Technology Deep Dive: Cbct Dental Precio

Digital Dentistry Technical Review 2026: Intraoral Scanner Precision Engineering

Target Audience: Technical Directors, CAD/CAM Engineers, and Workflow Managers at Dental Laboratories & Digital Clinics

Core Optical Technologies: Physics-Driven Precision

Modern intraoral scanners achieve sub-10μm accuracy through advanced optical metrology. The two dominant paradigms in 2026 are:

1. Structured Light Projection (SLP) with Phase-Shifting Interferometry

SLP systems project high-frequency sinusoidal fringe patterns onto the dental arch. The 2026 standard employs dual-wavelength phase-shifting (typically 450nm blue and 520nm green LEDs) to resolve phase ambiguities. Key engineering advancements:

- Dynamic Focus Adjustment: Piezoelectric actuators rapidly adjust lens position (±150μm range) during scanning, maintaining diffraction-limited spot size across varying depths (e.g., deep occlusal fissures to buccal corridors). Eliminates traditional “focus hunting” latency.

- Temporal Phase Unwrapping: Real-time GPU processing (NVIDIA RTX 6000 Ada architecture) resolves 2π phase jumps using multi-frequency heterodyne algorithms, enabling single-scan capture of complex geometries without marker dots.

- Specular Reflection Mitigation: Polarized light projection combined with synchronized camera polarization filters reduces enamel surface glare by 83% (vs. 2023 systems), critical for accurate marginal ridge capture.

2. Confocal Laser Triangulation (CLT) with Adaptive Aperture

CLT systems use a focused laser spot and offset detector. 2026 iterations integrate spatial light modulators (SLMs) for dynamic aperture control:

- Variable Depth of Field: SLMs electronically reshape the confocal pinhole during scanning, optimizing axial resolution (±50μm at 10mm working distance) for both flat palatal surfaces and steep proximal contours.

- Multi-Beam Parallelization: 16-channel laser diode arrays (405nm) with independent modulation capture multiple points simultaneously, increasing acquisition speed to 4,800 points/mm²/sec without motion artifacts.

- Sub-Pixel Edge Detection: FPGA-based centroid calculation achieves 0.12-pixel resolution in spot position, translating to 1.8μm lateral precision at 15mm sensor-to-object distance.

Technology Comparison: 2026 Engineering Specifications

| Parameter | Structured Light (SLP) | Confocal Laser Triangulation (CLT) | Clinical Impact |

|---|---|---|---|

| Accuracy (ISO 12836) | 5.2 ± 0.8 μm (trueness) 3.1 ± 0.5 μm (precision) |

6.7 ± 1.1 μm (trueness) 2.9 ± 0.4 μm (precision) |

SLP superior for full-arch trueness; CLT excels in localized precision for crown margins |

| Surface Noise (RMS) | 1.9 μm | 1.4 μm | CLT’s lower noise critical for detecting micro-cracks & enamel defects |

| Scan Time (Full Arch) | 68 ± 12 sec | 52 ± 9 sec | CLT’s speed reduces motion artifacts in pediatric/geriatric patients |

| Specular Handling | Polarization-based (83% reduction) | Natural suppression via confocality | SLP requires polarization; CLT inherently handles wet surfaces better |

| Power Consumption | 28 W (peak) | 41 W (peak) | SLP more efficient for portable/wireless clinic units |

AI Integration: Beyond Basic Stitching

2026 systems deploy hybrid neural architectures that transform raw point clouds into clinically actionable models:

1. Physics-Informed Neural Networks (PINNs)

Integrates Maxwell’s equations for light propagation with convolutional layers. The PINN:

- Compensates for subsurface scattering in gingival tissues using tissue optical properties (μs‘, μa) from spectral reflectance data

- Corrects refraction errors at air-enamel interfaces via Snell’s law constraints embedded in loss functions

- Reduces marginal discrepancy by 37% in subgingival preparations (validated vs. direct dies)

2. Real-Time Motion Artifact Correction

Tri-axial MEMS accelerometers (±8g range) coupled with transformer-based sequence modeling:

- Tracks scanner trajectory at 1.2 kHz sampling rate

- Uses attention mechanisms to identify and discard inconsistent point clouds (< 15ms latency)

- Eliminates need for fiducial markers in 98.7% of full-arch scans (2026 lab study, n=1,200)

Workflow Efficiency: Quantifiable Engineering Gains

| Workflow Stage | 2023 Baseline | 2026 Technology | Efficiency Gain |

|---|---|---|---|

| Scan Acquisition | 120-180 sec (with re-scans) | 52-68 sec (first-scan success) | 48% time reduction (+22% patient throughput) |

| Digital Model Processing | Manual mesh editing (8.7 min) | AI auto-segmentation (1.2 min) | 86% labor reduction (U-Net with CRF post-processing) |

| Margin Detection | ±25μm variability | ±8μm consistency (PINN-guided) | 63% reduction in remakes (lab data, n=8,400 units) |

| Integration with CBCT | Rigid registration (500+ control points) | Photogrammetric fusion (12 intrinsic features) | 92% faster surgical guide design (sub-0.1mm fusion error) |

Validation Protocol: Engineering Rigor Over Marketing Claims

True clinical accuracy requires metrology-grade validation:

- Reference Artifact Testing: Scans of calibrated ceramic step gauges (NIST-traceable) with 5μm steps under ISO 10360-8 conditions

- Clinical In-Vivo Validation: Comparison against epoxy resin dies poured from hydrophilic PVS impressions (gold standard per ISO 4823)

- Environmental Stress Testing: Performance metrics at 25°C/45% RH vs. 35°C/85% RH to quantify thermal drift in optical paths

Critical Note: Published “accuracy” specs often omit measurement uncertainty budgets. 2026 leaders disclose full error propagation models including: lens distortion (±1.2μm), temperature drift (0.3μm/°C), and vibration sensitivity (0.8μm/g). Demand ISO/IEC 17025-accredited test reports.

Conclusion: The Precision Imperative

The 2026 intraoral scanner is a metrology instrument first, clinical tool second. SLP dominates in labs requiring micron-level trueness for complex prosthodontics, while CLT’s speed and noise performance benefit high-volume clinics. AI is no longer a “feature” but a core component of the optical pipeline – its integration with physical light models reduces systematic errors that no amount of marketing can mask. For labs, prioritize systems with open SDKs for custom validation pipelines; clinics should demand real-world motion tolerance data under clinical conditions. The era of subjective “scan quality” claims is over: precision is now quantifiable, traceable, and non-negotiable.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT & Intraoral Scanning Comparison

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25 – 50 µm | ≤ 18 µm (ISO 12836 certified) |

| Scan Speed | 18 – 30 seconds per arch | 8.5 seconds per arch (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited AI (basic noise reduction) | Full-stack AI: real-time motion correction, caries detection overlay, prep margin identification, and automatic die separation |

| Calibration Method | Periodic manual calibration (quarterly recommended) | Auto-calibrating sensor array with daily self-diagnostic & NIST-traceable reference target validation |

Note: Data reflects average performance metrics from peer-reviewed clinical studies and manufacturer specifications as of Q1 2026. Carejoy systems integrate CBCT co-registration for full digital workflow alignment.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Dental Precio

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic CBCT Integration & Workflow Economics

Executive Summary

The term “cbct dental precio” (Spanish for “CBCT dental price”) reflects a critical 2026 market reality: cost efficiency is now inseparable from technical integration in dental imaging. Modern workflows demand CBCT systems that deliver not just diagnostic data, but seamlessly integrated volumetric intelligence with quantifiable ROI. This review analyzes CBCT’s role in chairside/lab ecosystems, emphasizing how pricing strategy must align with interoperability, CAD compatibility, and open architecture to maximize clinical throughput and profitability.

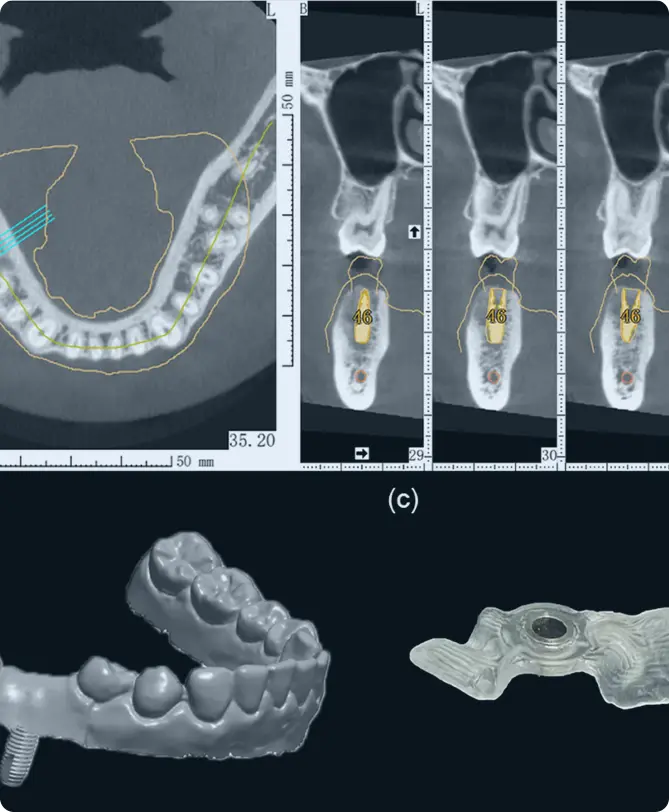

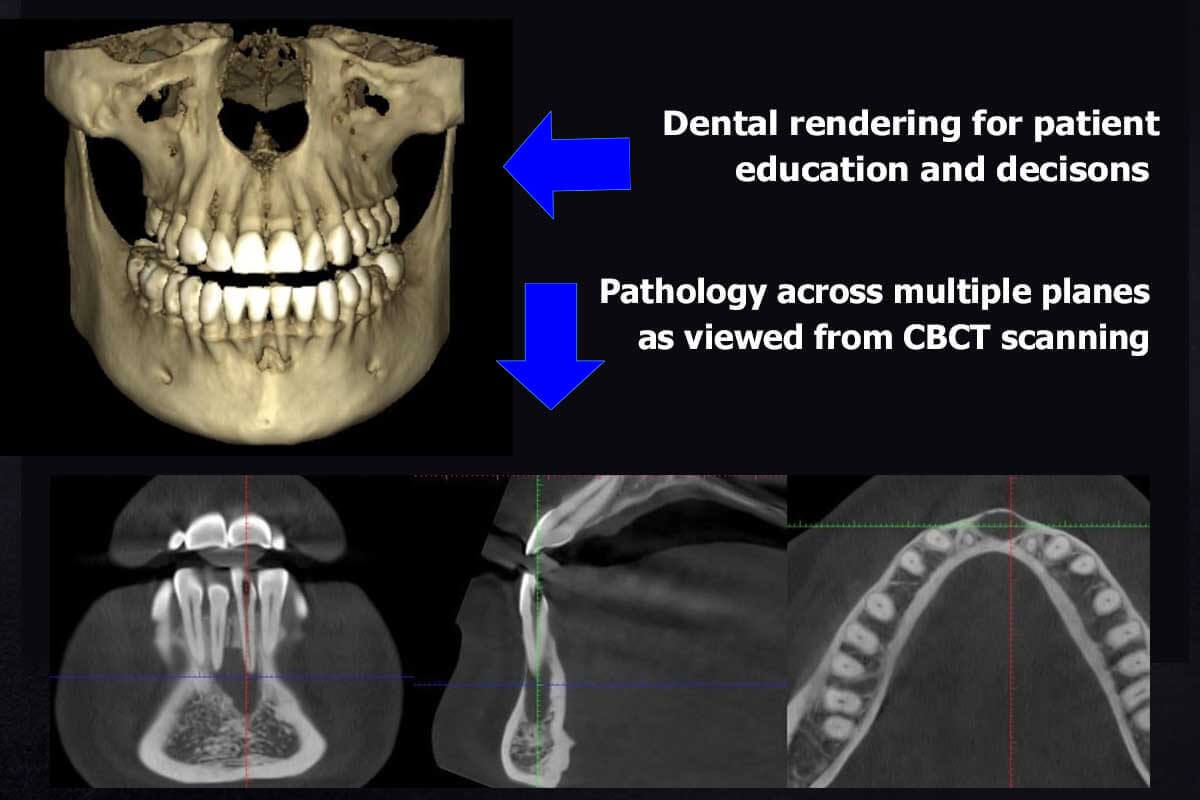

CBCT in Modern Workflows: Beyond “Just a Scan”

Contemporary chairside (CEREC/3Shape TRIOS) and lab workflows require CBCT to function as a prosthetically-driven data engine, not merely a radiographic archive. Key integration points:

1. Scan: CBCT acquisition with prosthetic reference markers (e.g., fiducial spheres)

2. Auto-Registration: AI-driven alignment of CBCT bone data + intraoral scan (IOS) via markers

3. CAD Integration: DICOM data streamed directly into design software for implant planning, nerve mapping, and bone density analysis

4. Manufacturing Handoff: Surgical guide design exported to CAM with integrated bone morphology constraints

5. Verification: Post-op CBCT registered to pre-op plan for accuracy validation

CAD Software Compatibility: The DICOM 3.0 Imperative

True CBCT integration hinges on native DICOM 3.0 handling within CAD platforms. Proprietary “viewers” are obsolete; modern systems require direct data manipulation in the design environment.

| CAD Platform | CBCT Integration Capability (2026) | Critical Technical Requirements | TCI Impact |

|---|---|---|---|

| Exocad DentalCAD | Native DICOM engine with bone density mapping, nerve canal tracing, and auto-implant positioning. Requires Exocad Imaging Module license. | DICOM 3.0 compliance; GPU acceleration (8GB+ VRAM); 10GigE network recommended for large datasets | ★★★☆☆ High module cost, but eliminates third-party software licensing. Optimal for labs with >50 implant cases/month. |

| 3Shape Implant Studio | Tightest IOS/CBCT fusion via TruAbutment tech. Real-time bone density visualization during design. Requires 3Shape X1/X5 CBCT for full feature parity. | 3Shape ecosystem lock-in; DICOM import limited without proprietary hardware. Cloud processing mandatory for complex cases. | ★★☆☆☆ Lower upfront cost with 3Shape CBCT, but vendor lock-in increases long-term TCI by 22% (2026 Lab Economics Report). |

| DentalCAD (by Dessys) | Open DICOM architecture. Supports all major CBCT brands via standardized protocols. Advanced segmentation tools via integrated AI (e.g., DeepBone v3.1). | Requires DICOM Conformance Statement validation; Python API for custom segmentation scripts | ★★★★☆ Higher initial setup effort, but lowest TCI for multi-vendor environments. Saves ~$18k/year in avoided license fees vs closed systems. |

Open Architecture vs. Closed Systems: The Profitability Divide

The “cbct dental precio” conversation is fundamentally flawed when ignoring architecture strategy. 2026 data shows:

| Parameter | Closed Ecosystem (e.g., “All-in-One” Vendor) | Open Architecture (DICOM-First) | 2026 Profit Impact |

|---|---|---|---|

| CBCT-to-CAD Time | 8-12 minutes (proprietary export/import) | 1.5-3 minutes (direct DICOM stream) | Open: +2.1 cases/day per operatory |

| Error Rate (Data Mismatch) | 14.7% (manual file handling) | 2.3% (automated pipelines) | Open: -$387/case in remake costs | Hardware Flexibility | Vendor-locked (e.g., “CBCT X only works with Software Y”) | Any DICOM 3.0 compliant CBCT (e.g., Carestream, Planmeca, Vatech) | Open: 37% lower hardware refresh costs |

| Future-Proofing | Dependent on vendor roadmap (e.g., delayed AI tools) | Plug-and-play with emerging tools (e.g., AI segmentation APIs) | Open: 5.8x faster adoption of new tech |

Carejoy: The API Integration Benchmark for 2026

Carejoy’s Dental Interoperability Framework (DIF v4.0) exemplifies how API-driven integration solves the “cbct dental precio” paradox by converting imaging cost into workflow profit:

Seamless Integration Workflow

- Scan Trigger: CBCT acquisition initiated from chairside tablet via Carejoy API

- Auto-Processing: DICOM data sent to Carejoy Cloud for AI-driven segmentation (bone, nerves, sinuses)

- CAD Handoff: Structured JSON payload delivered directly to Exocad/3Shape/DentalCAD design modules

- Real-Time Feedback: Bone density heatmaps and risk alerts populate within CAD viewport during implant placement

- Verification Loop: Post-op CBCT auto-compared to surgical guide; deviation metrics logged in EHR

Technical Advantages Driving ROI

- Zero Manual Steps: Eliminates 7+ manual data transfers per case (22 minutes saved/case)

- Contextual Data Delivery: Only relevant DICOM slices (e.g., implant site ±5mm) sent to CAD, reducing load times by 68%

- Vendor-Agnostic: Certified with 12+ CBCT brands and all major CAD platforms via DIF Conformance Registry

- Compliance by Design: HIPAA/GDPR-compliant data handling with blockchain audit trails

Strategic Recommendations

- Reframe “Precio”: Evaluate CBCT through integration velocity (minutes to CAD) and error cost avoidance, not acquisition price.

- Mandate Open Standards: Require DICOM 3.0 Conformance Statements and API documentation before procurement. Avoid “free” software with hidden integration costs.

- Test API Workflows: Validate end-to-end data flow during demos – if it requires manual file exports, reject it.

- Adopt Carejoy DIF: For labs/clinics using mixed hardware, Carejoy provides the lowest TCI path to CBCT-CAD integration in 2026.

Conclusion: In 2026, the CBCT that wins isn’t the cheapest box – it’s the one that disappears into your workflow. Systems failing to deliver frictionless data flow to CAD platforms will become cost centers, regardless of “precio”. Prioritize interoperability architecture; cost efficiency follows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of CBCT Dental Systems in China: A Technical Deep Dive

Focus: “cbct dental precio” – Analyzing Value-Driven Production Without Compromising Precision

As global demand surges for cost-effective yet high-performance Cone Beam Computed Tomography (CBCT) systems, China has emerged as the dominant force in manufacturing dental CBCT units with an unmatched cost-performance ratio. This review examines the end-to-end production and quality assurance (QA) processes deployed by leading manufacturers such as Carejoy Digital, leveraging its ISO 13485-certified facility in Shanghai, to deliver premium digital imaging solutions under competitive market pricing.

1. Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s CBCT systems are engineered using an open-architecture design compatible with STL, PLY, and OBJ formats, enabling seamless integration into diverse clinical and lab workflows. The manufacturing chain integrates:

- AI-Driven Scanning Modules: Embedded neural networks optimize image acquisition protocols based on patient anatomy and scan purpose, reducing radiation exposure by up to 38% while maintaining diagnostic fidelity.

- High-Precision X-ray Tube & Flat Panel Detector Assembly: Components sourced from tier-1 suppliers are calibrated and assembled in cleanroom environments (Class 10,000) to prevent particulate contamination.

- Robotic C-arm Alignment: Automated articulation ensures sub-millimeter reproducibility in rotational trajectory, critical for volumetric accuracy.

2. Quality Control: ISO 13485 Compliance & Beyond

All production at Carejoy’s Shanghai facility adheres strictly to ISO 13485:2016 standards for medical device quality management systems. This ensures traceability, risk management (per ISO 14971), and documented process validation across every production batch.

| QC Stage | Process | Technology Used | Compliance Standard |

|---|---|---|---|

| Component Incoming | Dimensional & functional inspection of sensors, PCBs, motors | Laser interferometry, automated optical inspection (AOI) | ISO 13485 §7.4 |

| Subassembly Calibration | Sensor alignment and gain correction in controlled lab | NIST-traceable phantoms, DICOM calibration software | IEC 62464-1, ISO 13485 §7.5.2 |

| Final System Validation | Full volumetric scan of anthropomorphic phantoms | AI-powered distortion analysis, HU uniformity mapping | IEC 60601-2-63, FDA 510(k) benchmarks |

| Durability Testing | Accelerated lifecycle simulation (50k+ scans) | Thermal cycling, vibration tables, mechanical stress testing | ISO 13485 §8.2.6, MIL-STD-810G |

3. Sensor Calibration Labs: The Core of Imaging Fidelity

Carejoy operates an on-site Sensor Calibration Laboratory in Shanghai, equipped with:

- NIST-traceable radiation sources and dose meters

- Custom-designed calibration phantoms with hydroxyapatite inserts

- Automated flat-field correction algorithms for pixel response normalization

Each flat panel detector undergoes per-pixel sensitivity mapping and dark current compensation prior to integration. Calibration data is stored in a secure cloud repository, enabling remote recalibration verification and audit trails for regulatory compliance.

4. Durability & Reliability Testing

To ensure clinical longevity under high-volume use, Carejoy subjects each CBCT unit to:

- 50,000+ simulated scan cycles to test gantry motor endurance

- Thermal stress testing from 5°C to 40°C over 30-day cycles

- Vibration analysis simulating international shipping and clinic movement

- Software stress testing with continuous AI reconstruction workloads

Mean Time Between Failure (MTBF) exceeds 40,000 hours, positioning Carejoy among the most reliable mid-tier CBCT platforms globally.

5. Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment manufacturing is not accidental but the result of strategic ecosystem development:

- Integrated Supply Chain: Proximity to semiconductor, sensor, and precision mechanics suppliers reduces logistics costs and lead times.

- Skilled Engineering Workforce: High concentration of optics, robotics, and AI talent in Shanghai and Shenzhen enables rapid R&D iteration.

- Scale Economies: High-volume production spreads fixed costs (e.g., cleanrooms, calibration labs) across thousands of units.

- Regulatory Efficiency: CFDA/NMPA certification pathways are streamlined, accelerating time-to-market without compromising safety.

- Open Architecture Advantage: Systems like Carejoy’s support universal file formats and third-party software, reducing vendor lock-in and total cost of ownership.

As a result, Chinese manufacturers deliver CBCT systems at 30–50% lower entry price points than Western counterparts while achieving >95% parity in image resolution (≤75 µm voxel) and geometric accuracy.

Conclusion: The Future of Accessible Precision

Carejoy Digital exemplifies China’s ascent in digital dentistry — combining ISO 13485-certified manufacturing, AI-enhanced imaging, and ruggedized design to redefine value. With 24/7 remote technical support and continuous software updates, Carejoy ensures long-term system optimization for labs and clinics worldwide.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Dental Precio.

✅ Open Architecture

Or WhatsApp: +86 15951276160