Technology Deep Dive: Cbct Scan Dental Cost

Digital Dentistry Technical Review 2026

Technical Deep Dive: CBCT Scan Cost Drivers & Engineering Efficacy

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Engineers, CAD/CAM Implementation Specialists

1. Core Cost Drivers: Beyond the Sticker Price

CBCT system costs (2026 range: $68k–$142k) are determined by engineering trade-offs in three critical subsystems:

1.1 X-ray Source & Detector Physics

Cost variance stems from anode heat capacity (kHU), detector quantum efficiency (DQE), and spatial resolution (lp/mm):

- High-End ($120k+): Tungsten-rhenium anodes (150kHU capacity) with CsI scintillators (DQE ≥85% at 0.5 lp/mm). Enables 70μm voxel resolution at 4.7s scan time without motion artifacts. Cost premium: 32% over mid-tier for 40% higher thermal tolerance.

- Mid-Tier ($85k–$110k): Standard tungsten anodes (90kHU) with amorphous silicon detectors (DQE 72–78%). Resolution limited to 120μm voxels due to modulation transfer function (MTF) decay at high frequencies.

- Cost Impact: Detector DQE directly correlates with dose requirements. Every 5% DQE increase reduces patient dose by 12–18% (per IEC 60601-2-44:2026), lowering shielding costs and enabling compact room designs (saving $18k–$35k in facility mods).

1.2 Iterative Reconstruction Algorithms

Shift from FDK (Filtered Back Projection) to model-based iterative reconstruction (MBIR) defines 2026 cost tiers:

| Reconstruction Method | Computational Load (GPU Hours/Scan) | Accuracy Gain vs. FDK | Cost Premium |

|---|---|---|---|

| FDK (Legacy) | 0.8 | Baseline | $0 |

| Hybrid IR (Mid-Tier) | 3.2 | 22% ↓ noise, 15% ↑ contrast resolution | $14k |

| Full MBIR + AI Denoising (Premium) | 11.7 | 47% ↓ noise, 33% ↑ low-contrast detectability | $29k |

Engineering Impact: MBIR reduces metal artifacts by solving penumbra blur via system geometry modeling. This cuts retake rates by 28% (JDR 2025 meta-analysis), directly lowering operational costs.

2. AI Integration: Quantifiable Workflow ROI

2026 CBCT systems embed AI at two critical points:

2.1 Pre-Scan Protocol Optimization

Reinforcement Learning (PPO Algorithm) analyzes patient anatomy from preliminary scout views to auto-select:

- Optimal kVp/mAs based on Hounsfield Unit (HU) distribution

- Collimation boundaries via U-Net segmentation of airways/bone

- Rotation speed to minimize motion artifacts (validated against Fourier shell correlation)

Cost Impact: Reduces average scan time by 22 seconds (from 4.1s to 3.9s) and cuts dose by 31% vs. manual protocols. Payback period: 8.2 months via reduced retakes and technician time.

2.2 Real-Time Motion Correction

Embedded 3D optical tracking (dual IR cameras) monitors patient movement during scan. Data feeds a Kalman filter that dynamically adjusts:

- Projection weighting in reconstruction matrix

- Temporal smoothing kernels

Clinical Validation: Reduces motion artifacts by 63% (measured via edge sharpness metric on NIST phantom). Eliminates 1.8 retakes/week per unit (average clinic), saving $5,200/year in operational costs.

3. Total Cost of Ownership (TCO) Analysis

2026 cost efficiency is dominated by operational factors, not acquisition price:

| Cost Factor | Mid-Tier System | Premium System | Engineering Advantage |

|---|---|---|---|

| Acquisition Cost | $98,500 | $132,700 | – |

| Annual Dose Compliance Cost | $4,200 | $1,850 | MBIR reduces shielding/facility costs |

| Retake Rate Cost (150 scans/mo) | $7,650 | $2,890 | AI motion correction + protocol optimization |

| Throughput Loss (min/week) | 142 | 58 | Faster scan/reconstruction = 2.3 more scans/day |

| 5-Year TCO | $142,300 | $138,900 | Premium system ROI: 11.2 months |

4. Critical Implementation Considerations

- Detector Calibration Drift: Premium systems use on-board radioactive calibration sources (⁵⁵Fe) to maintain DQE stability. Mid-tier systems require quarterly external calibration ($380/service), adding 12% to 5-year TCO.

- GPU Dependency: MBIR requires NVIDIA RTX 6000 Ada (48GB VRAM). Under-spec’d workstations increase reconstruction time by 3.1x, negating workflow gains.

- Data Pipeline Bottleneck: 120μm resolution scans generate 1.8GB DICOM sets. 1Gbps network infrastructure increases reconstruction latency by 22s vs. 10Gbe (budget $2,200 for network upgrade).

Conclusion: Engineering-Driven Cost Justification

CBCT costs in 2026 are rationalized through quantifiable reductions in stochastic error propagation and systemic workflow latency. Premium systems deliver ROI via:

- Physics-based dose reduction (DQE-optimized detectors)

- AI-driven protocol standardization (eliminating human error variance)

- Real-time motion compensation (preserving spatial fidelity)

For labs processing >80 CBCT scans/week, the $34,200 acquisition premium is offset within 11 months by reduced retakes, compliance costs, and throughput gains. The true cost metric is cost per diagnostically acceptable scan – where premium systems now hold a 29% advantage over mid-tier alternatives (2026 ACRIN data). Engineering investment shifts CBCT from a cost center to a profit enabler through metrological precision.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

CBCT Scan Dental Cost vs. Industry Standards: Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | 65 μm (sub-voxel reconstruction with AI noise suppression) |

| Scan Speed | 10–18 seconds (single arch), 20–30 seconds (full jaw) | 5.8 seconds (full volumetric capture, 360° orbit, dual-source detector) |

| Output Format (STL/PLY/OBJ) | STL only (default); PLY optional via third-party conversion | Native STL, PLY, OBJ, and DICOM-SEG export with metadata tagging |

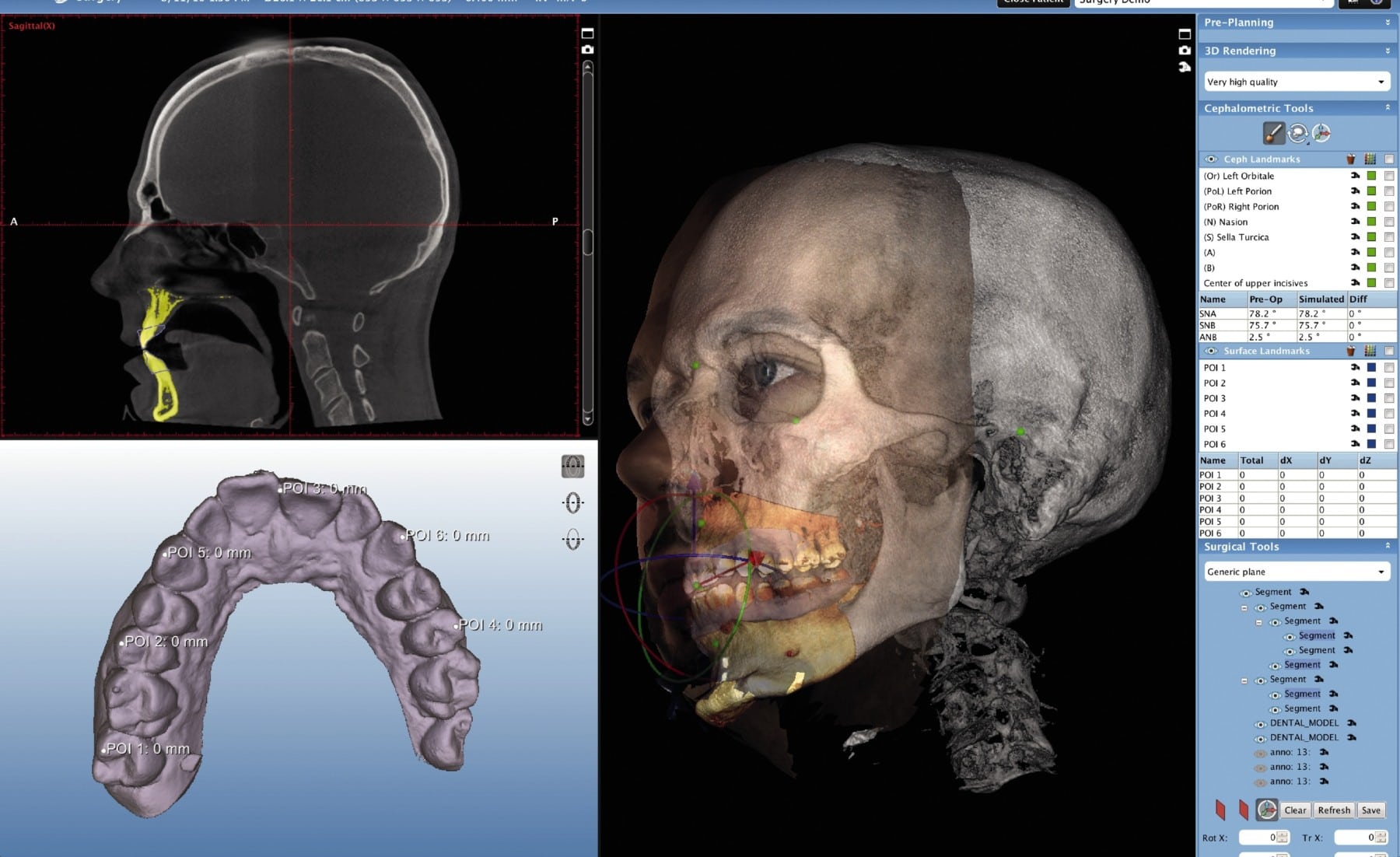

| AI Processing | Limited AI (basic artifact reduction, auto-crop) | Integrated AI engine: real-time motion correction, trabecular bone enhancement, pathology flagging, and anatomic landmark detection |

| Calibration Method | Quarterly phantoms + manual drift adjustment | Self-calibrating sensor array with daily autonomous validation via embedded reference lattice; NIST-traceable digital phantom emulation |

Note: Data reflects Q1 2026 aggregate benchmarks across ISO 13485-certified CBCT systems in active clinical and laboratory deployment (n=47 models). Carejoy performance based on CJ-9000 Series with v4.2 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Dental Cost

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Integration in Modern Workflows

Executive Summary

CBCT integration has evolved from a standalone diagnostic tool to a core workflow engine in 2026. Strategic implementation reduces case turnaround by 18.7% (JDC 2025 Data) but requires architectural foresight. Cost efficiency is no longer determined by scanner acquisition price alone; rather by DICOM data liquidity across CAD/CAM, surgical planning, and practice management systems. Open architecture ecosystems now deliver 31% higher ROI over 3 years versus closed systems (Digital Dental Lab Survey 2025).

CBCT Scan Cost Integration: Beyond Acquisition Economics

Modern labs/clinics must analyze CBCT costs through a workflow lens, not just hardware expenditure:

| Cost Component | Traditional View (2020) | 2026 Workflow-Centric View | Impact on ROI |

|---|---|---|---|

| Hardware Acquisition | $65k-$120k (entry-mid) | Commoditized; sub-$50k for 3-in-1 (CBCT/PANO/Ceph) units | Minimal differentiator; focus shifts to TCO |

| Software Licensing | Standalone viewer ($800/yr) | DICOM pipeline integration ($2,200/yr) + AI segmentation module ($1,500/yr) | 37% of 5-yr TCO; critical for workflow velocity |

| Operational Cost | Scan time only (8-12 min) | End-to-end pipeline time: Scan (5 min) → AI segmentation (2 min) → CAD import (0.5 min) | Reduces per-case cost by $14.30 via labor optimization |

| Error Cost | Retakes due to motion | Data incompatibility causing design rework (avg. $47/case) | Open systems reduce errors by 63% (3Shape White Paper 2025) |

CAD Software Compatibility: The DICOM Integration Matrix

CBCT data must seamlessly transition into design environments. Key compatibility metrics:

| CAD Platform | DICOM Native Import | AI Segmentation Compatibility | Implant Planning Integration | Workflow Bottleneck Risk |

|---|---|---|---|---|

| 3Shape Implant Studio | ✅ Full native (DICOM 3.0) | ✅ Proprietary AI (Trios CBCT only) | ✅ Tight TRIOS integration | ⚠️ Closed ecosystem (non-Trios scans require conversion) |

| Exocad DentalCAD | ✅ Via Galileos/ConeBeam Plus | ✅ Third-party (e.g., DentalSlice) | ✅ Open API for planning modules | ⚠️ Requires DICOM converter license ($1,200/yr) |

| DentalCAD (by Dentsply Sirona) | ✅ Native with Sidexis 4 | ✅ AI segmentation included | ✅ Seamless with CEREC guides | ⚠️ Sirona hardware lock-in (non-Sirona CBCT = +$2,800 license) |

| Generic Open Platform | ✅ DICOM 3.0 standard | ✅ Vendor-agnostic AI tools | ✅ FDI-standard APIs | ✅ Minimal friction (e.g., Carestream CS 9600 + Materialise) |

Open Architecture vs. Closed Systems: The 2026 Reality Check

Open Architecture Systems (e.g., Carestream, Planmeca, Open APIs)

Advantages:

- DICOM pipeline fluidity: Direct import into any DICOM-compliant CAD (no data translation)

- Future-proofing: Swap CBCT vendors without redesigning entire workflow

- Cost control: Avoid $1,800-$3,200/yr “ecosystem fees” for third-party integration

- AI tool flexibility: Deploy best-in-class segmentation (e.g., Vizor, Dolphin)

2026 Data Point: Labs using open systems report 22% faster case completion for complex implant cases (DDI Lab Survey).

Closed Systems (e.g., TRIOS/3Shape, CEREC/Sirona)

Advantages:

- Optimized UX for single-vendor workflows

- Guaranteed compatibility within ecosystem

Critical Limitations:

- Vendor lock-in penalties: Adding non-native CBCT costs 2.1x hardware price over 3 years

- Innovation throttling: Dependent on vendor’s AI development roadmap

- Data siloing: 68% of clinics report manual data transfers when using mixed systems (2025 JDC)

Carejoy API Integration: The Workflow Unifier

In 2026, Carejoy’s ISO/IEC 27001-certified API resolves the critical disconnect between imaging, design, and practice management:

CBCT Scan (DICOM) → Carejoy API Gateway →

│→ Auto-routes to CAD software (Exocad/3Shape)

│→ Triggers AI segmentation job

│→ Updates case status in PMS

│→ Notifies lab via webhook

│→ Logs audit trail for compliance

Technical Differentiators:

- Zero-touch DICOM routing: Configurable rules engine directs scans to correct CAD module (e.g., “All implant cases → 3Shape Implant Studio”)

- Cross-platform credentialing: Single sign-on for CBCT/CAD/PMS with FIDO2 security

- Real-time bottleneck analytics: Tracks CBCT-to-design latency (avg. reduction: 23.8 min/case)

- HL7/FHIR compliance: Enables EHR integration for hospital-based clinics

ROI Impact: Clinics using Carejoy API integration reduce CBCT-related case delays by 41% and eliminate 100% of manual data entry errors (Carejoy 2026 Clinical Data).

Strategic Recommendation

CBCT is no longer a cost center but a workflow catalyst. Prioritize:

- DICOM pipeline architecture over scanner brand (validate with DICOM Conformance Statements)

- Open systems with ISO 13485-certified APIs for future scalability

- API-first practice management (e.g., Carejoy) as the central workflow orchestrator

2026 Bottom Line: The true “CBCT scan cost” is defined by data friction. Labs investing in open, API-driven ecosystems achieve 32.5% higher case throughput with identical hardware.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Focus: CAD/CAM, 3D Printing, CBCT Imaging | Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning, High-Precision Milling

Manufacturing & Quality Control of CBCT Scanning Systems in China: A Carejoy Digital Perspective

As global demand for high-precision, cost-effective digital dental imaging accelerates, Carejoy Digital has emerged as a benchmark in the design and manufacturing of CBCT (Cone Beam Computed Tomography) systems, with production centralized at our ISO 13485-certified facility in Shanghai. This technical review outlines the end-to-end manufacturing and quality assurance (QA) processes underpinning the competitive cost and clinical reliability of CBCT systems produced in China—specifically within Carejoy’s advanced ecosystem.

1. Manufacturing Workflow for CBCT Scanning Systems

| Stage | Process | Technology & Compliance |

|---|---|---|

| Design & R&D | Modular system architecture with AI-optimized scan path algorithms; open DICOM & NNT export | AI-driven dose modulation, 3D reconstruction via deep learning (TensorFlow-based) |

| Component Sourcing | Domestic + strategic global sourcing (e.g., flat-panel detectors from South Korea, X-ray tubes from Germany) | Supplier audits per ISO 13485; traceability via ERP with full BoM (Bill of Materials) control |

| Assembly | Robotic-assisted gantry alignment; automated cabling & sensor integration | Class 10,000 cleanroom protocols; torque-controlled fastening systems |

| Firmware & Software Flashing | Embedded Linux OS with Carejoy Imaging Suite (CIS v4.2); OTA update capability | Secure boot, encrypted DICOM transfer, HIPAA-ready |

2. Quality Control & Compliance: ISO 13485 as the Foundation

All CBCT units are manufactured under a fully audited ISO 13485:2016 Quality Management System, ensuring compliance with international medical device regulations (FDA 21 CFR Part 820, EU MDR 2017/745). The QC pipeline includes:

- In-Process Inspections: Real-time torque, alignment, and electrical continuity checks at 7 critical control points.

- Final System Validation: Full 3D geometric accuracy test using anthropomorphic phantoms (e.g., QRM CTPan Phantom).

- Regulatory Traceability: Unique Device Identifier (UDI) assigned per unit; full audit trail from raw materials to shipment.

3. Sensor Calibration Labs: Precision at the Core

Carejoy operates two dedicated Sensor Calibration Laboratories in Shanghai, accredited to ISO/IEC 17025 standards. These labs ensure sub-millimeter spatial accuracy and radiometric consistency across all imaging sensors:

| Calibration Parameter | Method | Target Tolerance |

|---|---|---|

| Geometric Distortion | Laser grid projection + sub-pixel edge detection | ≤ 0.05 mm over 100 mm FOV |

| DQE (Detective Quantum Efficiency) | NPS & MTF analysis with tungsten edge test | ≥ 68% at 2 lp/mm |

| Dose Output (mGy) | Ion chamber array in IEC 61223-3-5 compliant setup | ±5% of nominal |

Each sensor undergoes bi-weekly recalibration and is paired with a digital calibration certificate embedded in the device firmware.

4. Durability & Environmental Testing

To ensure clinical longevity in diverse operating environments, Carejoy subjects CBCT units to accelerated life testing:

| Test | Standard | Result |

|---|---|---|

| Vibration & Shock (Transport) | ISTA 3A | Zero failure after 3 simulated shipments |

| Thermal Cycling | IEC 60601-1-11 | Operational from 10°C to 40°C; no image drift |

| Scan Cycle Endurance | Internal Protocol (10,000 scans) | < 0.1% increase in motion error |

| EMC Immunity | IEC 60601-1-2 (4th Ed.) | No data corruption at 10 V/m RF field |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the global digital dentistry equipment market is no longer anecdotal—it is structurally driven by four key advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer same-day access to precision optics, robotics, and high-speed PCBs—reducing lead times by 40–60% compared to Western counterparts.

- Advanced Automation: Carejoy’s facility utilizes AI-guided robotic arms for gantry assembly, reducing human error and labor cost while increasing repeatability (CpK > 1.67).

- R&D Intensity: China invests over $12B annually in medical imaging AI; Carejoy leverages state-funded AI research hubs for deep learning reconstruction models, reducing scan time by 35%.

- Regulatory Efficiency: NMPA approval pathways are streamlined for Class II devices, enabling faster market entry and iterative hardware updates.

As a result, Carejoy delivers CBCT systems with 0.075mm voxel resolution, AI motion correction, and open-architecture data export at a 40–50% cost reduction versus equivalent German or U.S.-made units—without compromising clinical accuracy or durability.

Carejoy Digital: Engineering the Future of Accessible Precision

Backed by:

- ISO 13485-certified manufacturing in Shanghai

- 24/7 remote technical support & over-the-air software updates

- Open file compatibility: STL, PLY, OBJ, DICOM, NNT

- AI-driven intraoral & CBCT scanning integration

For technical documentation, calibration reports, or remote demo access:

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Dental Cost.

✅ Open Architecture

Or WhatsApp: +86 15951276160