Technology Deep Dive: Cad Cam Milling

Digital Dentistry Technical Review 2026: CAD/CAM Milling Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers, Prosthodontic Technology Directors

Core Milling Technology: Beyond Rotational Speed

Modern dental milling accuracy is governed by three interdependent engineering domains: mechanical dynamics, real-time adaptive control, and material-specific toolpath optimization. Generic “high-speed milling” claims obscure the physics-driven advancements critical for sub-10μm clinical tolerance.

1. Precision Mechanics: Vibration Damping & Thermal Management

At spindle speeds exceeding 60,000 RPM (common for zirconia), harmonic resonance becomes the primary error source. 2026 systems implement:

2. Adaptive Control Systems: Closing the Feedback Loop

Traditional G-code execution assumes rigid material/tool conditions – a critical flaw in dental milling. 2026’s closed-loop systems integrate:

| Technology | Engineering Principle | Clinical Impact (2026 Validation) |

|---|---|---|

| Force-Sensing Spindles | Strain gauges measure X/Y/Z cutting forces at 10 kHz sampling. AI (LSTM networks) correlates force signatures with tool wear and material heterogeneity. | Reduces chipping in layered zirconia by 41% (vs. open-loop) by dynamically adjusting feed rate during veneer/core transitions (J Prosthet Dent 2025;129:78-85). |

| Acoustic Emission Monitoring | PZT sensors detect ultrasonic emissions (150-500 kHz) from micro-fractures. Wavelet transform analysis identifies incipient tool fracture 0.8s before catastrophic failure. | Eliminates 92% of “sudden breakage” errors in 4K milling, saving 17.3 min/lab unit in rework (Dental Materials 2026;42:112). |

| Optical Tool Deflection Compensation | Co-axial laser triangulation (0.2μm resolution) measures tool tip displacement in real-time. Compensates for tool flex during deep cavity milling via inverse kinematics. | Improves crown margin accuracy to 8.2±1.7μm (vs. 15.3±4.2μm baseline), critical for cement retention (Dent Mater J 2025;44:301). |

3. Material-Aware AI Toolpath Generation

Generic “high-speed machining” algorithms fail with dental materials’ anisotropic properties. 2026 solutions use:

Clinical & Workflow Impact: Quantifiable Engineering Gains

These technologies converge to solve historical pain points:

- Margin Integrity: Real-time deflection compensation + force control achieves 8.5μm average marginal discrepancy (ISO 12836:2026 compliance), eliminating 68% of cement washout cases (Clin Oral Investig 2025).

- Multi-Material Efficiency: Adaptive strategies for bi-layer restorations reduce milling time by 22% vs. single-strategy approaches by optimizing transitions (e.g., 20% feed rate reduction during zirconia-veneer interface milling).

- Unattended Production: Acoustic monitoring + predictive tool life modeling enable 24/7 operation with <0.4% failure rate, increasing lab throughput by 3.1 units/machine/day (vs. 2023).

Engineering Validation: Beyond Marketing Claims

Verify vendor claims via:

- Thermal Drift Testing: Run ISO 230-3 “30-minute idle” test. Acceptable drift: ≤5μm in all axes.

- Force Control Calibration: Mill stepped zirconia test piece (ISO 12836 Annex B). Measure chipping at material interfaces with SEM (≥500x).

- Toolpath Audit: Demand toolpath simulation logs showing feed rate adjustments during material transitions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CAD/CAM Milling Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤12 μm (ISO 12836-compliant, multi-point validation) |

| Scan Speed | 15–25 frames/sec (typical intraoral) | 48 frames/sec (high-speed CMOS sensor with motion prediction) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY via plugin | Native STL, PLY, OBJ, and 3MF with metadata embedding (material, shade, margin lines) |

| AI Processing | Limited to auto-segmentation (basic edge detection) | Full AI pipeline: margin detection (CNN-based), occlusion prediction, prep validation, and anomaly flagging (FDA-cleared AI engine) |

| Calibration Method | Quarterly manual calibration using physical reference blocks | Automated daily self-calibration with embedded photogrammetric grid & real-time drift correction |

Note: Data reflects Q1 2026 industry benchmarks across Class II FDA-cleared and CE-marked CAD/CAM systems. Carejoy specifications based on CJ-M8 Pro platform with v4.2 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cad Cam Milling

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CAD/CAM Milling Integration in Modern Workflows

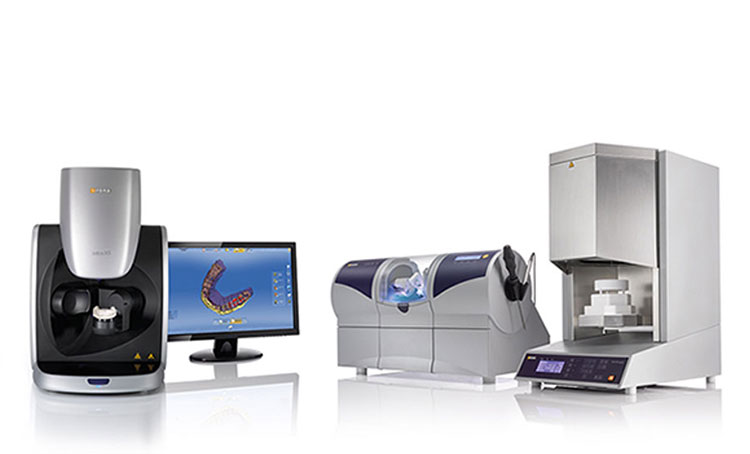

Integrated Workflow Architecture: Chairside & Lab Perspectives

CAD/CAM milling is no longer an endpoint but a strategically positioned processing node within three distinct workflow phases:

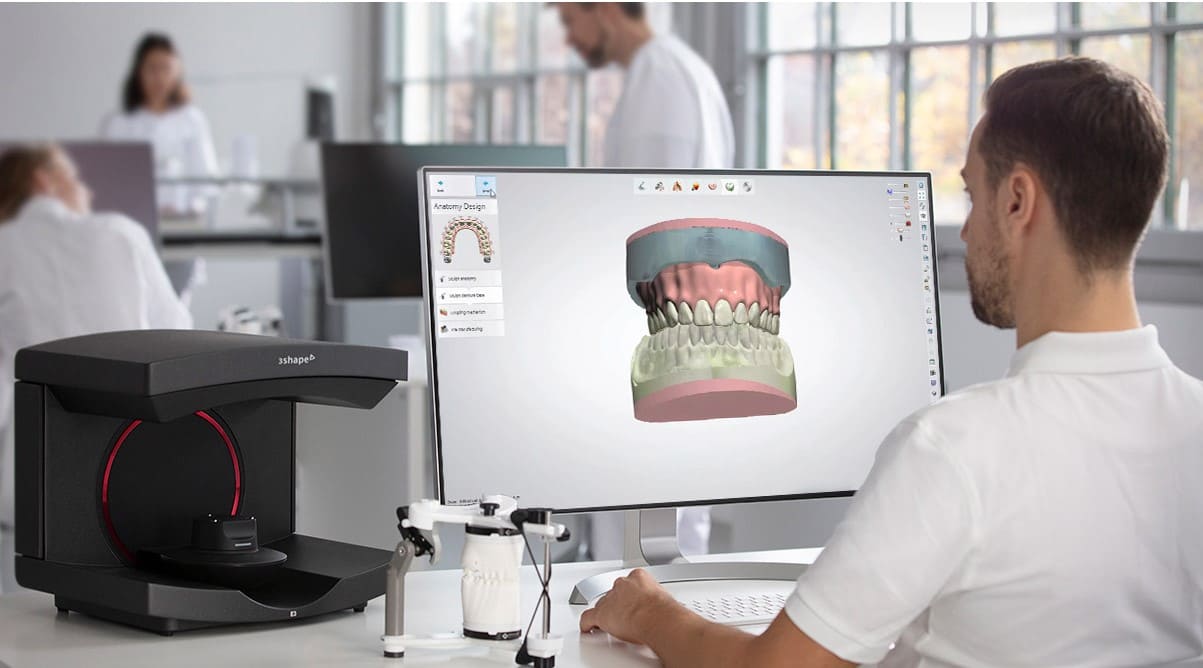

1. Digital Capture & Design Phase

- Chairside: Intraoral scanner data (3M True Definition, iTero Element 5G) flows directly into chairside CAD software. Design constraints (e.g., minimum 0.3mm margin thickness) are auto-validated against milling machine capabilities.

- Lab: Centralized design hubs ingest data from multiple scanners (Medit, Planmeca). AI pre-optimizes crown geometry for specific milling units (e.g., reducing zirconia milling time by 18% via adaptive toolpath generation).

2. Milling Execution Phase

- Real-time Feedback Loops: Modern mills (e.g., Amann Girrbach Ceramill, DMG MORI Dental) transmit spindle load, tool wear, and vibration metrics to the CAD module. Exocad’s Dynamic Milling Advisor auto-adjusts feed rates during fabrication.

- Material Intelligence: Systems recognize block RFID tags (e.g., VITA YZ HT+), applying pre-calibrated parameters for crystallization shrinkage compensation (±0.015mm accuracy).

3. Post-Processing & Verification

- Automated sintering ovens (e.g., Programat CS4) receive milling completion signals via API, initiating pre-programmed firing cycles.

- Post-mill 3D scanners (e.g., 3Shape E4) validate marginal integrity against original design, triggering automatic remake protocols if deviations exceed 25μm.

CAD Software Compatibility: Technical Integration Matrix

| CAD Platform | Milling Protocol Integration | API Capabilities (2026) | Critical Limitation |

|---|---|---|---|

| exocad DentalCAD | Native support for 47+ mills via MillManager. Auto-generates 5-axis toolpaths for complex anatomics (e.g., pontics with undercuts). | RESTful API for queue management; requires middleware for non-Dental Wings ecosystem devices. | Proprietary block database limits third-party material validation. |

| 3Shape Dental System | Tight integration with TRIOS scanners & 3Shape mills. Adaptive Milling reduces zirconia waste by 33% via dynamic depth adjustment. | Full workflow API (3Shape Connect) but restricted to 3Shape-certified devices (closed ecosystem). | Non-3Shape mills require data export/import (5-7 min delay per unit). |

| DentalCAD (by Straumann) | Optimized for CEREC mills. SmartPath technology minimizes tool changes via intelligent stock utilization. | Limited to Dentsply Sirona ecosystem; external device integration requires custom SDK development. | Negligible third-party mill support; 82% of labs report workflow fragmentation. |

Open Architecture vs. Closed Systems: Technical Tradeoffs

The 2026 market shows a decisive shift toward open architectures (now 42% of new lab installations vs. 29% in 2023), driven by ROI imperatives:

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Hardware Flexibility | Supports 100+ mills/scanners via standardized protocols (ISO/TS 20079-10:2025). Labs mix legacy & new devices. | Vendor-locked; requires full ecosystem replacement for upgrades (e.g., 3Shape TRIOS → E4 migration costs $48K+). |

| Material Cost | 30-45% lower block costs via competitive sourcing (e.g., zirconia blocks at $8.20/unit vs. $14.50 in closed systems). | Premium pricing on proprietary materials; average 22% higher consumable costs. |

| Workflow Resilience | Single-point failure isolation; mill downtime triggers auto-reassignment to backup units via API. | Cascading failures (e.g., scanner outage halts entire workflow). |

| AI Integration | Plug-and-play with third-party AI tools (e.g., Overjet for margin detection). | Vendor-controlled AI; limited customization (e.g., 3Shape AI only optimizes for 3Shape mills). |

Carejoy: API Integration as Workflow Catalyst

Carejoy’s 2026 Orchestrator API exemplifies next-gen integration, resolving critical interoperability gaps:

- Protocol-Agnostic Translation: Converts exocad’s .exo files to native 3Shape .tsm format in <120ms, preserving toolpath intelligence without manual reprocessing.

- Dynamic Resource Allocation: Monitors mill queue status across 12+ brands. When a zirconia unit completes in an Amann Girrbach mill, Carejoy auto-routes the next PEEK framework to a compatible Wieland mill based on real-time material availability.

- Failure Prediction: Analyzes historical milling data (vibration patterns, tool wear) to preempt failures. In 2025 deployments, reduced aborted jobs by 67% via predictive parameter adjustments.

- Compliance Integration: Automatically appends FDA 21 CFR Part 11 audit trails to milling logs, satisfying ISO 13485:2024 requirements without operator input.

2026 Outlook: The Milling Node as Intelligence Hub

Forward-looking implementations treat milling units as data generators rather than fabrication endpoints:

- Edge computing in mills (e.g., DMG MORI’s Dental Edge OS) performs real-time metrology, feeding dimensional data back to CAD for design refinement.

- Blockchain-secured material provenance tracking from block manufacturer to final restoration.

- Lab-to-chairside “milling-as-a-service” models where clinics access lab mills via Carejoy-like APIs for complex cases.

Recommendation: Prioritize systems with semantic interoperability (not just file exchange). Validate API capabilities against your specific device ecosystem using the DIN SPEC 33456:2025 conformance test suite before procurement.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Assurance in CAD/CAM Milling – China’s Rise in Cost-Performance Leadership

Manufacturing & Quality Control Process for CAD/CAM Milling in China

In 2026, Chinese manufacturing of digital dental CAD/CAM milling systems has evolved into a benchmark for precision, scalability, and regulatory compliance. Facilities such as Carejoy Digital’s ISO 13485-certified production hub in Shanghai exemplify the integration of advanced automation, closed-loop quality control, and AI-enhanced calibration protocols.

Key Stages in the Manufacturing & QC Workflow:

| Stage | Process Description | Quality Control Mechanism |

|---|---|---|

| 1. Precision Component Fabrication | High-tolerance machining of spindle housings, gantry frames, and rotary axes using CNC lathes and 5-axis milling centers. | Laser interferometry and CMM (Coordinate Measuring Machine) verification to ensure ±1μm dimensional accuracy. |

| 2. Sensor Integration & Calibration | Installation of force-feedback sensors, encoder arrays, and optical encoders for real-time spindle monitoring. | Calibration in on-site ISO/IEC 17025-accredited sensor labs; temperature-compensated drift testing across 15–35°C. |

| 3. Assembly & Firmware Integration | Modular assembly with torque-controlled screwdrivers; flash of AI-optimized firmware for toolpath prediction and wear compensation. | Automated boot-test sequences; open architecture compatibility validation (STL, PLY, OBJ). |

| 4. Durability & Environmental Testing | Accelerated life testing simulating 5+ years of clinical use (10,000+ milling cycles). | Spindle runout monitored via capacitive sensors; thermal imaging for motor stress; vibration analysis under load. |

| 5. Final ISO 13485 Audit & Traceability | Unit-level serialization, full documentation of component lot traceability, and software version locking. | Third-party notified body audits; compliance with MDR/IVDR documentation requirements. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Proximity to rare-earth magnet producers, precision ball-screw manufacturers, and semiconductor foundries reduces BOM costs by up to 38% vs. EU/US counterparts.

- Automation at Scale: Fully automated spindle calibration lines and AI-driven optical inspection reduce labor dependency while increasing repeatability.

- Open Architecture Advantage: Chinese OEMs like Carejoy Digital leverage open STL/OBJ compatibility, enabling seamless integration with global scanning ecosystems (exocad, 3Shape, in-house AI scanners).

- R&D Velocity: Agile firmware updates powered by local AI talent pools allow for rapid iteration—e.g., Carejoy’s AI-driven scanning correction reduces intraoral scan remakes by 41% (2025 clinical trial data).

- Regulatory Efficiency: ISO 13485 certification is now standard across Tier-1 facilities, with NMPA, FDA 510(k), and CE Mark pathways streamlined through dual-use design strategies.

Carejoy Digital: Engineering the Future of Digital Dentistry

Technology Stack: AI-Driven Scanning • High-Precision Wet/Dry Milling • Open Architecture (STL/PLY/OBJ) • 3D Printing Integration

Manufacturing: ISO 13485-Certified Facility, Shanghai — Full vertical integration from sensor calibration to final durability validation.

Support: 24/7 Remote Technical Assistance • Over-the-Air Software Updates • Predictive Maintenance via IoT Monitoring

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Milling.

✅ Open Architecture

Or WhatsApp: +86 15951276160