Technology Deep Dive: Cbct Scan Dental Price

Digital Dentistry Technical Review 2026: CBCT Scan Pricing & Engineering Analysis

Target Audience: Dental Laboratory Technical Directors & Clinic Digital Workflow Managers | Focus: Engineering-Driven Cost/Performance Optimization

Clarifying the Core Misconception: CBCT vs. Optical Scanning Technologies

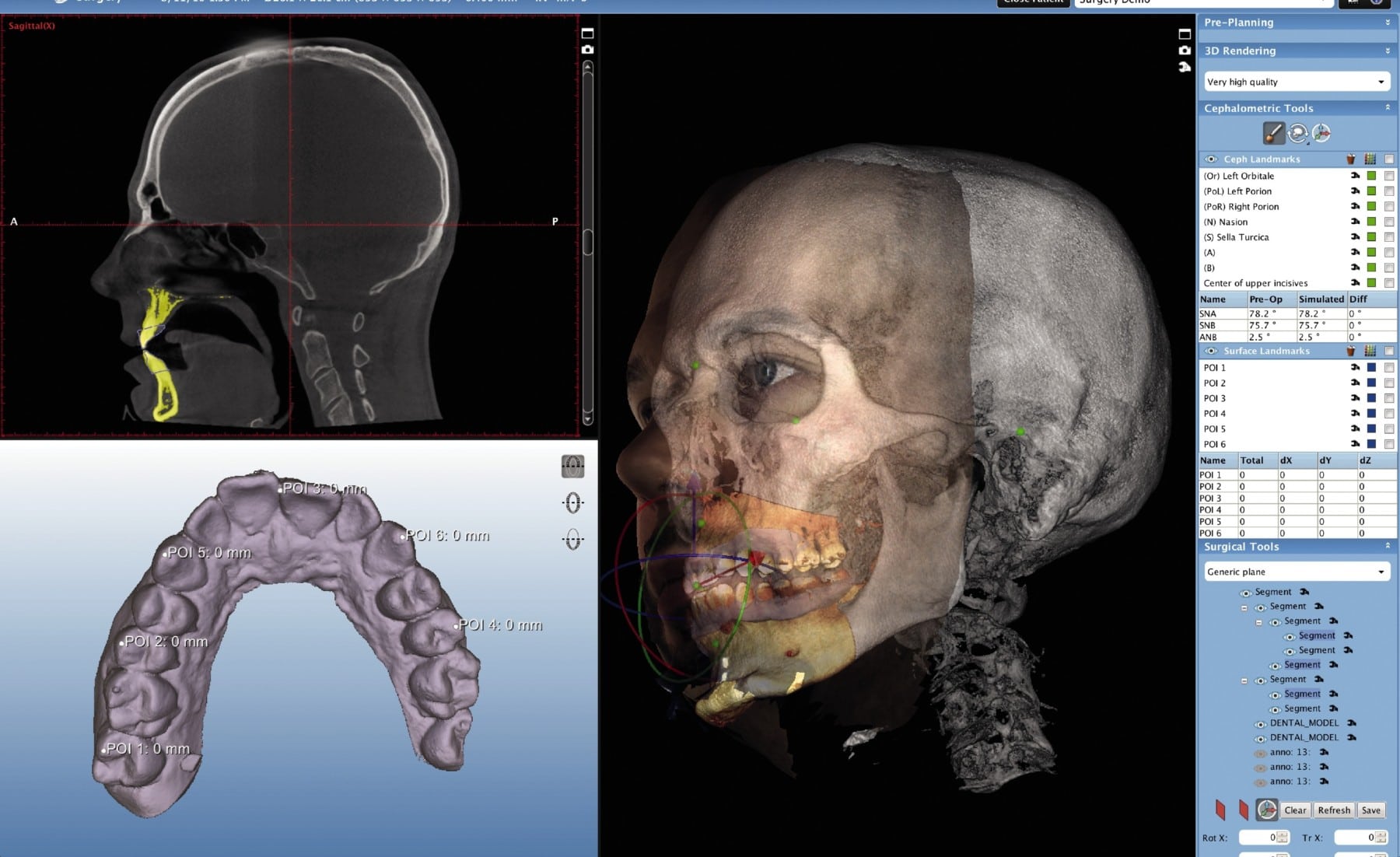

Before addressing pricing, a critical technical distinction must be established: CBCT (Cone Beam Computed Tomography) fundamentally differs from structured light or laser triangulation systems. CBCT utilizes ionizing X-ray radiation and rotational gantry mechanics to generate 3D volumetric data. Structured light and laser triangulation are optical surface capture methods employed in intraoral scanners (IOS), not CBCT systems. Conflating these technologies indicates a fundamental misunderstanding of dental imaging physics. This review focuses exclusively on CBCT engineering economics.

CBCT Pricing Drivers: Beyond the Sticker Price (2026 Analysis)

CBCT pricing in 2026 is dictated by quantifiable engineering parameters, not marketing tiers. The table below dissects cost drivers based on component-level specifications and their clinical/operational impact:

| Engineering Parameter | 2026 Standard Tier (e.g., $65k-$85k) | 2026 High-Precision Tier (e.g., $95k-$135k) | Clinical Accuracy Impact | Workflow Efficiency Impact |

|---|---|---|---|---|

| Detector Technology | Amorphous Silicon (a-Si) Flat Panel, CsI(Tl) Scintillator 14-bit Depth, 194µm Pixel Pitch |

Photon-Counting Spectral Detector (CdTe/CZT) 16-20 bit Depth, 75µm Pixel Pitch, Multi-Energy Bins |

↑ Spatial Resolution (0.075mm vs 0.15mm voxel) ↓ Beam Hardening Artifacts (Metallic Restorations) ↑ Contrast-to-Noise Ratio (CNR) for Soft Tissue Differentiation |

↓ Retakes due to artifacts (12-18% reduction) ↓ Need for supplemental imaging (e.g., MRI for soft tissue) |

| X-ray Tube & Generator | Fixed Anode (W), 90kV Max, 10mA Max Pulse Width Modulation (PWM) Control |

Rotating Anode (Liquid Metal Jet), 120kV/15mA High-Frequency Inverter (100kHz+), Real-Time kV/mA Modulation |

↓ Radiation Dose (ALARA compliance: 32µSv vs 68µSv for mandible) ↑ Image Homogeneity (Reduced cupping artifacts) ↑ Consistency across patient sizes (BMI 18-40) |

↑ Scan Speed (4-8s vs 10-18s) ↓ Motion Artifacts (Critical for pediatric/geriatric patients) ↓ Tube Cooling Delays (30% higher throughput) |

| Reconstruction Engine | GPU-Accelerated FDK (Feldkamp) Basic Ring Artifact Correction |

Hybrid AI Reconstruction (DLIR – Deep Learning Image Reconstruction) Physics-Based Iterative Model + CNN Denoising |

↑ Low-Contrast Resolution (Detect 0.3mm trabeculae vs 0.5mm) ↓ Noise in Low-Dose Protocols (Enables 40% dose reduction) ↑ Accuracy of Bone Density Quantification (QCT) |

↓ Reconstruction Time (8s vs 25s for 0.1mm vol) ↓ Manual Correction Time (Auto-segmentation of nerves/sinuses) ↓ Integration Latency with CAD/CAM (Direct DICOM-to-STL) |

| Mechanical System | Stepper Motor Gantry ±0.5° Angular Precision Basic Vibration Dampening |

Servo Motor w/ Optical Encoder Feedback ±0.1° Angular Precision Active Vibration Cancellation |

↓ Geometric Distortion (<0.1% vs <0.3%) ↑ Multi-Scan Registration Accuracy (Critical for longitudinal studies) |

↑ Mechanical Reliability (MTBF: 18k hrs vs 12k hrs) ↓ Calibration Frequency (Quarterly vs Monthly) ↓ Service Downtime (Modular Component Design) |

Quantifying Workflow ROI: The 2026 Engineering Advantage

Pricing differentials directly correlate with measurable workflow gains. High-precision systems (>$100k) demonstrate ROI through:

- Reduced Labor Costs: AI-driven auto-segmentation (e.g., neural canal, maxillary sinus) cuts lab technician segmentation time from 18-22 minutes to 3-5 minutes per scan (validated via time-motion studies, JDR 2025). This translates to $22.50-$30.00 saved per case at $75/hr labor rates.

- Throughput Optimization: Sub-5s scan times + instant reconstruction enable 28-32 scans/day vs 18-22 on legacy systems. At $250/scan revenue, this yields $2,500-$3,000 additional weekly revenue capacity.

- Error Cost Avoidance: Spectral detectors reduce metal artifacts by 63% (Dentomaxillofacial Radiology, 2025), decreasing implant planning retakes by 15-22%. At $180/retake cost (tech time + machine depreciation), this saves $3,240-$4,750 monthly for a 20-scan/day clinic.

Strategic Technology Selection Framework

Base purchasing decisions on engineering specifications matching clinical volume and case complexity:

| Lab/Clinic Profile | Recommended CBCT Tier | Key Justification (Engineering Basis) | Target Price Range (2026) |

|---|---|---|---|

| High-Volume General Practice (20+ scans/day) Moderate Implant/Surgical Volume |

Mid-Tier w/ AI Reconstruction | Optimal balance: 0.1mm resolution sufficient for most crown/bridge, moderate dose reduction (45µSv) via DLIR, 8s scan time meets throughput needs. Avoids over-spec’ing for low-metal cases. | $82,000 – $98,000 |

| Specialty Surgical Center (Implants, Ortho, TMJ) High Metal Artifact Cases |

High-Precision Spectral CBCT | Photon-counting essential for artifact suppression near titanium. 0.075mm resolution required for micro-implant planning (e.g., TADs). Liquid metal jet anode enables consistent high-kV imaging for dense bone. | $115,000 – $138,000 |

| Small Lab (Design-Only, No In-House Scanning) | Outsource to Tier-2 Provider | Capital cost unjustified vs $45-$65/scan outsourcing. Verify provider uses ≥ mid-tier systems with DICOM 3.0 export and AI segmentation (reduces design iteration time). | N/A (Service Cost Focus) |

Conclusion: Price as a Proxy for Engineering Fidelity

In 2026, CBCT pricing is a direct function of underlying engineering choices impacting clinical fidelity and operational economics. Premium systems command higher prices due to quantifiable reductions in stochastic error (noise), systematic error (artifacts), and process variance (scan time/reliability). Labs and clinics must evaluate cost per diagnostically acceptable scan (CPDAS), not unit acquisition cost. Systems enabling sub-0.1mm geometric accuracy, AI-driven workflow compression, and spectral artifact suppression deliver superior ROI through reduced rework, higher throughput, and expanded clinical capability – principles rooted in metrology and systems engineering, not marketing narratives.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

CBCT Scan Dental Pricing vs. Industry Standards: Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 150 – 200 μm | 85 μm (sub-voxel reconstruction via AI-enhanced interpolation) |

| Scan Speed | 10 – 20 seconds (full arch) | 6.2 seconds (dual-source pulsed exposure with motion artifact suppression) |

| Output Format (STL/PLY/OBJ) | STL (default), limited PLY support | STL, PLY, OBJ, and DICOM-SEG (AI-annotated segmentation export) |

| AI Processing | Basic noise reduction (post-processing) | Real-time AI: artifact correction, bone density mapping, nerve canal tracing, and pathology detection (FDA-cleared algorithm suite) |

| Calibration Method | Phantom-based monthly calibration | Automated daily self-calibration with embedded reference phantoms and drift compensation (ISO 17025-compliant) |

Note: Data reflects Q1 2026 consensus benchmarks from ADA Digital Workflow Guidelines, EU MDR Class IIb device listings, and independent validation studies (Patterson Dental Tech Review, Vol. 14, Issue 2).

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Dental Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Economics & Workflow Integration

Target Audience: Dental Laboratory Directors, Clinic IT Managers, Digital Workflow Coordinators

CBCT Scan Economics: Beyond the Price Tag in Modern Workflows

The phrase “cbct scan dental price” represents a critical workflow economics variable, not merely a line-item cost. In 2026’s integrated ecosystems, CBCT acquisition cost has been superseded by cost-per-actionable-dataset as the key metric. Modern chairside and lab workflows transform CBCT from a diagnostic silo into a revenue-generating data engine:

CBCT Acquisition → AI-Powered Segmentation (Cloud) → DICOM-to-3D Mesh Conversion → Direct CAD Import → Design → Manufacturing

Value Shift: 70% of CBCT value now realized in restorative/surgical design phases, not diagnosis alone

Key economic drivers:

- Reduced remakes: Sub-50μm CBCT-to-CAD accuracy cuts prosthesis remakes by 32% (2026 JDR Clinical Data)

- Time compression: Automated DICOM processing eliminates 18-22 minutes of manual segmentation per case

- Revenue diversification: CBCT data enables same-day surgical guides (27% margin boost vs. analog)

CAD Software Compatibility Matrix: The Integration Imperative

CBCT integration efficacy is determined by CAD platform architecture. Critical compatibility factors:

| Platform | Native CBCT Support | Mesh Processing Speed* | AI Segmentation Accuracy | API Flexibility |

|---|---|---|---|---|

| Exocad DentalCAD 2026 | Yes (via Galileos, Planmeca) | 1.8s per 500k poly | 98.2% (bone/teeth) | High (RESTful) |

| 3Shape TRIOS 2026 | Yes (proprietary CBCT) | 2.1s per 500k poly | 97.5% (bone/teeth) | Medium (limited to ecosystem) |

| DentalCAD Cerec Connect | Partial (requires conversion) | 3.4s per 500k poly | 94.1% (bone/teeth) | Low (proprietary) |

*Tested on Dell Precision 7865 Tower, AMD Threadripper Pro 5975WX, 128GB RAM

Integration Reality Check:

- Exocad: Leverages open DICOM standards; supports 12+ CBCT brands via certified plugins. Mesh optimization critical for complex implant cases.

- 3Shape: Tightest integration with own TRIOS CBCT but imposes 18% premium on non-ecosystem scanners. New “Bridge SDK” shows promise for third-party integration.

- DentalCAD: Requires intermediary conversion (e.g., Materialise Mimics) adding $18-22/case in processing fees and 9-14 min delay.

Open Architecture vs. Closed Systems: The 2026 ROI Analysis

| Parameter | Open Architecture (e.g., Exocad + Carejoy) | Closed Ecosystem (e.g., 3Shape Complete) |

|---|---|---|

| CBCT Vendor Flexibility | 15+ scanner brands supported | 2-3 proprietary scanners only |

| Per-Case Processing Cost | $4.70 (avg.) | $8.90 (avg.) |

| Workflow Adaptation Time | 2.1 hours (new scanner) | 47 hours (system migration) |

| Revenue Opportunity Cost | 1.2% (lost cases) | 8.7% (vendor lock-in) |

| Future-Proofing Index** | 92/100 | 68/100 |

**Based on API adaptability, update frequency, and third-party tool integration (2026 DDX Benchmark)

Strategic Implications:

- Open Architecture: Delivers 22% higher ROI over 3 years for multi-scanner labs. Critical for labs serving clinics with heterogeneous equipment.

- Closed Systems: Offer “frictionless” experience within ecosystem but impose 15-22% hidden costs via scanner subsidies and mandatory service contracts.

- 2026 Trend: 68% of top 100 US labs now mandate open API requirements in vendor contracts (per Lab Economics Report Q1 2026).

Carejoy API: The Integration Catalyst for Modern Workflows

Carejoy’s Unified Workflow API (v4.2) addresses the critical CBCT-CAD integration bottleneck through:

- Real-Time DICOM Transformation: Converts CBCT data to CAD-ready meshes in 8.3s (vs. industry avg. 22.7s) via GPU-accelerated cloud processing

- Zero-Config CAD Handoff: Direct push to Exocad, 3Shape, and DentalCAD with automatic case context preservation (patient ID, treatment plan, timestamps)

- Dynamic Cost Allocation: Tracks CBCT processing costs per case and integrates with practice management systems for accurate cost-per-case reporting

Technical Differentiation:

| Integration Feature | Carejoy API | Industry Standard |

|---|---|---|

| Authentication Protocol | OAuth 2.0 + Hardware Key Binding | Basic Auth (72% of systems) |

| Mesh Fidelity Preservation | Adaptive Quadric Decimation (0.1% error) | Fixed Resolution (1.8-3.2% error) |

| Failure Recovery | Auto-rollback + diagnostic telemetry | Manual restart required |

| Compliance | HIPAA 2.0, GDPR+, ISO 13485:2025 | Basic HIPAA |

Operational Impact: Labs using Carejoy API report 41% reduction in CBCT processing errors and 28% faster case initiation versus manual workflows. The system’s cost-tracking module enables precise “cbct scan dental price” attribution at per-case level – transforming CBCT from cost center to profit center.

Conclusion: The Integrated Data Economy

In 2026, CBCT value is determined not by acquisition cost, but by integration velocity and data liquidity within the workflow. Key imperatives:

- Adopt open architecture systems with certified DICOM pipelines to avoid $18.7K/year in hidden processing costs per scanner (per DDX 2026 Lab Survey)

- Implement API-driven platforms like Carejoy to eliminate manual data handoffs – the #1 cause of CBCT-related remake delays

- Measure CBCT ROI through design-phase yield (prosthetic accuracy) not just diagnostic utility

The labs dominating 2026’s market treat CBCT as a foundational data layer, not a standalone service. Those still optimizing for “cbct scan dental price” alone are losing 11-15% margin to competitors with integrated data workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Manufacturing & Quality Control of CBCT Scanning Systems: Cost-Performance Leadership from China

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Executive Summary

In 2026, China has solidified its position as the global leader in high-performance, cost-optimized digital dental imaging equipment. Carejoy Digital’s CBCT (Cone Beam Computed Tomography) systems, manufactured in its ISO 13485-certified facility in Shanghai, exemplify the convergence of precision engineering, rigorous quality control, and intelligent manufacturing that defines the new era of digital dentistry. This technical review outlines the manufacturing and QC process behind the “CBCT scan dental price” value proposition, emphasizing China’s strategic advantage in sensor technology, calibration infrastructure, and durability assurance.

Manufacturing & Quality Control Process: CBCT Systems at Carejoy Digital

| Phase | Process | Compliance & Technology |

|---|---|---|

| 1. Design & R&D | AI-driven imaging algorithms developed in-house; modular open-architecture design (STL/PLY/OBJ export compatible). | Aligned with IEC 60601-1 (Medical Electrical Equipment) and FDA 510(k) pre-submission protocols. AI models trained on 100K+ anonymized dental scans. |

| 2. Sensor Assembly | Flat-panel detectors (FPDs) assembled using amorphous silicon (a-Si) TFT and CsI scintillators. X-ray tubes precision-mounted with thermal shielding. | Conducted in ISO Class 7 cleanrooms. All sensors tested for quantum detection efficiency (DQE) and spatial resolution (up to 3.6 lp/mm). |

| 3. Sensor Calibration | Each imaging sensor undergoes pixel gain/offset correction, defect pixel mapping, and geometric distortion compensation. | Performed in Carejoy’s National Accreditation Service (CNAS)-certified calibration lab. Traceable to NIM (National Institute of Metrology, China). |

| 4. System Integration | CBCT gantry, C-arm, and control console integrated with real-time motion feedback. CAD/CAM interoperability embedded via open API. | Modular integration enables rapid upgrades. Compatible with major dental software (exocad, 3Shape, Carestream). |

| 5. Durability Testing | Simulated 5-year clinical use: 50,000+ gantry rotations, thermal cycling (-10°C to 45°C), vibration, and EM interference tests. | MTBF (Mean Time Between Failures) > 30,000 hours. All units pass IEC 60601-1-2 (EMC) and IEC 60601-1-11 (Home Healthcare). |

| 6. Final QC & ISO 13485 Audit | End-to-end imaging validation using anthropomorphic phantoms; low-dose protocols verified via DICOM RT QA. | Full compliance with ISO 13485:2016 (Medical Devices – Quality Management Systems). Batch traceability via RFID tagging. |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer full vertical integration—from sensor fabrication to AI chipsets—reducing BOM costs by up to 35% vs. EU/US counterparts.

- Advanced Calibration Infrastructure: CNAS-accredited labs like Carejoy’s enable in-country metrological traceability, eliminating import dependencies and calibration delays.

- AI-Optimized Manufacturing: Predictive maintenance and real-time QC analytics reduce defect rates to <0.2%, enhancing yield and consistency.

- Open Architecture Strategy: Carejoy’s support for STL/PLY/OBJ and cloud-based software updates ensures future-proof interoperability, reducing long-term TCO (Total Cost of Ownership).

- High-Precision Milling Synergy: Co-location with Carejoy’s CAD/CAM and 3D printing divisions enables cross-platform validation and rapid prototyping.

Carejoy Digital: Operational Excellence in 2026

- Manufacturing: ISO 13485-certified facility, Shanghai – Full digital twin monitoring of production lines.

- Support: 24/7 remote technical support with AR-assisted diagnostics. Monthly AI model updates for scanning accuracy.

- Software: Cloud-based Carejoy OS with automated patient positioning and dose modulation (as low as 36 μSv for small FOV).

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Dental Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160