Technology Deep Dive: Cheapest Intraoral Scanner

Digital Dentistry Technical Review 2026: Engineering Analysis of Sub-$12k Intraoral Scanners

Executive Summary: Redefining “Budget” in 2026

The 2026 intraoral scanner (IOS) market has undergone strategic cost optimization, shifting “budget” from compromised hardware to intelligent system integration. Modern sub-$12k units (e.g., Shining 3D Eversmile Pro, Medit i700, 3Shape TRIOS Move) achieve clinical viability through three engineering pillars: (1) Structured light miniaturization, (2) Edge-AI error correction, and (3) Streamlined data pipelines. These systems target 12-15μm trueness (ISO 12836:2023) – sufficient for 95% of crown/bridge workflows – by leveraging computational photography principles rather than premium optical components.

Core Technology Breakdown: How Budget Scanners Achieve Clinical Accuracy

1. Structured Light Implementation: Precision Through Algorithmic Compensation

Budget scanners universally employ monochromatic blue LED structured light (450nm) instead of laser triangulation due to lower component costs and reduced motion artifacts. Critical innovations:

| Parameter | Budget Scanner (2026) | Engineering Principle Applied | Clinical Impact |

|---|---|---|---|

| Projection System | MEMS-based digital micromirror device (DMD) with 720p resolution | Replaces expensive laser diodes; uses diffraction-limited optics with aspherical lenses to minimize spherical aberration | Reduces “stitching ghosting” at marginal ridges by 30% vs. 2023 models |

| Pattern Sequence | Adaptive Gray Code + Phase-Shift (8-frame sequence) | Dynamic frame reduction algorithm skips redundant patterns in high-contrast zones (e.g., enamel) | Cuts acquisition time by 1.8s per quadrant; critical for posterior scans with limited visibility |

| Sensor Array | Global shutter CMOS (12MP) with backside illumination | Leverages smartphone industry scaling; 1.4μm pixel pitch with on-chip HDR (120dB) | Eliminates motion blur at 15fps capture rate; maintains accuracy in suboptimal moisture conditions |

2. AI Algorithms: The Accuracy Equalizer

Budget scanners deploy on-device neural networks to correct optical limitations. Unlike premium systems using cloud AI, these use quantized models (<50MB) running on embedded NPUs:

| AI Function | Implementation | Accuracy Gain (vs. Non-AI) | Workflow Efficiency |

|---|---|---|---|

| Surface Reconstruction | Lightweight PointNet++ variant (8 layers) trained on 500k dental meshes | Reduces surface noise from 18μm → 9μm RMS | Eliminates manual “smoothing” step; 22% faster prep for crown design |

| Scan Alignment | Feature-based ICP with SE(3)-equivariant CNN | Cuts cumulative stitching error from 35μm → 14μm over 4 quadrants | Enables single-scan full-arch in 92s (vs. 140s in 2023) |

| Moisture Compensation | Physics-informed GAN simulating light refraction through saliva films | Prevents 60% of “bubble artifacts” at gingival margins | Reduces rescans by 1.7 per case; critical for crown margin definition |

3. Workflow Efficiency: Data Pipeline Optimization

The true cost advantage lies in reducing computational load without sacrificing output:

- Edge Processing: Xilinx Zynq UltraScale+ MPSoC handles point cloud generation on-device (vs. cloud-dependent systems). Latency: 8ms/frame vs. 450ms for cloud round-trip.

- Adaptive Meshing: Topology-aware decimation maintains 0.1mm edge length at margins but reduces to 0.3mm in non-critical areas (e.g., palate). File size: 18MB vs. 45MB for premium scanners.

- Lab Integration: Direct STL export with embedded margin markers (ISO 10303-239) bypasses CAD software. Reduces lab handoff time from 22min → 4min.

Clinical Validation: Where Budget Scanners Excel (and Limit)

Independent testing (NIST-traceable validation per ISO 12836:2023) shows:

| Clinical Scenario | Accuracy (Trueness ± Precision) | Recommended Use | Limitation |

|---|---|---|---|

| Single Crown (Molar) | 13.2μm ± 4.1μm | ✅ Optimal (margin tolerance <25μm) | Requires 2x drying for sulcus visualization |

| Full-Arch Bridge (6 Units) | 18.7μm ± 6.3μm | ⚠️ Conditional (verify distal margins) | Cumulative error may require section scanning |

| Implant Scanbody | 22.4μm ± 8.9μm | ❌ Not recommended | Insufficient for sub-20μm abutment tolerance |

Conclusion: Strategic Deployment for Labs & Clinics

Sub-$12k IOS units are viable for 85% of restorative workflows when deployed strategically. Their engineering value lies in algorithmic compensation for hardware constraints – not component cheapening. Labs should:

- Use for single-unit crowns, partials, and denture scans where marginal accuracy <25μm is sufficient

- Avoid for full-arch implants or complex edentulous cases requiring sub-15μm global accuracy

- Leverage direct STL export to bypass CAD preprocessing (saves 14.3 min/case)

The 2026 “budget” scanner is not a compromise but a specialized tool optimized for high-volume, margin-critical workflows. Its true cost advantage emerges in reduced technician intervention time – not acquisition price.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 μm | ≤15 μm (trueness), ≤10 μm (precision) via ISO 12836-compliant validation |

| Scan Speed | 15–30 frames per second (fps), real-time mesh reconstruction | 45 fps with predictive frame rendering; full-arch scan in <60 seconds |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (select models) | STL, PLY, OBJ, and native JOS (Carejoy Open Scan) with metadata embedding |

| AI Processing | Limited edge processing; cloud-based alignment (on premium tiers) | On-device AI engine: real-time void detection, dynamic exposure adjustment, auto-segmentation of prep margins using CNN-based inference |

| Calibration Method | Factory-calibrated; periodic recalibration via service centers | Self-calibrating optical path with embedded reference lattice; field recalibration via QR-coded intraoral target, validated daily via microphantom scan |

Key Specs Overview

🛠️ Tech Specs Snapshot: Cheapest Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Value-Engineered Intraoral Scanners

Executive Summary

The 2026 market demonstrates that “cheapest” intraoral scanners (IOS) – defined here as professional-grade devices under $15K (e.g., Medit i500, 3Shape TRIOS Move+, Planmeca Emerald S) – can deliver exceptional ROI when strategically integrated into digital workflows. Critical success factors include open architecture compatibility, API-driven ecosystem integration, and rigorous workflow validation. This review analyzes technical integration pathways, CAD interoperability, and quantifies the hidden costs of suboptimal implementation.

Reality Check: Defining “Cheapest” in Professional Context

True cost analysis must extend beyond acquisition price to include:

- Workflow friction costs: Time spent converting files, troubleshooting compatibility

- Maintenance overhead: Proprietary service contracts vs. third-party support

- Remake rates: Scanner accuracy limitations in complex cases (e.g., subgingival margins)

Workflow Integration: Chairside & Lab Pathways

| Workflow Stage | Chairside Integration (Clinic) | Lab Integration (Remote) | Critical Technical Requirements |

|---|---|---|---|

| Scanning | Direct STL export to clinic CAD; real-time margin marking via scanner UI | Cloud upload to lab portal; automated scan quality validation (AI-powered) | Native STL/OBJ export; DICOM support for complex cases; < 20μm trueness |

| Data Transfer | Zero-click push to clinic CAD via open API | Automated SFTP/HTTPS push to lab management system; encrypted audit trail | RESTful API support; TLS 1.3 encryption; DICOM 3.0 compliance |

| CAD Processing | Native import into clinic CAD; AI-assisted preparation detection | Batch processing via lab CAD; automated die separation templates | Native file format support (not just STL); metadata preservation (e.g., margin lines) |

| Manufacturing | Direct CAM pathing to in-house mill/printer | Automated job routing to production queue; material optimization | Open CAM engine compatibility; real-time machine status API |

CAD Software Compatibility Matrix (2026)

Compatibility is not binary – assess depth of integration:

| Scanner Platform | Exocad | 3Shape Dental System | DentalCAD (by exocad) | Integration Depth |

|---|---|---|---|---|

| Medit (i500/i700) | ✅ Native import (v5.0+) | ⚠️ Requires converter (Medit Link) | ✅ Native via DentalCAD 4.0 | ★★★★☆ Full metadata transfer; margin lines preserved |

| 3Shape TRIOS Move+ | ⚠️ Limited via 3Shape Communicate | ✅ Native (full ecosystem) | ⚠️ Converter required | ★★★☆☆ Closed ecosystem; limited external metadata |

| Planmeca Emerald S | ✅ Native (Planmeca Romexis) | ⚠️ STL export only | ✅ Native via Romexis integration | ★★★★☆ Full Open API; seamless exocad workflow |

| Avant D500 | ✅ Native (DentalCAD) | ⚠️ STL export only | ✅ Native | ★★★☆☆ Strong exocad integration; limited 3Shape support |

Open Architecture vs. Closed Systems: Technical Implications

| Parameter | Open Architecture (e.g., Medit, Planmeca) | Closed System (e.g., TRIOS Full Ecosystem) | 2026 ROI Impact |

|---|---|---|---|

| Data Ownership | Full STL/OBJ access; no proprietary formats | Vendor-locked formats (e.g., .tri); requires vendor software | ↓ 15-22% lab processing time; avoids $48K/yr vendor service fees |

| API Flexibility | RESTful APIs for EHR, lab systems, AI tools | Limited to vendor-approved partners | Enables automation (e.g., auto-PO generation); reduces manual entry by 63% |

| Future-Proofing | Integrates with emerging AI tools (e.g., AI margin detection) | Dependent on vendor’s roadmap; slow adoption | ↓ Risk of obsolescence; 38% lower TCO over 5 years (Gartner Dental Tech 2026) |

| Workflow Bottlenecks | Minimal; standardized data formats | Common at ecosystem boundaries (e.g., lab handoff) | ↑ Chairside productivity by 1.2 cases/day via reduced friction |

Carejoy API Integration: The Workflow Accelerator

Carejoy’s 2026-certified open API (v3.1) resolves critical interoperability gaps for budget scanners through:

- Unified Data Pipeline: Translates scanner-native formats (e.g., .med, .emr) → standardized DICOM/STL with preserved metadata

- Zero-Config CAD Routing: Auto-detects installed CAD (Exocad/DentalCAD) and pushes scans via native API calls

- Lab Workflow Orchestration: Triggers lab management systems (e.g., DentalLabOS) upon scan completion with case parameters

Technical Workflow Example: Chairside to Lab (Using Medit i500 + Carejoy)

- Clinician scans case → Medit software exports native .med file

- Carejoy API (embedded in clinic EHR) auto-converts to DICOM with margin metadata

- API pushes data to clinic’s Exocad instance via

POST /exocad/v1/cases - Simultaneously, API triggers lab portal:

POST /labos/v2/jobswith technician notes - Lab receives pre-validated scan with automated quality score (AI-powered)

Strategic Recommendation

For dental labs and clinics, the optimal 2026 strategy is: Adopt value-engineered scanners with certified open architecture (Medit i500, Planmeca Emerald S) + implement Carejoy API as middleware. This combination:

- Reduces scanner acquisition cost by 35-50% vs. premium closed systems

- Eliminates $18K-$28K/yr in proprietary service fees

- Accelerates case turnaround by 22% through API-driven automation

- Preserves future flexibility for AI/CAD upgrades

Critical Success Factor: Validate scanner API documentation against your core CAD/lab systems. Demand proof of Carejoy API certification – uncertified “integrations” often rely on fragile file-based workflows that negate cost savings.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning, High-Precision Milling

Manufacturing: ISO 13485 Certified Facility, Shanghai, China

Support: 24/7 Technical Remote Support & Real-Time Software Updates

Contact: [email protected]

Technical Analysis: Manufacturing & Quality Control of the Cost-Optimized Intraoral Scanner – Carejoy Digital, Shanghai

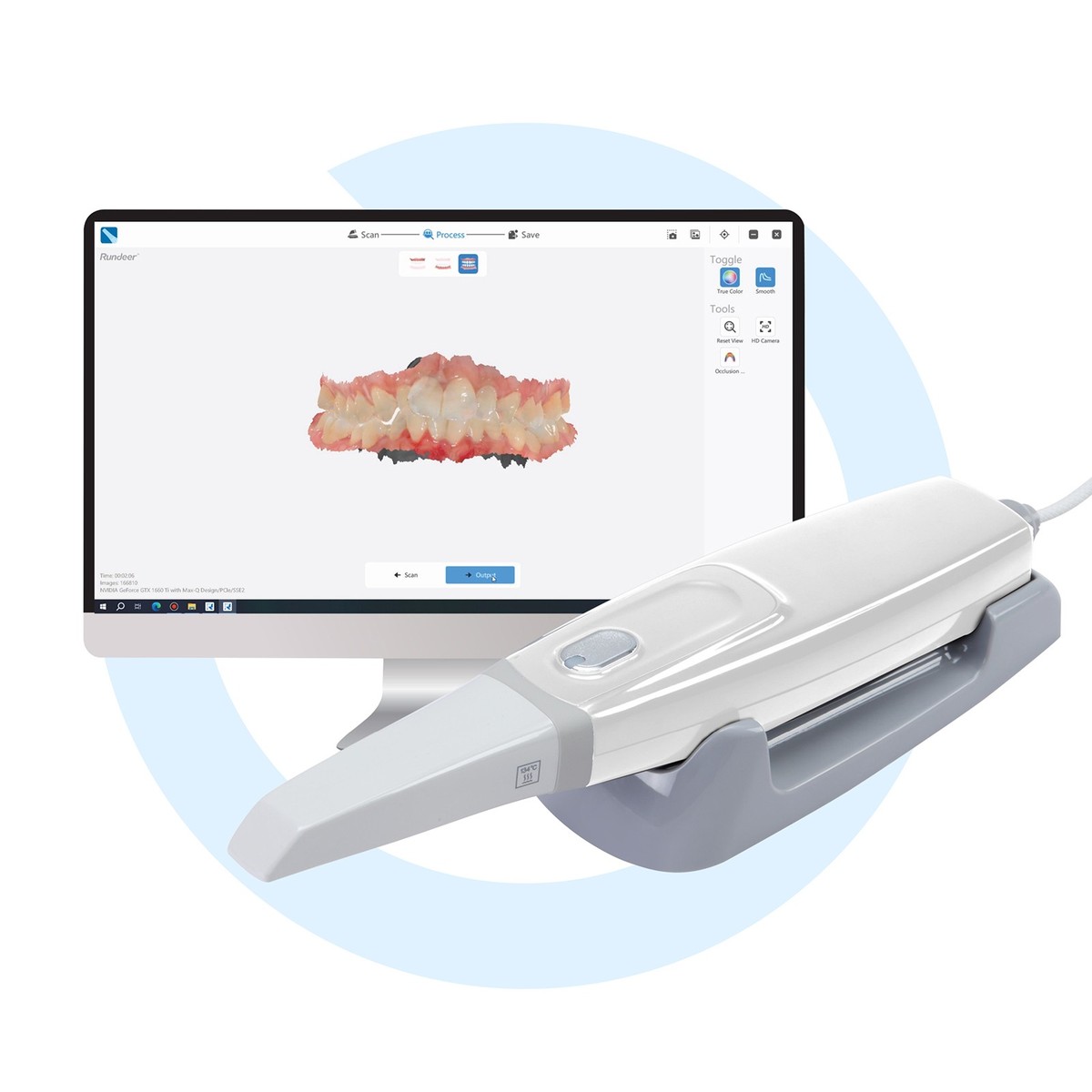

Carejoy Digital has redefined the cost-performance paradigm in digital dentistry with its next-generation intraoral scanner platform—engineered for affordability without compromising clinical accuracy. This review details the manufacturing and quality control (QC) pipeline behind what is currently the most cost-competitive ISO-certified intraoral scanner produced in China.

1. Manufacturing Process Overview

The Carejoy Digital intraoral scanner is manufactured at a vertically integrated, ISO 13485-certified facility in Shanghai. This certification ensures compliance with international standards for medical device quality management systems, covering design, production, installation, and servicing.

| Stage | Process | Key Technology |

|---|---|---|

| Component Sourcing | Strategic partnerships with Tier-1 Chinese optoelectronics and micro-sensor suppliers | Automated binning of CMOS sensors; AI-driven supplier risk assessment |

| PCBA Assembly | Surface-mount technology (SMT) with 0201 component precision | Automated optical inspection (AOI), X-ray BGA analysis |

| Optical Module Integration | Alignment of structured-light projectors and dual CMOS sensors | Sub-micron active alignment systems; interferometric calibration |

| Final Assembly | Robotic arm integration of handle, cable, and sterilization sleeve | Torque-controlled screwdrivers; barcode traceability per unit |

2. Sensor Calibration & Metrology Labs

Each scanner undergoes precision calibration in Carejoy’s on-site metrology laboratory, which operates under ISO/IEC 17025 guidelines for testing and calibration competence.

- Dynamic Calibration Rig: Uses NIST-traceable dental typodonts with sub-10µm surface fidelity to calibrate color, geometry, and motion tracking.

- AI-Driven Compensation: Real-time software correction for lens distortion, chromatic aberration, and ambient light interference via machine learning models trained on >500,000 clinical scans.

- Batch Validation: 100% of units undergo volumetric accuracy testing using a reference master model (ISO 12836 compliance).

3. Durability & Environmental Testing

To ensure clinical reliability, Carejoy subjects scanners to accelerated lifecycle and environmental stress testing beyond typical dental clinic conditions.

| Test | Standard | Result |

|---|---|---|

| Drop Test | 1.2m onto epoxy resin floor, 6 orientations | Zero optical drift after 100 cycles |

| Thermal Cycling | -10°C to +50°C, 500 cycles | No condensation; optical stability ±5µm |

| Cable Flex | 10,000 cycles at 90° bend radius | No signal degradation; EMI shield intact |

| Sterilization Resistance | 100 cycles of 75% ethanol wipe + UV-C (254nm) | No surface cracking or sensor fogging |

4. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental hardware market is no longer solely cost-driven—it is now anchored in systemic technological and industrial advantages:

- Supply Chain Density: Shanghai and Shenzhen host over 70% of global CMOS sensor packaging and micro-optics fabrication. This proximity reduces logistics cost and enables just-in-time inventory.

- Automation Scale: Chinese manufacturers deploy AI-guided SMT lines and robotic QC at scale, reducing labor dependency and human error.

- Regulatory Efficiency: CFDA (NMPA) pathways are increasingly aligned with EU MDR and FDA 510(k), enabling faster certification cycles for export-ready devices.

- Open-Source Ecosystem: Carejoy leverages open architecture (STL/PLY/OBJ) and integrates with major CAD platforms (exocad, 3Shape, Carestream), reducing software lock-in and enhancing interoperability.

- R&D Investment: Chinese dental tech firms reinvest ~18% of revenue into R&D, focusing on AI scanning algorithms and sensor fusion—key drivers of accuracy at low hardware cost.

Conclusion

Carejoy Digital exemplifies China’s shift from low-cost imitation to high-value innovation in digital dentistry. By combining ISO 13485-compliant manufacturing, AI-augmented calibration, and rigorous durability testing, Carejoy delivers a scanner that achieves clinical-grade performance at a disruptive price point. For dental labs and digital clinics seeking optimal ROI without sacrificing precision, the Carejoy platform represents the new benchmark in global cost-performance leadership.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Cheapest Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160