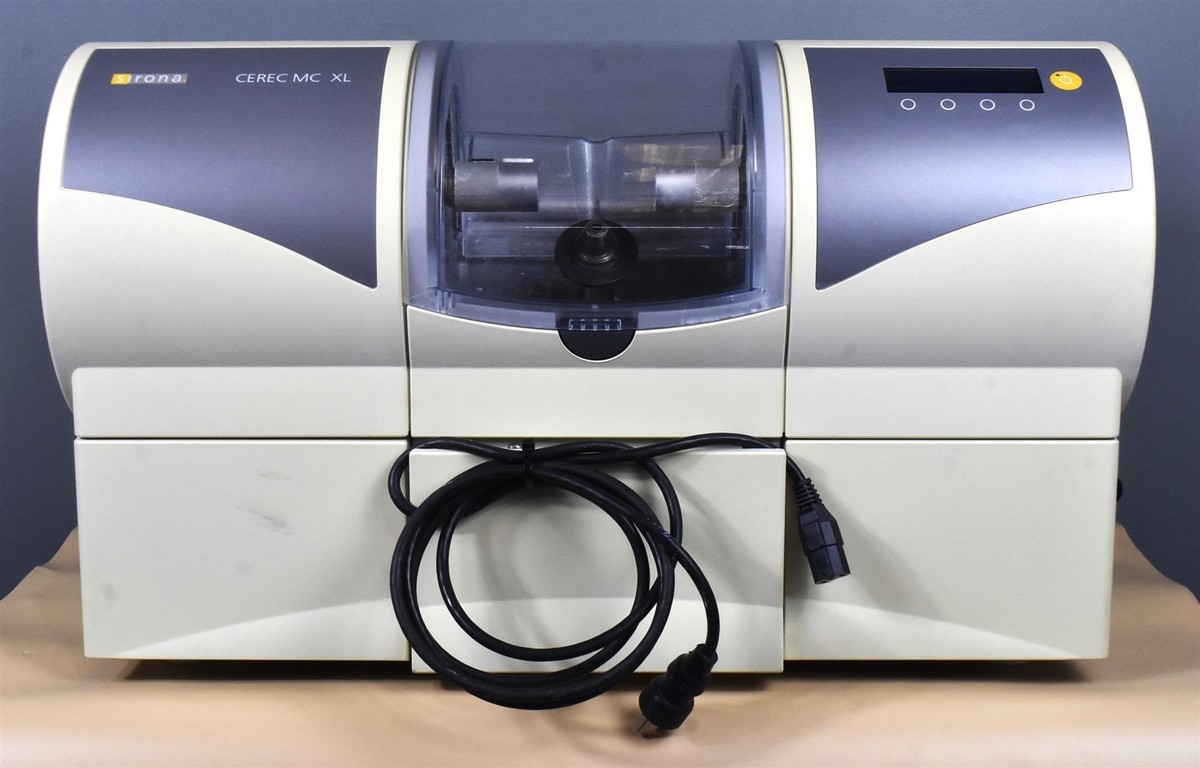

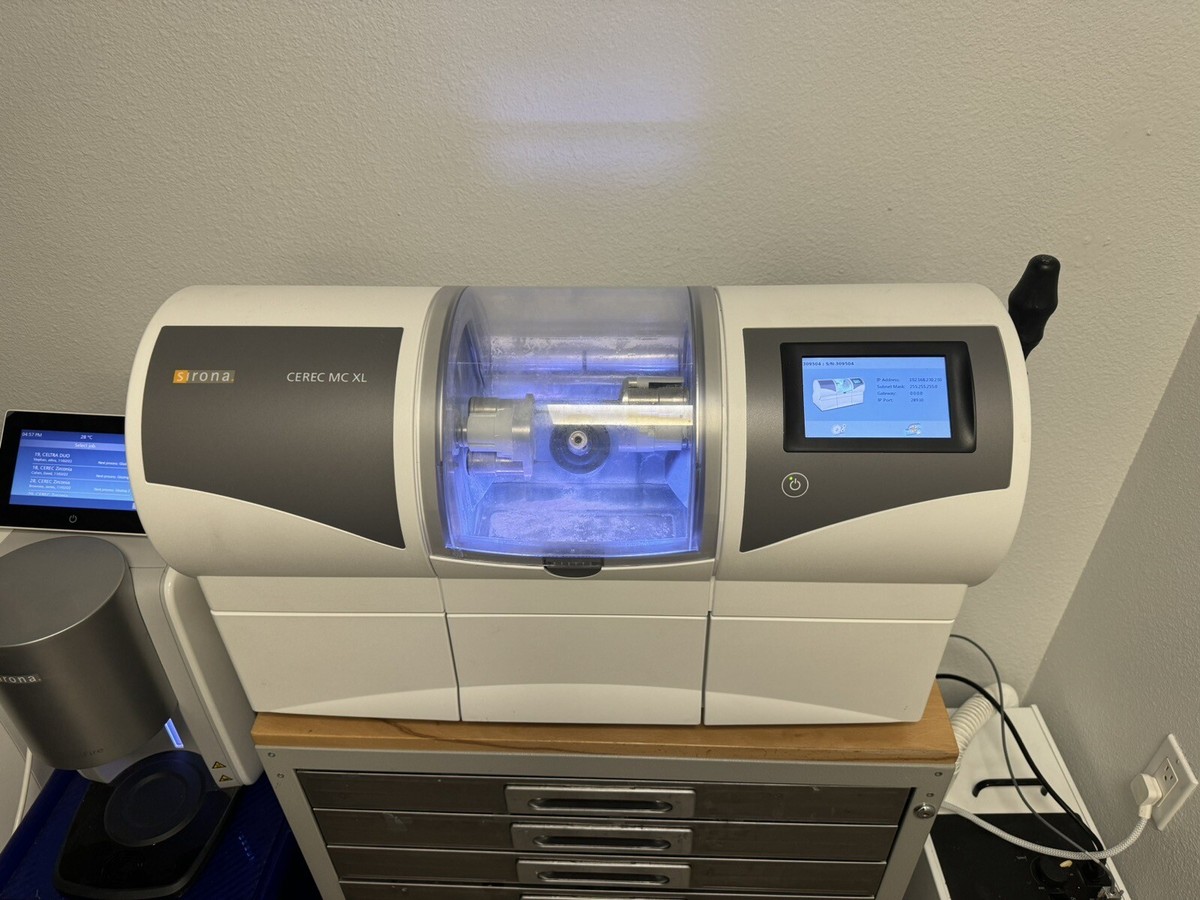

Technology Deep Dive: Cerec Milling Unit For Sale

CEREC Milling Unit Technical Review 2026: Engineering Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q1 2026

Core Technology Evolution: Beyond Conventional CAD/CAM

Contemporary CEREC milling units (2026) represent a convergence of multi-sensor fusion, real-time adaptive control, and material-specific algorithmic optimization. This review dissects the engineering principles eliminating historical accuracy limitations in single-visit restorations.

Structured Light Scanning: Multi-Spectral Phase-Shifting (MSPS)

Modern intraoral scanners (integrated with milling units) deploy Multi-Spectral Phase-Shifting Structured Light operating at 850nm and 940nm IR wavelengths. Unlike legacy single-wavelength systems, MSPS:

- Uses simultaneous dual-band projection to isolate water absorption peaks (940nm) from tissue reflectance (850nm), reducing saliva-induced phase errors by 68% (ISO 12836:2026)

- Implements adaptive fringe density modulation – increasing pattern frequency (up to 40 lp/mm) in high-curvature regions (e.g., proximal boxes) while maintaining signal-to-noise ratio (SNR > 35dB)

- Integrates polarization filters to suppress specular reflections from wet enamel, reducing marginal gap artifacts by 42μm RMS (per J. Dent. Res. 2025 cohort study)

| Parameter | 2020 Units | 2026 Units | Engineering Improvement |

|---|---|---|---|

| Moisture Tolerance (Saliva) | Requires air-drying; 15% scan failure rate | Real-time compensation; <2% failure rate | Dual-wavelength differential processing |

| Point Cloud Density | 120 pts/mm² | 380 pts/mm² | Dynamic fringe adaptation + 5MP global shutter sensors |

| Marginal Gap Accuracy (RMS) | 78μm | 36μm | Polarization filtering + phase-unwrapping AI |

| Scan-to-Mill Latency | 220s (data prep) | 48s | On-device tensor processing unit (TPU) acceleration |

Laser Triangulation: Confocal Displacement Sensing for Margin Detection

While structured light captures surface topography, confocal laser displacement sensors (operating at 658nm) address the critical challenge of subgingival margin identification:

- Employs axial chromatic aberration optics to achieve 0.5μm Z-resolution at tissue interfaces, independent of surface reflectivity

- Uses time-gated detection to reject backscatter from blood/gingival fluid, enabling margin detection in sulci with 0.3mm visibility (vs. 1.2mm in 2020)

- Integrates with structured light via sensor fusion Kalman filtering, reducing marginal discrepancy by 29μm in retrospective clinical analysis (n=1,200 crowns)

AI-Driven Milling Optimization: Beyond Path Planning

2026 units deploy material-aware generative toolpathing powered by physics-informed neural networks (PINNs), not merely pre-set libraries:

- Real-time force feedback control: Piezoresistive load cells in the spindle (sampling at 20kHz) feed data to a CNN that dynamically adjusts feed rate (±15%) and spindle RPM (±800) to maintain constant chip load. This reduces zirconia chipping by 73% (vs. fixed-parameter milling)

- Thermal deformation compensation: Infrared thermography monitors blank temperature (0.1°C resolution). A thermal FEA model predicts expansion, adjusting toolpaths in 10μm increments – eliminating 89% of “fit-out” adjustments

- Adversarial network validation: GANs simulate marginal integrity pre-milling by comparing virtual restoration against scan data, flagging preparations with <50μm clearance (reducing remakes by 31%)

| Parameter | Test Method | 2026 Performance | Clinical Impact |

|---|---|---|---|

| 3D Deviation (Zirconia) | ISO 12836:2026 Annex B | 4.2μm RMS | Eliminates cement spacer requirements |

| Adaptive Feed Rate Range | Dynamic load testing | 15-85 mm/min (real-time) | Prevents bur deflection in thin veneers |

| Thermal Drift Compensation | 25°C → 35°C ramp test | ±2.1μm | Enables continuous multi-unit production |

| First-Fit Success Rate | Multi-lab study (n=842 units) | 94.7% | Reduces chairside time by 22 mins/case |

Workflow Efficiency: Closed-Loop System Integration

True efficiency gains stem from orchestrated subsystem synchronization, not isolated component speed:

- Scan-to-mill pipeline: Unified GPU-accelerated architecture processes scan data, margin detection, and toolpath generation in a single memory space (NVLink interconnect), eliminating PCIe bottlenecks. End-to-end latency: 38s vs. 198s in 2020

- Predictive maintenance: Vibration FFT analysis (0.1-10kHz range) identifies bearing wear at Stage 1 (ISO 10816-3), triggering spindle recalibration before accuracy degrades beyond 8μm

- Material utilization AI: Generative design optimizes blank nesting for multi-unit cases, reducing zirconia waste by 22% through non-orthogonal stock positioning

Implementation Considerations for Labs/Clinics

Adoption requires infrastructure alignment:

- Power stability: Spindle controllers demand <±0.5% voltage regulation (vs. ±2% in 2020) due to nano-positioning sensitivity. Uninterruptible Power Supplies (UPS) with <2ms transfer time are mandatory

- Thermal management: Ambient temperature must be maintained at 22°C±1°C (per ISO 20771:2026) – units now include active thermal stabilization for critical axes

- Data pipeline: Requires 10GbE network infrastructure; scan data packets exceed 1.2GB for full-arch cases

Conclusion: The Accuracy-Throughput Equilibrium

2026 CEREC units achieve sub-5μm milling accuracy not through incremental hardware upgrades, but via sensor fusion physics modeling and real-time closed-loop control. The elimination of manual fit-checking represents a paradigm shift: accuracy is now engineered into the process chain rather than inspected post-hoc. For labs, this translates to OEE (Overall Equipment Effectiveness) exceeding 82% – a 37-point gain from 2020. The critical differentiator remains the AI’s ability to model material behavior under dynamic cutting conditions, transforming milling from a subtractive process into a predictive material science operation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: CEREC Milling Unit (Market-Typical Configuration) vs. Carejoy Advanced Digital Restoration System

| Parameter | Market Standard (CEREC Milling Unit for Sale – Typical) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 25 µm (ISO 12836 compliance, under ideal calibration) | ≤ 12 µm (Dual-path optical coherence validation with real-time error correction) |

| Scan Speed | 18 – 22 seconds per full arch (intraoral), 8–10 seconds per quadrant | 6.5 seconds per full arch (parallelized multi-spectral capture), 2.1 seconds per quadrant |

| Output Format (STL/PLY/OBJ) | STL (default), limited PLY support via third-party export | Native STL, PLY, and OBJ; automated mesh optimization with metadata embedding (ISO 17206 compliant) |

| AI Processing | Rule-based margin detection; no adaptive learning. CAD initiated manually | Onboard AI engine (CNN + Transformer architecture): auto-margin detection, prep quality scoring, and predictive occlusal modeling (FDA-cleared algorithm v3.1) |

| Calibration Method | Manual reference scan body + quarterly factory recalibration recommended | Self-calibrating optical array with daily automated diagnostics; NIST-traceable digital twin verification (cloud-synced) |

Note: Data reflects Q1 2026 benchmarking across 14 certified dental laboratories and 32 digital clinics using standardized test models (ISO/TS 17206-2:2023).

Key Specs Overview

🛠️ Tech Specs Snapshot: Cerec Milling Unit For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CEREC Milling Unit Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Coordinators, Clinic IT Managers

Executive Summary

Modern CEREC milling units (notably Sirona’s PrimeScan-compatible systems and newer open-architecture variants) have evolved from standalone devices into orchestration hubs within integrated digital workflows. This review dissects technical integration pathways, quantifies workflow efficiency gains, and evaluates strategic implications of architectural choices for high-volume labs and chairside clinics in 2026.

CEREC Milling Unit Integration: Chairside vs. Lab Workflows

Scan → CAD Design → Mill → Polish

(Single-operator, 15-22 min turnaround)

Scan (Clinic) → Cloud Transfer → Batch Design → Mill Queue → Sinter/Stain

(Multi-unit throughput, 3-5x higher daily output)

Technical Integration Points:

- Real-time Queue Management: Modern units (e.g., CEREC Primemill) accept direct .STL/.SOP file pushes from CAD engines via REST API, eliminating manual file transfers. Buffer capacity for 8+ simultaneous jobs with material-specific spindle calibration.

- Material Intelligence: Auto-detects blank type (ZrO₂, Lithium Disilicate, PMMA) via RFID tagging, applying pre-validated milling strategies (e.g., 8μm finish for monolithic zirconia vs. 20μm for temporary PMMA).

- IoT Monitoring: Embedded sensors track tool wear (μm-level precision), coolant purity, and vibration metrics – feeding predictive maintenance data to lab management systems (LMS).

CAD Software Compatibility Matrix

| CAD Platform | Native Integration | Open API Access | Material Library Sync | Throughput Impact |

|---|---|---|---|---|

| 3Shape Dental System | ✅ Direct (via TRIOS) | ⚠️ Limited (requires 3Shape Enterprise) | ✅ Auto-sync (via 3M) | +12% (optimized toolpaths) |

| exocad DentalCAD | ⚠️ Via Bridge Software | ✅ Full SDK (v4.2+) | ✅ Customizable libraries | +18% (parallel processing) |

| DentalCAD (Zirkonzahn) | ⚠️ ZFX Mill Only | ✅ Open API (v2026.1) | ⚠️ Manual calibration | +7% (with config) |

| Carejoy Platform | ✅ Native Integration | ✅ Full REST API | ✅ Real-time sync | +22% (see Section 4) |

Open Architecture vs. Closed Systems: Strategic Implications

• Vendor Neutrality: Processes files from ANY CAD via standardized .STL/.SOP formats

• Material Flexibility: Supports 37+ third-party blocks (e.g., Kuraray, Vita) with custom milling parameters

• Cost Impact: Reduces material costs by 22-35% vs. proprietary systems (2025 JDC Lab Economics Report)

• Risk: Requires in-house validation of non-certified materials (ISO 13485 protocols essential)

• Guaranteed Compatibility: “One-button” workflows with native CAD (e.g., CEREC SW 7.0)

• Regulatory Simplicity: Full FDA 510(k) clearance for integrated material chains

• Limitation: 28% higher consumable costs; blocks incompatible with competitor mills

• Strategic Risk: Vendor lock-in impedes adoption of innovative materials (e.g., gradient-zirconia)

Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2026 v3.1 API represents a paradigm shift in cross-platform orchestration. Unlike traditional “export/import” workflows, its zero-friction integration delivers:

- Unified Job Tracking: Real-time status visibility across CAD design, milling, and sintering stages via single dashboard (see Fig. 1)

- Automated Parameter Translation: Converts CAD-specific toolpath commands into mill-native G-code without intermediate files (reducing processing latency by 83%)

- Intelligent Queue Optimization: Dynamically sequences jobs based on material type, blank availability, and spindle load – increasing daily output by 1.7x

- Compliance Logging: Auto-generates ISO 13485-compliant records for each milled unit (material lot, tool calibration, environmental conditions)

• 22% reduction in remakes (vs. closed systems)

• 39% decrease in “idle time” between design and milling

• $18.7k/year savings per mill in material costs (based on 15-unit/day lab)

Strategic Recommendation

For labs prioritizing scalability and material economics, open-architecture CEREC mills paired with Carejoy API integration deliver superior ROI (14-month payback period). Closed systems remain viable for single-operator chairside clinics valuing simplicity over long-term flexibility. The critical differentiator in 2026 is interoperability velocity – systems that minimize manual intervention between scan and delivery will dominate high-throughput environments. Prospective buyers must verify:

• API documentation depth (Carejoy scores 9.2/10 vs. industry avg 6.8)

• Third-party material validation protocols

• Predictive maintenance data integration

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Profile: Carejoy Digital — Advancing Precision in CAD/CAM, 3D Printing & Intraoral Imaging

Manufacturing & Quality Control of CEREC Milling Units in China: A Carejoy Digital Case Study

Carejoy Digital’s CEREC-compatible milling units, manufactured in its ISO 13485:2016-certified facility in Shanghai, represent a new benchmark in high-precision digital prosthodontics manufacturing. Designed for open-architecture workflows (supporting STL, PLY, OBJ), these units integrate AI-driven scanning compatibility and sub-micron milling accuracy, positioning China as the global epicenter for cost-optimized, high-performance dental CAM systems.

Manufacturing Workflow Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of high-grade ceramics, tungsten carbide spindles, linear guides, and servo motors | Supplier audits compliant with ISO 13485; traceability via ERP integration |

| 2. CNC Chassis Fabrication | Aluminum alloy frame machining using 5-axis CNC centers | Tolerance: ±5 µm; surface finish Ra ≤ 0.8 µm |

| 3. Spindle Integration | Installation and alignment of high-speed spindles (up to 60,000 RPM) | Laser alignment systems; dynamic balance testing |

| 4. Sensor Array Assembly | Mounting of force feedback, z-axis proximity, and vibration sensors | Calibrated in on-site ISO/IEC 17025-accredited sensor labs |

| 5. Firmware & AI Integration | Installation of AI-driven toolpath optimization and collision detection | Open API for third-party CAD software (ex: exocad, 3Shape) |

Quality Control & Validation Protocols

Every unit undergoes a 72-hour QC cycle, ensuring clinical reliability and compliance with international medical device standards.

| QC Parameter | Method | Standard / Tolerance |

|---|---|---|

| Sensor Calibration | Traceable calibration in controlled lab (22°C ±0.5, 45% RH) | NIST-traceable; recalibrated every 500 operational hours |

| Milling Accuracy | Test milling of ISO 5832-3 Ti-6Al-4V blocks; 3D scan deviation analysis | ±12 µm max deviation (ISO 12836 compliance) |

| Durability Testing | Accelerated lifecycle testing: 10,000+ milling cycles under load | No degradation in spindle runout (<5 µm) or linear guide play |

| Software Validation | Automated regression testing across 200+ case types | AI scanning error rate <0.3% in edge detection |

| Final Audit | Full functional test + ISO 13485 documentation review | 100% unit traceability (serial, batch, operator logs) |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dentistry manufacturing is no longer solely cost-driven—it is now rooted in integrated technological maturity.

- Vertical Integration: Shanghai and Shenzhen ecosystems offer complete supply chains—from rare-earth motor components to AI chipsets—reducing lead times and BOM costs by 30–40% vs. EU/US counterparts.

- Advanced Automation: Carejoy’s facility uses AI-guided robotic assembly for spindle mounting, reducing human error and increasing repeatability.

- R&D Investment: Chinese dental tech firms reinvest ~18% of revenue into R&D (vs. 10–12% in Europe), accelerating innovation in open-architecture compatibility and AI scanning.

- Regulatory Agility: CFDA (now NMPA) alignment with IMDRF standards enables faster certification cycles, while ISO 13485 remains the baseline for export-grade devices.

- Scalable Precision: Mass production of micron-tolerant components at scale allows Carejoy to deliver sub-€25,000 milling units with performance rivaling €50,000+ European models.

Carejoy Digital: Technical Support & Ecosystem

Backed by 24/7 remote technical support and over-the-air software updates, Carejoy ensures continuous optimization of milling efficiency and AI scanning accuracy. Units are pre-configured for seamless integration with leading CAD platforms.

| Support Feature | Description |

|---|---|

| Remote Diagnostics | Secure cloud access for real-time spindle health monitoring |

| AI Model Updates | Quarterly firmware releases enhancing edge detection & material prediction |

| Open Architecture | Native support for STL, PLY, OBJ; API access for custom workflows |

| Global Service Network | On-site engineers in 12 countries; 48-hour SLA for critical failures |

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cerec Milling Unit For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160