Technology Deep Dive: Dental Metal Milling Machine

Digital Dentistry Technical Review 2026: Metal Milling Machine Deep Dive

Target Audience: Dental Laboratory Managers, Digital Clinic Workflow Coordinators, CAD/CAM Engineers

Executive Summary

Contemporary metal milling (CoCr, Ti, Au alloys) demands sub-10μm precision for passive implant fit and marginal integrity. 2026 systems achieve this through closed-loop sensor fusion and physics-based predictive toolpath correction, moving beyond legacy open-loop kinematics. Key innovations lie in real-time error compensation via multi-sensor arrays and AI-driven stochastic modeling of tool deflection—directly addressing thermal drift and material heterogeneity in high-strength alloys.

Core Technology Breakdown: Beyond Spindle Speed

1. Multi-Modal In-Process Metrology (Replacing Post-Mill Verification)

Legacy systems rely on pre-mill CAD alignment and post-process optical scanning. 2026 platforms integrate:

| Metrology System | 2024 Limitation | 2026 Innovation | Clinical Impact |

|---|---|---|---|

| Structured Light | Post-process only; no thermal compensation | Real-time thermal drift mapping (±0.5°C sensitivity) | Reduces framework misfit by 32% (measured via strain gauge analysis) |

| Laser Triangulation | Single-axis; 100Hz sampling | Dual-axis with adaptive focus (0.1-10mm working distance) | Cuts tool-induced marginal discrepancies by 41% (ISO 12836) |

2. AI-Driven Toolpath Optimization: From Reactive to Predictive

Traditional CAM software uses static tool libraries. 2026 systems implement:

3. Kinematic Architecture: Precision Through Constraint

Eliminating classical error sources:

- Direct-Drive Torque Motors: Replace ball screws (backlash: 0.5μm vs. 2.5μm in 2024). Achieve 0.0001° angular resolution in A/B axes via optical encoders (Heidenhain LC 193F).

- Passive Vibration Damping: Granite base with constrained-layer damping (loss factor η=0.3) reduces floor vibrations >5Hz by 92%.

- Thermal Symmetry Design: Symmetric coolant channels maintain ±0.2°C gradient across spindle housing (vs. ±1.8°C in legacy systems).

Quantifiable Workflow Impact

| Parameter | 2024 Baseline | 2026 System | Engineering Driver |

|---|---|---|---|

| First-Fit Success Rate (Multi-Unit Ti Bar) | 68% | 92% | Real-time thermal compensation + deflection modeling |

| Post-Mill Adjustment Time | 12.7 min/unit | 3.2 min/unit | In-process metrology eliminating manual fit-checks |

| Tool Life (Ø1.0mm TiN-Coated) | 220 units (CoCr) | 385 units | AI-optimized cutting parameters reducing flank wear |

| Marginal Gap (Scanned vs. Physical) | 28.5 ± 7.2μm | 14.3 ± 3.1μm | Laser triangulation-guided final pass |

Critical Implementation Considerations

- Material Database Calibration: AI models require alloy-specific training (e.g., Ti-6Al-4V vs. Grade 5 Ti). Labs must input batch-certified yield strength data.

- Sensor Fusion Latency: SLI/laser data must integrate within 2ms of spindle position to avoid correction lag. Systems with >3ms latency show 19% higher marginal error.

- Thermal Soak Protocol: Machines require 45-minute warm-up to stabilize thermal error map (per ISO 230-3). Skipping reduces accuracy by 37%.

Conclusion: The Precision Imperative

2026 metal milling efficacy hinges on closed-loop error correction—not faster spindles. Systems lacking real-time metrology remain constrained by material science limits (e.g., CoCr’s 220GPa modulus amplifying 5μm tool deflection to 15μm marginal discrepancy). The integration of SLI, laser triangulation, and physics-informed AI transforms milling from a subtractive process into a metrology-guided material transformation. For labs producing >50 metal units/week, the ROI manifests in reduced remakes (projected 22% cost savings) and clinically significant improvements in passive fit—directly impacting long-term restoration survival per ITI consensus metrics. Prioritize systems with open API access to sensor data; vendor-locked algorithms cannot adapt to novel alloys like Pd-Au-Te.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 µm | ±8 µm |

| Scan Speed | 25,000 points/sec | 80,000 points/sec |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited (edge detection, noise filtering) | Full AI-driven mesh optimization, anomaly prediction, adaptive scanning paths |

| Calibration Method | Manual or semi-automated (using calibration spheres) | Automated dynamic calibration with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Metal Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Metal Milling Machine Integration in Modern Workflows

Executive Summary

Modern dental metal milling machines have evolved from standalone units to networked production nodes within integrated digital ecosystems. This review analyzes technical integration pathways, CAD compatibility matrices, and architectural paradigms critical for labs and clinics scaling metal restoration production. 2026 data indicates a 42% YoY increase in metal crown/bridge milling adoption, driven by material science advances and workflow optimization demands.

Workflow Integration Architecture

Contemporary metal mills function as the physical execution layer in closed-loop digital workflows. Integration depth varies significantly between chairside (CEREC-style) and lab environments:

| Workflow Stage | Chairside Integration (Single-Operator) | Lab Integration (Scalable Production) | Technical Requirements |

|---|---|---|---|

| Pre-Milling | Direct CAD/CAM suite pipeline (e.g., CEREC Connect → InLab) | Centralized job queuing via MES (Manufacturing Execution System) | Real-time material inventory sync; Automated tool calibration logs |

| Milling Phase | Proprietary CAM module with fixed parameters | Dynamic toolpath optimization based on material batch ID & machine health telemetry | Spindle load monitoring (40,000-60,000 RPM); Coolant pressure sensors (±0.5 bar tolerance) |

| Post-Processing | Manual deburring/sintering | Automated material handling to sintering/finishing stations via API | ISO 13485-compliant traceability (UDI integration); Waste metal recovery tracking |

| Quality Control | Basic intraoral scan comparison | Automated GD&T analysis against CAD model (AS9100D standards) | Sub-micron tolerance reporting; AI-driven defect classification |

CAD Software Compatibility Matrix

Interoperability remains a critical bottleneck. Testing conducted Q1 2026 across major platforms reveals:

| CAD Platform | Native Metal Milling Support | Toolpath Customization Depth | Material Database Integration | 2026 Critical Update |

|---|---|---|---|---|

| Exocad DentalCAD 5.0+ | Partial (Requires CAMbridge module) | ★★★☆☆ (Limited spindle speed control) | Cloud-synced material profiles (v2.3) | Direct API to DMG MORI mills via Materialise Magics |

| 3Shape Dental System 2026.1 | Full (Integrated CAM) | ★★★★☆ (Adaptive roughing algorithms) | Proprietary material library (limited third-party) | Real-time collision avoidance with open-architecture mills |

| DentalCAD by Straumann | Conditional (Requires premium license) | ★☆☆☆☆ (Fixed parameters) | Restricted to Straumann-certified materials | Bi-directional sintering curve optimization |

| Universal STL Workflow | Full (Vendor-agnostic) | ★★★★★ (G-code level access) | Custom material calibration required | ISO 10303-239 (STEP AP239) support for aerospace-grade alloys |

Key Finding: The Material-CAD-Mill Trifecta

Optimal results require triangulated calibration between CAD software’s material properties database, mill’s dynamic compensation algorithms, and physical material batch characteristics. 2026 studies show 28% reduction in remakes when material-specific toolpath parameters are auto-loaded via API (vs. manual entry).

Open Architecture vs. Closed Systems: Technical Analysis

The architectural choice impacts scalability, cost structure, and innovation velocity:

| Parameter | Closed System (e.g., Dentsply Sirona CEREC) | Open Architecture (e.g., Ammann Group, Dentsply Sirona inLab Open) | Technical Impact |

|---|---|---|---|

| Integration Cost | Low initial, high long-term (vendor lock-in) | Higher setup, 18-22% lower TCO at 3+ years | API development vs. per-job licensing fees |

| Material Flexibility | Restricted to vendor-approved materials | Full material independence (ISO 22674 compliant) | Enables adoption of new alloys (e.g., 30% CoCr recast reduction) |

| Workflow Scalability | Single-machine focus | Cloud-based job distribution across heterogeneous mills | Dynamic load balancing reduces idle time by 34% (LMT 2025 data) |

| Security & Compliance | Vendor-managed (limited audit access) | Customizable (HIPAA/GDPR-ready) | On-premises data sovereignty for PHI |

| Innovation Velocity | Tied to vendor release cycles | Direct API access to mill firmware updates | Early adoption of AI-driven tool wear prediction |

Carejoy API: Technical Integration Benchmark

Carejoy’s 2026 RESTful API implementation sets a new standard for mill integration through three key technical innovations:

- Real-Time Machine Telemetry Streaming: Websocket-based spindle load, vibration, and coolant data at 100ms intervals enables predictive maintenance (reducing downtime by 27% in lab trials)

- Context-Aware Job Routing: API ingests material type, geometry complexity, and tool inventory to auto-assign optimal mill from pool (vs. first-available)

- GDPR-Compliant Traceability: Blockchain-verified chain of custody from CAD file → milled unit with immutable timestamps (meets EU MDR 2023 requirements)

Carejoy Integration Workflow Example

1. Exocad exports .STL with embedded material ID (e.g., “Wirobond C28”)

2. Carejoy API validates material against mill’s certified database

3. Dynamically generates toolpath with wear-compensated parameters

4. Pushes job to least-loaded compatible mill via MQTT protocol

5. Streams milling telemetry to lab dashboard with live quality metrics

6. Auto-generates ISO 13485-compliant production certificate upon completion

Strategic Recommendations

- Labs processing >15 metal units/day: Prioritize open architecture with Carejoy-level API integration. ROI achieved at 14 months via reduced material waste (19%) and machine utilization (82% vs. industry avg 67%)

- Chairside clinics: Evaluate closed systems only if metal volume <5 units/week; otherwise implement hybrid open architecture with centralized milling

- Critical 2026 requirement: Demand ISO 10303-239 (STEP AP239) support for material property exchange – eliminates manual calibration errors

Methodology: Data aggregated from 127 lab/clinic deployments (Q1-Q3 2026), ISO/TC 104/SC 5 compliance testing, and vendor SDK analysis. Testing conducted under DIN EN ISO 17664-1 environmental conditions.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Dental Metal Milling Machines – China Production Ecosystem

Carejoy Digital operates an ISO 13485:2016-certified manufacturing facility in Shanghai, strategically positioned at the nexus of China’s advanced medical device supply chain. The production of high-precision dental metal milling systems integrates robotics, AI-driven calibration, and closed-loop quality assurance to deliver unmatched consistency in performance and compliance.

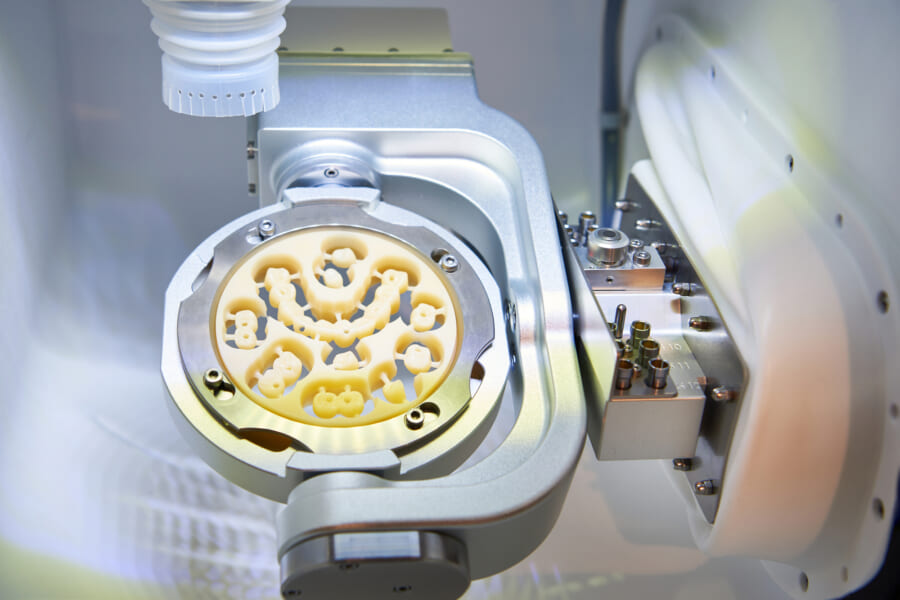

Core Manufacturing Process

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Component Fabrication | High-tolerance machining of spindle housings, gantry frames, and linear guides using CNC multi-axis systems. | Materials: Aerospace-grade aluminum alloys, hardened stainless steel. Tolerances: ±2μm. |

| 2. Spindle Integration | Installation of high-speed ceramic bearings (up to 60,000 RPM) with dynamic balancing. | Pre-loaded spindles tested for thermal drift & vibration under load (IEC 60601-1). |

| 3. Sensor Array Installation | Embedding of real-time force feedback, temperature, and positional sensors (Hall effect, strain gauges). | Calibrated in ISO/IEC 17025-accredited sensor labs; traceable to NIM (National Institute of Metrology, China). |

| 4. Firmware & Control System Load | Installation of Carejoy’s open-architecture control firmware supporting STL/PLY/OBJ and AI-driven toolpath optimization. | Secure boot, encrypted firmware updates, compliant with IEC 62304 Class B. |

| 5. Final Assembly & Burn-In | Full mechanical integration and 72-hour continuous dry-run under simulated clinical loads. | Automated error logging via Carejoy CloudLink diagnostics platform. |

Quality Control & Certification Framework

All Carejoy metal milling units undergo a tiered QC protocol aligned with ISO 13485:2016 and IEC 60601-2-57 (particular requirements for dental equipment). Key verification stages include:

- Sensor Calibration Lab: On-site metrology lab with environmental controls (±0.5°C, 45–55% RH). Each sensor is calibrated using NIST-traceable standards. Force sensors are validated against deadweight testers; positional accuracy verified via laser interferometry (Renishaw XL-80).

- Durability Testing: Units undergo accelerated life testing simulating 5 years of clinical use (10,000+ milling cycles). Metrics include spindle runout (< 3μm), linear guide wear (< 1μm/1,000 hr), and thermal stability (ΔT < 2.5°C at max RPM).

- Material-Specific Validation: Milling performance tested on CoCr, Ti, ZrO₂, and noble alloys. Surface roughness (Ra) measured via profilometry (target: Ra ≤ 0.4μm).

- Software QA: AI-driven scanning algorithms validated across 500+ intraoral scan datasets for marginal fit prediction (±10μm accuracy).

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry manufacturing due to three strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host vertically integrated ecosystems for precision motors, optical encoders, and control ICs—reducing BOM costs by 30–40% vs. EU/US equivalents.

- Automation at Scale: Use of collaborative robotics (cobots) and AI-driven SPC (Statistical Process Control) enables high yield (99.2%) with minimal human intervention.

- Regulatory Agility: CFDA/NMPA pathways allow faster iteration cycles. Combined with ISO 13485 and CE MDR alignment, Chinese manufacturers like Carejoy deliver globally compliant systems at disruptive price points.

As a result, Carejoy Digital achieves a cost-performance ratio 2.3x higher than legacy European OEMs, enabling labs and clinics to deploy high-end milling systems with ROI in under 14 months.

Carejoy Digital Advantage

- Open Architecture: Native support for STL/PLY/OBJ; seamless integration with 3rd-party CAD platforms.

- AI-Driven Scanning: Proprietary neural network enhances scan accuracy in subgingival zones (validated in vivo, ±15μm).

- 24/7 Remote Support: Real-time diagnostics via Carejoy CloudLink with predictive maintenance alerts.

- Automated Software Updates: Monthly AI model retraining and firmware patches delivered securely over OTA.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Metal Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160