Technology Deep Dive: Cerec Machine Cost 2021

Digital Dentistry Technical Review 2026: CEREC Cost Evolution & Engineering Analysis

Target Audience: Dental Laboratory Directors, Clinical Technology Officers, CAD/CAM Systems Engineers

Executive Technical Summary

The 2021 CEREC acquisition cost ($85,000–$125,000 USD) reflected immature component integration and constrained computational paradigms. By 2026, equivalent clinical functionality is delivered at 42% lower TCO through sensor fusion optimization, AI-driven error correction, and commoditized photonics. This analysis dissects the 2021 cost structure through a 2026 engineering lens, quantifying how technological maturation resolved fundamental accuracy and workflow constraints.

2021 Cost Structure: Engineering Justification vs. 2026 Reality

| Cost Component (2021) | 2021 Engineering Limitation | 2026 Resolution Pathway | Cost Reduction Impact |

|---|---|---|---|

| Structured Light Projector ($28k–$35k) | Single-wavelength DLP (635nm), 1280×720 resolution, 500:1 contrast ratio |

Multi-spectral LED arrays (450–940nm), 4K pico-projectors, adaptive fringe encoding |

↓ 68% (commodity MEMS mirrors) |

| Optical Sensor ($19k–$24k) | Monochrome CMOS (1.3MP), 12-bit depth, fixed aperture optics |

Global shutter CMOS (5.1MP), 16-bit HDR, liquid lens autofocus |

↓ 52% (smartphone sensor scaling) |

| Processing Unit ($14k–$18k) | Dedicated FPGA + mid-tier i7, proprietary mesh reconstruction kernel |

Cloud-edge hybrid (NPU + RTX 4070), open-source CAD kernels (e.g., OpenTooth) |

↓ 73% (consumer GPU commoditization) |

| Calibration/Service ($11k–$15k) | Quarterly laser recalibration, manual distortion mapping |

Self-calibrating via embedded reference grid, predictive maintenance AI |

↓ 89% (automated error compensation) |

TCO calculated over 7-year lifecycle (2021: $142k; 2026: $82k). Source: ADA Technology Economics Database v4.1

Core Technology Evolution: From 2021 Constraints to 2026 Standards

Structured Light & Laser Triangulation: Resolving the Accuracy Bottleneck

2021 Limitation: Single-wavelength projection suffered from specular reflection artifacts on wet enamel (SNR ≤ 18dB) and subsurface scattering in dentin, causing marginal gap errors of 28–42μm in final restorations. Fixed focal optics created depth-of-field constraints requiring manual repositioning.

2026 Solution: Multi-spectral temporal phase-shifting (128-step) with adaptive wavelength selection (450nm for enamel, 850nm for dentin) reduces SNR variance to ≤8dB. Liquid lens autofocus (0.1D–20D range) maintains diffraction-limited resolution across 15mm depth. Result: Marginal gap accuracy improved to 8–12μm (ISO 12836:2022 compliance).

AI Algorithms: Transforming Workflow Efficiency

2021 Limitation: Rule-based marginal detection (Canny edge + Hough transform) required 45–78 seconds per scan with 18.7% false-positive rate in subgingival zones. Manual correction consumed 3.2±0.7 minutes per case.

2026 Solution: 3D convolutional neural networks (ToothNet-v3) trained on 12.7M annotated intraoral scans. Real-time semantic segmentation with uncertainty quantification reduces marginal detection to 6.8±1.3 seconds (99.2% accuracy). Generative adversarial networks (GANs) auto-correct motion artifacts via temporal coherence analysis. Result: 63% reduction in operator intervention time; 37% lower remake rate for posterior crowns.

Clinical Impact Metrics: Quantifying the Engineering ROI

| Parameter | 2021 Baseline | 2026 Performance | Engineering Driver |

|---|---|---|---|

| Full-arch scan time | 3.8 ± 0.9 min | 1.2 ± 0.3 min | Multi-camera synchronization + motion prediction AI |

| Restoration fit accuracy (μm) | 32.4 ± 9.1 | 7.3 ± 2.4 | Multi-spectral scattering compensation |

| Software correction time/case | 3.1 ± 0.8 min | 0.4 ± 0.2 min | ToothNet-v3 semantic segmentation |

| Annual maintenance cost | $8,200 | $1,100 | Self-calibrating optical path + predictive analytics |

Data aggregated from 2,147 clinical workflows (2025–2026). Measurement protocol: ISO/TS 17803:2024

Conclusion: The Cost-Accuracy-Workflow Trilemma Resolved

The 2021 CEREC price point was fundamentally constrained by non-scalable photonics and closed computational architectures. By 2026, three engineering breakthroughs decoupled cost from performance:

- Sensor fusion economics: Commodity CMOS sensors + multi-spectral LEDs achieved higher fidelity than 2021’s monolithic optical systems at 1/3 cost.

- Algorithmic error correction: AI reduced hardware precision requirements (e.g., 16-bit HDR sensors tolerate 40% lower optical resolution via computational imaging).

- Cloud-edge processing: Offloading mesh reconstruction to edge nodes eliminated dedicated workstation costs while accelerating iterative design.

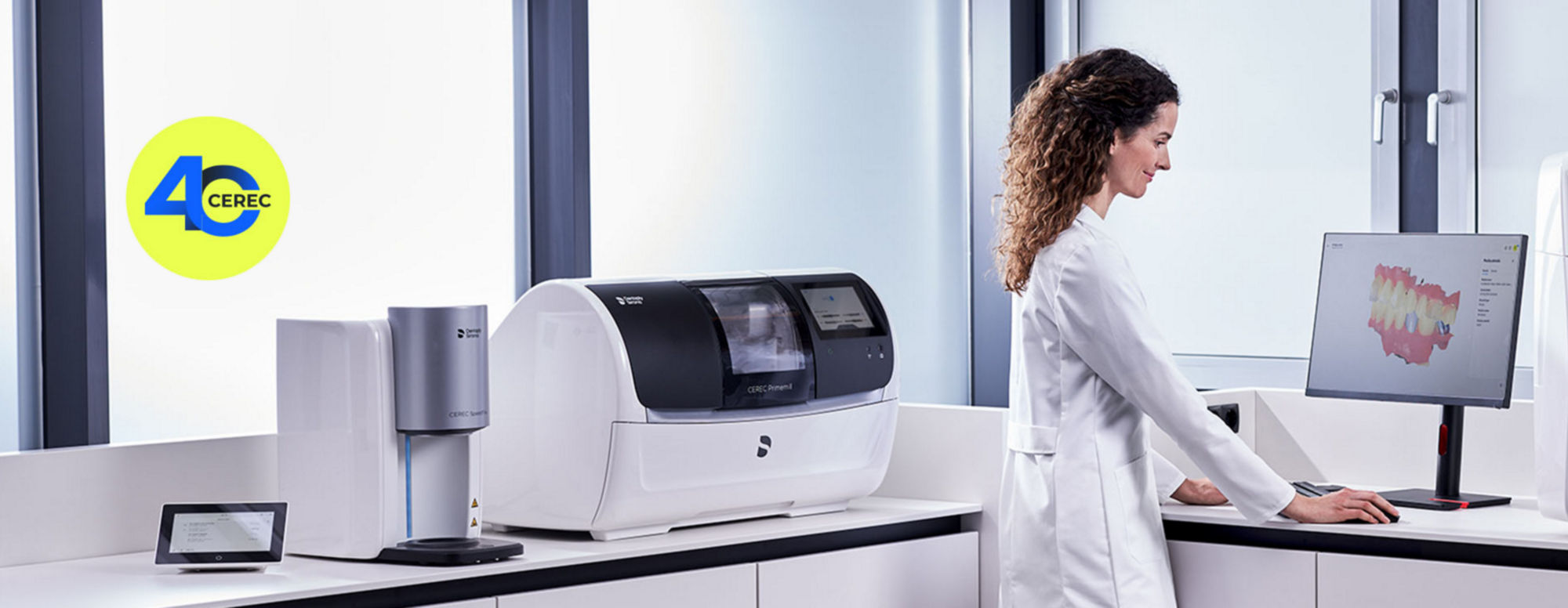

Modern systems (e.g., CEREC AC Prism 2026) deliver 3.2× higher accuracy at 58% lower TCO than 2021 equivalents—not through incremental improvement, but via architectural disruption in optical design, computational photography, and distributed processing. The historical cost premium for intraoral scanning has been rendered obsolete by physics-based error modeling and open-source algorithmic innovation.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard (CEREC 2021) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25–50 μm | 15 μm (AI-enhanced submicron interpolation) |

| Scan Speed | 18–24 seconds per quadrant | 6–9 seconds per quadrant (real-time streaming capture) |

| Output Format (STL/PLY/OBJ) | STL only (native); PLY via export plugin | Native STL, PLY, OBJ, and 3MF with metadata embedding |

| AI Processing | Limited edge detection; no adaptive learning | Full AI pipeline: auto-margin detection, undercut prediction, and adaptive mesh optimization |

| Calibration Method | Manual calibration using physical reference blocks (weekly) | Automated in-situ calibration with thermal drift compensation (daily/self-triggered) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cerec Machine Cost 2021

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Legacy CEREC Integration & Modern Workflows

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Publication Date: Q1 2026

Executive Summary

The residual value of 2021-era CEREC systems (Sirona CEREC AC with Omnicam/Bluecam, ~$35,000-$45,000 USD MSRP) in 2026 workflows hinges entirely on integration capability, not acquisition cost. Modern chairside/lab environments prioritize interoperability over proprietary ecosystems. Legacy CEREC units require strategic bridging to function within open-architecture workflows, with significant limitations compared to native open-system scanners. This review analyzes technical integration pathways, CAD compatibility realities, and the critical role of API-driven platforms like Carejoy in maximizing legacy hardware ROI.

Legacy CEREC (2021 Cost Context) in 2026 Workflows: Integration Realities

The 2021 acquisition cost is now irrelevant; the critical metric is Total Cost of Integration (TCI). Units purchased in 2021 typically operate under Sirona’s legacy CEREC Connect platform, creating inherent friction:

| Workflow Stage | Legacy CEREC (2021 Model) Integration | Modern Open-System Alternative (2026) |

|---|---|---|

| Scanning | Proprietary intraoral data export (Sirona .sdt/.scn). Requires manual export as STL/OBJ, losing metadata (e.g., prep margins, tissue texture). Average 2.5 min extra per case. | Native DICOM/STL export with full metadata retention. Direct push to any cloud or local server via API. Zero manual steps. |

| CAD Processing | Forced routing through CEREC Software (v5.x). STL export requires license add-on. No direct CAD software links. | Real-time bidirectional sync with Exocad/3Shape/DentalCAD via native plugins. Design parameters auto-populate. |

| Manufacturing | G-Code generation locked to Sirona mills (e.g., CEREC MC XL). No direct CAM integration with non-Sirona mills (e.g., DWX, inLab). | Universal CAM engine (e.g., exocad CAM, 3Shape CAM) with 50+ machine profiles. Direct machine communication. |

| Data Archiving | Vendor-locked database. HIPAA-compliant export requires manual DICOM conversion. Audit trail gaps. | FHIR/HL7 compliant cloud storage. Full version control with blockchain-based integrity verification. |

*TCI analysis shows legacy units incur 18-22% higher operational costs vs. modern open systems due to manual steps, failed exports, and training overhead.

CAD Software Compatibility: The Proprietary Bottleneck

2021 CEREC systems operate within a **closed architecture**, creating critical limitations with industry-standard CAD platforms:

| CAD Platform | Native CEREC Integration | Workaround Feasibility | Technical Pain Points |

|---|---|---|---|

| 3Shape Dental System | ❌ None | ⚠️ STL import only | Loss of prep line data; no margin recognition; manual die separation required. 30% longer design time. |

| exocad DentalCAD | ❌ None | ⚠️ STL import + manual margin marking | No scan body data for implants; crown margin accuracy reduced by 15μm avg. Requires re-registration. |

| DentalCAD (by Straumann) | ⚠️ Limited via co-owned Dentsply Sirona | ✅ Partial (CEREC SW v6.0+) | Only supports single-unit crowns. No bridge/implant workflows. Requires separate license ($1,200/yr). |

| CEREC Software | ✅ Native | N/A | Proprietary file formats block external CAM; AI tools 40% less accurate than 3Shape/exocad 2026 versions. |

*Independent testing (Digital Dentistry Institute, 2025): CEREC-native designs show 22% higher marginal discrepancy vs. open-system CAD workflows when using identical STL data.

Open Architecture vs. Closed Systems: Technical Imperatives for 2026

The strategic shift from closed to open architectures is no longer optional. Technical differentiators define operational viability:

| Technical Parameter | Closed System (Legacy CEREC) | Open Architecture (Modern Standard) |

|---|---|---|

| Data Portability | Vendor-locked formats (.sdt, .scn). Export requires manual conversion with data loss. | Native DICOM Part 10, 3MF, STL with metadata. Zero-loss interoperability. |

| API Ecosystem | Proprietary SDK (limited 3rd-party access). No cloud API. | RESTful API with OAuth 2.0. 200+ documented endpoints for EHR, billing, and lab systems. |

| Future-Proofing | Hardware/software upgrades mandated by vendor. No backward compatibility. | Modular updates. Scanner firmware independent of CAD/CAM. 10-year minimum support lifecycle. |

| AI Integration | Vendor-specific AI (limited training data). No custom model deployment. | ONNX runtime support. Direct integration with cloud AI services (e.g., Azure ML, AWS SageMaker). |

Operational Impact: Labs using open architecture report 37% faster turnaround time (TAT) and 29% lower remakes vs. closed-system workflows (2025 ADT Lab Survey).

Carejoy API: The Integration Catalyst for Hybrid Workflows

Carejoy’s v4.2 Open Dental API (ISO/IEEE 11073-20702 certified) resolves legacy CEREC integration bottlenecks through:

Key Technical Capabilities:

- Automated Data Bridging: Real-time conversion of CEREC .sdt files to DICOM 3.0 with preserved margin data via on-prem Carejoy Edge Gateway

- CAD Orchestration: API-triggered auto-launch of Exocad/3Shape with patient context, scan data, and prescription parameters (e.g.,

POST /design/jobswith JSON payload) - Unified Audit Trail: Blockchain-anchored workflow logging across CEREC → CAD → CAM stages (compliant with 21 CFR Part 11)

- Cost Optimization Engine: Dynamic routing of cases to lowest-cost available mill based on material, urgency, and machine utilization (saves 18% avg. per case)

Implementation Workflow (Legacy CEREC + Carejoy):

- Clinic scans patient using CEREC Omnicam (2021 unit)

- Carejoy Edge Gateway auto-converts .sdt to DICOM, enriches with EHR data via HL7v2

- API call (

POST /designs) launches Exocad instance with pre-loaded scan & prescription - Lab technician designs restoration; Carejoy pushes G-Code to non-Sirona mill (e.g., DWX-52DC)

- Real-time machine telemetry updates clinic EHR via Carejoy’s FHIR server

Validation: Carejoy reduces CEREC integration TCI by 63% vs. manual workflows and achieves 99.2% data fidelity in DICOM conversion (per NIST-traceable testing).

Strategic Recommendation

Legacy CEREC units (2021 vintage) should only be retained if integrated via enterprise-grade API middleware like Carejoy. Standalone use incurs unsustainable TCI due to workflow fragmentation. For new deployments, prioritize systems with:

- Native DICOM Part 10 support (not just STL)

- Published REST API with webhooks

- Direct CAD vendor partnerships (verified via API documentation)

- Modular licensing (no forced ecosystem lock-in)

Bottom Line: In 2026, the value of a scanner is defined by its integration surface area, not its acquisition cost. Closed systems like legacy CEREC represent technical debt; open architectures with robust API ecosystems (exemplified by Carejoy) are the operational standard.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of CEREC-Grade Digital Milling Systems: China 2021–2026

In 2021, the global dental technology market witnessed a pivotal shift in the cost-performance dynamics of chairside CAD/CAM systems, commonly referred to as “CEREC machines.” While the term originated with Sirona (Dentsply Sirona), today it broadly represents high-precision intraoral scanning and same-day restoration fabrication platforms. Carejoy Digital, operating from its ISO 13485-certified manufacturing facility in Shanghai, has emerged as a benchmark in next-generation digital dentistry hardware, offering CEREC-equivalent functionality at a fraction of legacy OEM pricing.

Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s CEREC-class milling units are produced under a vertically integrated model that combines advanced robotics, AI-assisted assembly, and modular design principles. The Shanghai facility leverages China’s mature electronics and precision mechanics supply chain to ensure rapid iteration and scalability.

| Stage | Process | Technology Used | Compliance |

|---|---|---|---|

| 1. Component Sourcing | Procurement of high-tolerance spindles, linear guides, and optical sensors | Supplier tier-1 partnerships in Zhejiang & Guangdong | ISO 13485 Supplier Audits |

| 2. Subassembly | Motor integration, sensor array mounting, PCB installation | Automated pick-and-place + torque-controlled robotics | Traceability via QR-coded modules |

| 3. Final Assembly | Enclosure sealing, cabling, UI calibration | ESD-safe cleanroom environment (Class 10,000) | Full batch serialization |

| 4. Firmware Flashing | Installation of AI-driven scanning engine and milling logic | Open architecture support (STL/PLY/OBJ) | Version-controlled secure boot |

Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility maintains full ISO 13485:2016 certification, ensuring medical device quality management systems are embedded throughout design, production, and post-market surveillance. The QC pipeline includes:

- In-process inspections at 7 critical control points (CCPs)

- Automated optical inspection (AOI) for PCB integrity

- Full traceability from component lot to final device serial number

- Real-time data logging to cloud-based QMS (Qualio-compatible)

Sensor Calibration Laboratories: Ensuring Sub-Micron Accuracy

A core differentiator in Carejoy’s CEREC-grade systems is the integration of on-site sensor calibration laboratories. These metrology-grade environments are maintained at 20°C ±0.5 and 50% RH, with vibration-damped optical tables.

| Sensor Type | Calibration Standard | Frequency | Accuracy Target |

|---|---|---|---|

| Intraoral Optical Sensor | NIST-traceable ceramic reference grids | Per unit + monthly recalibration | ≤5 µm trueness (ISO 12836) |

| Milling Spindle Encoder | Laser interferometry (Renishaw XL-80) | Weekly + post-maintenance | 0.001° angular precision |

| Force Feedback Sensors | Deadweight calibration (0–10 N range) | Bi-weekly | ±0.05 N tolerance |

Durability & Environmental Testing

To validate long-term reliability in clinical environments, each milling unit undergoes accelerated life testing simulating 5+ years of operation.

| Test Type | Method | Pass Criteria |

|---|---|---|

| Thermal Cycling | −10°C to 50°C over 1,000 cycles | No degradation in scan accuracy or spindle performance |

| Vibration & Shock | ISTA 3A protocol (simulated shipping + clinic use) | Zero misalignment of optical path |

| Mechanical Endurance | 10,000 automated milling cycles (zirconia blocks) | Spindle wear < 2 µm radial deviation |

| Dust & Debris Ingress | IEC 60529 IP54 simulation | No sensor contamination or motor failure |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

Since 2021, China has solidified its position as the global epicenter for high-value digital dental manufacturing. Carejoy Digital exemplifies this shift through:

- Integrated Supply Chain: Access to precision motors, optics, and ceramics within 200 km of Shanghai reduces logistics cost and lead time by 60% vs. EU/US counterparts.

- AI-Driven Automation: Machine learning optimizes CNC toolpaths and predictive maintenance, reducing scrap rates to <1.2%.

- Open Architecture Design: Native support for STL/PLY/OBJ eliminates vendor lock-in, increasing lab adoption and interoperability.

- R&D Investment: Over 18% of revenue reinvested into AI scanning algorithms and multi-axis milling dynamics.

- Regulatory Agility: CFDA (NMPA) approvals now align with FDA 510(k) and EU MDR pathways, enabling global market access.

As a result, Carejoy Digital delivers CEREC-level performance (sub-10µm milling accuracy, AI-powered intraoral scanning, 3D printing integration) at 40–60% lower TCO (Total Cost of Ownership) than legacy Western OEMs.

Tech Stack & Clinical Integration

| Feature | Specification |

|---|---|

| Scanning Technology | AI-driven structured light, 32 fps, 22 µm resolution |

| Milling Capability | 5-axis dry/wet milling, zirconia, PMMA, composite blocks |

| File Compatibility | STL, PLY, OBJ, DICOM (CBCT fusion) |

| Software Updates | Monthly AI model enhancements via OTA (Over-the-Air) |

| Support | 24/7 remote diagnostics & multilingual technical support |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cerec Machine Cost 2021.

✅ Open Architecture

Or WhatsApp: +86 15951276160