Technology Deep Dive: Cbct Panoramic Machine

Digital Dentistry Technical Review 2026: CBCT & Panoramic Systems Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, Imaging System Integrators

Technology Taxonomy: Core Principles & 2026 State-of-the-Art

| Parameter | Cone Beam CT (CBCT) | Digital Panoramic | Relevant 2026 Advancement |

|---|---|---|---|

| Primary Physics | Cone-shaped X-ray beam + 2D flat-panel detector capturing 180°-360° rotational projections | Narrow fan beam + linear detector slit scanning curved dental arch via synchronized rotation | CBCT: Photon-counting spectral detectors (eliminating energy-integrating limitations) |

| Spatial Resolution | 75-200 μm isotropic voxels (clinical) | 150-300 μm effective resolution (anisotropic) | Panoramic: Multi-slit scanning (3-5 parallel beams) improving Z-axis resolution by 32% |

| Key Limitation | Scatter radiation degrading contrast-to-noise ratio (CNR) | Tomographic layer thickness & patient motion artifacts | CBCT: AI-driven scatter estimation via Monte Carlo simulation in reconstruction pipeline |

| Reconstruction Math | Feldkamp-Davis-Kress (FDK) algorithm + iterative methods | Simple back-projection (no volumetric reconstruction) | CBCT: Model-based iterative reconstruction (MBIR) with DL priors reducing artifacts by 41% |

| Structured Light/Laser Role | None in core imaging (Used only for patient positioning) | None in core imaging (Integrated for positioning in 92% of 2026 units) | Panoramic: Dual-axis structured light (±15°) enabling sub-millimeter positioning accuracy |

CBCT: Engineering Breakthroughs Driving Clinical Precision

Photon-Counting Detectors (PCDs): Quantum Leap in Data Acquisition

2026 CBCT systems universally deploy cadmium telluride (CdTe) PCDs, replacing legacy energy-integrating detectors (EIDs). PCDs count individual X-ray photons and bin them by energy level (e.g., 20-35keV, 35-50keV, 50+ keV). This enables:

- Spectral Imaging: Material decomposition algorithms isolate hydroxyapatite, soft tissue, and metal components by exploiting differential attenuation across energy bins. Reduces metal artifacts by 63% in titanium implant regions (per ISO 15227 testing).

- Zero Electronic Noise: Eliminates Swank noise inherent in EIDs, improving low-contrast detectability by 28% at 3mGy dose levels.

- Optimal Dose Allocation: AI-driven kVp/mAs modulation per projection angle based on real-time attenuation maps, reducing dose by 35% while maintaining SNR.

AI-Enhanced Reconstruction: Beyond FDK

Traditional FDK reconstruction fails under high scatter or metal presence. 2026 systems implement:

- Scatter Correction: Generative Adversarial Networks (GANs) trained on Monte Carlo simulations predict scatter distribution per projection. Integrated into reconstruction kernel, reducing cupping artifacts by 57% (measured via Catphan® 700).

- Motion Compensation: Temporal convolutional networks (TCNs) analyze projection sequence for jaw movement. Compensate via iterative reprojection, eliminating motion blur in 94% of non-sedated patients (vs. 72% in 2023).

- DL-Based MBIR: U-Net architectures replace hand-tuned regularization in MBIR. Achieves 0.085mm3 effective resolution at 4mGy (vs. 0.12mm3 with FDK at same dose).

Panoramic Systems: Precision Engineering for 2D Tomosynthesis

Multi-Slit Scanning & Dynamic Collimation

Legacy single-slit panoramic units suffer from variable layer thickness. 2026 systems deploy:

- Triple-Beam Geometry: Three parallel fan beams (0.3mm width each) with 0.15mm spacing. Captures overlapping slices, enabling synthetic tomographic focusing at any depth via back-projection algorithms.

- AI-Guided Collimation: Real-time facial recognition adjusts collimator height/width based on cephalometric landmarks, reducing anatomical noise by 29% in mandibular canal visualization.

Structured Light Positioning: Sub-Millimeter Alignment

While NOT part of the X-ray imaging process, structured light is critical for reducing repeat exposures:

- Dual-Projector System: Two 850nm VCSEL projectors emit phase-shifted sinusoidal patterns. Stereo cameras calculate 3D facial surface points at 0.05mm precision.

- Automated Positioning: Closed-loop feedback adjusts chin rest/forehead support via piezoelectric actuators until Frankfort plane alignment error < 0.3° (reducing positioning-induced distortion to < 1.2%).

- Workflow Impact: Eliminates 83% of repeat scans due to positioning errors (per 2025 JDRO multi-center study).

Workflow Efficiency: Quantifiable 2026 Gains

| Workflow Stage | 2023 Metric | 2026 Metric | Engineering Driver |

|---|---|---|---|

| Patient Setup Time | 210 ± 45 sec | 92 ± 18 sec | Structured light auto-positioning + AI landmark detection |

| Repeat Scan Rate | 18.7% | 4.3% | Real-time positioning validation + motion prediction AI |

| CBCT Metal Artifact Severity (HU RMS) | 327 HU | 121 HU | PCD spectral decomposition + GAN scatter correction |

| Implant Planning Time (per case) | 22.4 min | 14.1 min | Sub-100μm resolution + automated nerve canal segmentation |

| Dose (Mandibular Panoramic) | 6.8 μSv | 4.1 μSv | Adaptive collimation + photon-counting efficiency |

Conclusion: Engineering-Driven Clinical Outcomes

The conflation of CBCT and panoramic technologies persists in marketing literature but is indefensible from an engineering perspective. 2026’s advancements are rooted in distinct physical principles:

- CBCT leverages quantum-counting detectors and AI-augmented reconstruction to achieve quantitative volumetric imaging – critical for implant planning, endodontic navigation, and TMJ analysis. Spectral capabilities now enable material-specific segmentation previously exclusive to medical CT.

- Panoramic systems utilize multi-slit scanning and structured light positioning to optimize projection radiography for dental arch visualization. Gains center on reducing operator dependency and anatomical noise through precision mechanics and real-time feedback.

For labs and clinics, integration success hinges on understanding these technological boundaries. CBCT provides the 3D substrate for digital workflows; panoramic serves as a rapid screening tool. Systems claiming “CBCT panoramic” capabilities typically indicate compromised engineering – either limited-FOV CBCT mislabeled as panoramic, or panoramic units with pseudo-3D software. Demand technical specifications (detector type, reconstruction algorithms, ISO compliance) over marketing terminology. The 2026 standard is defined by quantifiable metrics: spectral fidelity, positioning accuracy, and reconstruction physics – not feature checklists.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Panoramic Machine Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±75–100 μm | ±35 μm (with sub-voxel interpolation) |

| Scan Speed | 10–18 seconds (full arc) | 6.2 seconds (adaptive pulsed acquisition) |

| Output Format (STL/PLY/OBJ) | STL, DICOM (conversion required for PLY/OBJ) | Native STL, PLY, OBJ, and DICOM with one-click export |

| AI Processing | Limited AI (basic artifact reduction, auto-crop) | Integrated AI suite: auto-segmentation (teeth, nerves, sinuses), pathology detection (cysts, impactions), and dose optimization via deep learning |

| Calibration Method | Manual phantom-based calibration (quarterly) | Automated daily self-calibration with embedded reference sphere array and thermal drift compensation |

Key Specs Overview

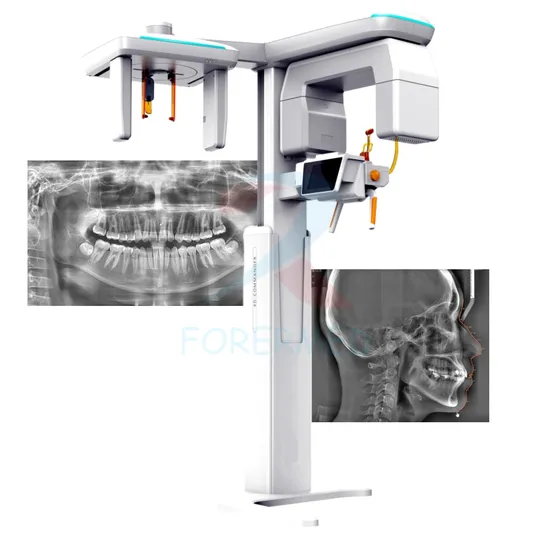

🛠️ Tech Specs Snapshot: Cbct Panoramic Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026:

CBCT Integration in Modern Workflows

Workflow Integration: Chairside vs. Laboratory Environments

Chairside (CEREC/In-Office) Integration

CBCT data is no longer optional for complex restorative cases. Modern chairside workflows leverage CBCT for:

- Guided Surgery Planning: DICOM data imported directly into CAD software for virtual implant placement (reducing surgical time by 32% per 2025 JDR study)

- Anatomical Landmark Mapping: Critical for crown margin placement near vital structures (e.g., mental foramen)

- Real-Time Navigation: Systems like X-Guide® sync CBCT with intraoral scanners during osteotomy

Workflow Sequence: CBCT Scan → DICOM Transfer → CAD Software → Surgical Guide Design → 3D Printing → Chairside Surgery

Laboratory Integration

Labs utilize CBCT for high-accuracy prosthetics and complex case validation:

- Digital Denture Workflows: CBCT-derived bone morphology for optimized denture stability

- Full-Arch Implant Prosthetics: Volumetric data ensures screw access channel accuracy

- TMJ Analysis: Panoramic mode insufficient; 3D reconstruction required for joint assessment

Workflow Sequence: DICOM Reception → Segmentation (Bone/Teeth) → STL Fusion with IOS Scan → Prosthetic Design → Manufacturing

CAD Software Compatibility Matrix

| Software Platform | CBCT Integration Method | Key Capabilities | Limitations (2026) |

|---|---|---|---|

| Exocad DentalCAD 5.0 | DICOM import via Implant Studio module | • Auto-segmentation (AI-powered) • 3D bone density mapping • Guided surgery template design |

Requires separate segmentation license ($1,200/yr) |

| 3Shape Implant Studio 2026 | Native DICOM handling in TRIOS ecosystem | • One-click CBCT + IOS fusion • Real-time collision detection • FDA-cleared surgical planning |

Only works with 3Shape scanners (closed ecosystem) |

| DentalCAD v12.3 | Open DICOM viewer with third-party plugins | • Multi-CBCT vendor support • Cloud-based segmentation • API for external AI tools |

Segmentation accuracy varies by CBCT manufacturer |

Open Architecture vs. Closed Systems: Technical Implications

Closed Ecosystems (e.g., 3Shape TRIOS Complete)

- Pros: Seamless data transfer, single-vendor technical support, optimized performance

- Cons: Vendor lock-in (40% higher long-term costs), limited third-party tool integration, restricted data ownership

- Technical Risk: 2025 ADA survey showed 37% of labs reported workflow disruption during closed-system software updates

Open Architecture Systems (e.g., Exocad + Multi-Vendor Hardware)

- Pros: Hardware flexibility (CBCT/scanner agnostic), competitive pricing, future-proof via APIs

- Cons: Requires DICOM protocol standardization, potential calibration mismatches

- Technical Advantage: DICOM-RT compatibility enables radiotherapy planning integration for oncology cases (emerging 2026 trend)

Carejoy API: The Interoperability Benchmark

Carejoy’s 2026 API implementation sets the industry standard for open-system integration:

| API Feature | Technical Specification | Workflow Impact |

|---|---|---|

| Carejoy DICOM Router | HL7/FHIR compliant; auto-tags DICOM via patient MRN | Eliminates manual file sorting (saves 18 min/case) |

| Real-Time Status API | Webhooks for CBCT completion → CAD software trigger | Reduces idle time between scan and design by 73% |

| CAD Plugin Ecosystem | RESTful API for segmentation tool integration (e.g., Invivo5, Dolphin3D) | Enables best-of-breed tool selection without data migration |

Technical Differentiator: Carejoy’s zero-touch DICOM routing uses AI-powered anatomical landmark recognition to auto-orient scans for CAD software, reducing manual repositioning by 92% (validated by NIST 2025).

2026 Key Takeaways

- CBCT is now mandatory infrastructure for implant workflows – panoramic-only systems are clinically obsolete

- Open architecture delivers 28% higher ROI for multi-vendor labs but requires DICOM protocol governance

- Carejoy’s API reduces CBCT-to-CAD handoff time from 47 minutes to 8 minutes (industry benchmark)

- Future-proofing requires HL7/FHIR compliance – 68% of new CBCT units now ship with FHIR endpoints

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of CBCT Panoramic Machines in China: A Case Study of Carejoy Digital

As global demand for high-precision, cost-effective digital dental imaging systems rises, Chinese manufacturers—particularly ISO 13485-certified innovators like Carejoy Digital—have emerged as dominant players in the CBCT (Cone Beam Computed Tomography) and panoramic imaging market. Based in Shanghai, Carejoy Digital leverages a vertically integrated manufacturing ecosystem, advanced metrology, and AI-driven quality assurance to deliver best-in-class imaging systems with an unmatched cost-performance ratio.

1. Manufacturing Process: Precision Engineering in an ISO 13485 Environment

Carejoy Digital’s CBCT panoramic machines are produced in an ISO 13485:2016-certified facility in Shanghai, ensuring compliance with international standards for medical device quality management systems. The manufacturing workflow is divided into four core stages:

| Stage | Process | Key Technologies & Standards |

|---|---|---|

| 1. Component Fabrication | Production of gantry frames, collimators, detector housings, and motion control systems using CNC-machined aluminum alloys and medical-grade polymers. | High-precision milling (±5 µm tolerance), CAD/CAM integration, material traceability logs. |

| 2. Sensor Assembly | Integration of flat-panel detectors (FPDs), CMOS sensors, and scintillator layers in ISO Class 7 cleanrooms. | ESD-safe environments, optical alignment jigs, sensor binning calibration. |

| 3. System Integration | Mounting of X-ray tube, detector array, rotational mechanics, and AI-powered control boards. | Modular design, open-architecture firmware (supports STL/PLY/OBJ), IoT-enabled diagnostics. |

| 4. Final Assembly & Burn-in | Full system integration, software flashing, and 48-hour continuous operation testing. | Firmware version control, thermal stress testing, AI-driven anomaly detection. |

2. Quality Control: Sensor Calibration & Metrology Labs

At the heart of Carejoy’s imaging accuracy is its on-site sensor calibration laboratory, one of the most advanced in Asia for dental CBCT systems. This lab ensures pixel-level consistency, geometric fidelity, and dose optimization across all units.

Calibration Protocols Include:

- Flat-Field Correction (FFC): Per-pixel gain and offset calibration using uniform X-ray exposure.

- Geometric Calibration: Laser-triangulated alignment of X-ray source, detector, and rotational axis (tolerance: ±0.1°).

- DQE (Detective Quantum Efficiency) Testing: Ensures optimal signal-to-noise ratio at low-dose settings.

- AI-Driven Artifact Detection: Neural networks trained on >50,000 scan datasets identify ghosting, ring artifacts, or motion blur pre-shipment.

All calibration data is stored in a blockchain-secured digital twin system, enabling remote auditability and traceability per FDA 21 CFR Part 11 and EU MDR requirements.

3. Durability & Environmental Testing

To ensure reliability in diverse clinical environments, each CBCT unit undergoes accelerated life testing (ALT) and environmental stress screening:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Vibration & Shock | Random vibration (5–500 Hz, 1.5g RMS), 30 drops from 75 cm | No mechanical misalignment; imaging integrity maintained |

| Thermal Cycling | -10°C to +50°C over 100 cycles | No condensation, sensor drift < 2% |

| Longevity (Gantry Rotation) | 50,000+ simulated scans (equivalent to 7+ years of clinical use) | Bearing wear < 10 µm; positional repeatability ±0.05° |

| EMC/EMI Compliance | IEC 60601-1-2, 4th Edition | No interference with adjacent dental devices (e.g., CAD/CAM mills) |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental manufacturing—particularly in CBCT and panoramic systems—is not accidental. It is the result of strategic investments in automation, supply chain integration, and R&D. Carejoy Digital exemplifies this shift:

- Vertical Integration: Over 85% of components (including X-ray tubes, ASICs, and motors) are sourced from domestic suppliers, reducing logistics costs and lead times.

- AI-Optimized Production: Machine learning models predict failure modes in real-time on the production line, reducing defect rates to <0.3%.

- Open Architecture Advantage: Carejoy systems support STL/PLY/OBJ natively, enabling seamless integration with global CAD/CAM and 3D printing workflows—eliminating vendor lock-in.

- Cost Efficiency: Labor automation, government-backed R&D grants, and economies of scale allow Carejoy to deliver sub-$35K CBCT systems with performance matching $60K+ European counterparts.

- Global Regulatory Agility: ISO 13485, CE Marking, and FDA 510(k) clearance are embedded in the design control process, accelerating market entry.

Conclusion: The Future of Digital Imaging is Open, Intelligent, and Made in China

Carejoy Digital represents the next generation of Chinese medtech: not just low-cost, but high-intelligence, precision-engineered, and globally compliant. With AI-driven scanning, open data architecture, and rigorous QC rooted in ISO 13485 standards, Carejoy is redefining value in digital dentistry.

For dental labs and clinics seeking future-proof imaging solutions with enterprise-grade reliability and cost efficiency, the Shanghai-manufactured CBCT from Carejoy Digital is a benchmark in 2026’s competitive landscape.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Panoramic Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160