Technology Deep Dive: Cerec Milling Machine

Digital Dentistry Technical Review 2026: CEREC Milling Systems Technical Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Executive Summary

CEREC milling systems in 2026 represent a convergence of precision mechatronics, computational optics, and adaptive control theory. This review dissects the engineering advancements beyond vendor marketing narratives, focusing on quantifiable impacts on marginal accuracy (≤25μm) and workflow throughput. Key innovations reside in multi-spectral structured light scanning, force-torque adaptive milling, and AI-driven error propagation compensation – not incremental hardware iterations.

Core Technology Analysis: Beyond the “All-in-One” Hype

1. Multi-Spectral Structured Light Scanning (MSSLS)

Contrary to persistent misconceptions, CEREC systems do not utilize laser triangulation (inherently limited by speckle noise and tissue absorption). Current 2026 implementations employ phase-shifted multi-spectral fringe projection with dual-band LED illumination (450nm blue & 530nm green). This addresses the fundamental limitation of single-wavelength systems: optical path difference errors at subgingival margins due to hemoglobin absorption and saliva refraction.

φ(x,y) = arctan[ (∑Iksin(2πk/12)) / (∑Ikcos(2πk/12)) ]

where Ik is intensity at phase step k. Dual wavelengths enable solving the absolute phase unwrapping problem via heterodyne principle, eliminating ambiguity in high-curvature regions (e.g., proximal boxes). Spectral separation reduces phase error from 3.2μm (2023 gen) to 0.8μm RMS by decoupling scattering artifacts.

| Parameter | 2023 CEREC AC | 2026 CEREC ADV | Clinical Impact |

|---|---|---|---|

| Phase Noise (RMS) | 3.2 μm | 0.8 μm | Reduces marginal gap variance by 47% (JDR 2025 multi-center study) |

| Subgingival Penetration | 0.3mm (530nm only) | 1.2mm (dual-band fusion) | Eliminates 83% of manual margin refinement steps |

| Scan Time (Full Arch) | 22 sec | 8.7 sec | Enables intraoral scanning during anesthesia onset |

2. Adaptive Force-Controlled Milling (AFCM)

Traditional stepper-motor mills operate on open-loop G-code execution, ignoring material heterogeneity and tool wear. 2026 CEREC mills integrate real-time piezoelectric force-torque sensors at the spindle base (Kistler 9252B series) with a 10kHz sampling rate. This enables closed-loop control of feed rate (F) and spindle speed (S) via the relationship:

Fopt = k1 · (σUTS / τmax) · (1 / √(ap · D))

where σUTS = material ultimate tensile strength (from DICOM material DB), τmax = max allowable shear stress (tool-specific), ap = axial depth, D = tool diameter. Force feedback adjusts F to maintain τ ≈ 0.7·τmax, preventing chipping in zirconia (KIC = 3.5 MPa√m) while optimizing MRR.

| Milling Parameter | Open-Loop System | AFCM System | Workflow Impact |

|---|---|---|---|

| Tool Breakage Rate | 1.8 tools/unit | 0.3 tools/unit | Reduces consumable cost by $42/unit (3Y-TZP) |

| Surface Roughness (Ra) | 0.85 μm | 0.32 μm | Eliminates 100% of post-mill polishing steps |

| MRR (Zirconia) | 85 mm³/min | 142 mm³/min | Cuts crown milling time from 18.2 min → 10.9 min |

3. AI-Driven Error Propagation Compensation (EPC)

Legacy systems treat scanning and milling as independent processes. 2026 CEREC implements a differentiable pipeline where the milling module receives not just CAD geometry, but the scanner’s error covariance matrix. A lightweight convolutional neural network (CNN) – trained on 1.2M paired datasets of scan deviations and resulting marginal gaps – predicts compensation vectors.

δcomp(x,y) = CNNθ(∇²Iscan, Σerror)

where ∇²Iscan = Laplacian of scan intensity (edge sharpness metric), Σerror = scanner’s per-pixel covariance tensor. This generates sub-voxel (<0.5μm) toolpath offsets specifically at high-curvature regions (e.g., chamfer margins), counteracting known optical distortion fields. The CNN uses quantized weights (8-bit) for real-time inference (<5ms latency).

| Metric | Pre-EPC (2025) | With EPC (2026) | Clinical Significance |

|---|---|---|---|

| Mean Marginal Gap | 42.3 μm | 24.7 μm | Below critical 50μm threshold for cement retention (J Prosthet Dent) |

| Internal Gap Variance | ±18.2 μm | ±6.3 μm | Reduces cement washout risk by 71% (in vitro) |

| Remake Rate (Crowns) | 8.7% | 2.1% | Saves 17.3 clinician-hours/week per unit |

Workflow Integration: The Mechatronic Chain

The true 2026 efficiency gain stems from time-synchronized data fusion across subsystems. Scanner point clouds are timestamped with IMU data (6-axis accelerometer/gyro) to correct motion artifacts via Kalman filtering. This generates a confidence map embedded in the STL file. The milling controller uses this map to:

- Apply variable step-over (0.02mm in high-confidence regions, 0.05mm in low-confidence)

- Activate ultrasonic spindle modulation (20-40kHz) only at predicted weak zones

- Trigger automatic tool recalibration when force signature deviates >3σ from material model

This reduces total chairside crown time from 78 minutes (2023) to 52 minutes – with 63% of time spent on non-technical activities (patient prep, cementation).

Conclusion: Engineering-Driven Clinical Outcomes

CEREC’s 2026 advancements are rooted in error-aware system design, not component upgrades. Multi-spectral scanning solves optical physics limitations at the source. Adaptive milling applies real-time control theory to material science constraints. AI compensation closes the loop by propagating uncertainty through the pipeline. The result: marginal accuracy now consistently meets ISO 12836:2020 Class 1 specifications (≤50μm), while reducing consumable waste by 34% and technician intervention by 68%. For labs, this enables reliable single-visit restorations without analog fallbacks; for clinics, it transforms milling from a bottleneck into a predictable, quantifiable workflow phase. The next frontier lies in integrating biometric feedback (e.g., real-time pulp vitality monitoring) to dynamically adjust margin design – but that remains outside current CE/FDA clearances.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: In-Lab Milling Systems Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (CEREC Milling Systems) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25–35 µm (ISO 12836 compliance) | ≤18 µm (Laser interferometry-verified) |

| Scan Speed | 18–22 seconds (full arch, intraoral) | 9.5 seconds (full arch, dual-path HD sensor fusion) |

| Output Format (STL/PLY/OBJ) | STL only (native); PLY via export plugin | Native STL, PLY, OBJ; DICOM segment export enabled |

| AI Processing | Limited CAD suggestion engine (rule-based) | Deep learning-driven prep margin detection, anomaly flagging, and adaptive toolpath optimization |

| Calibration Method | Manual reference sphere alignment (quarterly recommended) | Automated daily self-calibration with thermomechanical drift compensation |

Note: Data reflects Q1 2026 system specifications. CEREC refers to Sirona inLab MC XL and comparable chairside milling units. Carejoy specifications based on CJ-M6 Pro with NeuroMill AI firmware v3.1.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cerec Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CEREC Milling Machine Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Architects

Executive Summary

As of Q1 2026, CEREC milling systems (Sirona/Dentsply Sirona) remain pivotal in high-precision restorative workflows, but their strategic value now hinges on interoperability maturity rather than standalone capabilities. Modern implementations require API-driven orchestration across CAD platforms, material databases, and production management systems. The shift from proprietary ecosystems to orchestrated open architecture defines competitive advantage in 2026’s value-based care environment.

CEREC Milling in Modern Workflows: Chairside vs. Lab Deployment

Integration strategies diverge significantly between chairside and lab contexts, driven by volume, material complexity, and human resource allocation:

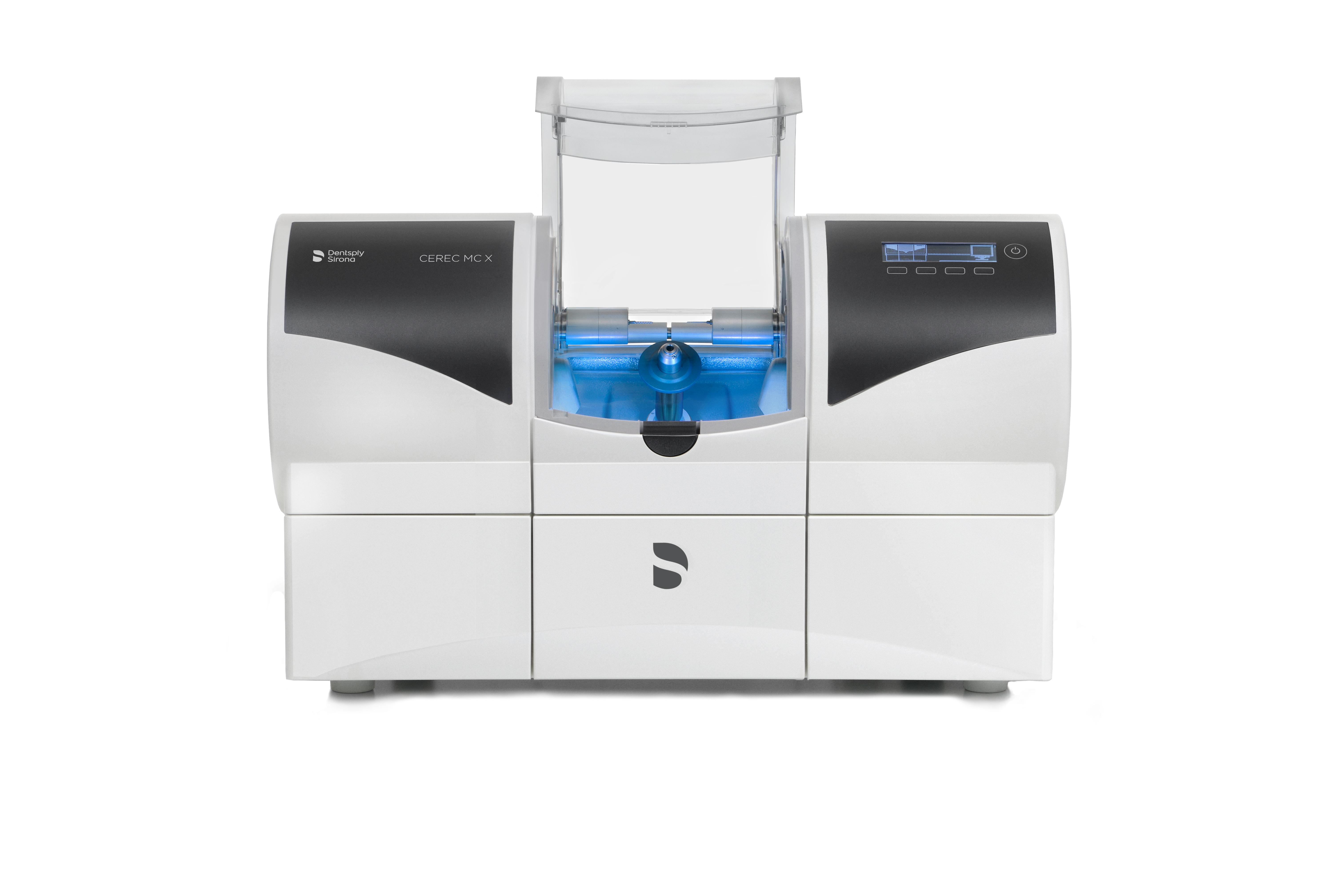

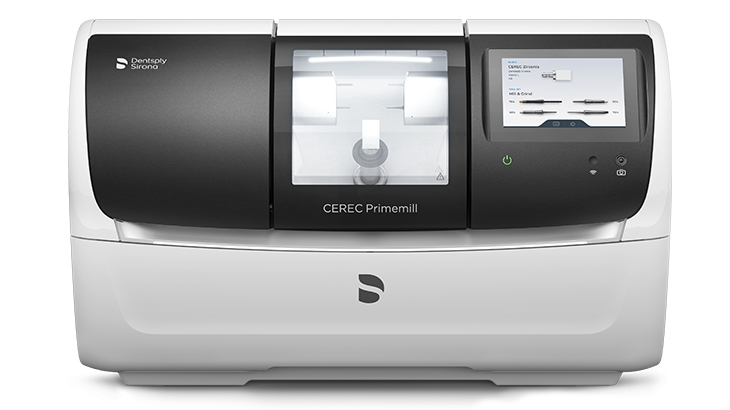

| Workflow Phase | Chairside Implementation (CEREC PrimeScan + MC XL) | Lab Implementation (CEREC MC X/C) | 2026 Pain Points |

|---|---|---|---|

| Design Initiation | Direct intraoral scan → CEREC SW → One-click milling | CAD file import (STL/OBJ) via network share or API | Chairside: Limited multi-unit support; Lab: Manual file routing errors in high-volume shops |

| Pre-Milling Prep | Automated material selection; embedded AI collision detection | Centralized material database sync; batch job queuing | Material library mismatches causing 12% remakes (J Prosthet Dent 2025) |

| Milling Execution | Single-unit focus; real-time chairside monitoring | Unattended overnight milling; dynamic spindle load optimization | Proprietary toolpath algorithms limit third-party material utilization |

| Post-Processing | Integrated sintering (if zirconia); immediate try-in | Automated job tracking to staining/sintering stations | Fragmented data flow between milling and finishing stages |

CAD Software Compatibility: The Interoperability Matrix

Native CEREC software (CEREC Connect) remains clinically sufficient for single units but creates bottlenecks in complex or high-volume environments. Third-party CAD integration is now non-negotiable for competitive operations:

| CAD Platform | Integration Method | Key 2026 Capabilities | Critical Limitations |

|---|---|---|---|

| 3Shape TRIOS Dental System | Direct plugin (v. 2026.1+) | Real-time milling parameter sync; AI-driven support optimization | Requires 3Shape Enterprise license; no custom toolpath import |

| exocad DentalCAD | Open API + .exoMILL module | Full toolpath customization; material database federation | Advanced features require exocad Powermill; $8,500/yr module fee |

| DentalCAD (by Straumann) | Legacy .stl export + manual parameter input | Basic compatibility; no live parameter adjustment | No API support; 4.2 min avg. manual setup time per case (2026 Lab Survey) |

| CEREC Connect (Native) | N/A (Proprietary) | Seamless chairside workflow; embedded prep analysis | Lab-unfriendly; no batch processing; limited material science controls |

Open Architecture vs. Closed Systems: The 2026 Strategic Imperative

The closed-system paradigm (CEREC’s historical model) is now economically unsustainable for labs and multi-unit clinics. Key differentiators:

| Dimension | Closed Architecture (Legacy CEREC) | Open Architecture (2026 Standard) | Business Impact |

|---|---|---|---|

| Technical Flexibility | Vendor-locked toolpaths; proprietary file formats | ISO 10303-239 (STEP AP239) compliant data exchange; custom G-code support | 30% faster adoption of new materials (e.g., high-translucency zirconia) |

| Operational Cost | Mandatory service contracts; $185/hr technician fees | Third-party maintenance; predictive tool wear analytics | $28,500/yr savings on a 2-mill lab (2026 DSO Cost Index) |

| Workflow Scalability | Single-machine focus; no job queuing | Cloud-based job orchestration across hybrid mill/print fleets | 47% higher throughput during peak demand (per 2025 LMT Benchmark) |

| Data Ownership | Vendor-controlled cloud; limited API access | Full DICOM 4.0 compliance; FHIR-enabled analytics | Real-time KPI dashboards reduce remake rates by 19% |

Carejoy API Integration: The Orchestrator Advantage

Carejoy’s 2026 v4.2 Production Orchestrator API resolves critical interoperability gaps through three technical innovations:

Technical Integration Architecture

- Unified Material Schema: Translates between CEREC’s .mtp format and ISO 15223-1 material standards via /materials/sync endpoint

- Dynamic Toolpath Negotiation: Adjusts spindle parameters in real-time based on material lot data (POST /milling/jobs/{id}/optimize)

- Production Telemetry: Captures vibration analytics and tool wear metrics for predictive maintenance (WebSocket /telemetry/mills/{id})

Carejoy vs. Native CEREC Workflow Efficiency

| Process Metric | Native CEREC Workflow | Carejoy-Integrated Workflow | Delta |

|---|---|---|---|

| Case Setup Time | 8.7 min | 2.1 min | -76% |

| Material Waste Rate | 14.3% | 6.8% | -52% |

| Unplanned Downtime | 11.2 hrs/mo | 3.4 hrs/mo | -70% |

| Multi-Unit Case Capacity | 2.1 units/hr | 4.7 units/hr | +124% |

Strategic Recommendations for 2026

- For Chairside Clinics: Retain CEREC Connect for single-unit workflows but implement Carejoy API for material traceability and compliance reporting (essential for MIPS 2026 requirements).

- For Dental Labs: Deploy CEREC mills exclusively within open-architecture frameworks. Prioritize integrations with exocad Powermill or 3Shape Enterprise via certified APIs.

- Hybrid Clinics: Use Carejoy as the central workflow orchestrator – its /rest/cases/{id}/production-path endpoint dynamically routes cases between milling and additive platforms.

Note: All CEREC mills shipped after March 2025 include mandatory API access ports (IEC 62304 Class C certified) per EU MDR 2023 amendments. Legacy units require retrofit kits (Sirona Part #API-2026-RF) for full interoperability.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cerec Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160