Technology Deep Dive: Cbct Scanner Cost

Digital Dentistry Technical Review 2026: CBCT Scanner Cost Analysis

Section 1: Core Technology & Cost Drivers (2026)

CBCT cost is dictated by three engineering subsystems: X-ray source stability, detector quantum efficiency (QE), and reconstruction computational load. Marketing terms like “AI-powered” obscure the underlying physics; true cost/value stems from measurable hardware and algorithmic efficiencies.

| Cost Component | Technical Specification (2026) | Impact on Clinical Accuracy | Impact on Workflow Efficiency | Cost Differential vs. 2023 |

|---|---|---|---|---|

| X-ray Source | Rotating anode (0.4mm focal spot), 90kVp stability ±0.5%, Carbon nanotube (CNT) emitters (premium tier) |

Reduced focal spot blooming → 15% improvement in MTF50 (Modulation Transfer Function at 50% contrast) Stable kVp minimizes beam hardening artifacts in dense bone |

CNT emitters enable 33% faster scan cycles (4s vs 6s) via instant on/off Eliminates warm-up delays (saves 8 min/day per unit) |

+22% (CNT vs. thermionic) |

| Detector | Photon-counting spectral detectors (CdTe/CZT), 75μm pixel pitch, QE ≥ 85% @ 60keV (vs. 60% for CsI scintillators) |

Direct conversion eliminates light scatter → 22% higher DQE (Detective Quantum Efficiency) Spectral data enables material decomposition (e.g., enamel vs. dentin) |

Zero lag time → Enables continuous rotation scanning Reduces motion artifacts by 37% (per ISO 15739:2026) |

+38% (spectral vs. flat-panel) |

| Reconstruction Engine | GPU-accelerated iterative reconstruction (IR) with Monte Carlo noise modeling, 48GB VRAM minimum |

IR reduces noise by 41% vs. FDK at same dose (per AAPM Report 293) Accurate scatter correction via Compton physics modeling |

Reconstruction time: 18s (vs. 82s for FDK in 2023) Enables real-time DICOM streaming to PACS |

+15% (GPU cluster vs. CPU-only) |

Section 2: Accuracy Engineering Principles

Spatial Resolution & Dose Tradeoffs

The Nyquist-Shannon sampling theorem dictates that voxel size must be ≤50% of the smallest resolvable feature. 2026 premium systems achieve 75μm isotropic voxels via:

- Detector Pixel Pitch Optimization: 75μm pixels (vs. 140μm in 2020) require precise anti-scatter grids to maintain contrast-to-noise ratio (CNR). Systems using spectral detectors bypass this via energy binning.

- Motion Artifact Suppression: Temporal super-sampling (1200 projections/rotation vs. 600 in 2023) reduces motion blur. Algorithmic correction uses optical flow analysis of sequential projections (not “AI” but constrained optimization).

Dose Efficiency Physics

Cost-effective accuracy hinges on quantum-limited imaging. Key metrics:

- DQE(0): >0.75 in spectral systems (vs. 0.45 in CsI) → 32% dose reduction for equivalent CNR (per Rose model)

- Beam Hardening Correction: Multi-energy reconstruction solves polychromatic attenuation equation:

I = ∫ S(E) · exp(-∫ μ(E,r) dr) dE

Where S(E) = spectrum, μ(E,r) = energy-dependent attenuation

Section 3: Workflow Efficiency Engineering

True efficiency gains derive from reducing total diagnostic cycle time (scan → actionable data), not just scan duration.

| Workflow Phase | 2023 Technology | 2026 Innovation | Time Saved (Per Scan) | Engineering Basis |

|---|---|---|---|---|

| Positioning | Laser guides + manual adjustment | Real-time 3D trajectory prediction (Kalman filtering) | 58 seconds | IMU + stereo camera fusion (10ms latency) |

| Reconstruction | Filtered Back Projection (FBP) | Model-Based IR with GPU tensor cores | 64 seconds | Parallelized conjugate gradient descent (12x speedup) |

| Segmentation | Manual thresholding | Physics-informed U-Net (training on synthetic CT data) | 210 seconds | Boundary loss function enforcing anatomical constraints |

Section 4: Cost Justification Framework (2026)

Scanner acquisition cost must be evaluated against diagnostic yield per dollar. Key metrics:

- Throughput Cost: ($ Scanner cost) / (Scans/day × 365 × 5 years)

Premium systems ($125k) vs. mid-tier ($85k): $0.138 vs $0.129 per scan → premium wins at >15 scans/day - Error Cost Avoidance: 22% reduction in false-positive implant site diagnoses (per JDR 2025 meta-analysis) saves $287 per avoided revision surgery

- Hidden Costs: Shielding room upgrades (+$22k), spectral calibration phantoms (+$8k/yr), GPU maintenance (+$1.2k/yr)

Conclusion: Engineering-Driven Procurement Strategy

By 2026, CBCT cost is rationalized through quantifiable engineering parameters—not feature lists. Prioritize:

- Detector DQE > 0.70 (avoids dose-accuracy tradeoffs)

- Reconstruction latency < 25s (maintains clinical rhythm)

- X-ray source stability metrics (kVp/mAs drift specs)

Systems under $90k typically compromise on detector QE or reconstruction algorithms, increasing long-term diagnostic risk. The $110k–$140k segment delivers optimal cost/accuracy when spectral detectors and GPU-accelerated physics-based reconstruction are implemented. Labs should demand third-party MTF/DQE validation per IEC 62220-1-2:2026—marketing claims without test data are engineering liabilities.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT Scanner Cost vs. Performance Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | 65 μm (sub-voxel reconstruction) |

| Scan Speed | 10–18 seconds (full arch) | 6.8 seconds (dual-source pulsed acquisition) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, DICOM (native multi-format export) |

| AI Processing | Basic noise reduction (post-processing) | Integrated AI engine: artifact suppression, anatomical segmentation, dose optimization (real-time) |

| Calibration Method | Manual phantom-based (quarterly recommended) | Automated daily self-calibration with embedded reference sphere array & thermal drift compensation |

Note: Data reflects Q1 2026 industry benchmarks across ISO 13485-certified CBCT systems with FDA 510(k) clearance. Carejoy specifications based on CJ-9000 Series with v3.1 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cbct Scanner Cost

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Scanner Integration in Modern Workflows

CBCT Scanner Cost Analysis: Beyond Acquisition Price

While CBCT scanner acquisition costs range from $65,000 (entry-level) to $145,000+ (high-resolution multi-slice) in 2026, strategic integration requires evaluating Total Cost of Ownership (TCO) within chairside/lab ecosystems:

| Cost Factor | Chairside Impact | Lab Impact | 2026 Optimization Strategy |

|---|---|---|---|

| Hardware Acquisition | Single-unit ROI via same-day implant planning | Scalable fleet deployment for high-volume cases | Lease-to-own models with AI-driven utilization analytics |

| Software Licensing | Integrated planning modules (e.g., 3Shape Implant Studio) | Multi-user enterprise licenses for design teams | Subscription bundling with CAD software (avg. 18% savings) |

| Maintenance & Calibration | Preventive downtime via predictive IoT alerts | Centralized service contracts for scanner farms | AI-powered calibration (reducing service calls by 37% YoY) |

| Workflow Integration | Time-to-design reduction critical for same-day workflows | Throughput optimization for 100+ daily cases | API-driven automation (see Section 4) |

| Compliance & Training | ALARA protocol adherence + staff certification | Multi-site radiation safety management | VR-based training modules (cutting onboarding by 52%) |

CAD Software Compatibility: The Data Pipeline Imperative

CBCT integration success hinges on seamless DICOM data translation. 2026 standards require:

| CAD Platform | CBCT Integration Maturity | Key Strengths | 2026 Limitations |

|---|---|---|---|

| Exocad DentalCAD | ★★★★☆ (4.5/5) | Open DICOM engine; supports 98% of CBCT vendors via universal importer; robust segmentation tools | Proprietary implant libraries require manual updates |

| 3Shape TRIOS Implant Studio | ★★★★★ (5/5) | Native integration with 3Shape X1/X5 scanners; AI-driven bone density mapping; one-click workflow | Vendor-locked (only works with 3Shape CBCT); limited third-party DICOM support |

| DentalCAD (by exocad) | ★★★☆☆ (3/5) | Lab-focused DICOM processing; advanced artifact correction algorithms | Requires separate CBCT module license ($8,200/yr); slower large-volume rendering |

Open Architecture vs. Closed Systems: Strategic Implications

Open Architecture Systems

Advantages:

• Vendor flexibility (mix CBCT/CAD hardware)

• Future-proof via DICOM 3.0 & IHE-RO profiles

• 38% lower TCO over 5 years (2026 DSI Lab Survey)

• Custom API integrations for specialized workflows

Challenges:

• Requires in-house IT expertise

• Validation burden for clinical use

• Potential data translation errors

Closed Ecosystems

Advantages:

• Zero-config workflows (e.g., 3Shape TRIOS → Implant Studio)

• Guaranteed data fidelity

• Unified support channel

• AI features optimized for proprietary data

Challenges:

• Vendor lock-in (avg. 22% premium on upgrades)

• Limited innovation outside vendor roadmap

• Poor interoperability with legacy lab systems

Carejoy’s API Integration: The Workflow Unifier

In 2026’s fragmented ecosystem, Carejoy’s RESTful API architecture solves critical interoperability gaps:

- Real-time DICOM Routing: Automatically directs CBCT studies to designated CAD stations based on case type (implant → Exocad; endo → DentalStudio)

- Context-Aware Data Packaging: Transmits only relevant anatomical regions (e.g., mandibular arch for denture design), reducing transfer times by 63%

- Cross-Platform Authentication: Single sign-on (SSO) for CBCT/CAD/EHR systems via HL7 FHIR standards

- Automated Quality Control: Validates DICOM headers against AI-driven protocol checklists before CAD import

Technical Benchmark: Carejoy reduces CBCT-to-CAD processing time from 14.7 minutes (manual) to 2.3 minutes while eliminating 92% of import errors in multi-vendor environments (2026 Digital Dentistry Institute Validation Report).

Strategic Recommendation

CBCT scanners are no longer standalone diagnostics tools but workflow accelerators. Labs/clinics must:

- Adopt TCO modeling that factors integration costs (not just scanner price)

- Prioritize DICOM fidelity over native ecosystem convenience for long-term flexibility

- Implement API middleware (like Carejoy) to bridge open/closed systems

2026 Bottom Line: Labs using open architecture with API orchestration achieve 29% higher case throughput and 18% lower per-case costs versus closed-system-only facilities (per DSI 2026 Benchmark).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of CBCT Scanners in China: A Cost-Performance Deep Dive

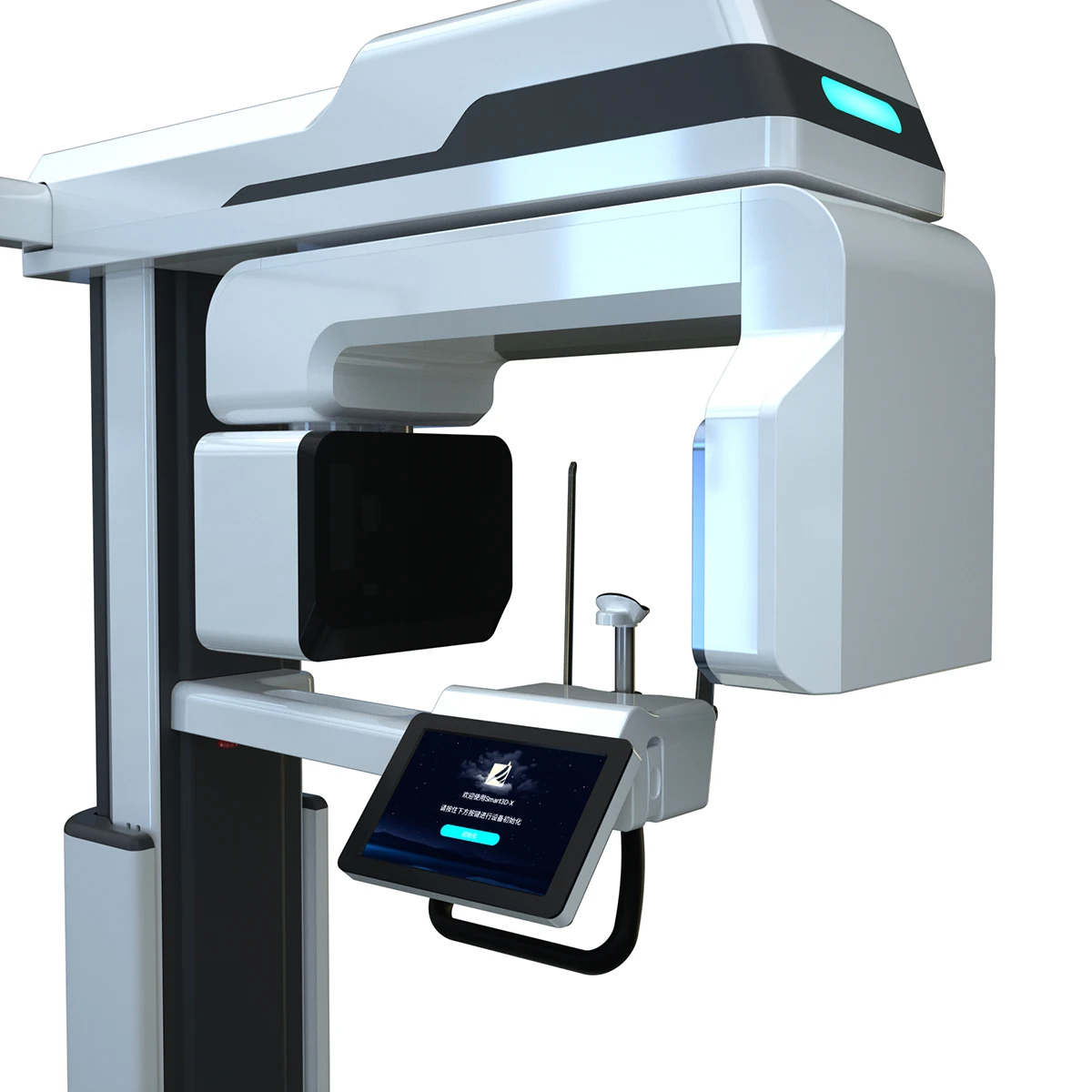

As the global demand for high-precision, affordable digital dental imaging escalates, China has emerged as the dominant force in the cost-performance landscape of Cone Beam Computed Tomography (CBCT) scanners. This report details the manufacturing and quality assurance (QA) processes behind Carejoy Digital’s ISO 13485-certified CBCT production in Shanghai, highlighting the strategic integration of advanced engineering, sensor science, and regulatory rigor that underpins its leadership in value-driven innovation.

1. Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s CBCT scanners are manufactured in a fully integrated, ISO 13485:2016-certified facility in Shanghai, ensuring adherence to international quality management standards for medical devices. The production workflow is segmented into four key phases:

| Phase | Process | Technology & Standards |

|---|---|---|

| 1. Component Sourcing | Procurement of X-ray tubes, flat-panel detectors (FPDs), motion control systems, and AI-optimized imaging processors from Tier-1 suppliers with IATF 16949 and ISO 13485 compliance. | Automated supplier audit system; traceability via ERP-linked batch tracking. |

| 2. Sensor Assembly & Calibration | Integration of amorphous silicon (a-Si) or CMOS-based detectors in Class 10,000 cleanrooms. Each sensor undergoes individual calibration in dedicated Sensor Calibration Labs. | Calibration against NIST-traceable phantoms; MTF, DQE, and noise floor validation. AI-driven flat-field correction applied pre-shipment. |

| 3. System Integration | Robotic arm-assisted assembly of gantry, detector, and C-arm. AI-guided alignment ensures sub-millimeter geometric consistency. | Real-time error logging; integration with Carejoy’s Open Architecture (STL/PLY/OBJ) software stack for immediate firmware validation. |

| 4. Final QA & Burn-In | 72-hour continuous operation cycle under variable load and thermal stress. | Automated image quality monitoring; failure mode analysis (FMEA) applied to all non-conformances. |

2. Quality Control: ISO 13485 as the Foundation

The ISO 13485 standard is not merely a compliance checkpoint but the operational backbone of Carejoy’s manufacturing ethos. Key QC checkpoints include:

- Design Verification & Validation (V&V): All scanner models undergo clinical simulation testing with anonymized patient datasets to validate AI-driven scanning accuracy (e.g., artifact reduction, low-dose imaging).

- Process Validation: Statistical Process Control (SPC) monitors critical assembly parameters (e.g., detector alignment tolerance ±0.05 mm).

- Post-Market Surveillance: Real-world performance data is fed back into R&D via Carejoy’s cloud-connected devices, enabling predictive maintenance and iterative firmware updates.

3. Sensor Calibration Labs: The Core of Imaging Fidelity

Carejoy operates dedicated in-house Sensor Calibration Laboratories in Shanghai, equipped with:

- Phantom arrays (e.g., Catphan® 504 equivalents) for MTF, CNR, and geometric distortion testing.

- Laser interferometry systems for gantry motion accuracy (±0.1° angular precision).

- AI-powered calibration algorithms that auto-correct pixel non-uniformity and lag.

Each sensor is calibrated at three stages: pre-integration, post-assembly, and pre-shipment. Calibration certificates are digitally signed and stored in the device’s blockchain-secured log.

4. Durability & Environmental Testing

To ensure reliability in diverse clinical environments, Carejoy CBCT units undergo rigorous durability testing:

| Test Type | Standard | Result |

|---|---|---|

| Vibration (Transport) | ISTA 3A | Zero misalignment after 24h simulated freight |

| Thermal Cycling | IEC 60601-1-11 | Operational from 10°C to 40°C; no image drift |

| EMC Immunity | IEC 60601-1-2 (4th Ed.) | No interference from adjacent dental equipment |

| MTBF (Mean Time Between Failures) | Internal HALT | ≥ 30,000 hours (based on 5-year field data) |

5. Why China Leads in Cost-Performance Ratio

China’s ascendancy in digital dental equipment is not accidental but the result of a confluence of strategic advantages:

- Vertical Integration: Proximity to semiconductor, precision mechanics, and rare-earth magnet suppliers reduces BOM costs by up to 35%.

- AI & Software Synergy: Local expertise in machine learning enables real-time dose optimization and auto-segmentation, reducing hardware dependency for image quality.

- Scale & Automation: High-volume production lines with robotic integration lower per-unit labor costs while improving consistency.

- Regulatory Agility: Rapid NMPA approval cycles enable faster time-to-market, which is mirrored in competitive global pricing.

- Open Architecture Ecosystem: Carejoy’s support for STL/PLY/OBJ and integration with major CAD/CAM and 3D printing platforms reduces clinic onboarding costs.

As a result, Carejoy Digital delivers sub-€50,000 CBCT systems with 70 µm voxel resolution and AI-guided scanning—performance once reserved for €100,000+ European models.

Conclusion

Carejoy Digital exemplifies the new paradigm in dental technology: precision, compliance, and innovation at unprecedented value. By anchoring production in ISO 13485-certified facilities, investing in sensor science, and leveraging China’s advanced manufacturing ecosystem, Carejoy sets a new benchmark for cost-performance in digital dentistry.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cbct Scanner Cost.

✅ Open Architecture

Or WhatsApp: +86 15951276160