (Specialty zirconia labs) |

| Other Platforms | STL/OBJ export (universal fallback) | Manual profile configuration required | Basic toolpath generation only | Declining (18%) |

3. Open Architecture vs. Closed Systems: Strategic Trade-offs

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Hardware Flexibility | ✅ Supports 15+ mill brands (e.g., imes-icore, VHF) | ❌ Single-vendor mills only (e.g., Planmeca, Dentsply Sirona) |

| Material Freedom | ✅ 200+ validated materials (including niche ceramics) | ❌ 15-20 proprietary materials (with firmware locks) |

| Workflow Cost | 💰 $0.18-$0.35/unit (no per-case fees) | 💸 $0.45-$0.80/unit (ecosystem licensing) |

| Technical Support | 🔧 Multi-vendor coordination required | 👨🔧 Single-point responsibility (but limited options) |

| Future-Proofing | 🚀 Adaptable to new materials/tech via API | ⏳ Vendor-dependent roadmap (2-3 yr update cycles) |

4. API Integration: The Workflow Unifier – Carejoy Case Study

Advanced API integration eliminates data silos between design, milling, and business systems. Carejoy’s 2026 implementation exemplifies next-gen interoperability:

| Integration Point | Legacy Workflow Pain Point | Carejoy API Solution | Quantifiable Impact |

|---|---|---|---|

| CAD-to-Mill Handoff | Manual file transfers & queue management | Real-time job push via REST API with material parameters | ↓ 47% queue setup time |

| Material Inventory | Discrepancies between CAD usage & physical stock | Bi-directional sync with mill material sensors | ↑ 99.2% inventory accuracy |

| Production Tracking | Blind spots in milling stage status | Live mill telemetry (job progress, errors) | ↓ 31% remake rate via early error detection |

| Business Systems | Disconnected billing & production data | Automated cost-per-unit reporting to ERP | ↑ 19% margin visibility |

Technical Implementation Highlights

- Protocol: GraphQL API with OAuth 2.0 security (HIPAA-compliant)

- Latency: < 800ms end-to-end transaction (tested on AWS US-East)

- Adapters: Pre-built connectors for 3Shape, exocad, DentalCAD, and 12 mill brands

- Validation: ISO/IEC 27001 certified data pipeline with audit trails

Conclusion: The Milling Imperative in 2026

CAD/CAM milling has evolved from a standalone fabrication tool to the central nervous system of digital dental production. Key adoption drivers:

- Open architecture systems now dominate lab environments (61% market share) due to material economics and scalability

- API-driven integration reduces workflow friction by 58% compared to manual data handling (per ADA 2026 benchmark)

- Real-time mill telemetry enables predictive quality control – reducing remakes by up to 33%

Strategic Takeaway: Prioritize solutions with certified CAD integrations and robust API capabilities. The true ROI of milling technology lies not in the hardware itself, but in its seamless orchestration within the digital ecosystem – where platforms like Carejoy transform milling from a cost center into a data-powered profit engine.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control in Chinese CAD/CAM Dental Milling: A 2026 Benchmark

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing. At the forefront of this transformation are ISO 13485-certified facilities like Carejoy Digital’s Shanghai production campus, setting new standards in precision, reliability, and throughput for CAD/CAM milling systems.

End-to-End Manufacturing & QC Workflow at Carejoy Digital (Shanghai ISO 13485 Facility)

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Design & Engineering | Modular architecture design using open file formats (STL, PLY, OBJ); AI-driven kinematic optimization of milling paths | Integrated with DICOM, intraoral scanner APIs; compliant with IEC 60601-1 (medical electrical equipment) |

| 2. Component Sourcing | Strategic procurement of linear guides, spindles (80,000 RPM), and ceramic tooling from Tier-1 suppliers (Japan, Germany) with local precision machining | Supplier audits under ISO 13485; traceability via ERP-linked batch tracking |

| 3. Assembly | Modular build in ESD-protected cleanrooms; automated torque control for critical joints | Calibration-integrated assembly line; real-time torque and alignment logging |

| 4. Sensor Calibration | On-site metrology labs perform laser interferometry and capacitive probe calibration | NIST-traceable standards; bi-weekly recalibration cycles; lab accredited to ISO/IEC 17025 |

| 5. Milling Accuracy Validation | Test milling of ISO 5838-2 reference geometries in zirconia, PMMA, and CoCr | Post-process measurement via 3D optical profilometry (±1.5 µm repeatability) |

| 6. Durability Testing | Accelerated life testing: 2,000+ hour spindle runouts, thermal cycling (5–45°C), vibration stress | Failure Mode Analysis (FMEA); MTBF >15,000 hours; exceeds ISO 14971 risk management |

| 7. Final QC & Release | Full system integration test; AI-based anomaly detection in motion profiles | Documented under ISO 13485 DHR (Device History Record); serialized firmware locking |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Vertical integration of electronics, motion control, and software within Shanghai’s high-tech corridor reduces BOM costs by ~35% vs. EU/US equivalents.

- Advanced Metrology Infrastructure: On-campus sensor calibration labs with femtometer-resolution laser interferometers ensure sub-micron motion accuracy—eliminating reliance on third-party services.

- AI-Optimized Production: Predictive maintenance algorithms reduce assembly line downtime by 42%; machine learning tunes spindle harmonics in real time.

- Software Agility: Open architecture (STL/PLY/OBJ) enables seamless integration with global CAD platforms; monthly AI-driven software updates enhance scanning fidelity and toolpath efficiency.

- Regulatory Maturity: ISO 13485 certification is now standard across top-tier manufacturers, enabling CE, FDA 510(k), and NMPA compliance from a single production line.

Carejoy Digital: Engineering the Future of Precision Milling

At Carejoy Digital, our Shanghai-based manufacturing hub leverages China’s advanced industrial ecosystem to deliver CAD/CAM milling systems with unmatched cost-performance efficiency. Every unit undergoes 117 QC checkpoints, including:

- Pre-shipment AI-based scan-to-mill deviation analysis

- Thermal drift compensation across 8-hour continuous operation

- Automated tool wear compensation using acoustic emission sensors

Backed by 24/7 remote technical support and over-the-air software updates, Carejoy systems ensure maximum uptime and clinical precision.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Dental Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160