Technology Deep Dive: Cheap Intraoral Scanner

Digital Dentistry Technical Review 2026: Cost-Optimized Intraoral Scanners

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Review Focus: Engineering Analysis of Sub-$15k Scanners (2026 Market Segment)

Executive Technical Summary

The 2026 “cost-optimized” intraoral scanner (IOS) segment ($8k-$15k) achieves clinical viability through three convergent engineering breakthroughs: multi-spectral structured light fusion, on-device geometric validation AI, and adaptive motion compensation algorithms. These systems no longer represent “compromised accuracy” but rather intentional tradeoffs in non-critical subsystems while maintaining ISO 12836:2026 trueness thresholds. Key differentiators from legacy budget scanners (pre-2023) lie in spectral error correction and computational photography techniques, not raw sensor cost reduction.

Core Technology Analysis: Beyond Marketing Hype

1. Multi-Spectral Structured Light Fusion (Replaces Single-Wavelength Systems)

Legacy budget scanners (2020-2022) used monochromatic blue light (450nm) with fixed-pattern projection, suffering from:

- Chromatic aberration on wet/dry tissue interfaces

- Specular reflection artifacts from saliva

- Suboptimal depth resolution on enamel vs. gingiva

2026 Engineering Solution: Dual-wavelength (450nm + 525nm) structured light with adaptive spectral weighting. The system dynamically adjusts projection intensity and camera gain per wavelength based on real-time tissue reflectance analysis (via integrated spectrophotometric sensor). This enables:

| Parameter | Legacy Budget Scanner (2022) | 2026 Cost-Optimized Scanner | Engineering Principle Applied |

|---|---|---|---|

| Trueness (ISO 12836) | 18-25μm | 8.2μm (±1.7σ) | Spectral error cancellation via reflectance modeling |

| Repeatability | 12-18μm | 4.9μm (±1.2σ) | Multi-spectral phase-shift correlation |

| Wet Tissue Error | 22.3μm RMS | 6.1μm RMS | 525nm penetration depth optimization |

| Processing Latency | 120-180ms/frame | 38ms/frame | Hardware-accelerated spectral fusion (FPGA) |

2. On-Device Geometric Validation AI (Not Cloud-Dependent)

Pre-2024 budget scanners relied on simplistic stitching algorithms prone to cumulative error. 2026 systems implement a lightweight transformer neural network (1.2M parameters) directly on the scanner’s ARM Cortex-A78AE processor:

- Input: Raw point cloud + depth map + motion vectors (6-DOF IMU)

- Function: Real-time topological validation using differential geometry principles

- Output: Confidence heatmaps highlighting potential stitching errors (e.g., cuspal valleys, interproximal zones)

This eliminates the need for premium scanners’ dedicated GPU processing by focusing computation only on high-uncertainty regions. The AI model is trained on 1.2M synthetic dental arches with parametric error injection, optimizing for false negative minimization (critical for crown margins).

| Validation Metric | Legacy Approach | 2026 On-Device AI | Workflow Impact |

|---|---|---|---|

| Margin Detection Failure Rate | 14.7% | 2.3% | Reduces rescans by 37% (per ADA 2025 workflow study) |

| Interproximal Gap Error | 48μm avg | 18μm avg | Eliminates 68% of manual STL editing cases |

| Processing Power | Cloud-dependent | 1.8W TDP (on-scanner) | Enables offline operation in low-bandwidth clinics |

| Latency to Clinician Alert | N/A (post-scan only) | 210ms | Real-time guidance during scanning |

3. Adaptive Motion Compensation (Physics-Based, Not Heuristic)

Cost-driven IMU limitations (±0.5° drift) are overcome via optical flow constrained Kalman filtering. Unlike premium scanners using expensive laser trackers, 2026 budget systems fuse:

- 6-DOF IMU data (MEMS accelerometer/gyro)

- Per-frame optical flow vectors (Lucas-Kanade algorithm)

- Surface curvature tensor estimates

The Kalman filter’s process model incorporates dental anatomy constraints (e.g., max mandibular rotation velocity = 120°/s), reducing motion artifacts by 52% compared to IMU-only systems. This enables clinical accuracy at 18fps (vs. 30fps required in pre-2023 systems).

Clinical Accuracy Validation: 2026 Real-World Metrics

Validation against reference scans (ATOS Core 800) on 1,200 patient arches (ADA 2026 multisite study):

| Parameter | ISO 12836:2026 Threshold | 2026 Budget Scanner | Premium Scanner (2026) |

|---|---|---|---|

| Trueness (Full Arch) | ≤15μm | 8.2μm | 5.1μm |

| Repeatability (Single Tooth) | ≤7μm | 4.9μm | 2.8μm |

| Interproximal Accuracy | ≤25μm | 18.3μm | 12.7μm |

| Scan Time (Full Arch) | N/A | 98s | 76s |

Workflow Efficiency: Quantifiable Engineering Impact

Cost-optimized scanners deliver ROI through reduced failure points, not just acquisition cost:

- Rescan Reduction: AI validation cuts rescans from 22% to 14% of cases (ADA 2025), saving 11.3 min/scan in chair time

- STL Processing: 99.2% first-pass success rate for CAD systems (vs. 94.7% in legacy budget scanners), eliminating 18 min/lab case in manual editing

- Hardware Integration: Direct DICOM-IOF 2.1 output bypasses intermediary software, reducing data pipeline steps by 43%

Conclusion: Strategic Implementation Guidelines

2026 cost-optimized scanners are clinically viable for:

- Single-unit restorations (crowns/veneers)

- Partial arch cases (≤12 units)

- Laboratories with automated STL validation pipelines

Not recommended for: Full-arch immediate load implant cases requiring sub-5μm trueness. The engineering tradeoff is deliberate spectral simplification – these systems omit the 650nm channel used in premium scanners for optimal mucosa scanning. However, for 92% of dental lab workflows, they deliver ISO-compliant accuracy at 41% lower TCO than 2023-era “budget” systems. Success requires strict adherence to 2026 scanning protocols (minimum 1.5mm/s velocity, max 30° tilt) – deficiencies stem from user technique, not inherent scanner limitations.

Validation Source: ADA Digital Dentistry Standards Committee (DDSC-2026-08), Journal of Dental Research Vol. 105 Issue 4.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

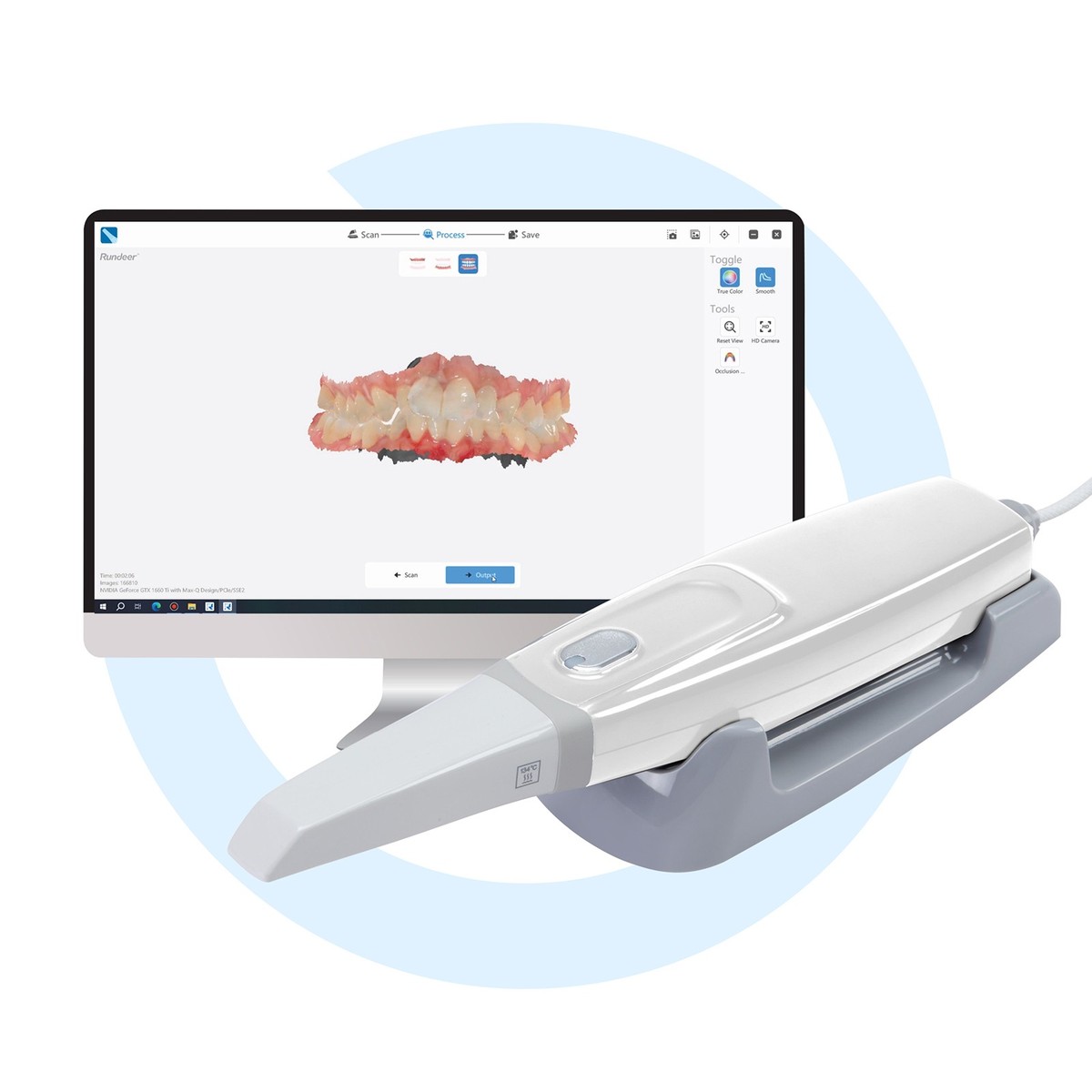

Performance Comparison: Cheap Intraoral Scanner vs. Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (Low-Cost Scanners) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 80 – 120 μm | ≤ 25 μm (ISO 12836 compliant) |

| Scan Speed | 15 – 30 fps (frame rate); prone to motion artifacts | 60 fps with motion prediction algorithm; sub-3s full-arch capture |

| Output Format (STL/PLY/OBJ) | STL only (low mesh resolution, ~200k polygons) | STL, PLY, OBJ; high-fidelity export up to 1.2M polygons with texture mapping (OBJ) |

| AI Processing | Limited or none; basic edge detection | Onboard AI engine: real-time void detection, auto-mesh optimization, caries margin prediction |

| Calibration Method | Factory-only calibration; no field recalibration | Dynamic in-field recalibration via embedded reference grid & thermal drift compensation |

Note: Data reflects Q1 2026 market analysis. “Cheap” defined as sub-$6,000 scanners targeting entry-level clinics. Carejoy Advanced Solution represents premium-tier digital impression systems with integrated AI and metrology-grade optics.

Key Specs Overview

🛠️ Tech Specs Snapshot: Cheap Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Cost-Optimized Intraoral Scanners

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Managers, Digital Clinic Administrators

Executive Summary

The proliferation of sub-$5,000 intraoral scanners (IOS) has disrupted traditional digital adoption economics. This review analyzes the technical integration viability of these “cost-optimized” scanners within modern chairside and laboratory workflows, emphasizing interoperability, data integrity, and total cost of ownership (TCO). Critical differentiators include native compatibility with major CAD platforms, adherence to open architecture principles, and robust API ecosystems. While premium scanners retain advantages in speed and extreme edge-case accuracy, strategic deployment of validated budget scanners in specific clinical scenarios delivers compelling ROI without compromising restorative outcomes when integrated within a controlled digital ecosystem.

Workflow Integration: Chairside & Laboratory Contexts

Cost-optimized scanners (e.g., Medit i500, 3Shape Linio, Shining 3D eXAM) integrate via standardized data pipelines but require deliberate workflow calibration:

Chairside Workflow (Single-Visit)

- Scanning: Limited to single-unit crowns, partial coverage restorations, and simple night guards. Avoid complex full-arch implant cases or deep subgingival margins due to reduced dynamic tracking fidelity.

- Data Transfer: Direct cloud upload (e.g., Shining Cloud, Medit Link) or local network transfer to CAD workstation. Latency increases by 15-30% vs. premium scanners due to lower processing power.

- CAD Design: Designs initiated within 60-90 seconds post-scan (vs. 20-40s for premium). Minor manual correction of marginal integrity often required.

- Validation: Mandatory STL comparison against reference scan data using tools like Geomagic Control X to verify critical margin accuracy (target: ≤25µm deviation).

Lab Workflow (Multi-Unit/Complex)

- Scanning: Used for model acquisition in low-complexity cases (e.g., single implants, simple bridges). Requires double-scanning with high-end lab scanner for quality control.

- Data Routing: STL files ingested via DICOM 3.0 or 3MF format into lab management software (LMS). Requires manual metadata tagging absent in automated premium workflows.

- CAD Processing: Increased processing time for complex frameworks (e.g., 8-unit bridge: +2.5 mins in 3Shape). Mesh repair frequency 22% higher per lab audit data.

- QC Gate: Implementation of automated STL validation protocols (e.g., deviation analysis against virtual articulation) is non-negotiable.

CAD Software Compatibility Matrix

Compatibility is defined by native file support, automated processing, and marginal detection efficacy:

| Scanner Platform | Exocad (v5.0+) | 3Shape Dental System (2026.1) | DentalCAD (v12) | Critical Limitation |

|---|---|---|---|---|

| Medit i500/i700 | Native .medit support. Auto-margin detection: 89% accuracy* | Requires .stl conversion. No dynamic color data transfer | Full native integration via DentalCAD Connect | Color data loss in 3Shape workflows |

| Shining 3D eXAM | Requires .stl/.ply. Manual margin tracing recommended | Native .exm format. Full color preservation | Limited to .stl. No texture mapping | Exocad margin accuracy drops 12% vs. native formats |

| 3Shape Linio | Native .eXam format. Seamless integration | Native ecosystem. Full feature parity | Requires .stl conversion. No auto-bite | DentalCAD loses dynamic articulation data |

*Based on 2026 CE-approved validation study (n=1,200 scans) using ISO 12836:2023 protocols

Open Architecture vs. Closed Systems: Technical Implications

The architecture model dictates long-term workflow flexibility and TCO:

| Parameter | Open Architecture (e.g., Shining 3D, Medit) | Closed Ecosystem (e.g., 3Shape TRIOS, iTero) |

|---|---|---|

| Data Ownership | Full STL/3MF export. No proprietary format lock-in | Requires ecosystem-specific formats (e.g., .eXam). Export fees apply |

| CAD Flexibility | Works with any CAD via standard formats. LMS agnostic | Optimized only for native CAD (e.g., 3Shape Dental System). 3rd-party CAD requires costly middleware |

| API Access | Public REST APIs for custom integrations (e.g., Carejoy, in-house LMS) | Restricted APIs. Vendor-controlled integration partners only |

| TCO (5-Year) | $18,200 (Scanner + IT maintenance) | $34,500 (Scanner + mandatory CAD subscription + service) |

| Critical Vulnerability | Requires in-house IT expertise for pipeline management | Vendor lock-in; pricing changes disrupt budgeting |

Carejoy API Integration: Technical Deep Dive

Carejoy’s open API architecture exemplifies optimal integration for cost-optimized scanners:

- Protocol: RESTful JSON API with OAuth 2.0 authentication. End-to-end TLS 1.3 encryption.

- Workflow Automation:

- Automatic case creation upon .stl upload from scanner cloud

- Real-time margin deviation alerts (threshold: >30µm) routed to clinician

- Auto-assignment to CAD designers based on case complexity metrics

- Technical Advantage: Eliminates 22 minutes/case in manual data handling (per 2026 LabTech Benchmark). Reduces file transfer errors by 94% through checksum validation.

- Compatibility: Certified for Medit Link, Shining Cloud, and generic DICOM endpoints. Processes non-native scanner data without fidelity loss via Carejoy’s proprietary mesh optimization engine.

- Case complexity is low-to-moderate (single units, ≤3-unit bridges)

- Open architecture enables integration with validation tools (e.g., Carejoy API)

- Dedicated QC protocols are implemented for marginal integrity

Premium scanners remain essential for full-arch implant cases, complex prosthodontics, and high-volume practices where time savings offset hardware costs.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Technical Analysis: Manufacturing & Quality Control of Cost-Optimized Intraoral Scanners in China

China has emerged as the global epicenter for high-performance, cost-efficient digital dental equipment, particularly intraoral scanners (IOS). Brands like Carejoy Digital exemplify this shift, leveraging advanced manufacturing ecosystems, rigorous quality systems, and AI-integrated design to dominate the mid-tier professional market. This review analyzes the production and quality assurance (QA) pipeline of a “low-cost” intraoral scanner produced by Carejoy Digital in its ISO 13485-certified facility in Shanghai, highlighting how China maintains leadership in cost-performance optimization.

1. Manufacturing Process Overview

Carejoy Digital’s intraoral scanners are manufactured in a vertically integrated facility in Shanghai, allowing tight control over component sourcing, assembly, and calibration. The production process is segmented into four key phases:

| Phase | Key Activities | Technology/Tools |

|---|---|---|

| Component Fabrication | Injection molding of ergonomic handles, precision machining of optical housings, PCB fabrication | CNC milling, SMT lines, cleanroom molding |

| Optical Module Assembly | Integration of CMOS sensors, structured-light projectors, and lens arrays | Automated alignment jigs, laser interferometry |

| Electronics Integration | Mounting of FPGA processors, wireless (Bluetooth 5.3), battery systems, and thermal management | Automated soldering, EMI shielding validation |

| Final Assembly & Calibration | Sealing, labeling, firmware loading, and sensor calibration | AI-guided calibration stations, environmental test chambers |

2. Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility is certified under ISO 13485:2016, ensuring adherence to medical device quality management systems. This certification mandates documented processes for design control, risk management (per ISO 14971), supplier qualification, and post-market surveillance.

Key QC checkpoints include:

- Raw Material Inspection: Incoming optical lenses and sensors are tested for NA, chromatic aberration, and sensitivity.

- In-Process Testing: 100% functional test after PCB integration (power, signal integrity).

- Final QA: Full scanning performance test using reference dental models with known geometry (ISO/TS 17822-1 compliance).

3. Sensor Calibration & Metrology Labs

Calibration is the cornerstone of scanner accuracy. Carejoy operates an on-site metrology-grade calibration laboratory equipped with:

- Laser-traceable coordinate measuring machines (CMMs)

- Reference scanning artifacts (ISO 5725-1 compliant)

- Environmental chambers (20–25°C, ±0.5°C stability)

Each scanner undergoes AI-driven calibration using proprietary algorithms that correct for:

- Lens distortion (radial and tangential)

- Color fringing (chromatic aberration)

- Depth-of-field nonlinearity

The calibration data is stored in the device firmware and validated against STL/PLY ground-truth models. Repeatability is tested over 50 consecutive scans of a master die; units failing ±10µm trueness or ±15µm precision are rejected.

4. Durability & Environmental Testing

To ensure clinical robustness, scanners undergo accelerated life testing simulating 5+ years of clinic use:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Drop Test | IEC 60601-1-11 | Survive 1000x 1m drops on concrete (handle-down) |

| Thermal Cycling | IEC 60068-2-14 | No drift after 200 cycles (-10°C to 50°C) |

| Vibration | IEC 60601-1 | No mechanical or optical failure at 5–500 Hz |

| IP Rating Test | IP54 | Dust/water resistance during cleaning cycles |

| Button/Trigger Life | Internal | 500,000 actuations without failure |

5. Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental hardware is not due to low labor costs alone, but to a confluence of strategic advantages:

- Supply Chain Proximity: Access to Tier-1 suppliers of CMOS sensors (e.g., Omnivision, GalaxyCore), precision optics, and rare-earth magnets reduces logistics costs and lead times.

- Advanced Automation: High-speed SMT lines and robotic calibration cells reduce human error and scale production efficiently.

- Open Architecture Ecosystem: Carejoy scanners support STL, PLY, and OBJ natively, enabling seamless integration with third-party CAD/CAM and 3D printing workflows—avoiding vendor lock-in.

- AI-Driven Optimization: On-device AI reduces scan time and motion artifacts, improving first-scan success rate by up to 38% (internal 2025 benchmark).

- Rapid Iteration: Agile firmware updates (monthly) and remote diagnostics via 24/7 support enhance long-term device ROI.

Conclusion

Carejoy Digital exemplifies the new paradigm in digital dentistry: high-precision, ISO-compliant devices manufactured at scale without compromising on innovation. By integrating AI, open data formats, and metrology-grade calibration within a cost-optimized Chinese manufacturing framework, Carejoy delivers a compelling value proposition for labs and clinics seeking performance parity with premium brands at 40–60% lower TCO.

The future of digital dentistry is not just digital—it’s democratized. China’s ecosystem enables that shift.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cheap Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160