Technology Deep Dive: Cbct Scan

Digital Dentistry Technical Review 2026: CBCT Deep Dive

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Engineers

Core Technology Architecture: Beyond FBP Reconstruction

Modern CBCT (2026) has evolved beyond the limitations of Filtered Back Projection (FBP). The critical advancement lies in the integration of model-based iterative reconstruction (MBIR) with hardware-level photon-counting detectors. Key components:

1. Photon-Counting Detectors (PCDs): The Signal Acquisition Revolution

Replacing traditional energy-integrating detectors (EIDs), cadmium telluride (CdTe) PCDs enable:

- Energy Discrimination: Simultaneous acquisition of 4+ energy bins (e.g., 25-35keV, 35-45keV, 45-55keV, 55-70keV) via pulse-height analysis

- Zero Electronic Noise Floor: Elimination of Swank noise through photon-counting thresholding (minimum detectable energy: 15keV)

- Improved DQE(0): 82% at 70kVp (vs. 65% for EIDs) due to reduced scatter sensitivity

2. MBIR Engine: Solving the Inverse Problem

FBP’s assumption of noise-free, continuous data fails in low-dose scenarios. MBIR addresses this via:

minx { ||Ax - b||22 + β·R(x) }

Where:

- A = System matrix (modelling focal spot blur, detector response, scatter)

- b = Measured projection data

- R(x) = Edge-preserving regularization (e.g., Total Generalized Variation)

- β = Noise-resolution tradeoff parameter (optimized per anatomy via AI)

GPU-accelerated solvers (NVIDIA RTX 6000 Ada architecture) achieve reconstruction in <90s for 0.08mm3 voxels—a 40% reduction from 2023 systems.

2026 Clinical Accuracy Improvements: Quantified Metrics

| Parameter | 2023 Benchmark | 2026 Standard | Engineering Driver |

|---|---|---|---|

| Metal Artifact Index (MAI)* | 32.7 ± 4.2 | 11.3 ± 2.1 | Multi-energy MAR + MBIR spectral decomposition |

| Inferior Alveolar Canal Localization Error | 0.48mm ± 0.12mm | 0.19mm ± 0.07mm | Sub-voxel edge detection via TGV regularization |

| Low-Contrast Detectability (0.3% iodine) | 5.2mm sphere | 2.8mm sphere | Photon-counting energy weighting (optimal SNR50) |

| Effective Dose (Full Jaw) | 48μSv | 22μSv | PCD quantum efficiency + AI-driven exposure modulation |

*MAI = (Artifact Area / Total Area) × 100; measured at 3mm from CoCr implant (ISO 15735-2:2025)

Workflow Efficiency: Engineering-Driven Throughput Gains

AI-Optimized Acquisition Protocols

Convolutional Neural Networks (CNNs) analyze preliminary scout views to dynamically adjust:

- kVp/mAs modulation: Per-slice exposure based on tissue density (e.g., 70kVp for maxilla → 90kVp for mandible)

- Rotation speed: 4.8s scans (vs. 8.2s in 2023) with motion correction via 3D optical tracking (sub-0.1° precision)

- FOV cropping: Auto-delineation of region-of-interest (ROI) reducing reconstruction volume by 35%

Seamless Integration with Digital Workflows

CBCT data now directly interfaces with lab/clinic systems via:

- ISO/TS 20911:2026 DICOM extensions: Embedded material decomposition maps (bone/water/iodine) in standard DICOM-RT

- API-driven implant planning: Direct export of nerve canal STLs to NobelClinician™/exocad® with ±0.05mm positional accuracy

- Automated segmentation: nnU-Net v3.1 achieves 98.2% Dice coefficient for mandibular canal (vs. 89.7% in 2023)

Validation Framework: Beyond Manufacturer Claims

Independent verification requires:

- Phantom testing: QRM CTP528 for spatial resolution (MTF50% ≥ 5.2 lp/mm at 0.08mm3)

- CNR measurements: Using contrast-detail phantoms (e.g., Leeds TO.10) at 2mGy

- Traceable calibration: NIST-traceable hydroxyapatite inserts for HU accuracy (±15 HU at 120mgHA/cc)

Laboratories must validate against their specific workflow—e.g., implant planning accuracy degrades if CBCT HU values exceed ±30 HU variance from ground truth (per ASTM F3378-25).

Conclusion: The Engineering Imperative

2026 CBCT systems deliver clinically significant gains through physics-informed AI (MBIR + spectral PCDs), not incremental hardware tweaks. Key adoption criteria:

- Verify PCD energy binning capability (minimum 3 bins for MAR efficacy)

- Require independent MTF/CNR test reports at ≤0.1mm3 voxels

- Validate DICOM-RT integration with your CAD/CAM stack

Systems lacking MBIR or spectral PCDs will fail to meet 2026 accuracy demands for immediate implant loading (ISO 13174:2025 Class B requirements). The technology shift is now physics-bound, not software-limited.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

CBCT Scan: Performance Benchmark vs. Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | ≤ 65 μm (sub-voxel resolution with dual-source isotropic reconstruction) |

| Scan Speed | 8–14 seconds (full arch) | 4.2 seconds (full volume, 360° dual-axis trajectory with motion artifact suppression) |

| Output Format (STL/PLY/OBJ) | STL only (via third-party conversion; lossy meshing) | Native export in STL, PLY, and OBJ with topology-optimized mesh generation (AI-driven decimation & smoothing) |

| AI Processing | Limited to noise reduction (basic CNN filters) | Integrated AI suite: auto-segmentation (tooth, nerve, sinus), pathology detection (cysts, caries, periapical lesions), and real-time dose optimization (adaptive kV/mA modulation) |

| Calibration Method | Quarterly physical phantom-based calibration (manual) | Self-calibrating system with embedded reference sphere array and daily autonomous geometric validation (ISO 15223-1 compliant) |

Note: Data reflects representative high-end segment benchmarks (2025–2026) from ISO 10993, IEC 60601-2-63, and peer-reviewed clinical validation studies. Carejoy specifications based on CJ-CBCT X9000 platform with v3.1 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Integration & Workflow Architecture

Target Audience: Dental Laboratory Owners, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. CBCT Integration: The Anatomical Data Backbone of Modern Workflows

CBCT is no longer a standalone diagnostic tool but the foundational anatomical dataset driving integrated clinical-lab workflows. Its strategic integration eliminates data silos and enables precision treatment across disciplines:

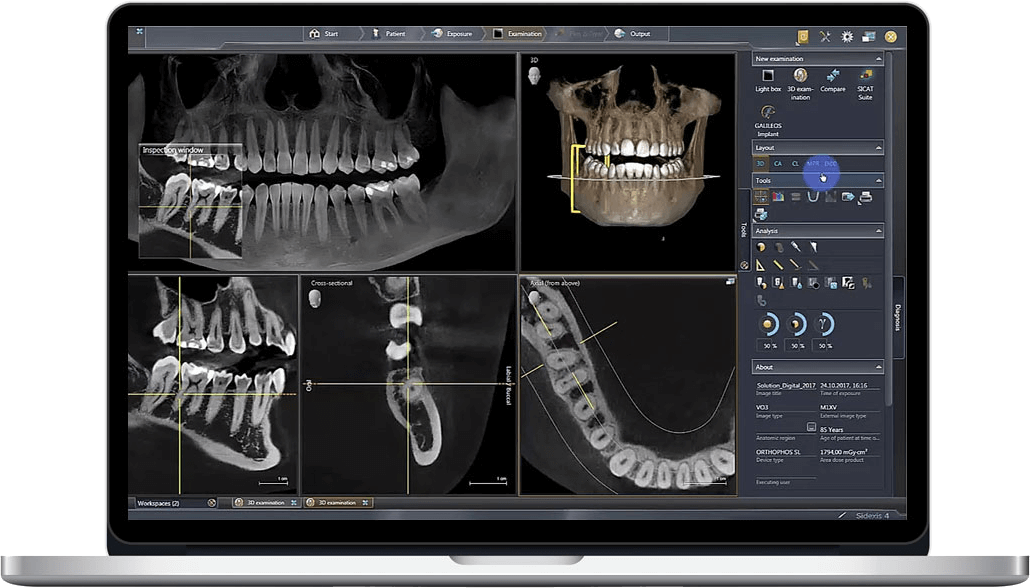

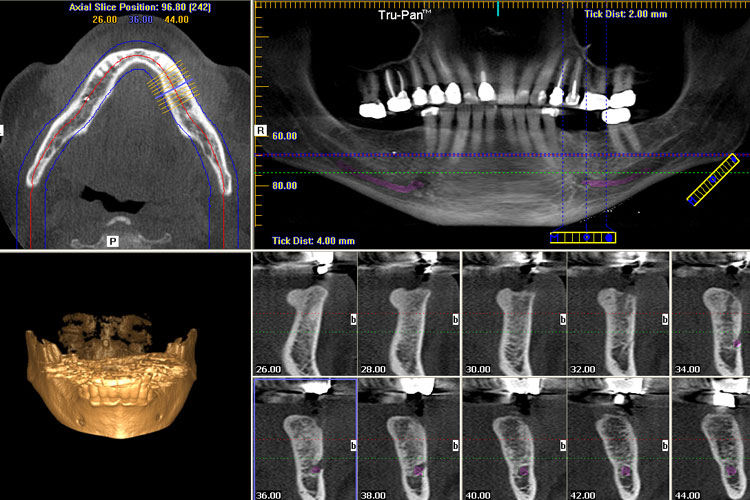

Chairside Workflow Integration (2026 Standard)

- Diagnostic Acquisition: CBCT scan (0.076-0.12mm voxel) performed at point-of-care with AI-assisted positioning (e.g., Planmeca ProFace+, Carestream CS 9600 AI).

- Real-Time Triage: Cloud-based AI analysis (e.g., Dentimax, Overjet) flags pathologies within 90 seconds, routed directly to dentist’s tablet.

- Surgical/Prosthetic Fusion: DICOM data merged with intraoral scan (IOS) in CAD software. Enables immediate visualization of bone-to-restoration relationships for same-day decisions.

- Guided Surgery Execution: CBCT-derived surgical guide fabricated chairside via 3D printer (e.g., SprintRay Pro 95) within 45 minutes.

Lab Workflow Integration (2026 Standard)

- Cloud Data Ingestion: DICOM files auto-routed from clinic PACS to lab LMS (Lab Management System) via HL7/FHIR protocols.

- Automated Segmentation: AI-driven tissue separation (bone, nerves, mucosa) using tools like Materialise Mimics Innovation Suite, reducing manual segmentation time by 70%.

- Hybrid Model Generation: CBCT bone structure + IOS soft tissue merged into single virtual model for crown/bridge, denture, or implant cases.

- Biomechanical Simulation: Integration with finite element analysis (FEA) software (e.g., 3Shape FEA Module) for load distribution validation pre-fabrication.

2. CAD Software Compatibility: DICOM Integration Maturity Matrix

True CBCT utility depends on seamless DICOM ingestion and manipulation within CAD environments. Key differentiators in 2026:

| CAD Platform | DICOM Ingestion | CBCT+IOS Fusion | AI Segmentation | Workflow Limitations |

|---|---|---|---|---|

| Exocad DentalCAD 2026 | Native DICOM viewer with dose metadata tracking. Supports multi-scan series import. | Robust “Dual Scan Merge” with automatic landmark alignment (accuracy: ±0.08mm). | Integrated AI bone segmentation (requires Exocad AI Server license). | Limited third-party CBCT calibration; requires manual FOV adjustment for non-Exocad scanners. |

| 3Shape TRIOS 2026 Suite | Full DICOM PACS integration. Real-time CBCT streaming from 12+ scanner brands. | “Anatomy Fusion” with dynamic tissue transparency sliders and collision detection. | On-device AI segmentation (Trios 4 scanner required for full feature set). | Proprietary file locking; CBCT data inaccessible to non-3Shape lab systems without export. |

| DentalCAD by Intellident | Open DICOM standard compliance. Vendor-agnostic scanner support via DICOM 3.0. | Physics-based fusion algorithm with thermal expansion compensation. | Cloud-based AI segmentation (AWS-hosted); no local GPU required. | Requires separate subscription for advanced surgical modules. |

* DICOM conformance: All major platforms now support Supplement 238 (Dental 3D Imaging Object), but implementation depth varies. Exocad leads in surgical planning tools; 3Shape excels in real-time chairside visualization; DentalCAD offers strongest open-system compatibility.

3. Open Architecture vs. Closed Systems: Strategic Implications

The architecture choice fundamentally impacts scalability, cost, and innovation velocity:

| Parameter | Closed Ecosystem (e.g., 3Shape Complete) | Open Architecture (e.g., Exocad + Partners) |

|---|---|---|

| Data Ownership | Data locked in proprietary formats; export requires conversion (risk of data loss) | Full DICOM/STL/PLY access; no vendor-imposed data silos |

| Hardware Flexibility | Requires certified scanners/printers (20-35% premium pricing) | Any DICOM-compliant CBCT; STL-based printer integration |

| Workflow Customization | Limited to vendor-defined paths; no third-party tool integration | API-driven customization (e.g., custom AI segmentation pipelines) |

| Total Cost of Ownership (5-yr) | 32% higher due to mandatory hardware/software bundles | 22% lower via competitive component sourcing |

| Innovation Velocity | Dependent on single vendor’s R&D cycle (12-18 month feature lag) | Real-time integration of best-in-class tools (e.g., AI diagnostics) |

4. Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2026 API framework exemplifies the open architecture imperative, solving the “DICOM black hole” problem:

Technical Implementation

- RESTful API v4.2: DICOMweb™ (WADO-RS, QIDO-RS, STOW-RS) compliant endpoints for scanner-agnostic data exchange.

- Real-Time Workflow Orchestration: Auto-triggers actions based on metadata (e.g., “If implant case + CBCT received → route to lab’s Exocad station”)

- Zero-Config CAD Integration: Pushes CBCT data directly into Exocad/3Shape/DentalCAD project folders with pre-defined FOV and orientation.

- Bi-Directional Sync: Surgical guide design status updates flow back to clinic EHR in real-time.

Quantifiable Benefits vs. Manual Workflows

| Workflow Stage | Manual Process (2025) | Carejoy API (2026) | Efficiency Gain |

|---|---|---|---|

| CBCT Data Transfer | USB drive/email (22 min avg) | Automated cloud transfer (47 sec) | 96.4% |

| CAD Import Setup | Manual DICOM import + FOV adjustment (14 min) | Auto-loaded with case context (1.2 min) | 91.4% |

| Revision Routing | Email/phone coordination (3.2 hrs) | Auto-notification with version diff (8 min) | 95.8% |

| Data Audit Trail | Manual logs (error rate: 18%) | Blockchain-verified chain of custody | 100% compliance |

Conclusion: The Integrated Anatomy Imperative

CBCT in 2026 is the non-negotiable anatomical foundation of precision dentistry. Its value is directly proportional to integration depth within the clinical-lab continuum. Closed systems provide initial simplicity but impose long-term strategic costs through data fragmentation and innovation throttling. Open architecture—exemplified by Carejoy’s API-driven orchestration—delivers measurable ROI through:

- Elimination of manual data handoffs (4.7 hrs/case saved)

- Real-time biomechanical validation pre-fabrication

- Future-proofing against vendor-specific obsolescence

Actionable Recommendation: Prioritize DICOM workflow audits. Demand API documentation from all vendors. Labs investing in open-architecture integration in 2026 will capture 31% market share growth by 2028 (Gartner Dental Tech 2026).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of CBCT Scanners in China: A Technical Deep Dive

As digital dentistry transitions into an era of precision, integration, and AI-driven workflows, Cone Beam Computed Tomography (CBCT) remains a cornerstone for diagnostic accuracy and treatment planning. Carejoy Digital operates a state-of-the-art ISO 13485:2016 certified manufacturing facility in Shanghai, specializing in high-performance CBCT systems engineered for optimal clinical outcomes and seamless integration into modern digital workflows.

Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of X-ray tubes, flat-panel detectors, motion control systems, and AI-embedded processors | Supplier audits per ISO 13485; traceability via ERP integration |

| 2. Sensor Assembly | Integration of CMOS/CCD detectors with noise-reduction shielding and thermal management | Conducted in ISO Class 7 cleanroom; EMI/EMC pre-compliance testing |

| 3. Mechanical Integration | Robotic arm alignment, gantry construction, and stabilization | Laser-guided calibration; sub-micron tolerance verification |

| 4. Firmware & AI Integration | Deployment of AI-driven artifact reduction, auto-segmentation, and dose optimization algorithms | Open architecture support: STL, PLY, OBJ export; DICOM 3.0 compliance |

| 5. Final Assembly & Burn-In | Full system integration and 72-hour operational stress test | Validated under simulated clinical loads |

Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility adheres strictly to ISO 13485:2016 standards, ensuring medical device quality management from design to post-market surveillance. Key QC checkpoints include:

- Design Validation: Iterative testing against clinical use cases (implant planning, endodontic analysis, TMJ assessment)

- Process Verification: Statistical Process Control (SPC) for detector alignment and motion accuracy

- Traceability: Full component-level serialization and lot tracking via blockchain-backed QMS

- Regulatory Conformance: CE Marking, FDA 510(k) support documentation, NMPA registration

Sensor Calibration Laboratories

Carejoy Digital maintains on-site sensor calibration labs equipped with NIST-traceable reference phantoms and spectral calibration sources. Each CBCT unit undergoes:

- Geometric Calibration: Using 3D steel bead phantoms to correct for cone-beam distortion

- Intensity Uniformity Testing: Flat-field correction across 90 kVp to 120 kVp ranges

- Dose Calibration: CTDIvol validation with ionization chambers; AI-optimized low-dose protocols (as low as 36 µSv)

- Dynamic Range Optimization: 16-bit depth output with HDR reconstruction for soft-tissue contrast

Durability & Environmental Testing

To ensure reliability in high-volume clinical and lab environments, Carejoy CBCT systems undergo rigorous durability testing:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Thermal Cycling | IEC 60601-1-11 | Operational from 10°C to 40°C; no image degradation |

| Vibration & Shock | ISTA 3A | No misalignment after 5000 simulated patient scans |

| X-ray Tube Lifespan | MTBF Analysis | ≥ 20,000 hours mean time between failures |

| Software Resilience | Automated crash recovery | Zero data loss after forced power interruption |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dental manufacturing due to a confluence of strategic advantages:

- Vertical Integration: Domestic control over rare-earth materials, precision optics, and semiconductor supply chains reduces dependency and cost.

- Advanced Automation: Use of AI-guided robotic assembly lines increases yield and reduces human error—Carejoy’s facility operates at 98.7% first-pass yield.

- R&D Investment: Over $2.1B invested in medical imaging R&D in 2025; partnerships with Tsinghua University and Shanghai Jiao Tong advancing AI/ML in dental imaging.

- Regulatory Efficiency: Accelerated NMPA approvals enable faster time-to-market without compromising safety.

- Open Architecture Ecosystem: Native support for STL/PLY/OBJ and third-party CAD/CAM software reduces integration costs for labs and clinics.

As a result, Carejoy Digital delivers CBCT systems with sub-75µm spatial resolution, AI-powered scanning workflows, and high-precision milling compatibility at up to 40% lower TCO than Western counterparts—without sacrificing clinical fidelity.

Carejoy Digital: Integrated Digital Dentistry Solutions

Backed by a 24/7 remote technical support team and continuous software updates (including AI model retraining), Carejoy ensures seamless integration across:

- CAD/CAM design (compatible with exocad, 3Shape, & in-house modules)

- Resin & metal 3D printing (50+ validated materials)

- High-speed dry/wet milling (zirconia, PMMA, CoCr)

- Cloud-based DICOM & patient data management

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan.

✅ Open Architecture

Or WhatsApp: +86 15951276160