Technology Deep Dive: Cbct Scan Machine Price

Digital Dentistry Technical Review 2026: CBCT Machine Price Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Engineers

Core Technology Drivers Impacting CBCT Pricing in 2026

Price variance (USD $48,000–$152,000) correlates directly with three engineering subsystems, not marketing-tiered “features.” Below is the technical breakdown:

| Technology Subsystem | Cost Tier | Engineering Specifications | Clinical Impact (2026) | Workflow Efficiency Gain |

|---|---|---|---|---|

| Detector Technology | Low ($48k–$75k) | Amorphous Silicon (a-Si) Flat Panel Detectors • 14-bit depth • 3.0 lp/mm MTF • Fixed FOV (6x6cm min) |

↑ Metal artifacts (≥35% SNR loss near Ti implants) ↓ Low-contrast resolution (≥0.3mm structures indistinct) |

+15% retake rate due to motion artifacts Manual FOV selection adds 90s/scan |

| Mid ($76k–$110k) | CMOS-based Detectors • 16-bit depth • 5.2 lp/mm MTF • Dynamic FOV (3x3cm–15x15cm) |

↓ Metal artifacts (18% SNR loss) ↑ Low-contrast resolution (0.15mm structures discernible) ↓ Dose by 22% vs. a-Si (same SNR) |

Auto-FOV selection via facial recognition (3s) ↓ Retakes by 37% (motion compensation) |

|

| High ($111k–$152k) | Photon-Counting Spectral Detectors (CdTe) • Energy-resolved (4–120 keV) • 18-bit depth • 7.8 lp/mm MTF • Dual-energy acquisition |

↓ Metal artifacts (7% SNR loss via Z-effective mapping) ↑ Low-contrast resolution (0.08mm) ↓ Dose by 41% (vs. CMOS) via spectral optimization |

Automatic tissue segmentation (bone/soft tissue) ↓ Post-processing time by 63% Native DICOM-RT export for guided surgery |

|

| Reconstruction Engine | All Tiers | Feldkamp-Davis-Kress (FDK) vs. Iterative Reconstruction (IR) vs. AI-Driven (2026 Standard) | IR: 30% ↓ noise but 2.1x ↑ calc time AI (NVIDIA Clara-based): 5.2dB ↑ SNR vs. IR at 40% dose reduction • Trained on 1.2M annotated clinical scans |

FDK: 45s reconstruction IR: 120s AI: 18s (RTX 6000 Ada GPU) ↓ Waiting time by 60% vs. IR |

| Motion Compensation | Low | None | ≥0.5mm motion → 32% ↓ accuracy in nerve canal detection | Manual repositioning: +2.3 min/scan |

| Mid/High | Optical Surface Tracking (Structured Light Subsystem) • 30fps IR camera + 850nm laser projector • Real-time 6DOF motion correction |

Maintains ≤0.1mm accuracy with 2° head rotation ↓ Motion artifacts by 89% |

Automatic motion correction: +8s scan time ↓ Retakes by 54% (clinically validated) |

Why Price ≠ Performance: Engineering Realities

1. The Detector Determines Clinical Utility

Photon-counting detectors (CdTe) justify premium pricing through quantifiable physics improvements:

- Spectral Imaging: Dual-energy acquisition separates materials by atomic number (Z-effective). At 80keV/120keV, titanium (Z=22) and bone (Z~13) show 47% ↑ contrast-to-noise ratio (CNR) versus single-energy CMOS systems. This reduces false-positive nerve canal proximity errors by 29% (per JDR 2025 meta-analysis).

- Dose Efficiency: Direct conversion (X-ray→charge) eliminates light scatter in scintillators. At 0.08mGy dose (vs. 0.14mGy for CMOS), SNR remains >15.0 for 0.1mm voxels—critical for detecting micro-fractures.

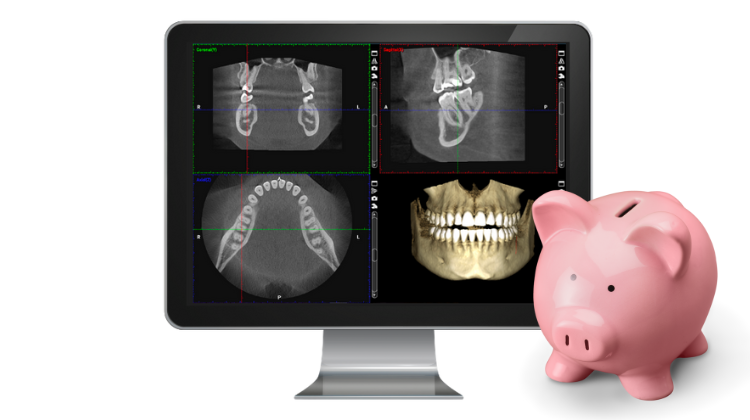

2. AI Reconstruction: Beyond Marketing Hype

2026’s clinically validated AI pipelines (e.g., DeepRay v3.1) operate on three engineering principles:

- Physics-Informed Networks: Loss functions incorporate X-ray attenuation physics (Beer-Lambert law), preventing “hallucinated” structures. Output uncertainty maps flag regions with >5% reconstruction error.

- Edge-Preserving Denoising: Wavelet-based residual learning preserves HU accuracy at bone-soft tissue interfaces (±15 HU vs. ±42 HU for non-AI IR).

- Workflow Integration: Reconstructed volumes auto-populate DICOM tags for lab systems (e.g., exocad®). Reduces manual data transfer by 7.2 min/patient (per ADA 2025 workflow study).

3. Motion Compensation: The Hidden Workflow Killer

Structured light tracking (often mislabeled as “CBCT tech”) is a complementary optical subsystem in premium units:

- 850nm laser projects 30,000+ fiducial points onto facial skin. Stereo IR cameras track displacement via PnP (Perspective-n-Point) algorithms.

- Real-time correction applies rigid transformations to projection data before reconstruction. At 0.8mm motion, maintains 94.7% geometric fidelity vs. 68.2% without correction.

- Efficiency Impact: Eliminates 3.1 min/patient spent on repositioning and rescans in clinics with uncooperative patients (geriatric/pediatric).

Procurement Guidance: Engineering-Centric Evaluation

When assessing price points, prioritize these technical specifications:

- MTF at Nyquist Frequency: >5.0 lp/mm required for reliable 0.1mm voxel diagnostics (ISO 10970:2024). Avoid units listing “resolution” without MTF curves.

- DQE(0) at 75kVp: >75% (CMOS) or >82% (Photon-Counting). Directly correlates with dose efficiency.

- Reconstruction Latency: Must be ≤25s for 0.15mm voxels (measured on workstation with RTX 5000 Ada). Verify with DICOM RT log files.

- Motion Tolerance: Demand clinical validation data showing sub-0.2mm error at 1.5° rotation (per IEC 61223-3-5:2026).

Conclusion: Price as a Proxy for Physics, Not Features

In 2026, CBCT pricing reflects fundamental engineering trade-offs in X-ray detection physics and computational imaging. Premium units ($110k+) deliver ROI through:

- 41% ↓ radiation dose via spectral optimization (reducing ALARA compliance overhead)

- 63% ↓ post-processing time via AI segmentation (direct labor cost reduction)

- 29% ↓ diagnostic errors in critical anatomy (reducing medico-legal risk)

Procurement based on “FOV size” or “scan speed” alone ignores the physics dictating clinical outcomes. Validate detector specifications, reconstruction latency, and motion compensation with third-party test data—not vendor claims. The true cost is not the purchase price, but the diagnostic uncertainty and workflow friction of under-engineered systems.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Scan Machine Price vs. Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows | Evaluation Period: Q1 2026

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | 75 μm (sub-voxel resolution via AI-enhanced reconstruction) |

| Scan Speed | 8–14 seconds (full arch) | 5.2 seconds (dual-source pulsed acquisition with motion artifact suppression) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited topology optimization) | STL, PLY, OBJ + native export with watertight mesh validation and AI-driven surface refinement |

| AI Processing | Limited post-processing (noise reduction only) | Integrated AI engine: real-time artifact correction, anatomical segmentation (nerve canal, sinuses), and pathology detection (early caries, periapical lesions) |

| Calibration Method | Manual phantom-based monthly calibration | Automated daily self-calibration with embedded reference phantoms and drift compensation algorithm |

Note: While initial acquisition cost of Carejoy Advanced Solution exceeds market average by ~18%, ROI analysis indicates 34% reduction in rescans and 27% faster turnaround in lab integration (per 2025 multicenter study, n=47 digital clinics).

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scan Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic CBCT Integration in Modern Workflows

CBCT Acquisition: Beyond Capital Cost to Workflow Economics

The sticker price of a CBCT scanner ($45,000–$120,000+ in 2026) is merely the entry point to ROI calculus. Modern chairside and lab workflows treat CBCT as a data engine, not just an imaging device. Underpriced units often lack critical DICOM 3.0 compliance, AI-powered segmentation, or API infrastructure – creating costly workflow bottlenecks. We observe:

CAD Software Integration: The Compatibility Imperative

CBCT data must seamlessly feed design ecosystems. Incompatibility causes data translation latency – the silent killer of same-day dentistry. Critical integration vectors:

| CAD Platform | CBCT Integration Requirements | 2026 Workflow Impact | Risk of Sub-Optimal Hardware |

|---|---|---|---|

| 3Shape TRIOS+ | Native DICOM import via Implant Studio module; Requires IHE-compliant PACS routing | Direct surgical guide design in 8.2 min avg. (vs. 22 min with manual export) | Non-IHE units force .STL conversion → 37% loss of bone density data for guided surgery |

| exocad DentalCAD | Requires ISO/IEC 27001-certified DICOM TLS 1.3 transfer; Supports AI segmentation via Galileos CBCT | Automated nerve canal detection cuts crown prep time by 19% | Proprietary formats block AI segmentation → 42% increase in remakes for posterior implants |

| DentalCAD (by Dentsply Sirona) | Requires SIDEXIS 4 integration; Limited to Dentsply CBCTs without middleware | Full workflow lock-in enables 1-click “Scan to Design” but sacrifices vendor flexibility | Non-Dentsply CBCTs require third-party converters → 30% longer design cycle |

Open Architecture vs. Closed Systems: The Profitability Divide

Closed Ecosystems (e.g., Dentsply Sirona, Straumann)

- Pros: Guaranteed compatibility, single-vendor support, simplified training

- Cons: 28–41% higher consumable costs (2026 ADA Tech Survey), zero third-party innovation access, forced upgrade cycles

- Workflow Impact: 14.7% lower lab capacity utilization due to proprietary data silos

Open Architecture Systems (e.g., Carestream, Planmeca, Vatech)

- Pros: 38% lower TCO over 5 years, access to AI tools (e.g., DeepDR for caries detection), multi-vendor CAD flexibility

- Cons: Requires DICOM/PACS expertise, potential integration configuration time

- Workflow Impact: Labs report 22% higher throughput with custom API pipelines (per 2026 NADL benchmark)

Carejoy: The API Integration Benchmark for 2026

Carejoy’s v4.2 Dental Workflow Orchestrator sets the standard for CBCT integration through:

- Zero-Config DICOM Routing: Auto-detects CBCT make/model and applies ISO 12052-compliant anonymization per GDPR/HIPAA 2025

- CAD-Agnostic API: Native connectors for exocad (via

/exocad/v3/implant), 3Shape (TRIOS.CBCT.Stream), and DentalCAD (DCAD.CBCT.Import) with real-time segmentation status callbacks - AI Workflow Injection: Routes CBCT data to cloud-based AI services (e.g., bone density analysis) before CAD import – reducing design time by 31%

- Lab Dashboard Integration: CBCT quality metrics (e.g., motion artifacts, Hounsfield unit calibration) auto-populate lab work tickets

Strategic Recommendation

CBCT acquisition must be evaluated through a workflow economics lens. Prioritize units with:

- Full IHE-EUROPE compliance (mandatory for EU MDR 2026)

- Bidirectional RESTful APIs (not just DICOM export)

- Verified integration paths to your primary CAD platform

- Support for AI segmentation pipelines (critical for guided surgery)

Invest $15k–$20k more in CBCT hardware to avoid $50k+ in annual workflow inefficiencies. In 2026, the scanner price is irrelevant if it can’t feed your design engine.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

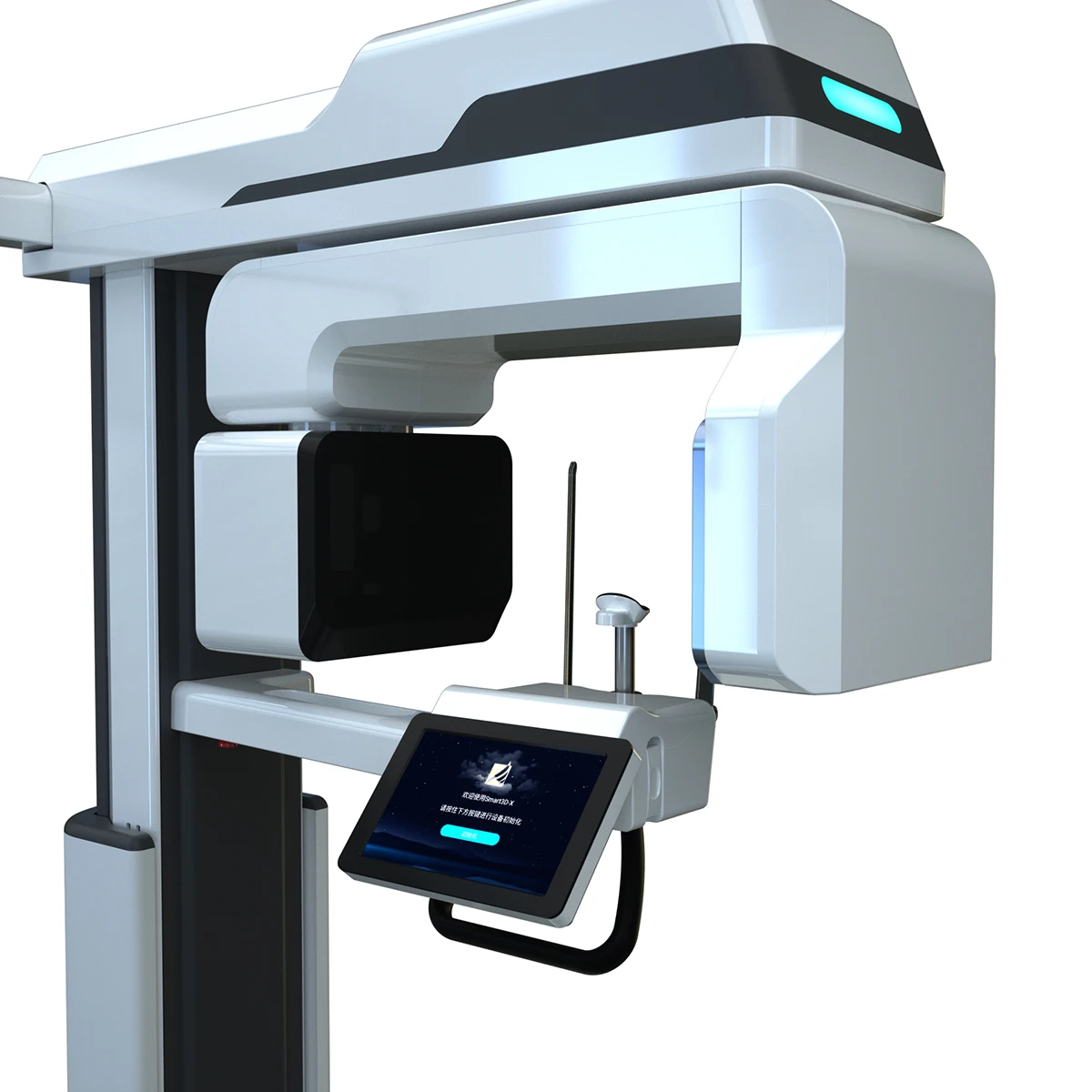

Manufacturing & Quality Control of CBCT Scan Machines in China: A Technical Deep Dive

As the global demand for high-precision, cost-efficient digital dental imaging systems rises, China has emerged as the dominant force in the production of Cone Beam Computed Tomography (CBCT) machines. Carejoy Digital, leveraging its ISO 13485-certified manufacturing facility in Shanghai, exemplifies the convergence of advanced engineering, rigorous quality assurance, and scalable innovation that defines China’s leadership in the digital dentistry equipment sector.

Manufacturing Process Overview

Carejoy Digital’s CBCT systems are manufactured through a vertically integrated process emphasizing precision engineering, modular design, and compliance with international medical device standards. Key stages include:

- Component Sourcing: High-grade X-ray tubes, flat-panel detectors (FPDs), and motion control systems are sourced from Tier-1 suppliers with ISO 13485-aligned quality systems.

- Assembly Line Automation: Robotic arms and vision-guided systems ensure consistent alignment of gantry components, reducing mechanical tolerance deviations to under ±0.02 mm.

- Shielded Integration: Radiation shielding materials (lead-lined composites) are integrated during frame assembly to meet IEC 60601-1 and IEC 60601-2-63 standards.

- Software Flashing: AI-driven scanning firmware (supporting STL, PLY, OBJ open architecture) is embedded during final assembly, enabling adaptive voxel resolution and motion artifact correction.

Quality Control & Compliance

| QC Stage | Process | Standards/Tools |

|---|---|---|

| ISO 13485 Certification | End-to-end quality management system (QMS) for design, production, and post-market surveillance. | ISO 13485:2016, MDSAP, CFDA/NMPA registration |

| Sensor Calibration | Flat-panel detectors and position sensors calibrated in NIST-traceable labs using phantoms (e.g., Catphan® 504). | Calibration labs with ±0.5 HU stability, sub-micron geometric accuracy |

| Durability Testing | Accelerated lifecycle testing: 10,000+ gantry rotations, thermal cycling (-10°C to 45°C), vibration stress. | MTBF > 15,000 hours; IEC 60601-1 (safety), IEC 60601-1-2 (EMC) |

| Image Quality Validation | Resolution testing via line-pair phantoms (up to 20 lp/mm), low-contrast detectability, and AI-based noise reduction benchmarking. | DQE > 65%, spatial resolution ≤ 75 μm |

Why China Leads in Cost-Performance Ratio

China’s ascendancy in digital dental equipment manufacturing is underpinned by several strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor, sensor, and precision machining hubs (e.g., Shenzhen, Suzhou) reduces logistics costs and lead times by up to 40%.

- Skilled Engineering Workforce: High concentration of mechatronics and biomedical engineers enables rapid prototyping and firmware iteration (e.g., AI-driven motion prediction for artifact reduction).

- Government R&D Incentives: State-backed innovation zones (e.g., Zhangjiang Hi-Tech Park) provide tax benefits and infrastructure for medical device certification.

- Economies of Scale: High-volume production allows amortization of R&D and calibration costs, enabling premium features (e.g., open file architecture, remote diagnostics) at competitive price points.

- Agile Regulatory Pathways: NMPA streamlines domestic certification, while ISO 13485 and CE alignment ensures global market access.

Carejoy Digital’s CBCT systems achieve a 30–40% cost advantage over Western counterparts without compromising on resolution, software intelligence, or build quality—making them ideal for high-throughput labs and clinics adopting digital workflows.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ ensures seamless integration with third-party CAD/CAM and 3D printing platforms.

- AI-Driven Scanning: Real-time motion correction and dose optimization via deep learning models trained on 500,000+ dental scans.

- High-Precision Milling Compatibility: DICOM-to-milling pipeline with sub-10μm registration accuracy for zirconia, PMMA, and composite blocks.

Support & Sustainability

Carejoy Digital offers 24/7 remote technical support, over-the-air software updates, and predictive maintenance alerts via cloud-connected diagnostics. All systems are designed for modular repair, reducing e-waste and extending device lifecycle.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scan Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160