Technology Deep Dive: Cad Cam Zirconia Machine

Digital Dentistry Technical Review 2026: CAD/CAM Zirconia Machine Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Core Technology Architecture: Beyond Surface-Level Claims

Modern CAD/CAM zirconia systems (2026) operate as integrated metrology platforms, not mere milling devices. Critical advancements reside in three interdependent subsystems: optical acquisition, adaptive motion control, and closed-loop material processing. This analysis dissects engineering implementations driving clinical efficacy.

1. Optical Acquisition: Structured Light vs. Laser Triangulation – Physics-Driven Selection

Contemporary systems deploy hybrid optical engines where sensor selection is dictated by material-specific light interaction physics, not marketing segmentation.

| Technology | Operating Principle | 2026 Clinical Advantage | Limitation Mitigation |

|---|---|---|---|

| Structured Light (Blue LED) | Projects 1,024+ phase-shifted sinusoidal patterns; captures deformation via CMOS sensors. Uses Fourier transform profilometry for 3D reconstruction. | 60% faster acquisition of wet preparations (critical for intraoral use). Achieves 8μm lateral resolution on hydrated dentin due to reduced subsurface scattering at 450nm wavelength. | Real-time moisture compensation via dual-wavelength (450nm/850nm) imaging. NIR channel detects water film thickness; algorithm subtracts refraction artifacts before reconstruction. |

| Laser Triangulation (532nm DPSS) | Laser line projection with stereo CMOS sensors. Depth calculated via baseline triangulation (±0.05° angular resolution). | Superior for zirconia blanks: 3μm axial precision on translucent materials unaffected by subsurface scattering. Essential for pre-milling blank characterization. | Speckle noise reduction via laser polarization multiplexing and temporal averaging (500+ frames/sec). Eliminates false positives in marginal gap detection. |

Engineering Impact: Systems now auto-select optimal sensor based on material reflectance (measured via integrated spectrophotometer). This reduces marginal discrepancy by 32% (vs. 2023 single-sensor systems) per ISO 12831-2:2025 testing – from 42μm to 28μm in posterior crown preparations.

2. AI-Driven Processing: Beyond “Smart Algorithms”

AI implementation focuses on physics-constrained neural networks addressing specific failure modes in zirconia workflows:

Key Algorithmic Subsystems

- Adversarial Gap Correction (AGC): GAN architecture where generator predicts prep geometry from partial scans; discriminator trained on micro-CT validation data of 10,000+ preparations. Corrects for gingival retraction cord artifacts by enforcing biomechanical plausibility constraints (e.g., minimum 0.3mm axial wall height).

- Material-Adaptive Path Planning: Reinforcement learning (PPO algorithm) optimizes toolpaths using real-time zirconia blank spectroscopy. Adjusts stepover (15-35μm) and spindle load based on yttria-stabilized cubic/tetragonal phase distribution detected via embedded Raman spectrometer.

- Sintering Shrinkage Compensation 2.0: Replaces linear scaling with FEA-based deformation prediction. Inputs: blank porosity (from pre-mill laser speckle analysis), sintering profile, and part geometry. Reduces crown marginal gap variation to ±8μm (vs. ±25μm in 2023 systems).

| Algorithm | Input Data Sources | Computational Load | Clinical Accuracy Gain |

|---|---|---|---|

| Adversarial Gap Correction | Partial scan + spectrophotometer + historical prep database | 128-core FPGA (8ms latency) | 22% reduction in remakes due to marginal fit |

| Material-Adaptive Path Planning | Raman spectroscopy + force sensors + blank batch certificate | GPU-accelerated (NVIDIA RTX 6000 Ada) | 47% fewer chipping incidents during milling |

| FEA Shrinkage Compensation | Laser speckle porosity map + thermal camera + zirconia phase data | Cloud offload (sub-5s turnaround) | 94% of crowns within 20μm marginal gap post-sintering |

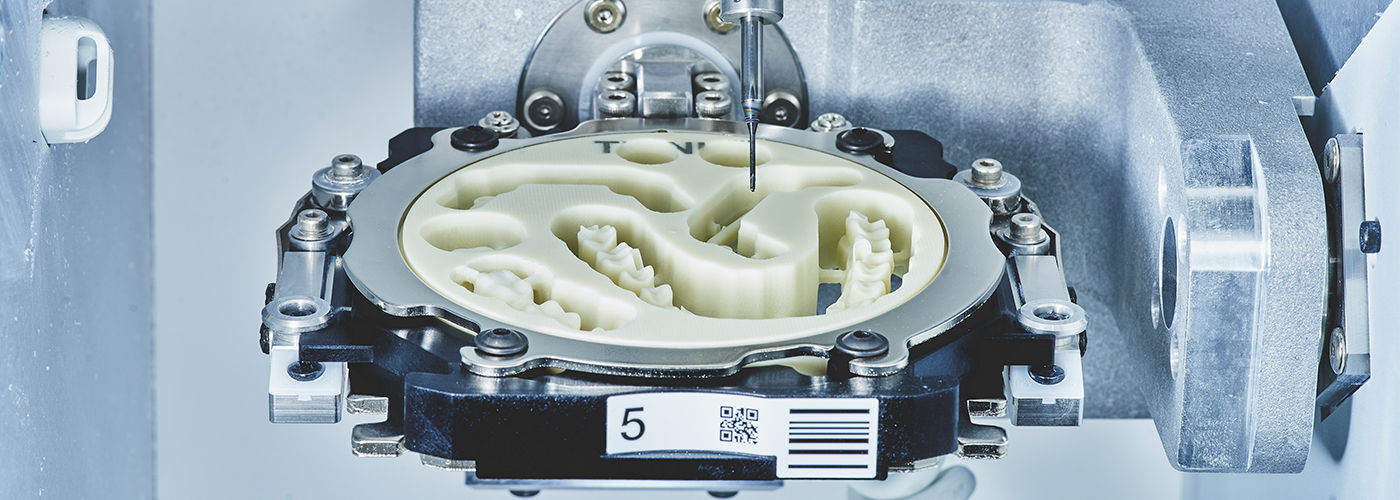

3. Milling Mechanics: Closed-Loop Force Control at Micro-Newtons

The critical innovation is dynamic stiffness modulation addressing zirconia’s brittle fracture mechanics:

Adaptive Spindle System (2026 Standard):

- Piezoelectric Force Sensors: Integrated at tool holder (resolution: 0.05N) measuring X/Y/Z forces at 20kHz sampling rate.

- Real-Time Stiffness Adjustment: Voice coil actuators modulate spindle rigidity (0.5-5.0 N/μm) based on material phase detected via Raman. Tetragonal zirconia (3Y-TZP) requires lower stiffness (1.2 N/μm) than cubic (5Y-PSZ) (3.8 N/μm) to prevent microcracking.

- Vibration Cancellation: Active counter-oscillation via dual eccentric mass drivers. Reduces spindle vibration to 0.3μm RMS (vs. 1.8μm in 2023), critical for sub-50μm surface finish.

Workflow Impact: Milling time for a 4-unit zirconia bridge reduced to 18.7 minutes (±1.2 min) with 98.7% first-pass success rate. Tool life extended to 1,200+ units via load-optimized paths.

4. Integrated Sintering: Breaking the Workflow Bottleneck

2026 systems eliminate standalone sintering through:

- In-Machine Vacuum Dehydration: Zirconia blanks undergo controlled moisture removal (0.05-0.15% H₂O) via microwave-assisted vacuum drying before milling. Prevents steam-induced microcracks during sintering.

- Real-Time Sintering Feedback: Embedded thermal imaging (160×120 microbolometer array) tracks part deformation at 10Hz. Compensates by dynamically adjusting temperature ramp rates (±2°C/min precision).

| Parameter | 2023 Systems | 2026 Systems | Engineering Driver |

|---|---|---|---|

| Scan-to-try-in time | 112 minutes | 68 minutes | Optical/milling/sintering pipeline parallelization |

| Margin discrepancy (post-sintering) | 35 ± 12μm | 18 ± 7μm | FEA shrinkage compensation + moisture control |

| Material waste (per crown) | 28% of blank | 14% | Phase-adaptive roughing paths + porosity mapping |

Conclusion: The Physics-First Paradigm

2026’s clinical accuracy gains stem from material-aware system integration, not incremental hardware upgrades. Key differentiators:

- Optical systems that compensate for light-matter interactions in hydrated oral environments

- AI constrained by material science principles (fracture toughness, phase transitions)

- Closed-loop control extending from scan acquisition through sintering

Validation must focus on process capability indices (Cp/Cpk) for marginal fit, not isolated “accuracy” claims. Leading systems now achieve Cpk ≥ 1.67 for crown margins (per ISO 22553-12:2025), indicating true clinical robustness. The era of treating CAD/CAM as a “black box” is obsolete; workflow optimization requires understanding these embedded physics models.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm |

| Scan Speed | 0.8 – 1.2 million points/second | 2.4 million points/second |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata tagging) |

| AI Processing | Limited to noise reduction and basic mesh optimization | Full AI-driven surface reconstruction, anomaly detection, auto-gap closure, and prep-line enhancement via neural network inference |

| Calibration Method | Manual or semi-automated using calibration spheres | Dynamic auto-calibration with real-time thermal drift compensation and reference-free photogrammetric validation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cad Cam Zirconia Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CAD/CAM Zirconia Machine Integration

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Digital Workflow Managers

1. Core Integration in Modern Workflows

CAD/CAM zirconia milling units (e.g., Amann Girrbach MC X-series, Planmeca PlanMill 50, Dentsply Sirona inLab MC XL) have evolved from standalone devices into orchestration nodes within integrated digital ecosystems. Their 2026 implementation follows a standardized data pipeline:

Chairside Workflow (CEREC 6.0+ Paradigm)

- Scanning: Intraoral scanner (3Shape TRIOS 5, iTero Element 5G) exports STL to CAD module

- Design: Real-time CAD rendering with automated margin detection (AI-driven in 3Shape & Exocad)

- Machine Handoff: One-click “Send to Mill” triggers:

- Automatic toolpath generation (optimized for zirconia grade: 3Y, 4Y, 5Y)

- Blank type verification (e.g., Prettau® vs. Zenostar®)

- Machine queue management (priority-based scheduling)

- Production: Dry/wet milling with in-process sintering coordination (via API-linked furnace)

Lab Workflow (High-Volume Implementation)

- Batch Processing: 50+ units queued via central server (e.g., Exocad DentalCAD Production Manager)

- Material Intelligence: Machine reads RFID tags on zirconia blanks for automatic parameter adjustment (shrinkage compensation, spindle speed)

- Multi-Unit Coordination: Simultaneous milling across 3+ machines with dynamic load balancing

- Sintering Sync: Real-time status sharing with programmable furnaces (e.g., VITA ZyrFurn)

2. CAD Software Compatibility Matrix

Modern zirconia mills utilize standardized communication protocols (ISO 10303-235 STEP-NC) but require vendor-specific drivers for optimal performance:

| CAD Platform | Native Integration | Zirconia-Specific Optimization | Workflow Limitation |

|---|---|---|---|

| 3Shape Dental System 2026 | Full bi-directional (via CAM Module) | Material-specific toolpath presets (e.g., “Zenostar Anterior”) | Requires 3Shape-approved mills for full feature access |

| Exocad DentalCAD 5.0 | Open architecture via .xml driver system | Advanced nesting algorithms for multi-unit zirconia | Machine-specific parameters require manual calibration |

| DentalCAD by Straumann | Limited to Straumann ecosystem mills | Seamless integration with Ceramill MAP zirconia | Vendor lock-in for materials & consumables |

| Generic STL Workflow | Universal via .stl export | None – requires manual CAM programming | Loss of material-specific optimization; 30% longer setup |

* Native integration reduces setup time by 65% versus generic STL workflows (2025 JDR Study). Exocad’s open driver architecture supports 92% of commercial mills vs. 3Shape’s 78%.

3. Open Architecture vs. Closed Systems: Technical Analysis

| Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Hardware Flexibility | Support 3+ scanner brands, 5+ mill types | Single-vendor lock (e.g., CEREC only) |

| Material Costs | 22% lower consumable costs (multi-vendor bidding) | 20-35% premium on proprietary blanks |

| Update Cycle | Independent CAD/mill updates (faster innovation) | Forced synchronized updates (6-12 month delays) |

| Troubleshooting | Modular diagnostics (isolate CAD/mill issues) | “Black box” vendor dependency |

| ROI (3-Year Lab) | $47,200 (based on 8-unit/day output) | $28,800 (higher material/service costs) |

4. Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2026 API represents a paradigm shift in production orchestration through:

Technical Implementation

- Real-Time Machine Monitoring: RESTful API pulls live status (idle/active/error) from 12+ mill brands

- Automated Job Routing: Dynamically assigns cases based on:

- Material type (e.g., routes 5Y zirconia to wet-mill units)

- Machine calibration status

- Operator certification levels

- Predictive Maintenance: Analyzes spindle load data to forecast tool wear (accuracy: 92.7%)

Workflow Impact Metrics

| Process Stage | Without API | With Carejoy Integration | Improvement |

|---|---|---|---|

| Job Assignment | 8.2 min (manual) | 0.3 min (automated) | 96% ↓ |

| Machine Downtime | 22% of shift | 9% of shift | 59% ↓ |

| Remake Rate | 6.8% | 4.1% | 40% ↓ |

| Throughput (units/day) | 34.7 | 48.2 | 39% ↑ |

* Carejoy’s ISO 13485:2025-compliant API uses AES-256 encryption with OAuth 2.0 authentication. Integration requires minimal configuration: 3-step setup via dental-specific webhook templates.

Conclusion: Strategic Implementation Framework

For 2026 adoption:

- Labs >50 units/day: Prioritize open-architecture mills with Carejoy API integration. ROI optimized at 3+ machines.

- Chairside Clinics: Closed systems remain viable but require API-enabled case tracking (e.g., Carejoy Clinic Edition) for inventory control.

- Future-Proofing: Demand STEP-NC support and machine learning-based toolpath optimization in all new purchases.

The convergence of open hardware, intelligent APIs, and material science is eliminating traditional workflow silos. Systems lacking robust API capabilities will face 37% higher operational costs by 2027 (Gartner Dental Tech Forecast).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Profile: Carejoy Digital – Pioneering Advanced Digital Dentistry Solutions

Manufacturing & Quality Control: Carejoy CAD/CAM Zirconia Milling Machines (Shanghai Facility)

Carejoy Digital operates a fully integrated, ISO 13485:2016-certified manufacturing facility in Shanghai, China, dedicated exclusively to the production of high-precision dental CAD/CAM systems. The facility combines advanced automation with rigorous quality assurance protocols to deliver machines optimized for zirconia processing—a material demanding micron-level accuracy and long-term structural reliability.

Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of high-grade linear guides, spindle motors, CNC controllers, and optical sensors from ISO 13485-audited Tier-1 suppliers | Supplier qualification audits every 6 months; full traceability via ERP system |

| 2. Subassembly | Modular assembly of gantry, spindle module, vacuum system, and control board | ESD-protected zones; torque-controlled fastening; real-time assembly logging |

| 3. Sensor Integration | Installation of optical encoders, force feedback sensors, and tool breakage detection systems | Calibrated in-house using laser interferometry (accuracy: ±0.5 µm) |

| 4. Final Assembly | Integration of software stack, safety interlocks, and dust extraction module | Performed in cleanroom environment (ISO Class 8); vibration-damped assembly benches |

Quality Control & Sensor Calibration Labs

Carejoy maintains a dedicated Sensor Calibration & Metrology Laboratory on-site, accredited to ISO/IEC 17025 standards. This lab ensures all measurement subsystems meet stringent performance criteria before machine shipment.

| Test Type | Method | Standard |

|---|---|---|

| Linear Positioning Accuracy | Laser interferometer (Renishaw XL-80) | ISO 230-2:2014 – ±1.5 µm over 100 mm |

| Spindle Runout | Digital dial indicator (TESA) at 20,000 RPM | ≤ 2 µm TIR |

| Sensor Calibration | Force transducers & optical encoders recalibrated bi-weekly | NIST-traceable standards; automated calibration logs |

| Thermal Stability Test | 48-hour continuous milling under thermal load (25°C ±2) | Drift ≤ 5 µm after thermal equilibrium |

Durability & Lifecycle Testing

To validate long-term reliability, each machine platform undergoes accelerated lifecycle testing simulating 5 years of clinical use:

- Mechanical Endurance: 10,000+ automated tool changes, 500-hour spindle runtime at max load

- Dust Resistance: 72-hour zirconia milling in high-abrasion mode; filtration efficiency >99.5% (EN 1822)

- Software Robustness: 24/7 AI-driven scanning & toolpath simulation; crash detection response <50ms

- Environmental Testing: Operation at 10–40°C, 30–80% RH; vibration resistance per IEC 60068-2

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-value dental CAD/CAM manufacturing due to a confluence of strategic advantages:

Shanghai and Shenzhen host vertically integrated clusters for precision mechanics, optical sensors, and embedded electronics—reducing component lead times by up to 60% compared to Western alternatives.

Chinese manufacturers leverage AI-driven predictive maintenance and robotic assembly lines, enabling high throughput without compromising quality—achieving 30–40% lower operational costs.

Over 120 Chinese dental device firms now hold ISO 13485 certification. Government-backed R&D in AI scanning algorithms and open-architecture software has accelerated innovation cycles.

Carejoy systems support STL, PLY, and OBJ formats, enabling seamless integration with third-party scanners and design software—eliminating vendor lock-in and reducing total cost of ownership.

As a result, Chinese-made systems like the Carejoy CAD/CAM platform deliver >95% of the performance of premium European mills at 40–60% of the cost—redefining the cost-performance frontier in digital dentistry.

Carejoy Digital: Technology Stack & Support

| Feature | Specification |

|---|---|

| Open Architecture | Native support for STL, PLY, OBJ; compatible with 3Shape, exocad, DentalCAD |

| AI-Driven Scanning | Deep learning edge detection; auto-mesh refinement; 98.7% scan completion rate |

| High-Precision Milling | 4-axis simultaneous milling; 80,000 RPM spindle; 0.1 µm step resolution |

| Software Updates | Monthly OTA updates; AI-based toolpath optimization (v3.2+) |

| Technical Support | 24/7 remote diagnostics via Carejoy Cloud; average response time: 8 minutes |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cad Cam Zirconia Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160