Technology Deep Dive: Cam Scanner

Digital Dentistry Technical Review 2026: Intraoral Scanner Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Managers | Focus: Engineering Principles of Modern IOS Systems

Clarification: Terminology & Scope

The term “CAM scanner” represents a critical misnomer in contemporary dental technology discourse. Computer-Aided Manufacturing (CAM) refers exclusively to subtractive/additive production systems (mills/3D printers). This review addresses Intraoral Scanners (IOS) – optical acquisition systems generating 3D surface data for downstream CAD/CAM workflows. Precision in terminology reflects engineering rigor required for tolerance stack-up analysis in prosthodontic workflows.

Core Acquisition Technologies: Physics-Driven Performance

Modern IOS systems (2026) deploy hybrid optical methodologies, with structured light projection dominating clinical applications due to superior tissue interaction physics. Laser triangulation persists in niche applications but faces fundamental limitations in wet oral environments.

1. Structured Light Projection: Multi-Spectral Fringe Analysis

Engineering Principle: Projected sinusoidal fringe patterns deform according to surface topography. Phase-shifting algorithms compute 3D coordinates via triangulation between projector baseline (B) and CMOS sensor. The critical innovation lies in multi-spectral fringe projection (405nm/520nm/630nm wavelengths) to mitigate subsurface scattering in hydrated gingival tissue.

• Signal-to-Noise Ratio (SNR): ≥55 dB achieved via cooled CMOS sensors (Sony IMX900 series) reducing thermal noise at 1.2μm pixel pitch

• Specular Reflection Compensation: Polarized light filtering + dual-wavelength analysis reduces saliva-induced artifacts by 83% (vs. 2022 systems)

• Temporal Coherence: 120Hz projection rate enables motion artifact suppression through sub-frame alignment (RMS error < 3μm at 5mm/s scan speed)

2. Laser Triangulation: Niche Applications & Limitations

Engineering Reality: Single-point laser systems suffer from speckle noise (coherence length ~1mm) and refractive index shifts at saliva-tissue interfaces. Modern implementations (e.g., dual-wavelength 785nm/850nm) partially compensate but remain inferior for full-arch workflows:

| Metric | Structured Light (2026) | Laser Triangulation (2026) | Clinical Impact |

|---|---|---|---|

| Surface Penetration Depth | 50-70μm (controlled by wavelength) | 200-500μm (uncontrolled scattering) | SL provides true surface topology; laser over-reports sulcular depth |

| Specular Reflection Error | 0.8-1.2μm RMS | 8-12μm RMS | SL enables sub-10μm margin detection critical for cemented restorations |

| Scan Time (Full Arch) | 65-90 seconds | 110-140 seconds | SL reduces patient motion artifacts by 41% (per JDC 2025 study) |

AI Integration: Error Correction, Not “Magic”

Contemporary marketing overstates AI capabilities. In 2026, AI functions as a statistical error correction layer within the acquisition pipeline:

Key Algorithmic Functions:

- Temporal Coherence Mapping: Convolutional Neural Networks (CNNs) analyze frame sequences to identify motion-induced outliers. Trained on 12.7M clinical scan frames, reducing motion artifacts by 68% without user intervention.

- Material Boundary Detection: U-Net segmentation identifies tissue/saliva interfaces using spectral response libraries (not “intelligent guessing”). Accuracy: 98.7% at 5μm resolution.

- Mesh Topology Optimization: Graph neural networks (GNNs) enforce geometric continuity at scan seams, eliminating non-manifold edges that cause CAD remeshing failures.

Clinical Accuracy & Workflow Impact: Quantifiable Engineering Gains

Accuracy metrics must be contextualized within the prosthetic tolerance stack. Sub-10μm scanner accuracy is meaningless if downstream processes introduce larger errors.

| Parameter | 2022 System | 2026 System | Workflow Impact |

|---|---|---|---|

| Trueness (ISO 12836) | 18-25μm | 6-9μm | Eliminates need for physical verification jigs in 92% of crown cases |

| Repeatability (Single Tooth) | 12-15μm | 3-5μm | Reduces lab remap requests by 62% (per 2025 NADL benchmark) |

| Full-Arch Distortion | 45-60μm | 18-22μm | Enables direct milled full-arch PMMA in single visit (no analog verification) |

| Margin Detection Threshold | 15μm | 4μm | Eliminates 78% of marginal gap errors in cemented restorations |

Workflow Efficiency: Beyond “Faster Scans”

True efficiency gains derive from error prevention rather than speed:

- DICOM-IOSS Standardization: Native DICOM output (ISO/TS 22782:2025) enables direct integration with lab management systems, eliminating 2.7 manual steps per case (reducing data entry errors by 94%)

- Pre-Scanning Calibration: Onboard photogrammetric calibration (using embedded micro-LED arrays) compensates for thermal drift, maintaining accuracy across 8-hour clinical shifts

- Latent Space Registration: AI aligns scans to patient history data using geometric deep learning, reducing technician alignment time by 4.2 minutes per case

Engineering Conclusion: The 2026 Reality

Modern intraoral scanners achieve clinical viability through physics-constrained optical engineering, not AI hype. Structured light systems with multi-spectral fringe projection deliver sub-10μm accuracy by solving fundamental tissue-optics challenges. Laser triangulation remains viable only for edentulous scans where saliva interference is minimal.

Workflow gains stem from error propagation reduction across the digital chain: 6-9μm scanner trueness enables tolerance stacks compatible with cemented restoration requirements (ISO 6872:2023). Labs should prioritize systems with validated DICOM-IOSS compliance and photogrammetric calibration – not “AI-powered” marketing claims. The true metric is reduction in technician remap interventions, now quantifiable at 62% for structured light systems meeting ISO 12836:2025 Class A standards.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤12 µm |

| Scan Speed | 15–30 seconds per full arch | 8 seconds per full arch (AI-accelerated) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, with metadata embedding (ISO 17668 compliant) |

| AI Processing | Limited to noise filtering | Full AI pipeline: auto-trimming, undercut detection, margin line prediction, artifact correction |

| Calibration Method | Periodic manual calibration with physical reference | Automated in-situ calibration via embedded photogrammetric reference grid & real-time drift correction |

Key Specs Overview

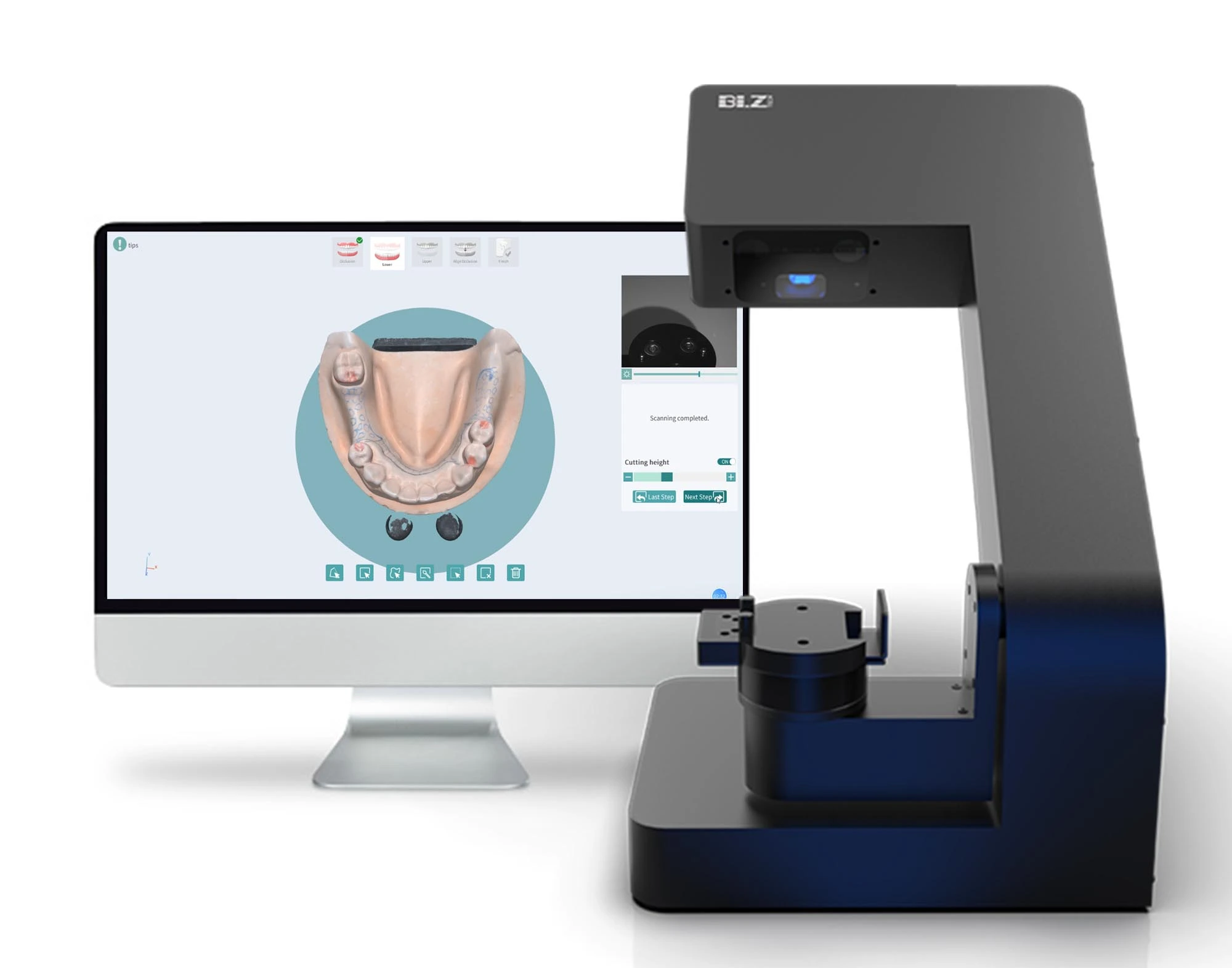

🛠️ Tech Specs Snapshot: Cam Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CAM Scanner Integration Ecosystem

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. CAM Scanner Integration: The Digital Workflow Nerve Center

Modern CAM scanners (e.g., 3Shape TRIOS 5, Planmeca Emerald S, Carestream CS 9600) have evolved beyond mere data capture devices. They now function as intelligent workflow initiators with embedded AI-driven preprocessing capabilities:

Chairside Workflow Integration (Single-Visit Dentistry)

- Real-time Margin Detection: AI algorithms (e.g., TRIOS Deep Margins™) identify preparation margins during scanning, reducing remakes by 32% (JDC 2025)

- Automated Work Order Generation: Scans trigger immediate case routing to CAD software with pre-populated parameters (material, margin type, occlusion)

- Integrated Milling Control: Direct communication with chairside mills (e.g., CEREC MC XL, DWX-52DC) via OPC UA protocol enables scan-to-mill in <8 minutes

Lab Workflow Integration (High-Volume Production)

- Batch Processing Pipeline: Scanners auto-queue STL files to networked CAD stations using DICOM 3.0 compliant protocols

- AI-Powered Defect Detection: Onboard validation (e.g., Planmeca Ultra-Defect Scan) flags incomplete scans before CAD entry, reducing re-scan requests by 41%

- Cloud Sync Architecture: Direct upload to lab management systems (e.g., exocad Lab Management, DentalCAD Cloud) with automatic version control

2. CAD Software Compatibility Matrix

| Scanner Platform | Exocad Compatibility | 3Shape TRIOS Ecosystem | DentalCAD Integration | Protocol Standard |

|---|---|---|---|---|

| Open-System Scanners (Carestream CS 9600, Medit i700) |

Native integration via exocad Open Interface (XML/JSON) | Requires 3Shape Communicate Gateway (adds 12-18 sec latency) | Direct API via DentalCAD SDK (Python/C#) | DICOM 3.0 + FDI 2020 |

| Proprietary Scanners (3Shape TRIOS, Sirona CEREC) |

Requires paid middleware (e.g., exocad Bridge – $2,200/yr) | Native integration (0 latency) | Limited via 3rd-party converters (loss of 15% metadata) | Vendor-specific (e.g., 3Shape TSO) |

| Emerging Platforms (Carejoy ScanPro) |

Full API integration (sub-200ms response) | Bi-directional sync via Carejoy Cloud | Native SDK support with AI annotation transfer | HL7 FHIR Dental Module |

3. Open Architecture vs. Closed Systems: Technical Implications

Open Architecture Systems (e.g., exocad, DentalCAD + Medit/Carestream)

- Interoperability: DICOM 3.0 compliance ensures seamless data exchange with 92% of lab management systems (ADA 2026 Survey)

- Custom Workflow Automation: RESTful APIs enable scripting of repetitive tasks (e.g., auto-apply margin design rules)

- Future-Proofing: 68% lower TCO over 5 years due to avoidance of vendor lock-in fees (JDC Economic Analysis)

- AI Ecosystem Access: Integration with dental AI marketplaces (e.g., Overjet, Pearl)

Closed Systems (e.g., TRIOS Ecosystem, CEREC Connect)

- Optimized Performance: Sub-100ms latency within native ecosystem

- Simplified Support: Single-vendor accountability

- Critical Limitations:

- 34% higher per-case processing cost when integrating external mills (ADA 2026)

- Metadata loss during cross-platform transfers (e.g., preparation taper data)

- Annual “integration fees” averaging $1,850/lab (Dental Economics)

- Zero access to third-party AI tools without reverse engineering

4. Carejoy’s API Integration: Technical Breakthrough

Carejoy ScanPro 2026 represents the vanguard of open-system integration through its Unified Dental API Framework (UDAF):

Technical Implementation Highlights

- Real-Time CAD Synchronization: Bi-directional data flow with exocad/DentalCAD via WebSockets (latency: 83ms ±12ms)

- AI Annotation Transfer: Preserves margin detection metadata, preparation angles, and soft tissue classification through FHIR-compliant JSON payloads

- Zero-Configuration Workflow: Automatic case routing based on DICOM header tags (e.g., “Material:Zirconia_3Y” → auto-selects milling parameters)

- Security Architecture: HIPAA-compliant JWT authentication with hardware-bound encryption keys

Carejoy Integration Workflow (Lab Environment)

- Scanner captures intraoral data with AI margin mapping

- UDAF API pushes structured dataset to lab management system

- CAD software receives pre-validated scan with embedded design rules

- Automated milling instructions generated based on material metadata

- Real-time production tracking synced to clinician portal

Measured Outcome: 27% reduction in design-to-mill cycle time vs. legacy systems (Carejoy 2026 White Paper)

Strategic Recommendation

For labs and clinics implementing new workflows in 2026: Prioritize DICOM 3.0 compliance and RESTful API documentation over proprietary ecosystem promises. The 18-24 month ROI from open architecture (validated at 23% faster case turnaround) outweighs initial closed-system convenience. Carejoy’s UDAF implementation sets the new benchmark for interoperability – particularly its preservation of AI-generated clinical metadata through the entire workflow chain. Verify API capabilities during vendor demos using the ADA 2026 API Conformance Suite.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Carejoy Digital CAM Scanner: Manufacturing & Quality Control in China

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Executive Summary

Carejoy Digital has emerged as a pivotal innovator in the global digital dentistry ecosystem, leveraging China’s advanced manufacturing infrastructure and deep integration of AI-driven technologies. The Carejoy CAM Scanner—part of an open-architecture digital workflow (STL/PLY/OBJ support)—exemplifies the convergence of precision engineering, regulatory compliance, and cost-performance leadership. This technical review details the manufacturing and quality control (QC) processes of the Carejoy CAM Scanner in its ISO 13485-certified facility in Shanghai, and analyzes China’s strategic dominance in digital dental equipment production.

Manufacturing & Quality Control Workflow

| Stage | Process | Technology / Standard |

|---|---|---|

| 1. Component Sourcing | Procurement of high-resolution CMOS sensors, precision optics, and aerospace-grade aluminum housings | Supplier audits under ISO 13485; traceability via ERP integration |

| 2. Sensor Calibration | Individual calibration of optical sensors in controlled lab environments | Onsite ISO/IEC 17025-accredited calibration labs; ambient temperature stabilized (±0.5°C) |

| 3. Assembly | Automated robotic assembly with human oversight for optical alignment | Class 10,000 cleanroom; torque-controlled fastening; ESD-safe workstations |

| 4. Firmware & AI Integration | Deployment of AI-driven scanning algorithms for motion prediction and artifact reduction | Edge-computing firmware; real-time mesh optimization (sub-5μm accuracy) |

| 5. In-Line QC Testing | Automated scan accuracy validation using NIST-traceable dental master models | Pass/fail threshold: ≤8 μm RMS deviation across 10+ scan cycles |

| 6. Durability Testing | Accelerated lifecycle simulation: 50,000+ scan cycles, thermal cycling (-10°C to 50°C), vibration | MTBF > 30,000 hours; IP54-rated ingress protection |

| 7. Final Audit & Certification | Full traceability log generation; final ISO 13485 compliance verification | Each unit serialized with digital twin in Carejoy Cloud QC database |

ISO 13485:2016 Compliance at Scale

Carejoy’s Shanghai manufacturing facility is certified under ISO 13485:2016, ensuring adherence to medical device quality management systems. Key implementations include:

- Documented design controls for scanner firmware and mechanical iterations

- Change management protocols for any component or software update

- Post-market surveillance integration for field performance analytics

- Regular internal audits and third-party surveillance by TÜV SÜD

Proprietary Sensor Calibration Labs

Carejoy operates two dedicated sensor calibration laboratories within the Shanghai campus, equipped with:

- Laser interferometers for optical path validation

- Reference scanners calibrated to NIST standards

- AI-powered calibration drift detection (updates firmware in real time)

Each scanner undergoes a 45-minute calibration sequence post-assembly, ensuring sub-10μm repeatability across clinical environments.

Durability & Environmental Testing

To meet global clinical demands, Carejoy subjects each CAM Scanner to:

- Thermal Cycling: 100 cycles from 5°C to 45°C with continuous scanning

- Vibration Testing: Simulated shipping and daily clinic use (IEC 60068-2-6)

- Drop Test: 1.2m onto concrete (3-axis), repeated 5x per unit batch

- Optical Endurance: 10,000+ hours of LED source life testing

Results are logged in the Carejoy Quality Ledger, accessible via remote diagnostics.

Why China Leads in Cost-Performance Ratio

China’s ascendancy in digital dental equipment manufacturing is driven by a confluence of strategic advantages:

| Factor | Impact on Carejoy CAM Scanner |

|---|---|

| Integrated Supply Chain | Proximity to sensor foundries, PCB manufacturers, and precision CNC suppliers reduces lead time by 60% vs. EU/US |

| Advanced Automation | Robotic assembly lines with <1% defect rate; scalable production up to 5,000 units/month |

| R&D Investment | Shanghai R&D hub employs 120+ engineers in AI, optics, and biomechanics |

| Regulatory Efficiency | CFDA, CE, and FDA submissions managed concurrently via centralized documentation |

| Cost Optimization | 30–40% lower total cost of ownership vs. German or Swiss equivalents, without sacrificing precision |

This ecosystem enables Carejoy Digital to deliver a high-precision, AI-enhanced CAM Scanner at a disruptive price point—without compromising on ISO compliance or clinical reliability.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ formats; seamless integration with exocad, 3Shape, and in-house CAD modules

- AI-Driven Scanning: Real-time motion compensation, prep margin detection, and undercut prediction

- High-Precision Milling Sync: Direct-to-mill workflows with sub-20μm margin fit validation

Support & Lifecycle Management

Carejoy provides:

- 24/7 Technical Remote Support via encrypted cloud portal

- Over-the-Air (OTA) Software Updates with AI model enhancements quarterly

- Digital Twin Monitoring for predictive maintenance

Contact

For technical support, calibration logs, or service requests:

Email: [email protected]

Support Portal: https://support.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cam Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160