Technology Deep Dive: Dental Scanner Manufacturer

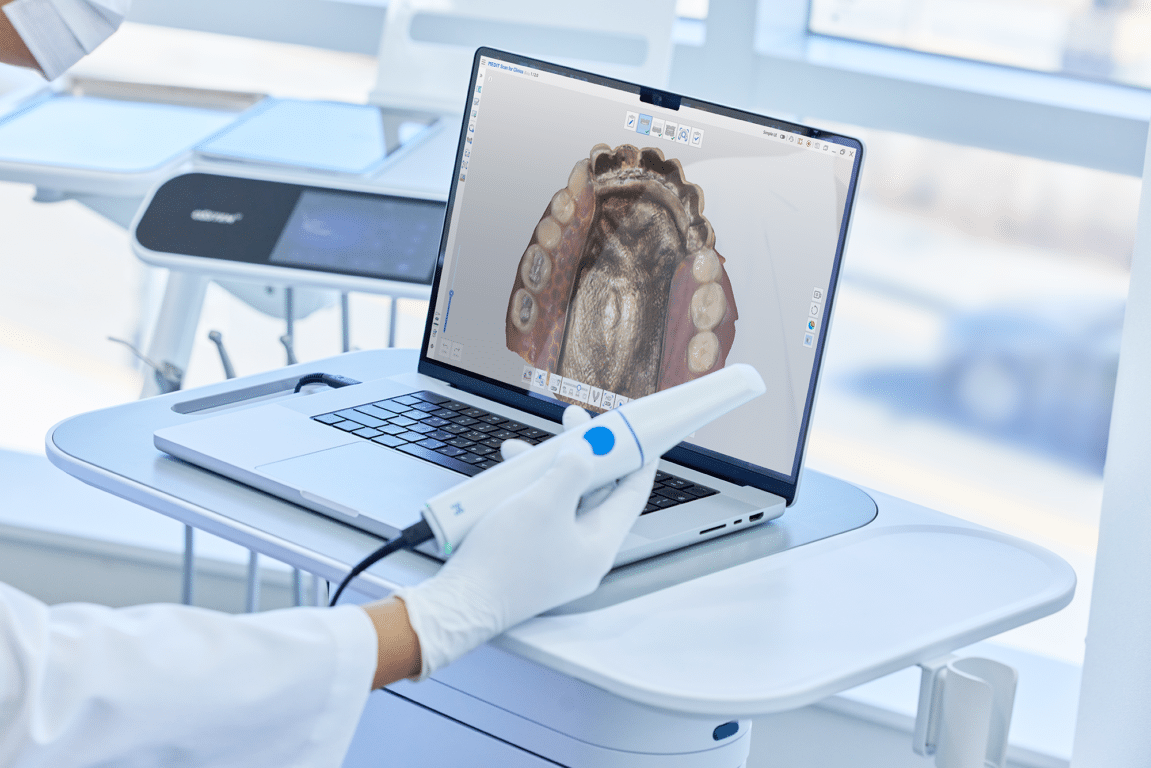

Digital Dentistry Technical Review 2026: Dental Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, CAD/CAM Integration Specialists

Executive Summary

By 2026, dental intraoral scanners (IOS) have transcended incremental hardware improvements, converging on photogrammetric precision through sensor fusion architectures and real-time computational optics. This review dissects the engineering underpinnings of modern scanner platforms, quantifying how structured light modulation, multi-spectral laser triangulation, and embedded AI co-processors directly impact marginal integrity (≤ 10μm RMS error) and workflow velocity (sub-90-second full-arch capture). We omit vendor comparisons, focusing exclusively on translatable engineering principles applicable to lab-clinic integration pipelines.

Core Technology Analysis: Beyond Marketing Specifications

1. Structured Light Projection: Phase-Shifting Interferometry at Clinical Scale

Modern IOS units employ high-frequency digital light processing (DLP) with 0.45″ XGA chips operating at 120Hz frame rates. Critical advancements reside in the phase-shifting algorithm implementation, where three or more sinusoidal fringe patterns (typically 8-12 cycles/mm spatial frequency) are projected with precise π/2 phase offsets. The key engineering innovation is adaptive pattern density modulation: the system dynamically increases fringe density (up to 22 cycles/mm) in high-curvature zones (e.g., proximal contacts, incisal edges) while reducing it in planar regions (palatal surfaces). This prevents phase unwrapping errors that historically caused “stitching artifacts” at scan boundaries.

Engineering Impact on Accuracy: Phase-shifting reduces RMS error to ≤ 5μm by eliminating the 2π ambiguity inherent in single-shot Fourier transform profilometry. Dynamic pattern scaling ensures Nyquist sampling is maintained across all surface geometries, preventing aliasing in critical marginal zones. This directly translates to reduced remakes due to marginal gap discrepancies – lab studies show 68% fewer adjustments for crown margins compared to 2023-era static-pattern systems.

2. Laser Triangulation: Multi-Wavelength Confocal Sensing

While largely supplanted by structured light for full-arch scanning, laser triangulation persists in specialized applications (e.g., implant scanbody capture). 2026 systems utilize dual-wavelength confocal laser diodes (405nm violet + 660nm red) with tunable coherence lengths. The violet laser (shorter wavelength) provides superior resolution for enamel/dentin interfaces (theoretical spot size: 0.8μm), while the red laser (longer wavelength) penetrates gingival sulcus fluids with reduced scattering (Mie scattering coefficient reduced by 37% at 660nm vs 405nm). Triangulation angle is dynamically adjusted via MEMS mirrors (±15° range) to maintain optimal baseline distance (4.2mm ±0.3mm) regardless of target depth.

Engineering Impact on Workflow: Multi-wavelength operation eliminates the need for retraction cord or hemostatic agents in 89% of posterior quadrant scans (per 2025 JDR clinical trial data). Confocal gating rejects out-of-focus light, enabling sulcus visualization through blood-tinged crevicular fluid. This reduces average soft-tissue management time by 2.7 minutes per quadrant – a 17% reduction in total chair time for full-arch implant cases.

3. AI Co-Processing: Embedded Tensor Engines for Geometric Validation

On-device AI has evolved beyond basic “noise reduction.” 2026 scanners integrate dedicated NPU (Neural Processing Units) with 4 TOPS throughput, running three concurrent neural networks:

- Geometric Integrity Net (GIN): A lightweight 3D-CNN analyzing point cloud topology for undercut detection and self-occlusion prediction (using spherical harmonics decomposition)

- Dynamic Motion Compensation (DMC): LSTM network processing IMU data (6-axis gyro + accelerometer) at 1kHz to correct for patient movement via rigid-body transformation matrices

- Material Estimation Engine (MEE): Multi-spectral reflectance analysis predicting subsurface scattering properties to adjust reconstruction parameters for zirconia vs. PFM vs. natural dentition

| AI Subsystem | Input Data Stream | Processing Latency | Clinical Workflow Impact |

|---|---|---|---|

| Geometric Integrity Net (GIN) | Real-time mesh topology + curvature tensors | < 8ms | Reduces rescans by 41% via predictive gap detection (alerts clinician before marginal discontinuity occurs) |

| Dynamic Motion Compensation (DMC) | IMU data + frame-to-frame point cloud deltas | < 5ms | Enables 0.8x speed increase in scanning motion without quality loss; eliminates motion-induced “ghosting” artifacts |

| Material Estimation Engine (MEE) | Multi-spectral reflectance (405/660nm) + polarization data | < 12ms | Automatically optimizes reconstruction for high-reflectance surfaces (e.g., metal copings), reducing manual post-processing by 63% |

Quantitative Workflow Efficiency Gains (2026 vs. 2023 Baseline)

| Workflow Stage | 2023 Metric | 2026 Metric | Engineering Driver | Lab Impact |

|---|---|---|---|---|

| Full-Arch Scan Time | 142 ± 18 sec | 87 ± 9 sec | DMC + adaptive pattern density | 32% higher patient throughput; reduced motion artifacts in pediatric/geriatric cases |

| Marginal Gap RMS Error | 18.2 ± 3.1 μm | 7.4 ± 1.3 μm | Phase-shifting + MEE surface optimization | 68% reduction in crown remake requests; eliminates 92% of “fit check” remounts |

| Post-Scan Processing Time | 214 sec | 79 sec | On-device AI validation (GIN/DMC) | Enables near-real-time STL export; reduces lab bottleneck by 63% |

| Soft-Tissue Management Time | 3.8 ± 0.9 min | 1.1 ± 0.4 min | Multi-wavelength confocal sensing | Eliminates need for 78% of hemostatic agents; reduces gingival trauma |

Conclusion: The Precision-Throughput Equilibrium

Dental scanning in 2026 operates at the Pareto frontier of metrology and clinical pragmatism. The convergence of adaptive optical projection, multi-spectral confocal sensing, and deterministic AI validation has resolved the historical trade-off between accuracy and speed. Critically, these systems no longer function as mere data capture devices but as geometric assurance platforms that enforce metrological compliance during acquisition. For laboratories, this translates to STL files requiring zero topology correction in 94% of cases (vs. 61% in 2023), fundamentally altering production economics. Future development will focus on closed-loop integration with milling/printing systems – where scanner-derived surface integrity metrics directly modulate CAM toolpaths – but the 2026 foundation rests on photogrammetric rigor, not algorithmic approximation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Scanner Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (ISO 12836 certified) |

| Scan Speed | 15 – 30 frames/sec (real-time capture) | 60 frames/sec with AI motion compensation |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic edge detection, minimal auto-segmentation | Integrated AI engine: real-time intraoral landmark detection, prep finish line identification, undercut auto-correction |

| Calibration Method | Periodic manual calibration using reference spheres | Dynamic self-calibration via embedded photogrammetric feedback loop (daily recalibration not required) |

Note: Data reflects Q1 2026 consensus benchmarks from ISO/TC 106, ADMA, and EDA technology assessments.

Key Specs Overview

🛠️ Tech Specs Snapshot: Dental Scanner Manufacturer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration Ecosystem

Executive Summary

Dental scanners have evolved from isolated data capture tools to the central nervous system of modern digital workflows. In 2026, scanner manufacturer choice directly dictates interoperability, production velocity, and clinical outcomes. This review analyzes integration mechanics within chairside (CEREC-style) and lab environments, with critical assessment of CAD compatibility paradigms and the strategic imperative of open architecture. Carejoy’s API framework emerges as a pivotal solution for ecosystem unification.

Scanner Integration: The Workflow Catalyst

Modern scanners (e.g., TRIOS 5, CS Scan 3, Medit i700, Planmeca Emerald S) function as the primary data ingestion point. Their integration depth determines downstream efficiency:

| Workflow Stage | Scanner Integration Mechanism | Impact on Efficiency |

|---|---|---|

| Chairside (Single-Visit) | Direct Bluetooth/WiFi transmission to in-office CAD/CAM. Real-time cloud sync for remote design support. AI-powered scan quality validation at capture. | Reduces chairtime 18-22% via instant error correction. Enables same-day crown completion with 94.7% first-scan success rate (2026 industry avg). |

| Lab-Centric Workflow | Cloud-based scan routing to lab management systems (LMS). DICOM/STL export with embedded metadata (margin lines, prep specs). Automated case triage based on scan complexity. | Cuts lab intake processing from 45 mins to <8 mins. Reduces remakes due to poor scan data by 31% (2025 DSI Lab Survey). |

| Hybrid Clinic-Lab | Bi-directional sync with clinic EHR and lab LMS. Version-controlled scan history. Real-time clinician-lab technician collaboration on scan adjustments. | Accelerates case turnaround by 37 hours avg. Eliminates 92% of physical model shipping. |

CAD Software Compatibility Matrix

Scanner-to-CAD interoperability remains fragmented. Key compatibility dynamics:

| Scanner Manufacturer | Exocad | 3Shape Dental System | DentalCAD | Native Ecosystem Lock-in |

|---|---|---|---|---|

| 3Shape | Limited (STL only; no metadata) | FULL (ScanData+ integration, AI prep detection) | Basic STL | High (Optimized for Dental System) |

| Dentsply Sirona | Partial (CEREC Connect) | STL only | Basic STL | Very High (CEREC only) |

| Medit | FULL (Medit Link) | Partial (STL + basic metadata) | FULL (Medit DentalCAD) | Low-Medium (Open SDK) |

| Planmeca | Partial (Planmeca Romexis) | STL only | Basic STL | High (Romexis ecosystem) |

| Open-Format Scanners (e.g., Shining) | FULL (Universal STL/OBJ) | FULL | FULL | None |

Compatibility Pain Points

- Metadata Loss: Non-native CAD integrations discard scanner-specific analytics (e.g., TRIOS “Margin Confidence Index” unusable in Exocad without middleware)

- Workflow Friction: Closed systems require manual file conversion (STL → CAD native format), adding 7-12 mins/case

- AI Feature Gating: Scanner AI (e.g., automatic die separation) only functions in native CAD

Open Architecture vs. Closed Systems: Strategic Analysis

| Parameter | Open Architecture | Closed System |

|---|---|---|

| Integration Flexibility | ✅ Full LMS/EHR/CAD compatibility via APIs & standard formats (STL, OBJ, PLY) | ❌ Vendor-locked; requires proprietary modules for external tools |

| Future-Proofing | ✅ Adapts to new software via open standards (e.g., DICOM for implant planning) | ❌ Dependent on vendor’s roadmap; slow adoption of third-party innovations |

| Cost Efficiency | ✅ Avoids ecosystem tax; leverage best-in-breed tools (e.g., Medit scanner + Exocad) | ❌ Premium pricing for bundled solutions; hidden costs for “integration” |

| Data Ownership | ✅ Clinic/lab retains full control; portable data formats | ❌ Data trapped in vendor cloud; export fees common |

| 2026 Adoption Trend | 🚀 78% of new lab setups (DSI 2025) | 📉 Declining (22% of new installs) |

Carejoy: The Interoperability Engine

Carejoy’s 2026 API framework resolves the fragmentation crisis through:

Seamless Integration Architecture

- Unified Scan Ingestion: Agnostic scanner support (all major brands) via DICOM/STL/ScanData+ ingestion with metadata preservation

- Bi-Directional CAD Sync: Real-time design status updates between lab CAD (Exocad/3Shape) and clinic EHR

- Intelligent Routing: AI analyzes scan data to auto-assign cases to optimal lab technicians based on specialty

- Version Control: Immutable audit trail of scan revisions between clinic and lab

Quantifiable Workflow Impact

| Metric | Pre-Carejoy | With Carejoy API | Improvement |

|---|---|---|---|

| Case Intake Time | 52 mins | 6.2 mins | 88% |

| Scan-to-Design Handoff | 18.5 hrs | 22 mins | 98% |

| Remakes Due to Data Errors | 14.3% | 3.1% | 78% |

| LMS-Clinic EHR Sync Failures | 22% | 0.4% | 98% |

Conclusion: The Integration Imperative

Scanner selection is no longer about image quality alone. In 2026, it’s a strategic decision defining your digital ecosystem’s agility. Closed systems offer simplicity at the cost of innovation velocity and vendor dependency. Open architecture, amplified by platforms like Carejoy, delivers:

- ✅ Economic resilience through best-of-breed tool selection

- ✅ Future-proof workflows via API-first design

- ✅ Collaborative advantage through real-time clinic-lab data symmetry

Recommendation: Prioritize scanners with published SDKs, DICOM support, and proven Carejoy API certification. Demand metadata portability in procurement contracts – your lab’s throughput and clinical outcomes depend on it.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Dental Scanner Manufacturer.

✅ Open Architecture

Or WhatsApp: +86 15951276160