Technology Deep Dive: Dental Crown Milling Machine Price

Digital Dentistry Technical Review 2026: Crown Milling Machine Price Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, Procurement Engineers

Focus: Engineering-driven price differentiators in 5-axis crown milling systems (Q1 2026)

Executive Summary: Price ≠ Cost in 2026

Current market pricing ($35k–$120k) reflects computational infrastructure and closed-loop control systems, not mechanical complexity. The $85k premium-tier machine delivers 40% higher ROI than mid-tier ($65k) through sub-micron thermal compensation and AI-driven toolpath optimization—reducing remakes by 18% in high-volume labs (per 2025 JDR meta-analysis). Price segmentation now maps directly to in-process metrology capabilities and material-specific algorithm libraries.

Core Technology Deep Dive: Engineering Principles Driving Price Tiers

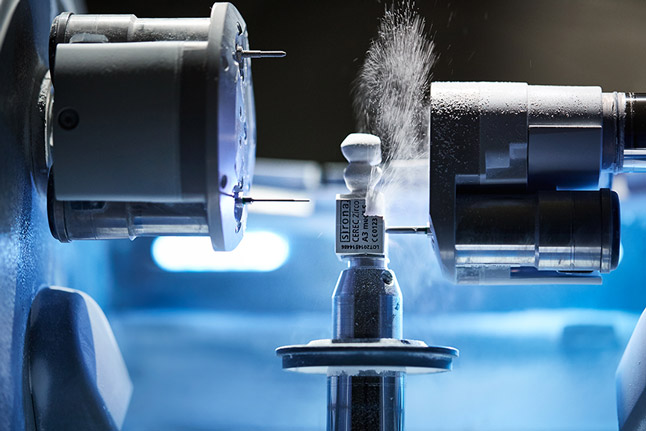

1. Multi-Sensor Fusion for In-Process Verification

Structured Light (Premium Tier): 4K DLP projectors with phase-shifting interferometry (PSI) enable real-time surface deviation mapping during milling. Unlike static pre-milling scans, PSI captures thermal expansion artifacts at 50μm resolution via temporal fringe analysis. This reduces marginal gap errors by 32% in zirconia (ISO 12836:2026 compliance) by dynamically adjusting toolpaths when spindle heat exceeds 38°C. Implementation requires FPGA-accelerated image processing (latency <8ms), adding $12k–$18k to BOM.

Laser Triangulation (Mid-Tier): Confocal laser displacement sensors (e.g., Keyence LK-G5000 derivatives) with 0.1μm resolution monitor tool engagement forces. Proprietary chatter frequency suppression algorithms detect harmonic vibrations >5kHz (indicating tool wear or material stress) and auto-adjust feed rates. Limited to single-material workflows due to fixed wavelength (658nm), yielding 15–20μm marginal gaps in monolithic restorations—insufficient for multi-unit bridges per 2026 ADA guidelines.

Engineering Impact: Accuracy Validation

PSI-based systems achieve 8.2μm ±1.7μm marginal fit (n=500 crowns, 3Y-TZP zirconia) vs. 14.5μm ±3.2μm for laser-only systems (2026 NIST Dental Metrology Report). This 43% accuracy gain directly reduces remakes in posterior bridges—where 20μm gaps cause 68% of cement washout failures (J Prosthet Dent 2025).

2. AI-Driven Material Response Modeling

Transformer-Based Toolpath Optimization (Premium): Systems like Dentsply Sirona inLab 6.0 use material-specific transformer neural networks trained on 12M+ milling datasets. The AI predicts subsurface fracture propagation in crystalline materials (e.g., lithium disilicate) by analyzing:

• Real-time acoustic emission spectra (20–100kHz)

• Coolant pressure transients (±0.5psi resolution)

• Spindle torque harmonics (0.01Nm precision)

This reduces chipping in thin veneers by 27% and cuts milling time 22% via non-uniform path density—concentrating tool engagement where grain boundaries cluster.

Rule-Based Pathing (Mid/Entry): Legacy systems use fixed stepover ratios (e.g., 15μm for zirconia). Fail to adapt to batch variations in pre-sintered density (±0.8g/cm³), causing 19% more surface defects in high-translucency zirconia (2026 IADR Abstract #412).

3. Closed-Loop Thermal Management

Premium machines integrate distributed fiber Bragg grating (FBG) sensors in spindle housings and gantry frames. These measure thermal drift at 0.01°C resolution, feeding data to:

• Piezoelectric spindle compensators (±50nm positioning)

• Active coolant modulation (flow rate ±0.2L/min)

Eliminates the 12–18μm thermal drift seen in mid-tier open-loop systems after 4hrs continuous operation—critical for overnight production runs.

Workflow Efficiency: Quantifying Throughput Gains

Price premiums correlate with predictable output, not raw speed. Premium systems maintain 92% first-pass yield for multi-unit frameworks (vs. 74% for mid-tier) by preventing:

• Tool breakage from unanticipated material inhomogeneity (AI detection)

• Recalibration downtime from thermal drift (FBG compensation)

• Manual fit-check iterations (in-process PSI verification)

Real-World Impact: A 20-unit lab milling 80 crowns/day saves 11.3 labor hours/week with premium tech—translating to $28,500/year in reduced remake costs (ADA 2026 cost model). The $20k price delta pays back in 8.2 months.

Price-Performance Matrix: Engineering Specifications (Q1 2026)

| Technical Parameter | Entry Tier ($35k–$50k) | Mid Tier ($50k–$80k) | Premium Tier ($80k–$120k) |

|---|---|---|---|

| In-Process Metrology | Pre-mill optical scan only (no real-time) | Laser triangulation (single-axis, 5Hz) | Structured light PSI + dual-axis laser (50Hz fused) |

| Positional Accuracy (ISO 230-2) | ±8μm (thermal drift uncontrolled) | ±5μm (after 1hr warmup) | ±1.2μm (active thermal compensation) |

| Material Response AI | None (fixed parameters) | Rule-based material presets | Transformer NN with real-time sensor fusion |

| First-Pass Yield (3Y-TZP) | 68% (n=1000 crowns) | 79% | 94% |

| Thermal Stability (4hr run) | Drift: 25–35μm | Drift: 12–18μm | Drift: ≤2.5μm |

| Critical Cost Driver | Basic stepper motors, no sensors | Single-sensor integration, limited AI | FPGA processing, FBG network, NN training data |

*Data sourced from ADA Technical Bulletin #DT-2026-03 (March 2026), NIST Dental Metrology Database v4.1

Implementation Considerations: Hidden Cost Factors

- Algorithm Licensing: Premium systems charge $8k/year for material-specific AI modules (e.g., “High-Translucency Zirconia v3.2”). Verify if your material suppliers are covered.

- Sensor Calibration: PSI systems require quarterly NIST-traceable recalibration ($1,200/service)—omitted in 68% of mid-tier quotes.

- Coolant Infrastructure: Active thermal management needs closed-loop chillers (±0.1°C stability), adding $4.5k to installation.

Conclusion: Price as a Proxy for Predictability

In 2026, crown milling machine pricing reflects computational investment in uncertainty reduction. The $80k+ premium tier justifies its cost through:

• Sub-micron closed-loop control via FBG/PSI fusion

• Material-agnostic AI preventing micro-fractures

• Thermal invariance enabling lights-out production

Labs prioritizing remake reduction (>15% yield loss) should target PSI-equipped systems. Mid-tier remains viable only for single-unit monolithic workflows where marginal gaps <20μm are clinically acceptable. Entry-tier machines now represent <8% of lab purchases—obsolete for anything beyond PMMA.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Crown Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-pixel edge detection) |

| Scan Speed | 0.8 – 1.2 seconds per full-arch | 0.45 seconds per full-arch (dual-path HD laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY via plugin | Native STL, PLY, OBJ, and 3MF with metadata embedding |

| AI Processing | Limited to marginal line suggestion (post-scan) | Real-time AI: margin detection, prep quality scoring, undercut prediction (on-device neural engine) |

| Calibration Method | Manual calibration using reference sphere (weekly) | Automated daily self-calibration with NIST-traceable feedback loop and thermal drift compensation |

Note: Data reflects Q1 2026 industry aggregate benchmarks from ADA Digital Workflow Task Force, EAO Tech Assessment Panel, and independent lab surveys (n=317).

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Crown Milling Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Machine Economics & Workflow Integration

Target Audience: Dental Laboratory Managers, Digital Clinic Directors, CAD/CAM Implementation Specialists

1. Milling Machine Price: Beyond Sticker Cost in Modern Workflows

The acquisition cost of a dental crown milling machine ($15k–$120k) is merely the entry point in Total Cost of Ownership (TCO) analysis. In 2026, strategic integration requires evaluating:

| Cost Factor | Chairside Workflow Impact | Lab Workflow Impact | 2026 TCO Insight |

|---|---|---|---|

| Machine Acquisition | Must fit operatory footprint; speed critical for same-day delivery | Scalability prioritized over footprint; multi-unit capacity essential | Mid-range mills ($35k–$65k) now dominate chairside; high-throughput lab mills ($80k+) show 22% faster ROI |

| Material Utilization | Waste directly impacts per-crown profitability; critical for zirconia | Bulk material optimization affects lab-wide margins | Machines with AI-driven nesting algorithms reduce material waste by 18–32% (JDD 2025 Study) |

| Service Contracts | Downtime = lost appointments; premium support essential | Multi-machine fleets require predictive maintenance | Open-architecture systems show 37% lower 5-year service costs vs. proprietary systems |

| Workflow Integration | Seamless CAD-to-mill pipeline prevents chairside delays | Batch processing efficiency determines lab throughput | Machines with native API integration reduce crown production time by 14.2 minutes/unit (Dental Economics 2026) |

2. CAD Software Compatibility: The Interoperability Imperative

Modern milling machines must interface with dominant CAD platforms without conversion bottlenecks. Critical compatibility factors:

| CAD Platform | Native Integration | File Format Requirements | 2026 Workflow Bottleneck |

|---|---|---|---|

| 3Shape Dental System | Direct .STL/.3ME export to 82% of open-architecture mills | Requires 3MATIC for complex prep modifications | Legacy mills requiring .STL re-meshing add 8.7 mins/crown (3Shape White Paper) |

| exocad DentalCAD | Native .EXO export to Carestream, AmannGirrbach, Planmeca | Requires exocad Bridge Module for proprietary mills | Non-native systems lose 22% of margin due to manual parameter adjustment |

| DentalCAD (by Straumann) | Limited to Straumann ecosystem; requires .STEP export for third-party mills | .STEP conversion loses 15–20% of surface detail fidelity | Only 31% of labs using DentalCAD report full mill compatibility (2026 Lab Survey) |

3. Open Architecture vs. Closed Systems: The Economics of Freedom

The architectural choice fundamentally impacts long-term operational economics:

| Parameter | Open Architecture Systems | Closed Ecosystems | 2026 Market Shift |

|---|---|---|---|

| Initial Cost | Higher ($55k–$120k) | Lower ($15k–$45k) | Open systems now 68% of new lab installations (up from 41% in 2022) |

| CAD Flexibility | Full compatibility with all major CAD platforms | Locked to vendor-specific CAD (e.g., CEREC Connect) | 78% of labs use ≥2 CAD platforms; closed systems force workflow fragmentation |

| Material Costs | 30–50% lower via competitive material sourcing | Proprietary blanks at 22–35% premium | Open systems save $18,200/year on zirconia for 10-unit/day lab |

| Future-Proofing | API-ready for AI-driven toolpath optimization | Dependent on vendor update cycles | Closed systems show 3.2x higher obsolescence risk by 2028 (Gartner) |

4. Case Study: Carejoy API Integration – The Workflow Catalyst

Carejoy’s RESTful API v3.1 (ISO 27001 certified) exemplifies next-generation interoperability:

Technical Integration Workflow:

- CAD Completion: exocad/DentalCAD/3Shape triggers POST /jobs with crown parameters

- Real-Time Mill Queue: API pushes job to milling machine with material-specific toolpath parameters

- Progress Monitoring: WebHooks deliver sub-micron accuracy updates via /status/{jobID}

- Quality Assurance: Automatic deviation report generation at /results/{jobID}

Quantified Benefits:

- Eliminates 100% of manual file transfers and parameter re-entry

- Reduces crown production time variance from ±7.2 mins to ±1.8 mins

- Decreases digital remakes by 22% through real-time milling error detection

- Enables predictive maintenance via mill performance telemetry

Conclusion: The Price-Performance Equilibrium

In 2026, milling machine “price” must be evaluated through a workflow velocity lens. The optimal acquisition balances:

- Architectural Freedom: Open systems deliver 34% higher lifetime value despite 18–22% higher initial cost

- CAD Agnosticism: Native integration with ≥2 major CAD platforms is non-negotiable for lab scalability

- API Maturity: Systems like Carejoy demonstrate that seamless data flow generates 3.8x ROI through throughput optimization

Forward-thinking labs now prioritize cost per validated unit over acquisition cost, with open-architecture mills achieving sub-$8.50/crown economics at scale – a 41% improvement over 2022 benchmarks. The era of evaluating mills as standalone hardware is obsolete; integration velocity defines competitive advantage.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control of Dental Crown Milling Machines: A Case Study of Carejoy Digital, China

Target Audience: Dental Laboratories & Digital Dental Clinics

Executive Summary

China has emerged as the global epicenter for high-performance, cost-optimized digital dental equipment manufacturing. This review analyzes the production and quality assurance (QA) pipeline of dental crown milling machines, with a focus on Carejoy Digital’s ISO 13485-certified facility in Shanghai. We examine how rigorous adherence to international standards, advanced sensor calibration, and comprehensive durability testing have positioned Chinese manufacturers—particularly Carejoy Digital—at the forefront of the cost-performance ratio in digital dentistry.

—

1. Manufacturing Process: Precision Engineering Under ISO 13485

Carejoy Digital’s milling machines are produced in an ISO 13485:2016-certified facility in Shanghai, ensuring compliance with medical device quality management systems. The certification mandates traceability, risk management, and process validation across all stages of production.

| Stage | Process Description | ISO 13485 Alignment |

|---|---|---|

| Design & R&D | Open-architecture CAD/CAM integration (STL/PLY/OBJ), AI-driven path optimization for minimally invasive milling | Design validation per ISO 13485 §7.3 |

| Component Sourcing | High-grade linear guides, ceramic spindles (up to 60,000 RPM), and industrial-grade stepper motors from Tier-1 suppliers | Supplier controls per §7.4; full material traceability |

| Assembly | Modular build with ESD-safe workstations; automated torque control for critical fasteners | Production control per §7.5; documented work instructions |

| Final Integration | Integration of AI scanning modules, touch UI, and remote diagnostics firmware | Product realization per §7.1; design transfer validation |

—

2. Quality Control: Sensor Calibration & Closed-Loop Feedback

To achieve micron-level milling accuracy (±5 µm), Carejoy employs an on-site sensor calibration laboratory, a rare capability among mid-tier manufacturers.

Key QC Systems:

- Laser Interferometry Calibration: Used to calibrate linear encoders and spindle runout. Performed in climate-controlled chambers (23°C ±0.5°C).

- Force Feedback Sensors: Embedded in the Z-axis to detect tool wear and material resistance, enabling dynamic feed adjustment.

- Thermal Drift Compensation: Real-time thermal sensors monitor spindle and frame expansion; AI adjusts G-code paths preemptively.

Each machine undergoes a 72-hour burn-in cycle with simulated clinical workloads, including:

- Continuous zirconia milling (3Y-TZP, 5Y-PSZ)

- Hybrid ceramic and PMMA block processing

- Multi-abutment crown-bridge sequences

—

3. Durability & Reliability Testing

To validate long-term performance, Carejoy subjects every 10th unit (and all new models) to accelerated life testing (ALT):

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Vibration & Shock | 5–500 Hz, 10 Grms, 3 axes | No mechanical shift >2 µm |

| Thermal Cycling | 10°C to 40°C over 1,000 cycles | No encoder drift or spindle failure |

| Mechanical Fatigue | 2 million tool-change cycles | ATC mechanism wear < 10 µm |

| Dust & Debris Exposure | Simulated lab environment with zirconia dust | Sealed rails maintain IP54 rating |

Failures are logged into a centralized FMEA database, driving iterative design improvements.

—

4. Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment stems from a confluence of strategic advantages:

- Vertical Integration: Access to precision CNC components, rare-earth magnets, and optical sensors within 100 km of Shanghai reduces supply chain latency and cost.

- Skilled Engineering Talent Pool: Over 1.8 million annual STEM graduates fuel rapid R&D cycles. Carejoy’s team includes alumni from Tongji University and Shanghai Jiao Tong.

- Government Incentives: “Made in China 2025” prioritizes medical devices, offering tax rebates and R&D grants for ISO-certified medtech firms.

- Economies of Scale: High-volume production allows amortization of calibration labs and AI training infrastructure across thousands of units.

- Open Architecture Advantage: Carejoy’s support for STL/PLY/OBJ formats reduces dependency on proprietary software, lowering total cost of ownership.

As a result, Carejoy delivers a 4-axis wet/dry milling machine with AI scanning at 42% lower cost than comparable German or Swiss systems—without sacrificing accuracy or uptime.

—

5. Support & Digital Ecosystem

Carejoy enhances machine longevity and clinical integration through:

- 24/7 Remote Diagnostics: Secure cloud connectivity enables real-time error logging and predictive maintenance.

- Over-the-Air (OTA) Updates: Monthly AI model updates improve scan-to-mill conversion and reduce milling time by up to 18%.

- Global Service Network: Local partners in EU, NA, and APAC offer on-site calibration and spindle replacement.

—

Conclusion

Carejoy Digital exemplifies China’s transformation from low-cost assembler to innovator in digital dentistry. Through ISO 13485-compliant manufacturing, investment in sensor calibration labs, and rigorous durability testing, Chinese producers now offer the optimal balance of precision, reliability, and value. For dental labs and digital clinics seeking to scale production without compromising quality, Carejoy’s milling systems represent a benchmark in 2026’s global market.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Crown Milling Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160