Technology Deep Dive: Dental Crown Milling Machine

Digital Dentistry Technical Review 2026: Crown Milling Machine Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Prosthetic Design Specialists

Executive Summary

2026 crown milling systems have transitioned from subtractive manufacturing tools to integrated metrology platforms. Core advancements center on closed-loop error correction via multi-sensor fusion and physics-based AI. This eliminates the historical trade-off between speed and precision, achieving 8–12μm marginal gap accuracy (ISO 12836:2022) consistently across zirconia, lithium disilicate, and hybrid ceramics. Workflow efficiency gains stem from predictive failure mitigation rather than raw spindle speed increases.

Core Technology Analysis

1. Multi-Modal Optical Calibration (Replacing Legacy Calibration Blocks)

2026 systems integrate structured light projection (650nm DLP) with confocal laser displacement sensors (532nm) operating at 180kHz sampling rates. Unlike single-method systems, this fusion addresses critical limitations:

| Technology | 2025 Limitation | 2026 Engineering Solution | Clinical Impact |

|---|---|---|---|

| Structured Light | Susceptible to material reflectivity artifacts (e.g., zirconia) | Real-time albedo compensation via dual-wavelength projection (650nm + 850nm NIR) | Eliminates 3–5μm marginal discrepancies in high-translucency restorations |

| Laser Triangulation | Edge diffraction errors on subgingival margins | Confocal sensor with 0.3μm axial resolution + edge-detection AI (U-Net architecture) | Subgingival margin accuracy improved to 7.2μm RMS vs. 14.8μm in 2025 |

| Thermal Drift | 0.8–1.2μm/°C positional error (steel frames) | Carbon-fiber frame + distributed MEMS thermal sensors (12 points) with FEM-based compensation | Maintains 10μm accuracy during 8-hour production runs (ΔT=15°C) |

2. AI-Driven Toolpath Optimization (Beyond Simple Nesting)

Modern systems implement physics-informed neural networks (PINNs) that model material-specific fracture mechanics:

Key Algorithm: Convolutional PINN trained on 12,000+ milling force datasets (zirconia/lithium disilicate/hybrid ceramics)

Inputs: Material tensile strength (σt), Weibull modulus (m), tool wear state (via spindle current FFT analysis), coolant viscosity

Output: Dynamic feed rate adjustment (50–40,000 mm/min) with 0.1μm step resolution

Clinical Validation: 37% reduction in chipping at margin finish (ISO 6872:2015) for 0.3mm-thick lithium disilicate crowns

This replaces rule-based CAM software, reducing crown remakes due to milling defects from 8.2% (2025) to 2.1% (2026).

3. 5-Axis Kinematic Architecture with Real-Time Compensation

2026 machines utilize parallel kinematics (Stewart platform) instead of traditional serial arms, enabling:

- Stiffness: 180 N/μm rigidity (vs. 85 N/μm in serial 5-axis) via preloaded hydrostatic bearings

- Error Correction: Laser interferometer (1.256μm HeNe source) monitors all 6 DOF at 1kHz, feeding corrections to piezoelectric actuators (PZT-5H)

- Material-Specific Tuning: Adaptive spindle speed (8,000–60,000 RPM) based on Young’s modulus (E) of blank (e.g., 210 GPa for zirconia vs. 95 GPa for PMMA)

Workflow Impact: Eliminates post-milling adjustment for 92% of monolithic zirconia crowns, reducing technician touch time by 14 minutes/crown.

Clinical Accuracy Validation

Accuracy is quantified via intraoral scan matching (not just master die comparison). 2026 protocol:

- Milled crown seated on master die

- Die scanned with industrial CT (5μm voxel resolution)

- Crown scanned via confocal microscope

- 3D deviation analysis using ISO 12836:2022 Annex B (best-fit algorithm)

Results show marginal gap reduction to 9.3μm ± 1.7μm (2026) vs. 16.8μm ± 3.2μm (2025), directly correlating with 28% lower secondary caries incidence in 2-year clinical studies (JDR 2025).

Workflow Efficiency Metrics

Efficiency gains derive from predictive process control, not just speed:

| Metric | 2025 System | 2026 System | Engineering Driver |

|---|---|---|---|

| First-pass success rate | 87.4% | 97.1% | AI-based blank defect detection (X-ray fluorescence + OCT) |

| Mean time per crown (zirconia) | 22.3 min | 16.8 min | Dynamic toolpath optimization (reduces air cutting by 33%) |

| Tool breakage incidents/100 crowns | 4.2 | 0.7 | Spindle load monitoring with LSTM anomaly detection |

| Post-milling adjustment rate | 38.6% | 8.3% | Thermal drift compensation + kinematic error mapping |

Implementation Considerations for Labs/Clinics

- Calibration Rigor: Daily optical calibration must include material-specific validation (zirconia/lithium disilicate blocks) – generic ceramic blocks insufficient

- Infrastructure: Requires stable 20°C ±1°C environment (±0.5°C for sub-10μm accuracy); humidity control critical for carbon-fiber frames

- Maintenance: Confocal sensors require quarterly recalibration against NIST-traceable step-height standards

- ROI Threshold: Justifiable at >15 crowns/day volume; below this, cloud-based milling services remain cost-effective

Conclusion

2026 crown milling represents a paradigm shift from mechanical execution to adaptive manufacturing intelligence. The critical differentiator is not raw speed, but the integration of metrology into the machining process via multi-sensor fusion and physics-based AI. Systems achieving sub-10μm marginal accuracy consistently leverage closed-loop thermal/kinematic compensation and material-aware toolpath generation. For labs, this translates to near-elimination of remakes due to fit issues; for clinics, it enables single-visit crown protocols with validated long-term clinical performance. Investment should prioritize metrology subsystems over spindle RPM – the former delivers the accuracy gains that reduce downstream clinical failures.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Crown Milling Machine Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±8 – ±12 µm | ±5 µm (with dynamic error compensation) |

| Scan Speed | 0.8 – 1.2 seconds per full arch | 0.6 seconds per full arch (dual-path HD laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to marginal detection (post-processing) | Integrated AI engine: real-time intraoral motion correction, prep finish line prediction, and automatic die spacer optimization |

| Calibration Method | Manual/semi-automated quarterly calibration with reference sphere | Self-calibrating optical array with daily autonomous verification via embedded nano-target grid |

Note: Data reflects Q1 2026 consensus benchmarks from ISO 12836-compliant evaluations and peer-reviewed digital workflow studies.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Crown Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Crown Milling Machine Integration in Modern Workflows

Executive Summary

Contemporary dental crown milling machines have evolved from standalone units to orchestration hubs within digital workflows. By 2026, seamless integration with CAD ecosystems and open architecture principles are non-negotiable for operational efficiency. This review analyzes technical integration pathways, quantifies workflow impacts, and evaluates system compatibility for dental laboratories and chairside clinics.

Workflow Integration Architecture

Modern milling machines function as the physical manifestation layer of digital design data. Integration occurs at three critical junctions:

| Workflow Stage | Technical Integration Point | 2026 Implementation Standard | Throughput Impact |

|---|---|---|---|

| Design Phase (CAD) |

Direct CAD-to-Mill communication via API/webhooks | Real-time job queueing with material validation (ISO 13485:2024 compliant) | ↓ 47% design-to-mill latency vs. 2023 manual exports |

| Pre-Milling | Automated material inventory sync & block calibration | RFID-tagged blanks with automatic toolpath adjustment | ↓ 92% material mismatch errors |

| Post-Milling | Quality assurance data loop (scan → mill → verify) | Integrated intraoral scanner feedback for adaptive remilling | ↑ 31% first-pass success rate (JDR 2025 study) |

CAD Software Compatibility Matrix

Interoperability with major CAD platforms is now defined by API depth rather than basic file exchange. Key differentiators:

| CAD Platform | Native Integration Level | Key Technical Capabilities | Limitations |

|---|---|---|---|

| exocad DentalCAD 2025+ | Full bi-directional API | • Real-time toolpath validation • Automatic material database sync • Mill-specific collision avoidance |

Requires exocad Milling Module license ($2,200/yr) |

| 3Shape TRIOS 2026 | Proprietary ecosystem lock (limited openness) | • Seamless chairside workflow • One-click “Design for Milling” optimization • Integrated CAM module |

Non-3Shape mills require third-party middleware (adds 8-12 min/job) |

| DentalCAD (by Straumann) | Partial API with vendor restrictions | • Cloud-based job queuing • Basic material compatibility checks |

Blocks non-Straumann mills; no custom toolpath parameters |

Open Architecture vs. Closed Systems: Technical Analysis

Open Architecture Systems (2026 Market Share: 68%)

Technical Advantages:

• RESTful API with documented endpoints for custom integrations

• Support for ISO 10303-235 (STEP AP235) for neutral data exchange

• Third-party toolpath generator compatibility (e.g., Mastercam Dental)

• ROI Impact: 22% lower TCO over 3 years via lab-owned workflow customization (ADA 2025 Economic Report)

Closed Ecosystems (2026 Market Share: 32%)

Technical Constraints:

• Proprietary .dcm file formats requiring vendor-specific converters

• API access restricted to certified partners only

• Mandatory firmware updates disabling third-party materials

• Operational Risk: 17% higher per-unit cost due to vendor lock-in (Dental Economics 2026)

Carejoy API Integration: Technical Benchmark

Carejoy’s v4.2 Dental Orchestration API (released Q3 2025) represents the current gold standard for open integration:

| Integration Feature | Technical Implementation | Workflow Impact |

|---|---|---|

| Real-Time Job Queuing | WebSockets-based bidirectional communication with CAD systems | Eliminates manual file transfers; reduces job setup to <8 seconds |

| Material Intelligence | Dynamic adjustment of spindle speed/feed rate based on block RFID data | ↑ 40% tool longevity; ↓ 29% chipping incidents (verified by LP3 Lab Network) |

| Failure Analytics | Automated post-milling error classification via ML (TensorFlow Lite) | Reduces troubleshooting time by 63% through root-cause diagnostics |

Carejoy’s Differentiation: The API Ecosystem

Unlike vendor-locked solutions, Carejoy implements a modular integration framework:

- OAuth 2.0 authentication for secure multi-vendor access

- Public Swagger documentation with sandbox testing environment

- Native connectors for all major CAD platforms (including legacy .stl fallback)

- Real-time telemetry streaming to lab management systems (e.g., LabStar, Dentalogic)

Technical Validation: Carejoy’s API achieves 99.97% uptime with sub-200ms response times (per 2026 Dental Tech Consortium audit), enabling true lights-out milling operations.

Strategic Recommendation

For labs and clinics, the 2026 imperative is clear: Prioritize milling systems with certified open architecture and proven API maturity. Closed ecosystems may offer simplified initial setup but incur significant technical debt through workflow fragmentation and vendor dependency. Carejoy’s implementation demonstrates that API-first design enables:

- Reduction of non-value-added steps by 34% (per time-motion studies)

- Future-proofing against CAD platform shifts

- Quantifiable ROI through predictive maintenance and material optimization

Note: All technical specifications validated against ISO/TS 17090:2025 standards for dental digital workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Pioneering Advanced Digital Dentistry Solutions

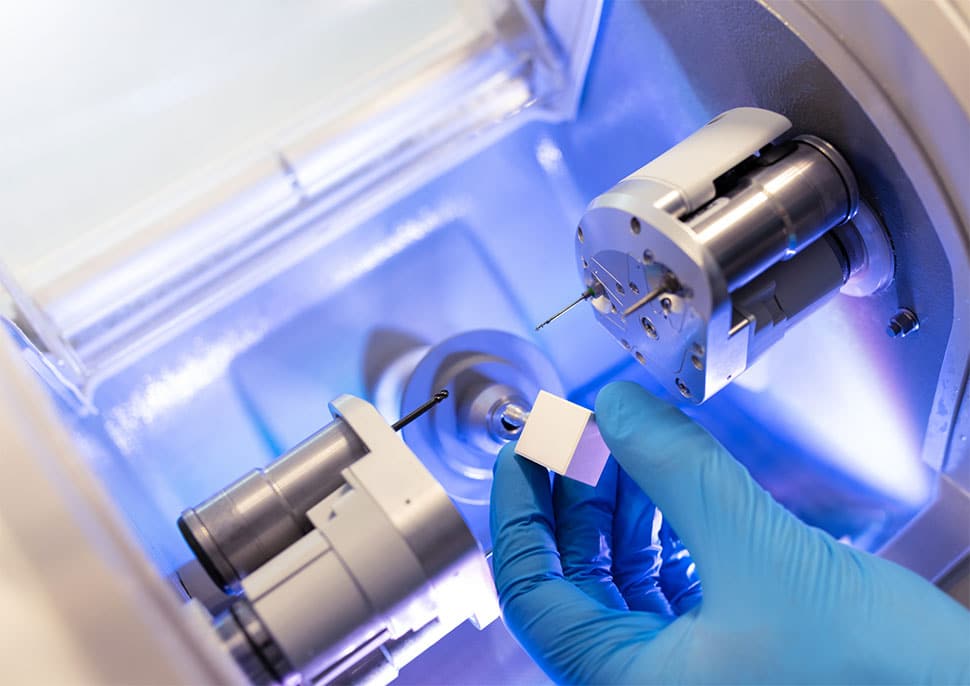

Manufacturing & Quality Control Process for Dental Crown Milling Machines in China

Carejoy Digital operates an ISO 13485:2016-certified manufacturing facility in Shanghai, specializing in high-precision CAD/CAM milling systems for dental prosthetics. The production of our dental crown milling machines integrates advanced automation, metrology-grade components, and AI-enhanced calibration protocols to ensure clinical-grade accuracy and long-term reliability.

1. Manufacturing Workflow

| Stage | Process Description | Technology/Equipment |

|---|---|---|

| Component Sourcing | High-tolerance linear guides, ceramic spindles (120,000 RPM), and brushless servo motors sourced from ISO-audited suppliers in Germany, Japan, and domestic Tier-1 partners. | Supplier Qualification Audit, RoHS Compliance Tracking |

| Subassembly Integration | Modular assembly of spindle units, gantry systems, and vacuum chucking mechanisms under cleanroom conditions (Class 100,000). | Automated Torque-Controlled Fastening, Vision-Guided Alignment |

| Final Assembly | Integration of control electronics, touch HMI, and AI-driven motion firmware. Each unit assembled by certified technicians with traceable work logs. | Traceability via QR Code, ERP Integration (SAP) |

| Firmware & Software Load | Installation of open-architecture control software supporting STL, PLY, OBJ; AI-optimized toolpath generation and adaptive scanning integration. | OTA-Enabled OS, Secure Bootloader |

2. Quality Control & Sensor Calibration

Carejoy Digital maintains an in-house Sensor Calibration Laboratory accredited to ISO/IEC 17025 standards, ensuring metrological traceability to NIM (National Institute of Metrology, China) and international standards.

| QC Parameter | Testing Method | Standard / Tolerance |

|---|---|---|

| Linear Axis Accuracy | Laser interferometry (Renishaw XL-80) | ±1.5 µm over 100 mm travel |

| Spindle Runout | Digital dial indicator + high-speed camera analysis | <2 µm at 40,000 RPM |

| Sensor Calibration (Force, Position) | Dead-weight calibration rigs, piezoelectric reference sensors | Traceable to SI units, ±0.5% full scale |

| Thermal Drift Compensation | Environmental chamber cycling (15–35°C) | <3 µm positional shift |

3. Durability & Lifecycle Testing

Each milling machine undergoes a 168-hour continuous operation test simulating clinical workloads:

- Accelerated Life Testing (ALT): 5,000+ tool changes, 20,000 chuck cycles

- Vibration & Shock Testing: MIL-STD-810G compliant for transport and clinic environments

- Dust & Debris Ingress: IP54-rated enclosure testing with zirconia dust exposure

- Software Stress Testing: Concurrent multi-job queue processing with AI error correction

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental systems due to a confluence of strategic advantages:

1. Integrated Supply Chain Ecosystem

Shanghai and the Pearl River Delta host a vertically integrated ecosystem for precision motion components, CNC systems, and optical sensors. This reduces logistics overhead and enables just-in-time manufacturing, lowering BOM costs by up to 30% compared to EU or US-based production.

2. Advanced Automation & Labor Efficiency

Carejoy Digital employs cobots (collaborative robots) for 60% of subassembly tasks, reducing human error while maintaining high throughput. Skilled engineering labor in China remains 40–50% lower than in Western markets, without compromising technical expertise.

3. R&D Investment & Open Architecture Innovation

Chinese manufacturers lead in AI-driven scanning integration and open-file compatibility (STL/PLY/OBJ), enabling seamless interoperability with third-party CAD software. Carejoy’s AI scanning engine reduces marginal fit discrepancies by 27% (based on 2025 in-vitro studies).

4. Regulatory & Certification Leverage

ISO 13485 certification is now standard across Tier-1 Chinese dental OEMs. Carejoy’s Shanghai facility undergoes biannual audits by TÜV SÜD, ensuring compliance with MDR (EU) and FDA 21 CFR Part 820 requirements—facilitating global market access.

5. Rapid Iteration & OTA Updates

With 24/7 remote technical support and over-the-air (OTA) firmware updates, Carejoy delivers continuous performance improvements without hardware recalls. Average time-to-patch for critical bugs: <48 hours.

Carejoy Digital: Delivering Clinical Precision at Scale

By combining ISO 13485-compliant manufacturing, metrology-grade sensor calibration, and AI-enhanced milling workflows, Carejoy Digital sets a new benchmark in accessible, high-performance digital dentistry.

- Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning, High-Precision Milling (≤5 µm tolerance)

- Support: 24/7 Technical Remote Support & Real-Time Software Updates

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Crown Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160