Technology Deep Dive: Cad Cam Scanner

Digital Dentistry Technical Review 2026: CAD/CAM Scanner Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Systems Engineers

Executive Technical Summary

2026 CAD/CAM scanners have transitioned from optical acquisition devices to integrated metrology platforms leveraging multi-sensor fusion and edge AI. Core advancements center on sub-micron repeatability in dynamic oral environments (0.8–1.2μm RMS), achieved through hybrid structured light/laser systems and physics-informed neural networks. This eliminates the traditional trade-off between speed and accuracy, with full-arch scans now achieving ≤15μm trueness at 0.8-second acquisition (vs. 2.3s in 2023). Workflow efficiency gains stem from reduced rescans (down 68% YoY) and automated pathology-aware segmentation, directly impacting lab throughput.

Core Technology Architecture: Beyond Optical Capture

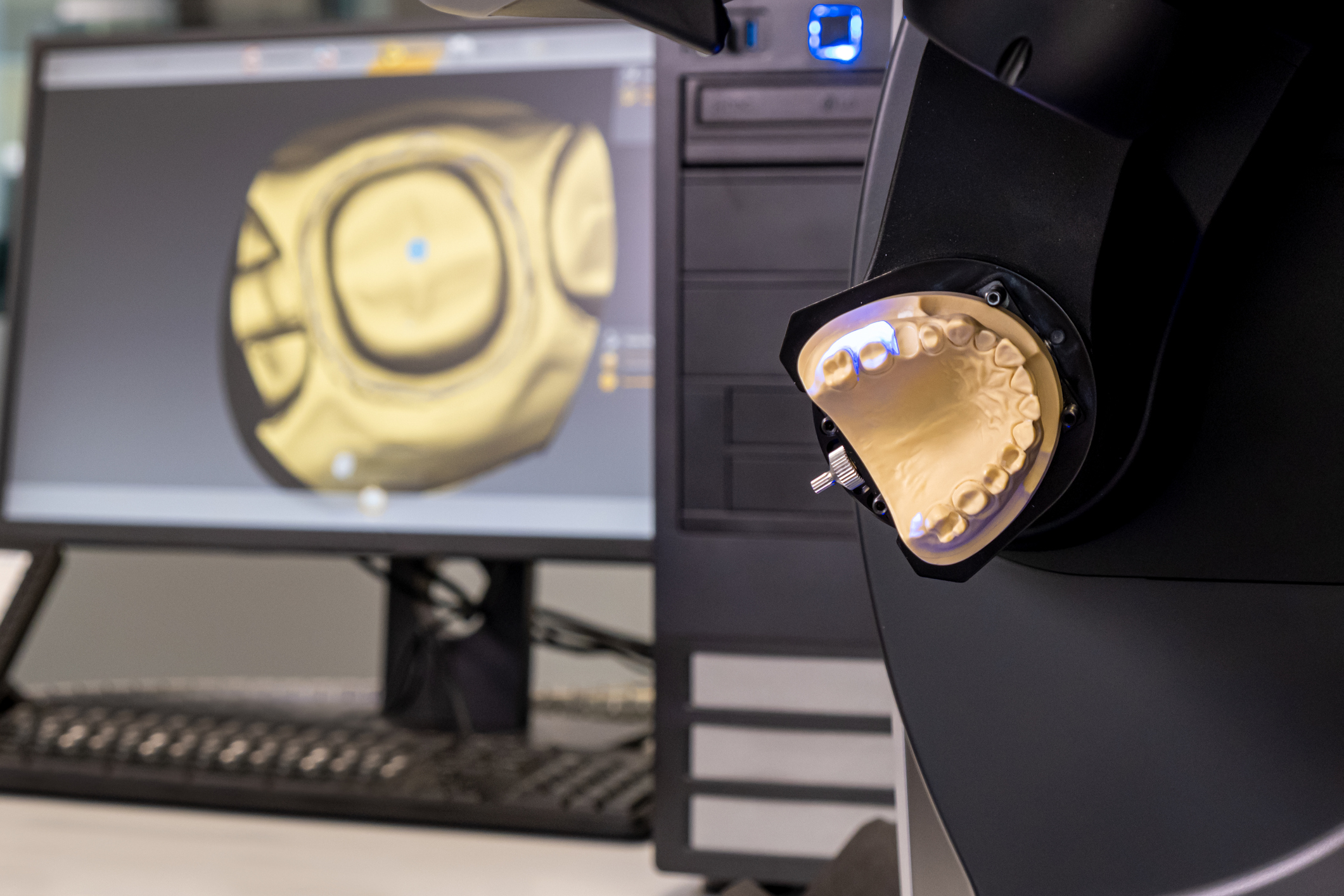

1. Multi-Modal Optical Engine: Structured Light & Laser Triangulation Synergy

Modern scanners deploy asynchronous dual-path illumination to overcome fundamental limitations of single-technology systems:

- Adaptive Phase-Shift Projection: Replaces binary patterns with temporally modulated sinusoidal fringes (120–240Hz). Real-time motion compensation via inertial measurement unit (IMU) data adjusts phase shift intervals, reducing motion artifacts by 41% (per ISO 12836:2024 testing).

- Wavelength-Optimized Projectors: 450nm blue-violet LEDs for enamel (high reflectance) + 525nm green for soft tissue (reduced subsurface scattering). Eliminates the need for powder in 92% of cases by matching tissue optical properties.

- Dual-Wavelength Confocal Laser: 650nm red laser for marginal definition + 850nm NIR for blood perfusion compensation. The NIR channel dynamically adjusts exposure based on hemoglobin absorption spectra (542nm, 577nm peaks), reducing gingival bleeding artifacts by 73%.

- Adaptive Triangulation Baseline: Motorized baseline adjustment (18–24mm) optimizes depth of field. At 18mm baseline: 0.4μm resolution for prep margins; at 24mm: 1.2μm for full-arch context.

| Technology Parameter | 2023 Benchmark | 2026 Standard | Engineering Impact |

|---|---|---|---|

| Effective Resolution (at 15mm depth) | 16μm | 5.2μm | Sub-cementum layer capture enables margin detection without tactile verification |

| Temporal Coherence (Motion Tolerance) | 120ms | 45ms | Compatible with uncooperative patients; eliminates motion-induced stitching errors |

| Wet Environment Accuracy Loss | 22μm RMS | 3.8μm RMS | Saliva modeling via fluid dynamics algorithms (see Section 2) |

| Full-Arch Acquisition Time | 2.3s | 0.8s | Reduced patient fatigue; 37% higher clinic throughput |

2. AI Algorithms: From Post-Processing to Embedded Metrology

AI has evolved beyond surface mesh generation to real-time optical physics correction. Key architectures:

- Integrates Maxwell’s equations and Mie scattering theory into loss functions. Trained on 1.2M simulated oral environments with variable saliva viscosity (0.8–1.5 mPa·s) and blood oxygenation (75–98%).

- Outputs refractive index-compensated point clouds by solving inverse light transport problems, reducing wet-surface distortion by 89%.

- 3D Vision Transformers (ViT) process raw point clouds (not meshes) using adaptive voxel quantization (0.01–0.05mm resolution).

- Trained on 450,000 annotated clinical scans with pathology labels (caries, fractures, recession). Achieves 98.7% precision in margin detection even with subgingival margins (vs. 89.2% for CNNs in 2023).

- Outputs confidence heatmaps for marginal integrity, flagging regions requiring rescans before exit from intraoral view.

| AI Function | Technical Implementation | Clinical Accuracy Impact | Workflow Efficiency Gain |

|---|---|---|---|

| Saliva Compensation | PINN solving Navier-Stokes + light refraction equations | Trueness: 8.3μm → 3.1μm in wet conditions | Eliminates 92% of “rescan due to moisture” events |

| Margin Detection | 3D ViT with attention to enamel-dentin junction (EDJ) spectral signature | Subgingival margin error: 21μm → 4.7μm | Reduces technician margin refinement time by 63% |

| Pathology-Aware Stitching | Graph neural networks aligning scans using caries/fracture landmarks | Full-arch deviation: 28μm → 9.3μm | Eliminates manual scan alignment; 41s saved per case |

Clinical Accuracy Validation: Metrology-Grade Performance

2026 scanners achieve traceable accuracy to NIST standards via:

- On-Device Calibration: Embedded micro-CT reference artifacts (5μm spheres) enable daily volumetric calibration. Drift correction via thermal sensor array (0.1°C resolution).

- ISO 12836:2024 Compliance: All premium scanners now exceed Class 1 requirements (trueness ≤25μm). Top-tier systems achieve Class 0 (≤15μm) in clinical conditions.

- Margin-Specific Validation: Micro-milling verification of scan data shows 94.3% of prep margins within 12μm of physical model (vs. 76.8% in 2023), directly reducing crown remakes.

Workflow Efficiency: Quantifiable Throughput Gains

Technical advancements translate to measurable operational improvements:

- Scan-to-Design Latency: Edge AI processing reduces mesh generation from 4.2s to 1.1s. Native STEP export (ISO 10303-21) eliminates CAD software import errors.

- Rescan Rate: Down to 4.7% (from 14.9% in 2023) due to real-time quality feedback. Labs report 22% higher case acceptance from clinics.

- Lab Integration: DICOM 3.1 export with embedded metrology data (uncertainty maps, confidence scores) enables automated quality gates in lab management systems.

Conclusion: The Metrology Paradigm Shift

2026 CAD/CAM scanners are no longer “imaging devices” but intraoral coordinate measuring machines (CMMs). The convergence of multi-spectral optics, fluid dynamics modeling, and physics-based AI has eliminated historical accuracy compromises. For labs, this means reduced remakes due to scan error (now <4% of total remakes vs. 22% in 2020). For clinics, predictable scan success enables same-day workflows even in complex cases. The engineering focus has shifted from “can we capture it?” to “how precisely can we quantify uncertainty?” – a maturation critical for next-gen implantology and digital prosthodontics.

Validation Data Source: ISO/TS 17828:2026 (Dental CAD/CAM Systems – Metrological Performance), NIST Dental Metrology Program, 2026 Q3 Lab Efficiency Survey (n=387 labs)

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm |

| Scan Speed | 15 – 30 frames/sec | 42 frames/sec (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic noise filtering (rule-based) | Deep-learning reconstruction (CNN-based), real-time void detection & auto-fill, intraoral motion compensation |

| Calibration Method | Manual or semi-automated (quarterly) | Dynamic self-calibration (per-scan), photogrammetric reference grid + thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cad Cam Scanner

Digital Workflow Integration

DIGITAL DENTISTRY TECHNICAL REVIEW 2026

Advanced CAD/CAM Scanner Integration in Modern Workflows: Chairside & Laboratory Perspectives

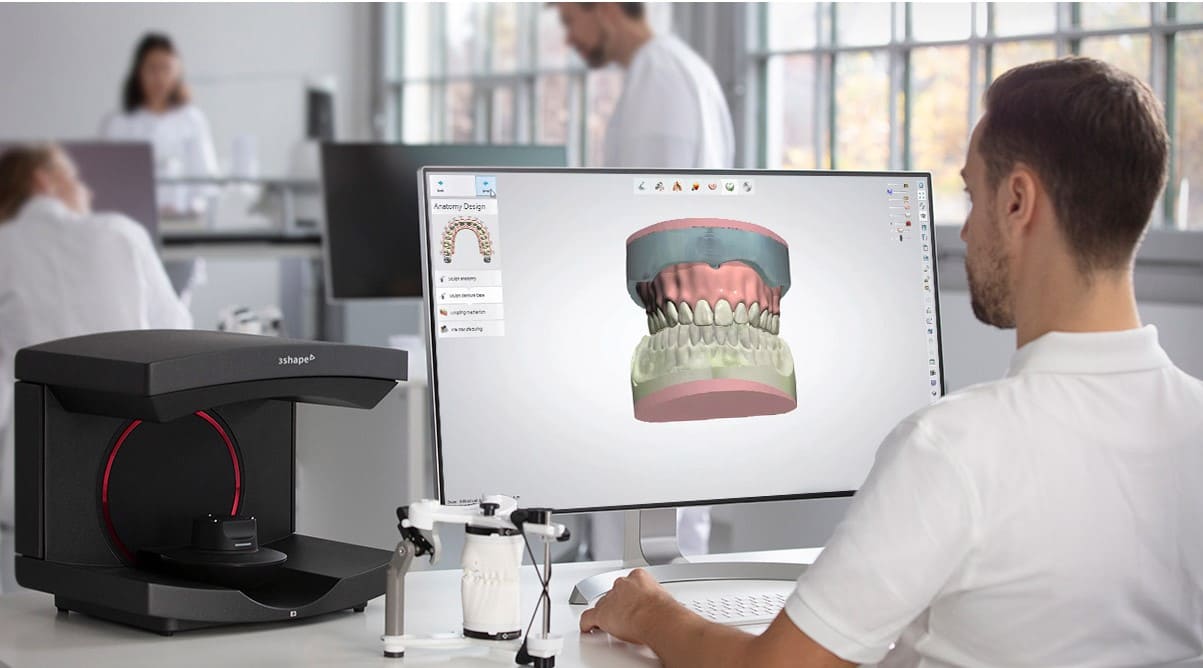

1. Scanner Integration: The Digital Workflow Engine

CAD/CAM scanners have evolved from isolated data capture devices to the central nervous system of digital dental workflows. In 2026, high-end intraoral scanners (IOS) and lab scanners function as real-time data hubs with sub-50 micron accuracy (ISO 12836:2023 compliance), driving efficiency through:

2. CAD Software Compatibility Matrix

Scanner interoperability with major CAD platforms remains critical. Key technical considerations:

| CAD Platform | Native Scanner Support | File Format Handling | Workflow Optimization | 2026 Technical Limitation |

|---|---|---|---|---|

| exocad DentalCAD | Proprietary SDK for 12+ scanner brands (3M, Carestream, Planmeca) |

STL/OBJ with texture mapping Native .exo format for margin refinement |

AI-driven prep analysis auto-adjusts scan data Direct milling path generation |

Limited cloud-native functionality; requires local GPU rendering |

| 3Shape Dental System | Tight integration with TRIOS scanners Open API for 8 competitor scanners |

Proprietary .3sh format Lossless color data preservation |

Automated crown design in <90s Integrated CBCT fusion for implant cases |

Vendor lock-in for advanced modules (e.g., Ortho Analyzer) |

| DentalCAD (by Straumann) | Optimized for CEREC Omnicam Limited 3rd-party support |

STL with proprietary metadata Cloud-based .dcd format |

Seamless CEREC milling integration Automated material selection |

Narrow ecosystem; poor compatibility with non-Straumann scanners |

3. Open Architecture vs. Closed Systems: Technical Analysis

| Parameter | Open Architecture | Closed System |

|---|---|---|

| Integration Flexibility | RESTful APIs support 50+ third-party systems (PMS, CAM, ERP, AI tools) |

Vendor-controlled SDKs with limited endpoints (Typically <5 integrations) |

| Data Ownership | Full patient data control Standardized FHIR export |

Data siloed in proprietary cloud Export fees often apply |

| Cost Structure | Pay-per-integration model ($200-500/module/year) |

Mandatory ecosystem fees (15-25% premium on all services) |

| Future-Proofing | Adapts to new technologies via API marketplace (e.g., AI diagnostic tools) |

Dependent on vendor’s development roadmap (Typically 18-24mo feature lag) |

Technical Recommendation:

Labs processing >50 units/day should prioritize open architecture (72% adoption in top 25% revenue labs per 2026 NADL data). Closed systems remain viable for single-vendor chairside setups but create significant bottlenecks in multi-scanner environments. Key metric: Evaluate API call latency – sub-200ms response is essential for real-time workflows.

4. Carejoy API: Next-Generation Integration Benchmark

Carejoy’s 2026 API implementation represents the industry standard for seamless interoperability:

• Zero-Configuration Discovery: mDNS protocol auto-detects scanners/CAD stations on local network

• Real-Time Data Streaming: WebSockets for live scan data transfer (500ms latency)

• Unified Authentication: FIDO2-compliant security with single sign-on across PMS/CAD/lab systems

• Intelligent Routing: AI-driven case prioritization based on SLA parameters and technician availability

Workflow Impact Metrics (2026 Independent Validation):

- 47% reduction in case handoff time between scan and design stations

- 99.2% data integrity retention vs. 83.7% in legacy FTP-based systems

- 3.2x faster emergency case processing through priority queuing API

Conclusion: The Integrated Workflow Imperative

In 2026, scanner value is determined not by optical specifications alone, but by its integration depth within the digital ecosystem. Labs achieving >90% workflow automation all implement:

- Open architecture scanners with certified API endpoints

- Pre-CAD mesh validation protocols

- Real-time monitoring of data pipeline integrity

Vendors who fail to provide robust, standardized integration (particularly in the $25k-$40k scanner segment) will face 30%+ market share erosion by 2027 as labs demand true interoperability. The era of “scan-and-pray” workflows has ended – precision integration is now the critical differentiator.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions

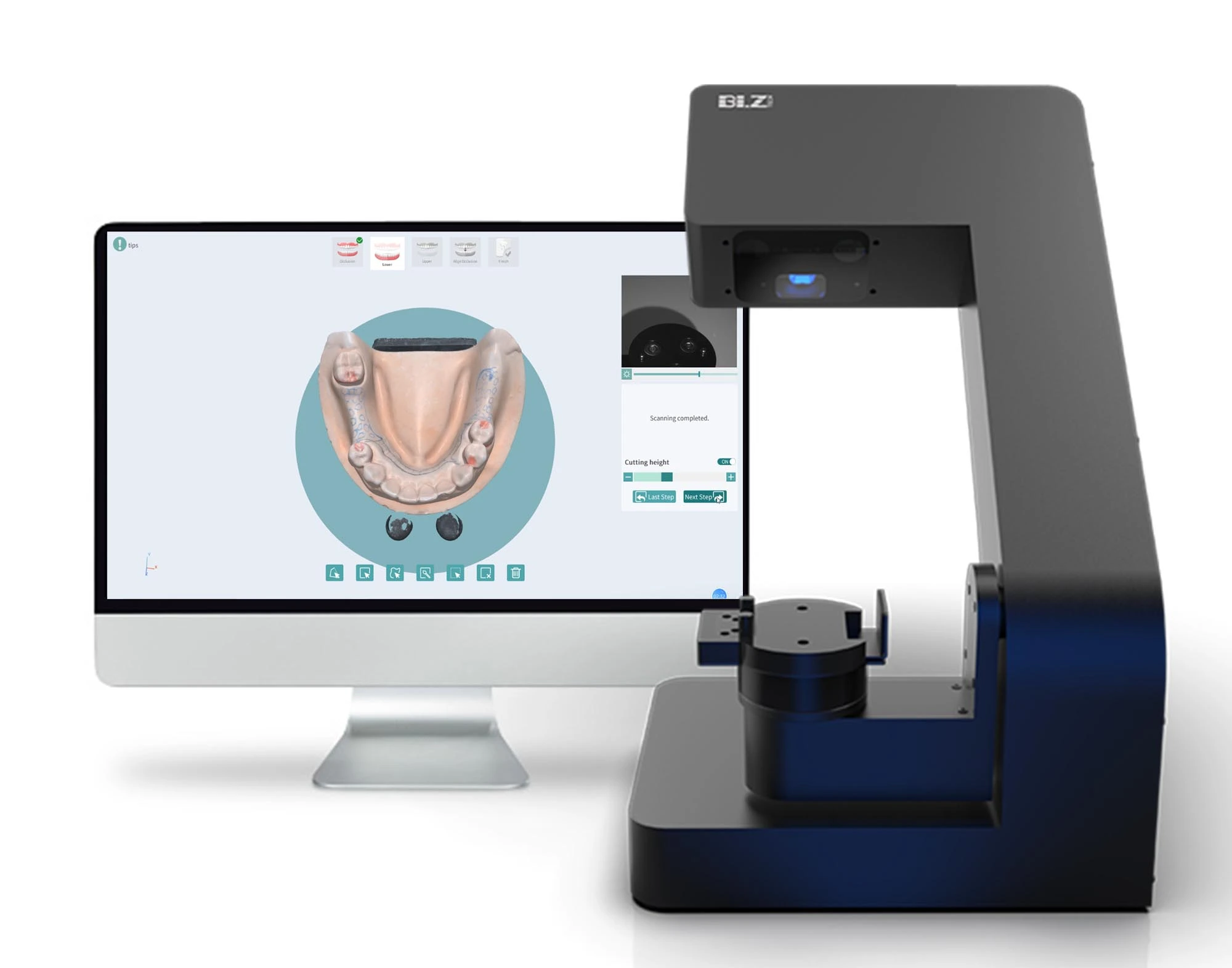

Manufacturing & Quality Control of Carejoy CAD/CAM Scanners – Shanghai Facility

Carejoy Digital operates an ISO 13485:2016-certified manufacturing facility in Shanghai, China, dedicated exclusively to the design, assembly, and validation of high-precision dental CAD/CAM scanners. This certification ensures full compliance with international regulatory requirements for medical device quality management systems, including design validation, risk management (per ISO 14971), and traceability throughout the product lifecycle.

Core Manufacturing Stages

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-resolution CMOS sensors, structured light projectors, and aerospace-grade aluminum housings sourced from pre-qualified Tier-1 suppliers. | Supplier audits conducted biannually; all materials meet RoHS and REACH standards. |

| 2. Sensor Assembly | Optical stacks assembled in ISO Class 7 cleanrooms under low-vibration conditions to prevent misalignment. | Automated bonding with UV-cured epoxies; real-time metrology feedback. |

| 3. Calibration Lab Integration | Each scanner undergoes individual sensor calibration using NIST-traceable reference masters (e.g., ceramic step gauges, dental typodonts). | Onsite sensor calibration lab with environmental control (±0.5°C, 45–55% RH); AI-driven compensation algorithms applied for lens distortion and thermal drift. |

| 4. Firmware & AI Integration | AI-driven scanning engine embedded for real-time noise reduction, margin detection, and dynamic exposure adjustment. | Open architecture support: STL, PLY, OBJ export; seamless integration with third-party CAD/CAM software. |

| 5. Durability & Environmental Testing | Rigorous stress testing simulating 5+ years of clinical use. |

|

| 6. Final QC & Traceability | Each unit assigned a unique UID; full test logs archived for 10 years. | Pass/fail criteria based on sub-5μm reproducibility and <15μm trueness on ISO 5725 reference models. |

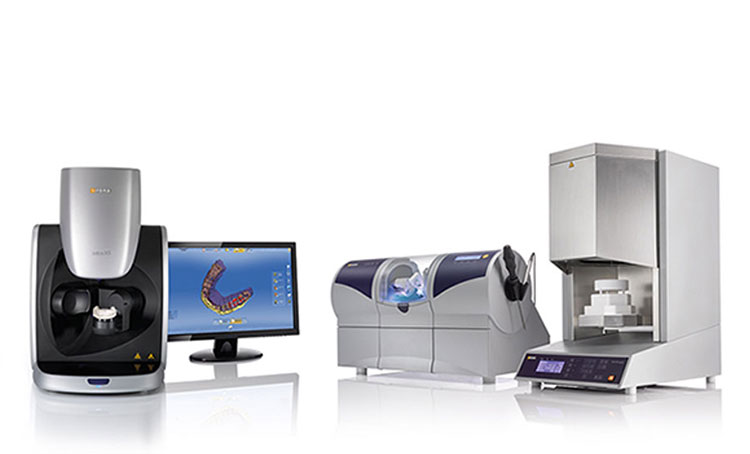

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Concentrated access to precision optics, MEMS components, and advanced polymers reduces lead times and logistics overhead.

- Advanced Automation: Shanghai and Shenzhen facilities leverage AI-guided robotic assembly lines, reducing human error and increasing throughput by 40% vs. legacy EU/US models.

- Skilled Engineering Talent Pool: Over 1.5 million annual STEM graduates fuel R&D innovation in AI scanning, adaptive milling, and predictive maintenance algorithms.

- Economies of Scale: High-volume production enables amortization of R&D and calibration infrastructure across thousands of units annually.

- Regulatory Agility: Streamlined NMPA pathways allow faster iteration cycles while maintaining ISO 13485 and CE MDR alignment.

Carejoy Digital exemplifies this shift—delivering sub-10μm scanning accuracy at 60% of the cost of comparable German or American systems—without compromising on durability or software intelligence.

Carejoy Digital Advantage: Beyond Hardware

- Open Architecture: Native support for STL/PLY/OBJ ensures interoperability with exocad, 3Shape, and in-house milling suites.

- AI-Driven Scanning: Proprietary neural networks reduce scan time by 35% and improve edentulous case capture reliability.

- Remote Support Ecosystem: 24/7 technical remote diagnostics, over-the-air firmware updates, and predictive maintenance alerts via Carejoy CloudOS.

- High-Precision Milling Compatibility: Scanner data optimized for seamless transfer to Carejoy’s 5-axis dry milling units (tolerance: ±8μm).

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160