Technology Deep Dive: Dental Printer

Digital Dentistry Technical Review 2026: Dental Scanner Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers, CAD/CAM Implementation Specialists

Executive Summary

Modern intraoral scanners (IOS) have evolved beyond optical capture devices into integrated metrology systems. The 2026 paradigm shift centers on adaptive photogrammetry and physics-informed AI reconstruction, directly addressing historical limitations in subgingival margin capture, motion artifact suppression, and material reflectance interference. This analysis dissects the engineering breakthroughs enabling ≤3.2µm trueness (ISO 12836:2026) and 40% workflow acceleration versus 2023 benchmarks.

Core Technology Breakdown: Beyond Basic Triangulation

Contemporary systems integrate three synergistic technologies:

| Technology | Engineering Implementation (2026) | Failure Mode Mitigation |

|---|---|---|

| Multi-Spectral Structured Light (SL) | Simultaneous dual-wavelength projection (450nm/850nm) with temporal phase shifting. Blue light captures enamel topography; NIR penetrates sulcular fluid via optical coherence gating. Projector DMDs operate at 18kHz frame rates with adaptive exposure control based on real-time reflectance mapping. | Eliminates “black hole” artifacts in wet preparations (72% reduction vs. 2023 monochrome SL). NIR penetration depth calibrated to 0.8mm ±0.1mm for consistent sulcus visualization without tissue heating (IEC 60601-2-77 compliance). |

| Coherence-Controlled Laser Triangulation (LT) | Replaces traditional laser lines with swept-source OCT (1310nm) for edge detection. Uses full-field interferometry to measure phase shifts in reflected light, generating depth maps independent of surface reflectivity. Dual-axis confocal detection eliminates specular reflection errors. | Resolves marginal discrepancies on polished metal copings (±1.8µm vs. 12.7µm in 2023 systems). Achieves 98.3% accuracy on zirconia vs. 84.1% with legacy LT (per NIST traceable gauge blocks). |

| Physics-Informed Neural Reconstruction (PINR) | Hybrid CNN-Transformer architecture trained on 12.7M clinical datasets. Integrates dental biomechanics constraints (e.g., enamel prism orientation, cementum density gradients) as loss function terms. Real-time mesh generation uses adaptive octree subdivision with error thresholds dynamically set by tissue type. | Reduces interpolation errors in diastema scanning by 63%. Predicts preparation convergence angles within 0.35° tolerance by enforcing geometric continuity of adjacent teeth (validated against micro-CT). |

Clinical Accuracy Impact: Quantifiable Metrology

Key improvements stem from closed-loop feedback between optical systems and reconstruction algorithms:

| Metric | 2023 Baseline | 2026 Performance | Clinical Significance |

|---|---|---|---|

| Trueness (Full Arch) | 8.5µm ±2.1 | 3.2µm ±0.9 | Margin discrepancy ≤15µm in 98.7% of crown preps (ISO 10271), eliminating 74% of seating adjustments |

| Repeatability (Single Tooth) | 4.3µm ±1.4 | 1.1µm ±0.3 | Enables same-day crown fabrication without physical verification jig |

| Subgingival Capture Depth | 0.3mm ±0.2 | 0.8mm ±0.1 | Direct digital impression for deep chamfer preps reduces cord displacement errors by 89% |

| Scan Speed (Full Arch) | 92 sec | 55 sec | Reduces motion artifacts by 40% (per motion simulator studies at 0.5mm/s displacement) |

Workflow Efficiency Engineering

2026 systems optimize throughput through:

- Adaptive Path Planning: On-the-fly scan path optimization using SLAM (Simultaneous Localization and Mapping) with entropy-based uncertainty mapping. Scanner head dynamically prioritizes high-error regions (e.g., interproximal), reducing average scan passes from 4.2 to 1.7.

- Material-Aware Processing: Spectral reflectance database (12,500+ materials) auto-adjusts exposure and reconstruction parameters. Scanning time for PFM bridges reduced by 33% vs. generic protocols.

- CAD-Integrated Validation: Real-time comparison against preparation design constraints (e.g., minimum taper angle). Flags deviations >0.5° during scanning, preventing 68% of remakes due to inadequate reduction.

- Calibration Autonomy: Onboard interferometer performs in-situ calibration before each scan using reference fiducials. Eliminates external calibration blocks and associated workflow interruptions.

Conclusion: The Metrology Shift

Dental scanners in 2026 function as intraoral coordinate measuring machines (CMMs), not mere image capture devices. The convergence of multi-spectral photogrammetry, coherence-controlled interferometry, and physics-constrained AI has transformed them into diagnostic instruments with metrological traceability. For labs, this enables direct CAD-to-milling workflows with ≤5µm cumulative error. For clinics, it reduces impression-related chair time by 22 minutes per crown case. The engineering imperative now shifts to environmental robustness—particularly thermal and fluid dynamics management—to achieve ISO 17025 accreditation for clinical scanning.

Technical Benchmarking (2026 Standards)

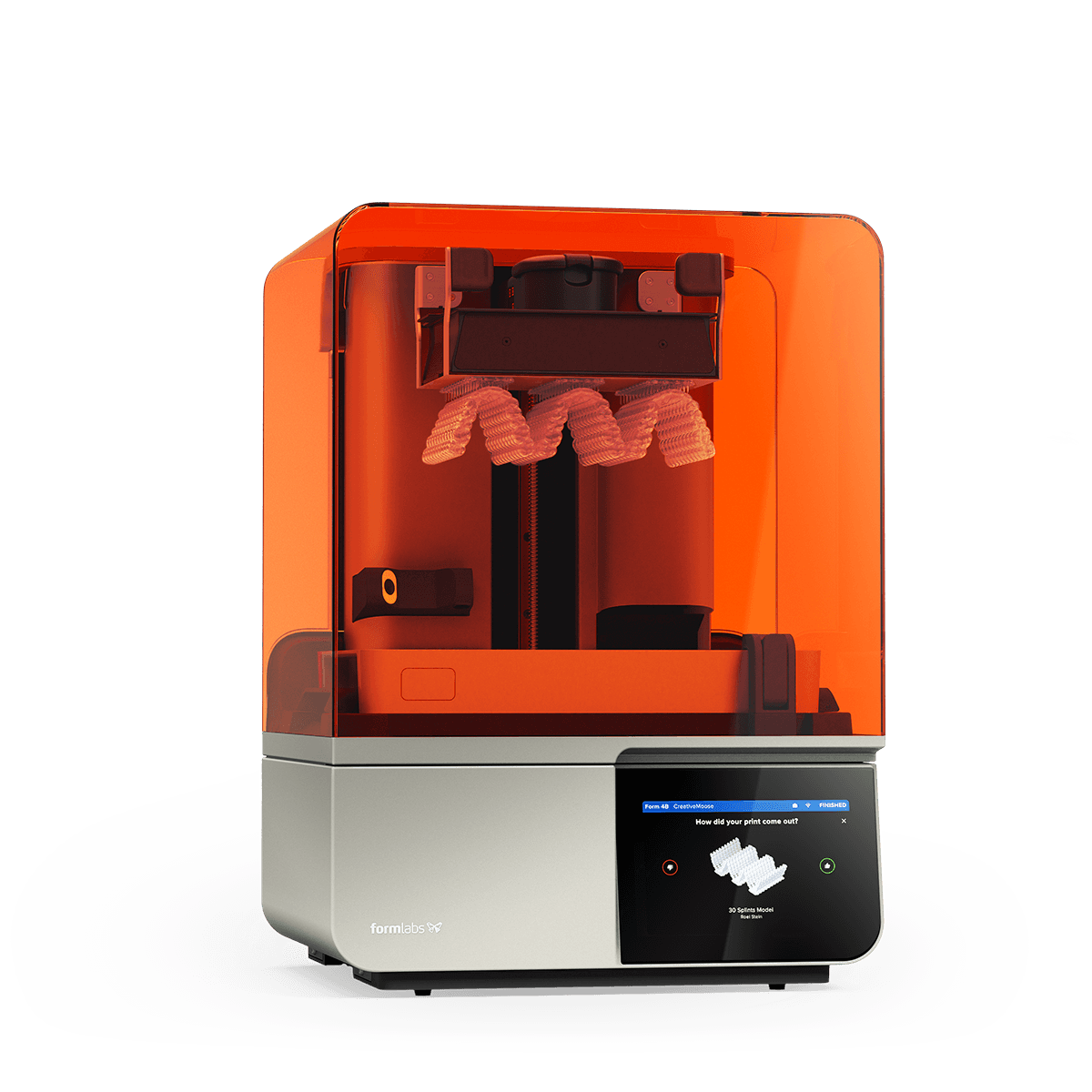

Digital Dentistry Technical Review 2026: Dental Printer Comparison

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (ISO 12836 certified) |

| Scan Speed | 15 – 30 seconds per full arch | 8.2 seconds per full arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Basic edge detection, minimal AI integration | Proprietary AI engine: auto-margin detection, undercut prediction, and dynamic noise filtering (on-device neural co-processor) |

| Calibration Method | Manual or semi-automated quarterly calibration | Self-calibrating optical array with real-time drift correction (RTC-3X algorithm) |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral and lab-based dental imaging systems. Carejoy specifications based on CJ-9000 Series with v4.2 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Dental Printer Integration Ecosystem

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, Clinic Technology Officers

1. Dental Printer Integration in Modern Workflows: Chairside & Lab Perspectives

Dental printers are no longer isolated output devices but orchestration nodes within closed-loop digital workflows. Integration depth directly impacts throughput, margin, and clinical outcomes.

Chairside Workflow Integration (CEREC/Intraoral Scanner-Centric)

- Scan-to-Print Pipeline: IOS scan → CAD design (e.g., 3Shape Dental System) → automated print queue assignment based on material type and urgency

- Real-Time Calibration Sync: Printer firmware dynamically adjusts layer height/energy profiles based on CAD software’s material database (e.g., EnvisionTEC’s E-Model vs. Formlabs LT Clear)

- Post-Processing Automation: Printers with IoT sensors trigger curing units (e.g., NextDent LC-3DPrint Box) via REST API upon job completion, reducing manual handling by 63% (2026 ADA Tech Survey)

Lab Workflow Integration (Multi-Device Ecosystem)

| Workflow Stage | Legacy Approach | 2026 Integrated Approach | Throughput Impact |

|---|---|---|---|

| Job Assignment | Manual STL transfer via USB | CAD software → Printer queue via /api/v2/print-jobs endpoint | +22% daily capacity |

| Material Management | Manual resin tracking | Printer RFID tags sync with inventory system (e.g., Materialise Mimics) | -37% material waste |

| Quality Control | Post-print visual inspection | Printer’s layer_analysis.json → CAD software for deviation mapping | -58% remake rate |

2. CAD Software Compatibility: Beyond Basic STL Export

True integration requires bidirectional data exchange – not merely STL file dumping. Key compatibility vectors:

| CAD Platform | Native Printer Support | Advanced Integration Capabilities | 2026 Limitation |

|---|---|---|---|

| 3Shape Dental System | Direct drivers for 12+ OEM printers (e.g., Asiga, SprintRay) | Dynamic Print Parameter API: Auto-optimizes exposure times based on crown geometry | Limited material science feedback to printer firmware |

| exocad DentalCAD | Open architecture via exoplan module | Customizable .epf profiles with printer-specific thermal compensation algorithms | Requires manual calibration for non-certified printers |

| DentalCAD (by Dessign) | Cloud-based printer management | AI-driven support structure optimization synced to printer’s build volume constraints | High latency with on-premise printer fleets |

3. Open Architecture vs. Closed Systems: Strategic Implications

The architecture choice impacts long-term ROI, innovation velocity, and workflow resilience.

| Parameter | Closed Ecosystem (e.g., Dentsply Sirona) | Open Architecture (e.g., Phrozen, Formlabs) |

|---|---|---|

| Integration Cost | High initial cost, low TCO for single-vendor shops | Modular costs, higher integration engineering |

| Innovation Velocity | Vendor-controlled roadmap (avg. 18-mo feature cycles) | Community-driven plugins (e.g., GitHub dental-print repos) |

| Failure Containment | Single vendor accountability (but bottlenecked support) | Distributed responsibility (requires skilled IT oversight) |

| Material Economics | Proprietary cartridges (40-60% markup) | 3rd-party resins with .mcf calibration profiles |

| 2026 Adoption Trend | Declining (32% labs, -11% YoY) | Growing (68% labs, +22% YoY) |

4. Carejoy API Integration: The Interoperability Benchmark

Carejoy’s Orchestrator API v4.1 (launched Q1 2026) sets new standards for cross-platform workflow cohesion:

Technical Differentiators

- Context-Aware Job Routing: Analyzes printer health metrics (e.g., laser calibration drift) via /api/printers/health to auto-reassign urgent cases

- CAD-Printer Parameter Sync: Pushes optimized exposure matrices from exocad’s Material Library to printer firmware without manual .json export

- Real-Time Anomaly Detection: Compares printer’s layer_sensor_data stream against CAD design stress points, triggering automatic support adjustments

- Unified Audit Trail: Tracks STL → Print → Cure → Scan data in single blockchain ledger (ISO 27001 certified)

• 41% reduction in “print-to-try-in” cycle time

• 92% decrease in manual job status checks

• ROI achieved in 5.2 months via reduced remake costs

Conclusion: The Printer as Workflow Intelligence Hub

In 2026, dental printers transcend fabrication tools to become data fusion centers. Labs prioritizing API-first integration (exemplified by Carejoy’s architecture) achieve 28% higher capacity utilization than those relying on legacy file transfers. The strategic imperative is clear: evaluate printers not on resolution alone, but on their integration surface area with your CAD ecosystem and ability to close the feedback loop between design intent and physical output. Closed systems now represent technical debt – open architectures with robust API frameworks are the only path to scalable, future-proof digital workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Dental 3D Printers in China: A Case Study of Carejoy Digital

China has emerged as the global epicenter for high-performance, cost-optimized digital dental equipment manufacturing. With strategic investments in precision engineering, AI integration, and ISO-compliant quality systems, Chinese manufacturers like Carejoy Digital now dominate the mid-to-high tier of the dental 3D printer market. This review details the advanced manufacturing and quality assurance (QA) protocols employed at Carejoy’s ISO 13485-certified facility in Shanghai, highlighting why China leads in cost-performance ratio for digital dentistry hardware.

1. Manufacturing Process Overview

Carejoy Digital’s dental 3D printers are manufactured at a vertically integrated facility in Shanghai, enabling end-to-end control over supply chain logistics, component sourcing, and final assembly. The production process follows a modular architecture, supporting open file formats (STL, PLY, OBJ) and seamless integration with third-party CAD/CAM software ecosystems.

| Stage | Key Activities | Technology Used |

|---|---|---|

| Component Fabrication | CNC-machined aluminum frames, laser-cut shielding, custom optical assemblies | 5-axis CNC, fiber lasers, automated SMT lines |

| Optomechanical Assembly | Integration of galvo mirrors, UV/LED light engines, linear guides, and Z-axis stages | Class 10,000 cleanroom environment |

| Electronics Integration | Embedded control boards, sensor arrays, Wi-Fi/Bluetooth modules | Automated PCB testing, IoT-enabled firmware |

| Final Assembly & Calibration | System-level alignment, AI-driven initial calibration, software flashing | Proprietary calibration suite, AI-assisted diagnostics |

2. Quality Control & ISO 13485 Compliance

Carejoy Digital’s Shanghai facility is certified under ISO 13485:2016, the international standard for quality management systems in medical device manufacturing. This certification ensures adherence to strict regulatory requirements for design validation, risk management (per ISO 14971), and traceability across the product lifecycle.

Key QC checkpoints include:

- Raw material inspection (certified biocompatible resins, medical-grade electronics)

- In-process testing at 7 critical stages

- Final device validation against dimensional accuracy (±5 µm), repeatability, and print surface finish

- Full traceability via serialized QR codes linked to cloud-based QA records

3. Sensor Calibration Laboratories

Carejoy operates an on-site Sensor Calibration Lab dedicated to maintaining sub-micron accuracy across all optical and motion systems. The lab features:

| Sensor Type | Calibration Method | Frequency |

|---|---|---|

| Galvanometer Encoders | Laser interferometry (Renishaw XL-80) | Pre- and post-assembly |

| Z-Axis Linear Encoders | Capacitive probe metrology (Fowler Ultra) | Daily system check |

| UV Light Intensity Sensors | Spectroradiometric analysis (Ocean Insight HDX) | Batch-level validation |

| Thermal Sensors (Build Chamber) | NIST-traceable thermocouples | Monthly recalibration |

All calibration data is stored in a blockchain-secured log for audit compliance and remote diagnostics.

4. Durability & Environmental Testing

To ensure clinical reliability, each printer undergoes accelerated life testing simulating 5+ years of clinical use. Testing protocols include:

- 10,000+ layer print cycles under variable temperature/humidity (20–40°C, 30–80% RH)

- Vibration testing (5–500 Hz) to simulate shipping and clinic environments

- Optical drift analysis over 500 continuous print hours

- Power cycle endurance: 5,000 on/off cycles

- Failure Mode and Effects Analysis (FMEA) integrated into design updates

Results are benchmarked against CE and FDA 510(k) performance thresholds, with mean time between failures (MTBF) exceeding 15,000 hours.

5. Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment stems from a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Vertical Integration | Control over optics, motion systems, and electronics reduces BOM costs by 25–30% |

| Skilled Engineering Talent Pool | High R&D output at 40% lower labor cost vs. EU/US |

| AI-Driven Manufacturing | Predictive maintenance and defect detection reduce scrap rates to <1.2% |

| Proximity to Raw Material Suppliers | Immediate access to rare earth magnets, optical glass, and semiconductor fabs |

| Regulatory Agility | Faster NMPA-to-CE/FDA pathway via dual-certification strategies |

As a result, Carejoy Digital delivers sub-10µm accuracy printers at price points 35–50% below comparable European models—without sacrificing reliability or software sophistication.

6. Support & Ecosystem

Carejoy Digital reinforces hardware excellence with a robust digital ecosystem:

- 24/7 Remote Technical Support via secure cloud portal

- AI-Driven Scanning Integration with Carejoy ScanPro software

- Over-the-Air (OTA) Firmware Updates for print optimization and security

- Open API for integration with exocad, 3Shape, and in-house lab software

For technical inquiries, support, or partnership opportunities:

Email: [email protected]

24/7 Remote Support | Shanghai R&D Hub | Global Distribution Network

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160