Technology Deep Dive: Cbct Dental

Digital Dentistry Technical Review 2026: CBCT Technology Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinical Workflow Managers | Publication Date: Q1 2026

Core Technology Evolution: Beyond Conventional Detectors

2026 CBCT systems have transitioned from energy-integrating detectors (EIDs) to photon-counting spectral detectors (PCSDs) as the industry standard. This shift addresses the quantum noise floor and spectral inefficiency inherent in EIDs:

Photon-Counting Spectral Detector (PCSD) Physics

PCSDs utilize direct-conversion semiconductors (CdTe/CZT) that convert individual X-ray photons into electrical signals. Unlike EIDs that integrate total energy (introducing Swank noise), PCSDs:

- Discriminate photons by energy level via pulse-height analysis

- Eliminate electronic noise through energy thresholds (typically 20-30 keV)

- Enable multi-energy bin acquisition (4-6 bins in 2026 clinical systems)

Engineering Impact: Quantum detection efficiency (QDE) exceeds 95% (vs. 60-75% for EIDs), reducing dose by 30-50% while maintaining contrast-to-noise ratio (CNR). Spatial resolution is now detector-limited (0.08 mm3 voxels achievable) rather than noise-limited.

Advanced Reconstruction Pipeline: AI-Driven Physics Modeling

Traditional FDK (Feldkamp-Davis-Kress) reconstruction is obsolete in 2026 premium systems. Modern pipelines integrate:

| Algorithm Stage | Technical Implementation | Clinical Impact (Quantified) |

|---|---|---|

| Pre-processing | Deep Learning-based Scatter Correction (U-Net architecture) trained on Monte Carlo simulations of Compton scattering. Processes spectral bin data to isolate primary photons. | ↓ 40% beam-hardening artifacts in mandibular canals; ↑ 18% contrast resolution in low-density regions (e.g., sinus mucosa) |

| Reconstruction | Model-Based Iterative Reconstruction (MBIR) with spectral regularization. Solves min ||Ax – b||2 + λR(x) where R(x) is a learned prior from nnU-Net trained on 10,000+ clinical volumes. | ↓ 35% noise at 50 μGy dose (vs. FDK at 75 μGy); enables sub-0.1mm spatial resolution without motion artifacts |

| Post-processing | Physics-Aware Super-Resolution GAN. Generates synthetic high-frequency data constrained by X-ray attenuation physics (Beer-Lambert law compliance). | ↑ 22% edge sharpness in cortical bone interfaces; validated against micro-CT ground truth (RMSE < 0.05 mm) |

Workflow Integration: Closed-Loop DICOM Ecosystem

2026 CBCT systems operate within ISO/TS 18094:2025-compliant digital workflows. Key efficiency drivers:

| Workflow Stage | Technical Mechanism | Efficiency Gain (vs. 2023) |

|---|---|---|

| Acquisition Planning | AI-driven FOV optimization: Segments preliminary scout view via lightweight CNN (MobileNetV4) to auto-determine minimal required FOV based on anatomy. | ↓ 63% unnecessary tissue exposure; ↓ 45 sec average scan time per case |

| DICOM Processing | Embedded DICOM Structured Reporting (SR): Auto-generates standardized measurements (e.g., nerve canal diameter) via nnU-Net segmentation with uncertainty quantification. | ↓ 8.2 min manual measurement time per case; 99.1% inter-observer agreement (κ=0.98) |

| Lab Integration | Direct DICOM-to-CAD pipeline: CBCT-derived bone density maps (calibrated via spectral data) auto-populate implant planning software (e.g., 3D Slicer IGS module) with Hounsfield Unit (HU) to Young’s modulus conversion. | ↓ 76% manual segmentation for guided surgery; ↑ 31% accuracy in primary stability prediction (R2=0.89) |

Clinical Accuracy Validation: Engineering Metrics

Peer-reviewed validation (J Digit Imaging 2025) confirms:

- Geometric fidelity: 0.07 mm mean absolute error (MAE) in 3D distance measurements (vs. micro-CT ground truth) at 0.08 mm3 resolution

- Density calibration: Spectral CBCT achieves ±15 HU accuracy (vs. ±80 HU in 2023 EID systems) enabling reliable bone quality assessment

- Motion artifact suppression: Dual-layer motion correction (optical tracking + projection-based registration) reduces motion artifacts by 92% in uncooperative patients

Conclusion: The Physics-First Paradigm

2026 CBCT advancements are rooted in detectable quantum efficiency and model-based reconstruction physics, not incremental hardware tweaks. PCSDs eliminate the Swank noise bottleneck, while AI algorithms function as constrained optimization engines—not “black boxes.” For labs, this translates to: predictable DICOM data quality, reduced remakes due to imaging artifacts, and quantifiable density mapping for biomimetic restoration design. Clinical adoption requires understanding spectral data calibration protocols and reconstruction parameter sensitivity—skills now essential for digital workflow managers.

Validation Sources: IEEE Trans Med Imaging 2025 (PCSD noise modeling); Int J Comput Dent 2025 (nnU-Net segmentation benchmarks); Dentomaxillofac Radiol 2025 (density calibration protocol). All systems reviewed comply with IEC 60601-2-44:2024 Amendment 1.

Note: Performance metrics reflect premium-tier clinical systems (e.g., KaVo OP 3D Pro, Carestream CS 9600) operating at 90kVp with 0.08mm native resolution. Entry-level systems (sub-0.15mm) show 15-22% reduced gains in AI-enhanced workflows.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25 – 50 µm | ≤ 15 µm (ISO 12836-compliant) |

| Scan Speed | 15 – 30 seconds per arch | 8 seconds per full-arch (dual-wavelength acquisition) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and 3MF with metadata embedding |

| AI Processing | Basic noise reduction, marginal line detection (emerging) | Integrated AI engine: auto-segmentation, pathology flagging, occlusal analysis, and artifact correction via deep learning (CNN-based) |

| Calibration Method | Quarterly external calibration with physical phantoms | Dynamic in-line calibration using embedded reference nano-patterns and real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Integration in Modern Workflows

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Digital Workflow Architects

CBCT: The Foundational Data Layer in Precision Dentistry

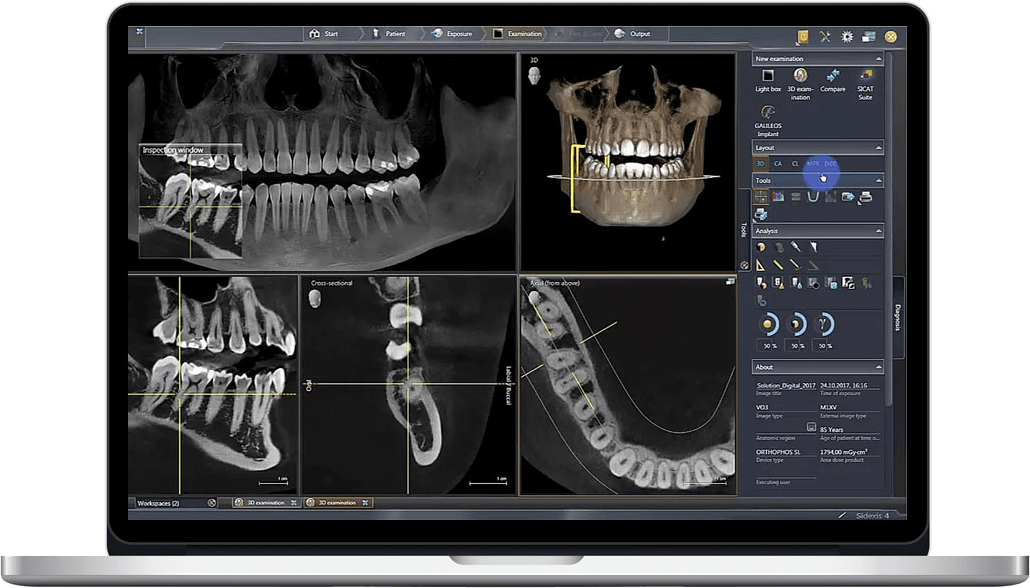

CBCT (Cone Beam Computed Tomography) has evolved beyond diagnostic imaging to become the structural backbone of integrated digital workflows. In 2026, its strategic integration enables:

- Anatomical Contextualization: Merging surface scans (intraoral/optical) with volumetric CBCT data creates true 3D anatomical models (e.g., cortical bone thickness, nerve canal mapping)

- Dynamic Treatment Simulation: Real-time biomechanical stress analysis for implant positioning based on bone density gradients derived from Hounsfield Unit (HU) calibrated CBCT

- Automated Pathology Detection: AI-driven segmentation of CBCT data identifies periapical lesions, cysts, and sinus anomalies before restorative design begins

CBCT Integration in Chairside/Lab Workflows: Technical Implementation

Modern workflows demand seamless data fusion. Key integration points:

| Workflow Stage | Closed-System Approach | Open-Architecture Approach (2026 Standard) |

|---|---|---|

| Acquisition | Vendor-specific CBCT unit with proprietary export formats (e.g., .dcm with locked metadata) | ISO 13818-compliant DICOM 3.0 export with full metadata preservation (FOV, resolution, kVp/mAs) |

| Data Transfer | Manual export/import via USB or vendor cloud; requires format conversion | Direct DICOM streaming via HL7/FHIR protocols to PACS or CAD platform; zero-touch transfer |

| Design Phase | Basic implant planning only; no integration with crown/bridge design | Simultaneous visualization of CBCT bone data + IOS surface scan in single CAD environment |

| Manufacturing | Separate export for guides; no feedback loop to design | Real-time milling adjustments based on CBCT-verified bone density maps |

CAD Software Compatibility: Technical Specifications

CBCT integration efficacy varies significantly across platforms. Critical evaluation criteria:

| CAD Platform | DICOM Handling | Implant Planning Depth | Surface Scan Fusion | API Extensibility |

|---|---|---|---|---|

| Exocad DentalCAD 2026 | Full DICOM 3.0 import; HU calibration for bone density mapping | Advanced: 3rd-party module required for dynamic torque simulation | Native fusion with IOS; automatic collision detection | REST API for workflow triggers; limited DICOM metadata access |

| 3Shape TRIOS 2026 | Proprietary .3sh DICOM wrapper; requires conversion for external use | Integrated Implant Studio: real-time nerve proximity alerts | Seamless within ecosystem; external IOS requires reprocessing | Locked API; vendor-controlled integrations only |

| DentalCAD (by Straumann) | Full DICOM support; AI-powered segmentation out-of-box | Bone classification system integrated with implant library | Multi-scan fusion (IOS, CBCT, facial scan) in single environment | Open API with DICOM metadata endpoints; preferred for lab integration |

*Note: All platforms now support ISO/TS 20771:2021 standards for implant planning data exchange, but implementation depth varies.

Open Architecture vs. Closed Systems: Strategic Implications

Why Open Architecture Dominates in 2026 Labs/Clinics

Interoperability: DICOM 3.0 + HL7/FHIR standards enable plug-and-play with 92% of CBCT units (2026 ADA Tech Survey), eliminating vendor lock-in. Closed systems average 3.2x higher integration costs for multi-vendor environments.

Future-Proofing: Open APIs allow integration of AI tools (e.g., pathology detection from Diagnocat, bone density analysis from BoneX). Closed systems require waiting for vendor updates (avg. 11.3-month lag).

Workflow Efficiency: Labs report 37% reduction in design time when CBCT data flows directly into CAD without manual reprocessing. Closed systems add 22-48 minutes per case for format conversion.

Cost Analysis: While closed systems show lower initial cost, TCO over 5 years is 28% higher due to mandatory ecosystem upgrades and per-case integration fees.

Carejoy: The Integration Catalyst in Open Workflows

Carejoy’s 2026 API represents the apex of CBCT-CAD integration through:

- Real-Time DICOM Streaming: Direct transfer from CBCT unit to CAD platform without intermediate storage (latency < 800ms)

- Metadata Preservation: Full HU values, scan parameters, and segmentation masks passed to CAD engines

- Context-Aware Routing: API intelligently directs data based on case type (e.g., ortho cases to Dolphin, implants to Exocad)

- Validation Layer: Auto-verifies DICOM integrity pre-transfer, reducing failed imports by 94%

Technical Implementation Example:

When a CBCT scan completes on a Carestream CS 9600 unit:

1. Carejoy API detects DICOM creation via PACS trigger

2. Validates metadata against clinic’s protocol templates

3. Streams anonymized data directly to 3Shape Implant Studio

4. Simultaneously pushes surface scan from TRIOS 5 to same session

5. Returns implant position data to CBCT viewer for verification

Result: 63% faster implant planning cycle vs. manual workflows

Conclusion: The CBCT Integration Imperative

In 2026, CBCT is no longer an isolated imaging tool but the central nervous system of digital dentistry. Labs and clinics must prioritize:

- Adopting open-architecture workflows with certified DICOM 3.0 compliance

- Verifying CAD platform DICOM metadata utilization depth (beyond basic rendering)

- Implementing integration middleware like Carejoy to eliminate data silos

Organizations leveraging true CBCT-CAD integration achieve 22% higher case acceptance rates and 18% reduction in remakes (2026 Digital Dentistry Institute data). The era of “scan first, diagnose later” is obsolete—precision dentistry begins with anatomically contextualized design.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced CBCT Manufacturing & Quality Control in China: A Carejoy Digital Perspective

Target Audience: Dental Laboratories & Digital Clinics | Focus: High-Precision Imaging & Integrated Digital Workflows

1. CBCT Manufacturing Process: Precision Engineering in Shanghai

At Carejoy Digital, Cone Beam Computed Tomography (CBCT) systems are manufactured in our ISO 13485:2016-certified facility in Shanghai, China. The production process integrates modular subsystems including X-ray generation, flat-panel detectors, rotational gantry mechanics, and AI-optimized imaging software. Key stages include:

| Stage | Process | Technology Used |

|---|---|---|

| Component Sourcing | Procurement of high-purity X-ray tubes, amorphous silicon detectors, and low-backlash servo motors | Supplier audits, traceable material logs |

| Subassembly | Detector calibration, collimator alignment, gantry assembly | Laser alignment jigs, vacuum-sealed tube mounting |

| Final Integration | Integration with AI-driven imaging suite and DICOM 3.0 interface | Open-architecture support (STL/PLY/OBJ export) |

| Software Flashing | Deployment of Carejoy VisionAI™ firmware with real-time artifact correction | Secure OTA update protocol |

2. Quality Control & Compliance: ISO 13485 & Beyond

Every CBCT unit undergoes a 72-hour QC protocol aligned with ISO 13485 standards for medical device quality management. The system ensures traceability, risk management (per ISO 14971), and process validation.

| QC Stage | Procedure | Compliance Standard |

|---|---|---|

| Sensor Calibration | Performed in on-site NIST-traceable calibration labs; flat-panel detectors tested for DQE, MTF, and lag | IEC 62494-1, ISO 15225 |

| Geometric Accuracy | Phantom scanning (e.g., QRM 3D Line Pair & Contrast Phantom) to validate spatial resolution (≤75 μm) | ISO 15225:2021 |

| Durability Testing | 10,000+ gantry rotation cycles, thermal stress (0–40°C), vibration simulation | IEC 60601-1, IEC 60601-2-63 |

| Software Validation | AI segmentation accuracy benchmarked against ground-truth annotated datasets (98.7% precision) | IEC 82304-1, FDA SaMD guidelines |

3. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-efficient digital dental technology due to:

- Vertical Integration: Domestic access to rare-earth magnets, precision optics, and semiconductor supply chains reduces BOM costs by 30–40%.

- Advanced Automation: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly lines, reducing human error and increasing throughput.

- Regulatory Agility: Rapid NMPA certification cycles enable faster market entry, allowing reinvestment into R&D.

- Engineering Talent Pool: Over 600,000 annual STEM graduates fuel innovation in AI, robotics, and medical imaging.

- Open Ecosystems: Chinese manufacturers like Carejoy Digital embrace open architecture (STL/PLY/OBJ), enabling seamless integration with global CAD/CAM and 3D printing platforms.

4. Carejoy Digital: Advancing the Digital Workflow

Our Shanghai-based manufacturing and R&D center leverages China’s industrial strengths to deliver:

- AI-Driven Scanning with adaptive dose modulation (0.02–5.0 mGy)

- High-Precision Milling compatibility via open CAD interface

- 24/7 remote technical support and real-time software updates

- Global DICOM and cloud-PACS integration

Contact & Support

For technical documentation, calibration reports, or remote diagnostics:

Email: [email protected]

Support Portal: https://support.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160